Integrated short-process efficient denitrification and phosphorus removal sewage treatment system and process

A sewage treatment system and short-process technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, energy wastewater treatment, etc., can solve the shortage of serialized complete sets of equipment, lack of market-oriented operation capabilities, small and medium-sized towns Problems such as the lagging development of sewage treatment business, to achieve the effect of improving life and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

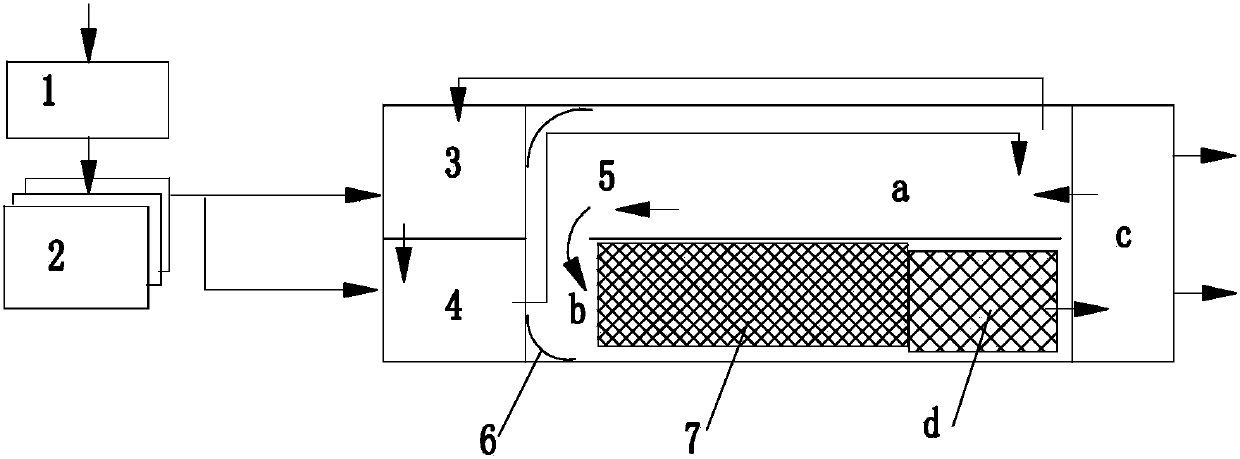

[0035] Embodiment 1: An integrated short-flow high-efficiency phosphorus and nitrogen removal wastewater treatment process, including the following steps:

