Anti-wear maintenance method for air conditioner compressor

An air-conditioning compressor and anti-wear technology, applied in the field of compressors, can solve the problems of high maintenance cost, mechanical wear, low efficiency, etc., and achieve the effects of improving comprehensive life, improving service life and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

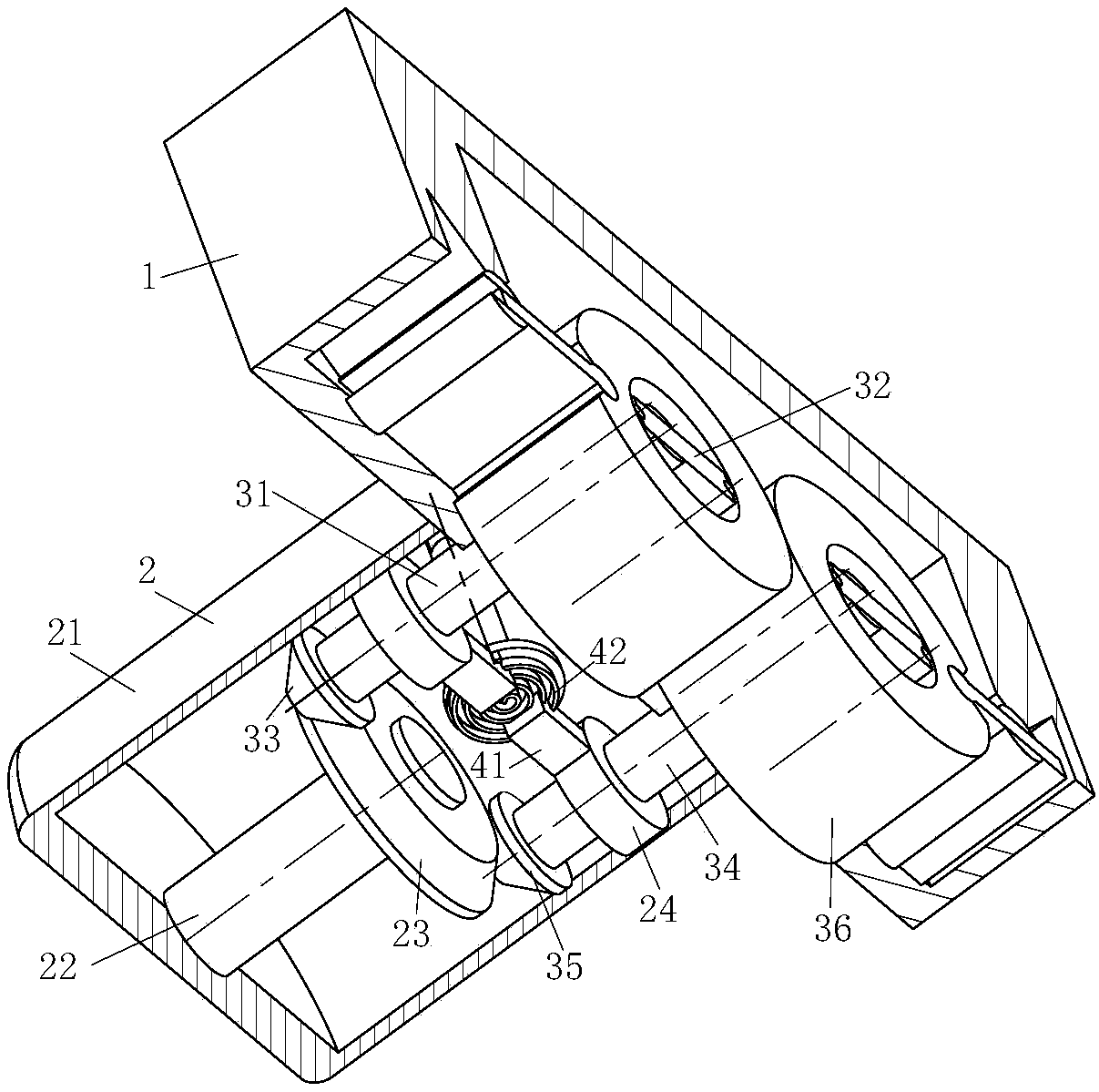

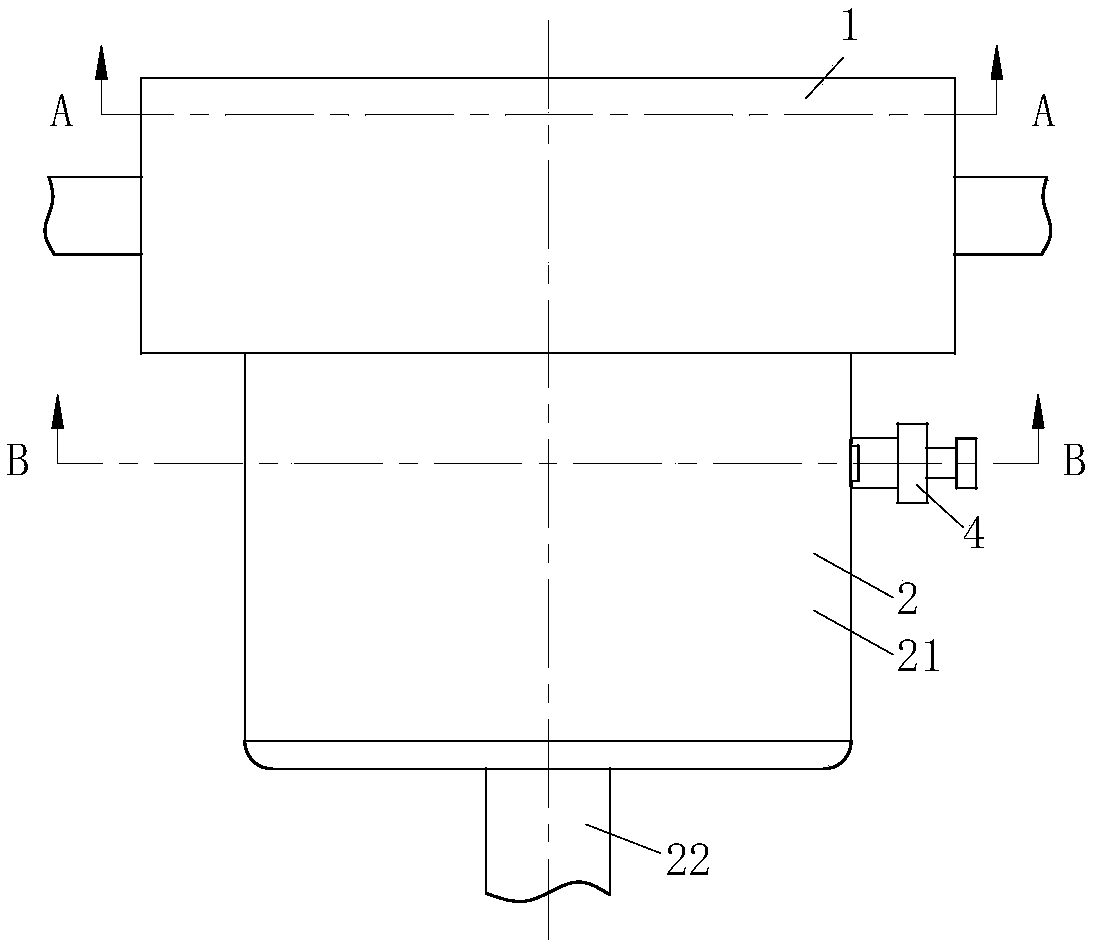

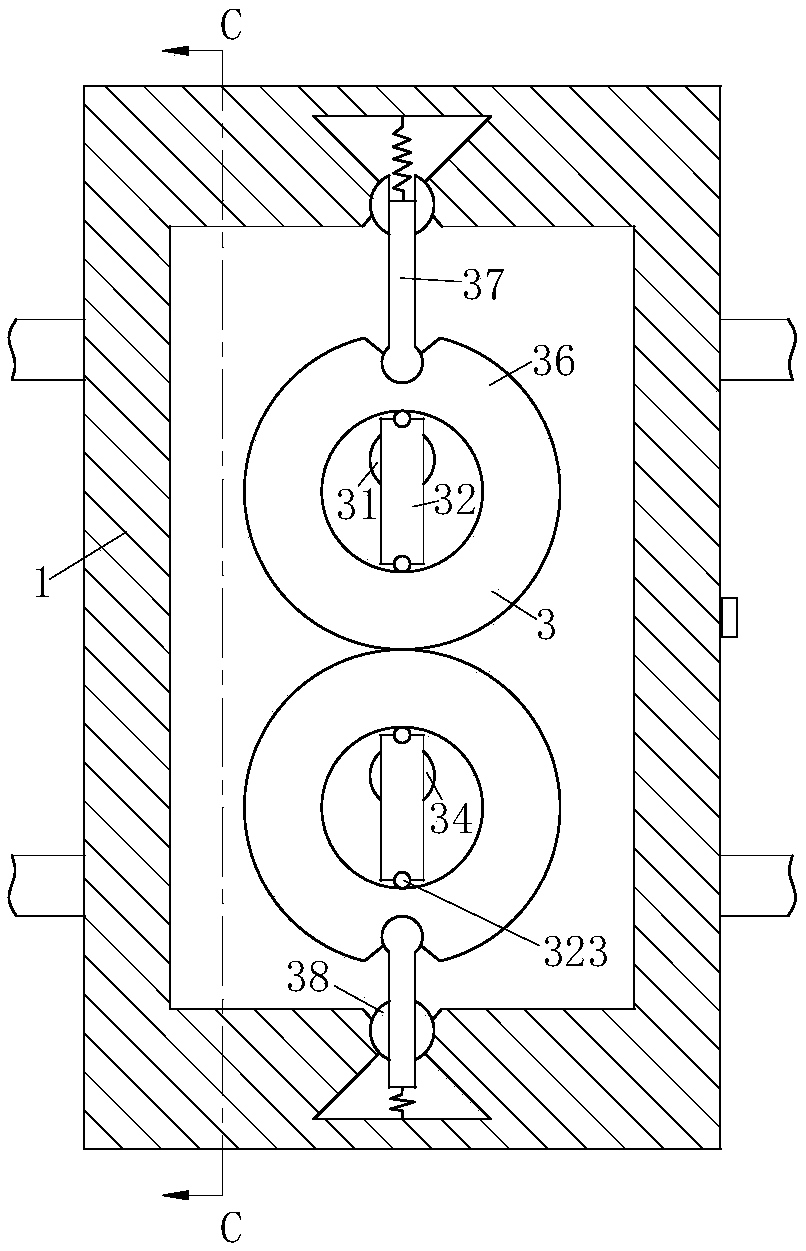

[0031] Such as Figure 1 to Figure 7 As shown, a kind of air conditioner compressor anti-wear maintenance method of the present invention, this anti-wear maintenance method comprises the following steps:

[0032] The first step is to install the compression module 3 in the cylinder 1, the compression module 3 can periodically change the volume on both sides of the cylinder 1; at the same time, install the drive module 2 on the side of the cylinder 1, and the drive module 2 drives the compression module 3 to achieve suction-compression - The cyclic working process of exhaust; the compression module 3 includes two rotors in contact with each other, and the rotor rotates to change the volume on both sides of the cylinder 1, realize the function of ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com