Automatic low-penetration lubricating grease delivery system

A technology of automatic conveying and lubricating grease, applied in the direction of engine lubrication, engine components, mechanical equipment, etc., can solve the problems of increasing the difficulty of grease conveying, equipment wear and overfilling, etc. Degree of automation, avoidance of wear and effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

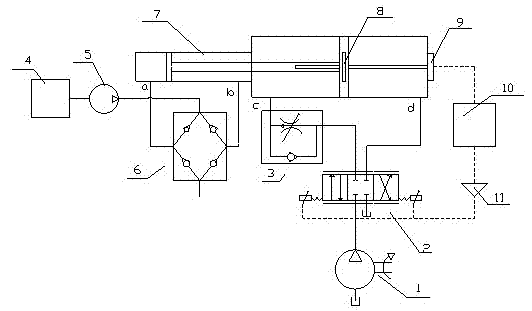

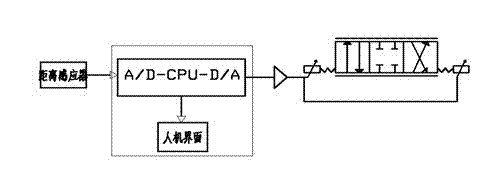

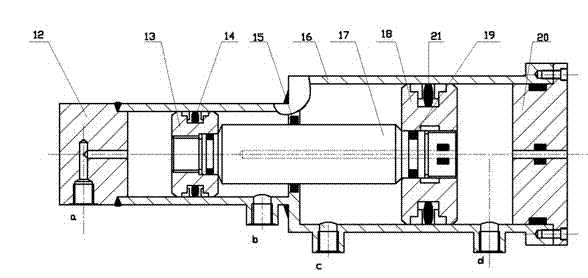

[0012] Such as figure 1 As shown, the low cone penetration grease automatic conveying system of the present invention is mainly composed of a hydraulic pump station 1, a three-position four-way electro-hydraulic proportional reversing valve 2, a one-way speed control valve 3, a grease processor 4, and a grease pump 5 , a one-way valve bridge 6, a composite hydraulic cylinder 7, a distance sensor 9, and an electro-hydraulic controller 10; the grease processor 4 has heating and stirring functions, and the composite hydraulic cylinder 7 includes four chambers, the left side The two chambers are grease chambers, and the two chambers on the right are hydraulic oil chambers. The left side of the composite hydraulic cylinder 7 is provided with the inlet and outlet of the grease chamber a, b, and the right side of the composite hydraulic cylinder 7 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com