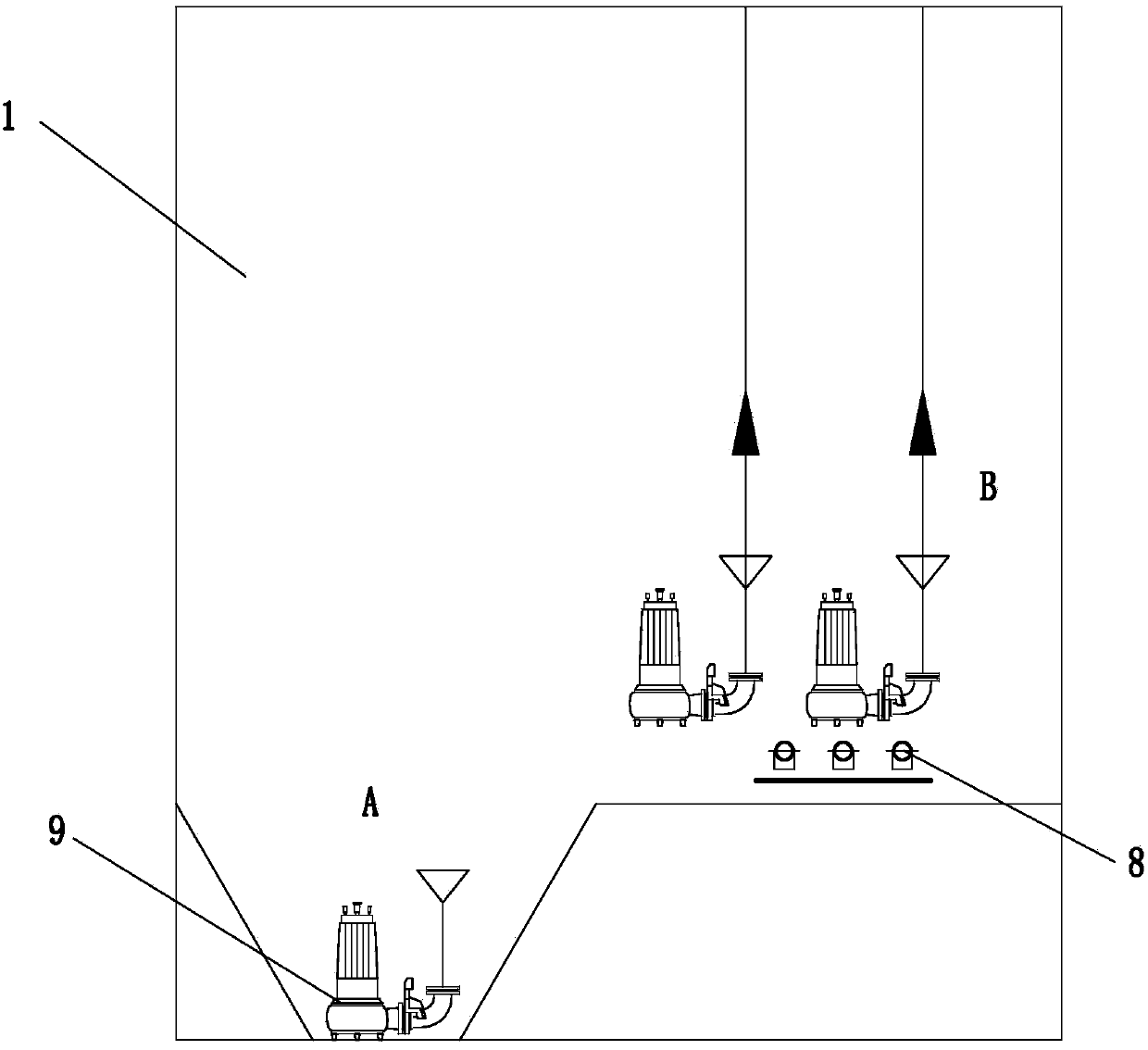

[0036] a. Sewage enters the water inlet adjustment tank 1, and the sand settling area A of the water inlet adjustment tank 1 removes suspended solids, sediment and other inorganic substances in the inlet water, and effectively adjusts the water quality and quantity of the inlet water. buffer;

