Coal drilling machine

A technology for a coal drilling machine and a drilling tool, which is applied in the field of four-axis linkage type two-way high-efficiency coal drilling machine, can solve the problems of low overall efficiency, high use cost and high failure rate of the coal drilling machine, so as to reduce the number of docking workers and reduce production efficiency. High, reduce wear and failure rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

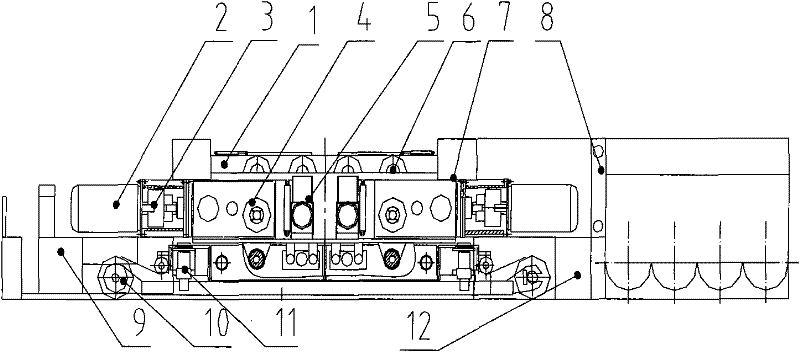

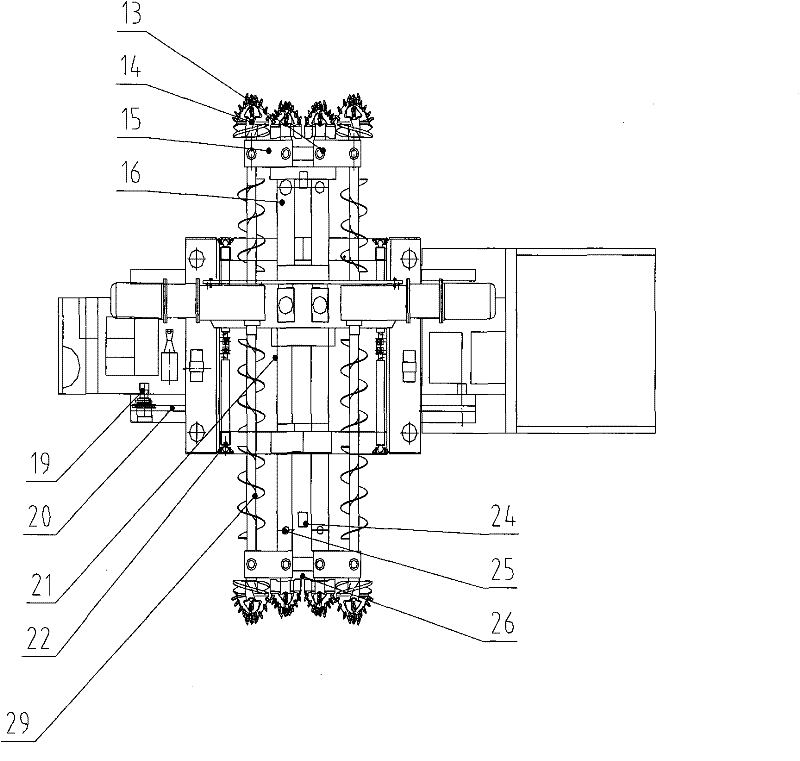

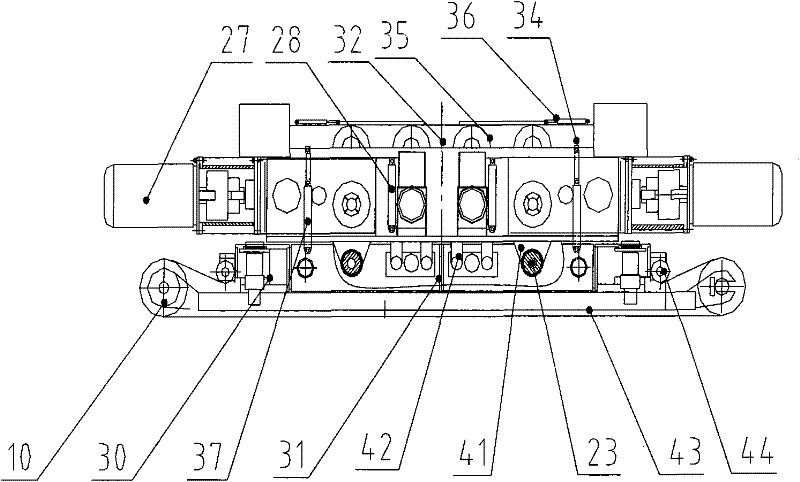

[0037] Below in conjunction with accompanying drawing, the present invention will be specifically described, as figure 1 , 2 , 3, 4, and 5, the coal drilling machine adopts the following technical solutions:

[0038] The whole coal drilling rig is composed of five parts: main engine, electric control system 12, hydraulic system 9, drilling tools and auxiliary system 8.

[0039](1) The host system is the core part of the drilling rig, and it is composed of six major parts: the support part 31, the positioning part 32, the orientation part 30, the propulsion part 28, the power part 27, and the walking part 10. , Bolts are connected together, wherein the support part 31 and the positioning part 32, the propulsion part 28 and the power part 27 are fixedly connected, and other parts are connected by oil cylinders and can be relatively rotated or moved to realize various operations of the coal drilling machine.

[0040] 1. The support part 31 is used to support the propulsion work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com