Fabric production process

A production process and fabric technology, applying online or similar mechanical methods or equipment, to the field of filament production, can solve the problems of wasting the environment, pollution, chemical reagent residue, etc., and achieve the goal of improving quality, avoiding polyester denaturation, and reducing transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

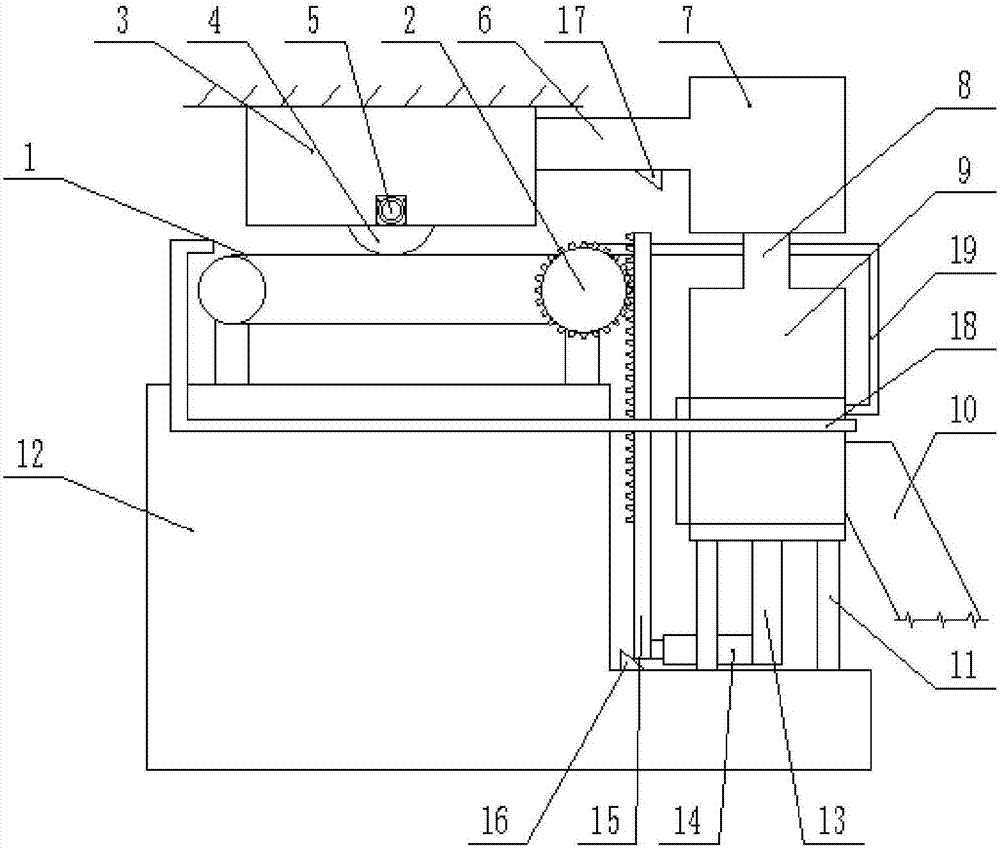

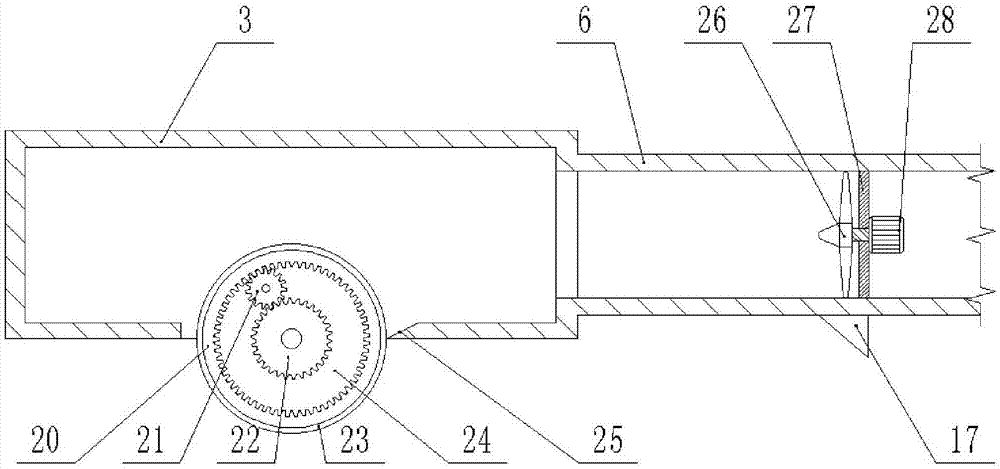

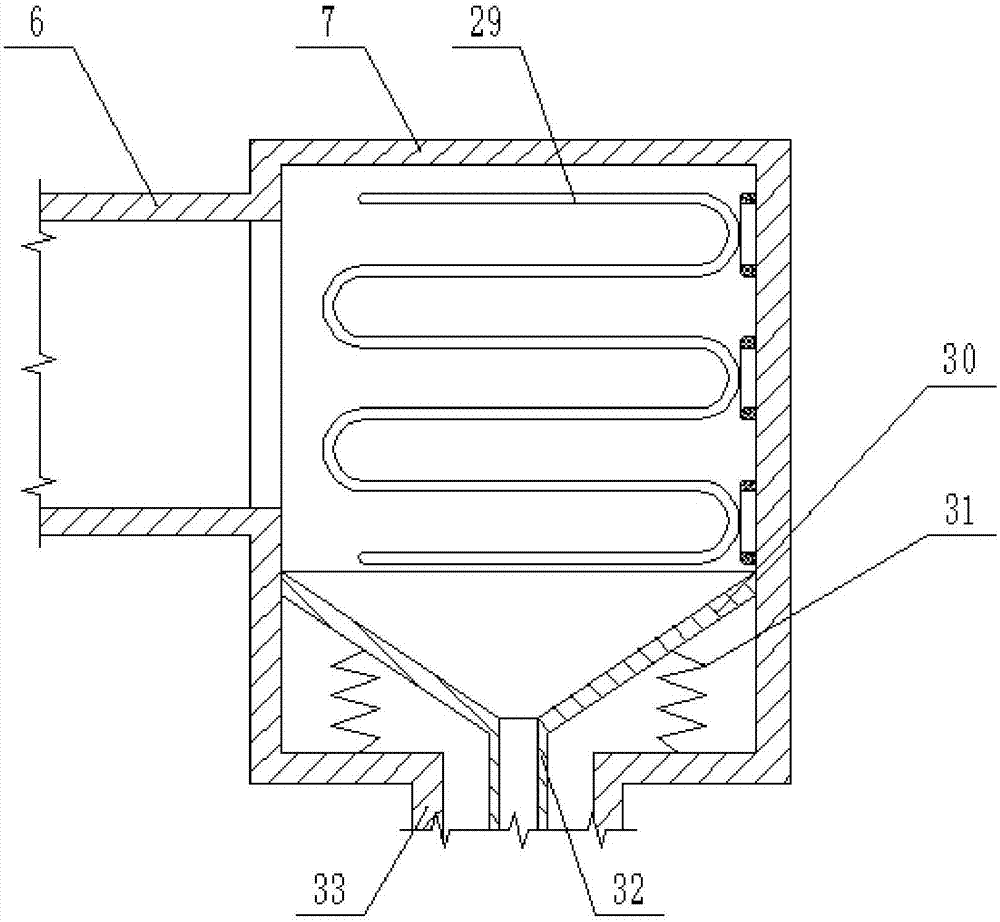

[0029] The reference signs in the drawings of the specification include: belt 1, driving gear 2, waste wire collection box 3, electrostatic roller 4, driving motor 5, wire feeding pipeline 6, fuse box 7, wire feeding channel 8, wire drawing box 9 , discharge pipe 10, pillar 11, frame 12, piston rod 13, telescopic rod 14, rack 15, return wedge 16, meshing wedge 17, first air supply channel 18, second air supply channel 19, Ring gear 20, planetary gear 21, sun gear 22, outer roller 23, inner roller 24, scraper 25, paddle 26, cage 27, fan motor 28, heating wire 29, loading hopper 30, first return spring 31, Feed pipe 32, feed channel 33, sealing door 34, air hole 35, spinning platform 36, spinning hole 37, piston plate 38, cooling mechanism 39, second return spring 40, discharge port 41, sliding door 42.

[0030] The embodiment is basically as figure 1 , figure 2 , image 3 and F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com