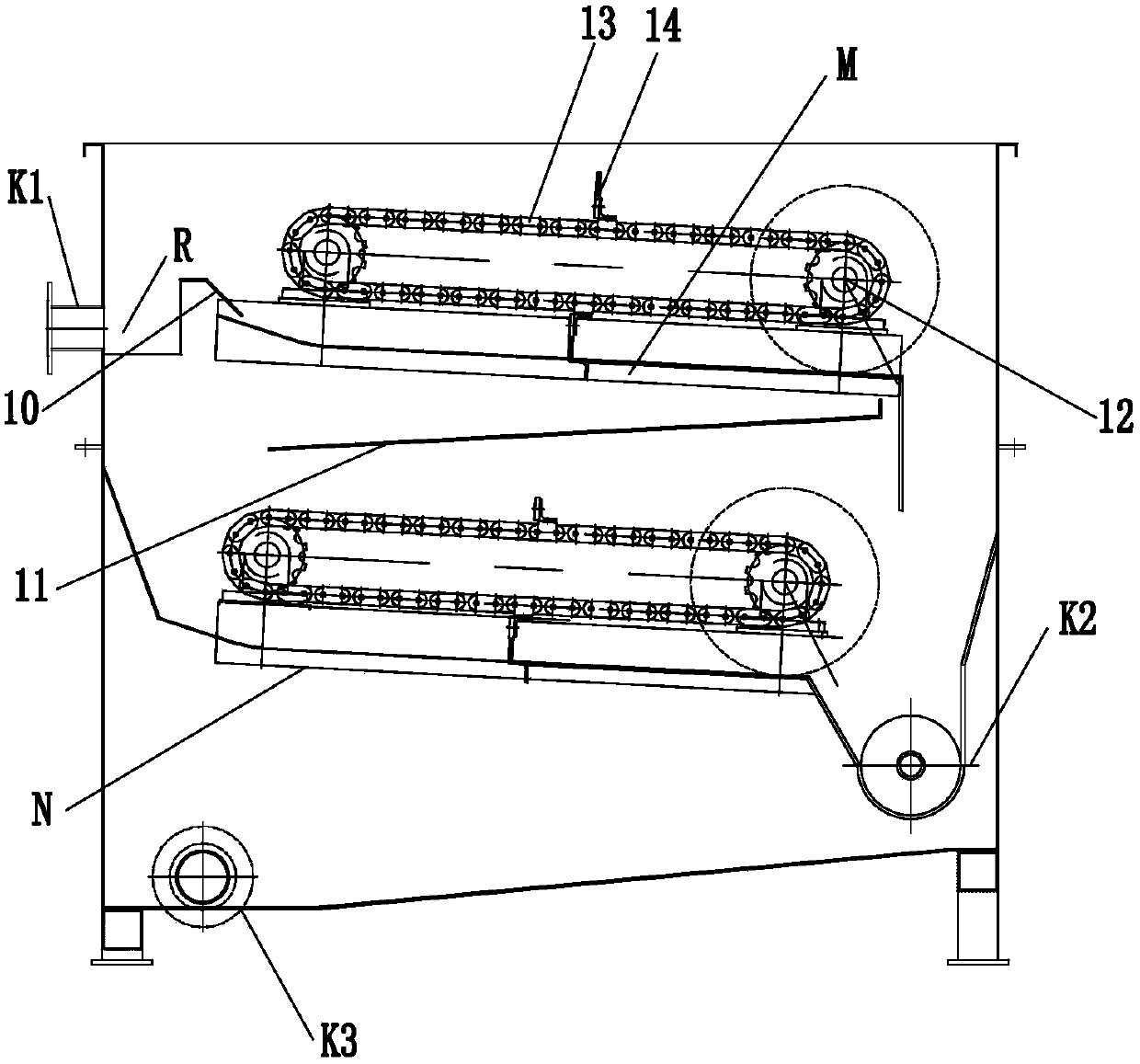

[0037] b. The sewage obtained in step a enters the water inlet groove R of the three-dimensional combined flat grille 2 through the lifting action of the sewage lifting pump 9, and the first deflector 10 at the slot of the water inlet groove R guides the water to the upper grille M, after being filtered by an orifice plate with a diameter of 5mm on the upper grid M, the second baffle 11 is guided under gravity through a lower grid N with a diameter of 1mm to further remove particles and entanglements in the influent;

[0038] c. 10% of th...

Embodiment 2

[0044] Embodiment 2: An integrated short-flow high-efficiency phosphorus and nitrogen removal wastewater treatment process, including the following steps:

[0045] a. Sewage enters the water inlet adjustment tank 1, and the sand settling area A of the water inlet adjustment tank 1 removes suspended solids, sediment and other inorganic substances in the inlet water, and effectively adjusts the water quality and quantity of the inlet water. buffer;

[0046] b. The sewage obtained in step a enters the water inlet groove R of the three-dimensional combined flat grille 2 through the lifting action of the sewage lifting pump 9, and the first deflector 10 at the slot of the water inlet groove R guides the water to the upper grille M, after being filtered by an orifice plate with a hole diameter of 8mm on the upper grid M, the second baffle 11 is guided under gravity through a lower grid N with a hole diameter of 2mm to further remove particles and entanglements in the influent;

[0047] c....

Embodiment 3

[0053] Example 3: The discharge standard of a small town in the Taihu Lake Basin is the first class A standard of the "Emission Standards for Pollutants for Urban Sewage Treatment Plants" (GB18918-2002). In small towns, there are large fluctuations in water quality and quantity, shortage of technical personnel, and insufficient operation and maintenance. Under such circumstances, how to ensure that the effluent is stable and meet the standard and achieve the goal of unattended installation has become an urgent problem to be solved. For this reason, a small town integrated short-process high-efficiency phosphorus and nitrogen removal sewage treatment system is proposed. According to the actual situation of the project, a test simulation is carried out. The specific simulation situation is as follows:

[0054] The simulation experiment device is made of stainless steel, the water inlet and sludge return are completed by the axial flow pump, and the designed capacity of the device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com