Optical measuring method for hole cubage

An optical measurement and hole volume technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of difficult to guarantee accuracy, easy to be limited by conditions, etc., to avoid scratches on holes, avoid probe wear, improve The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

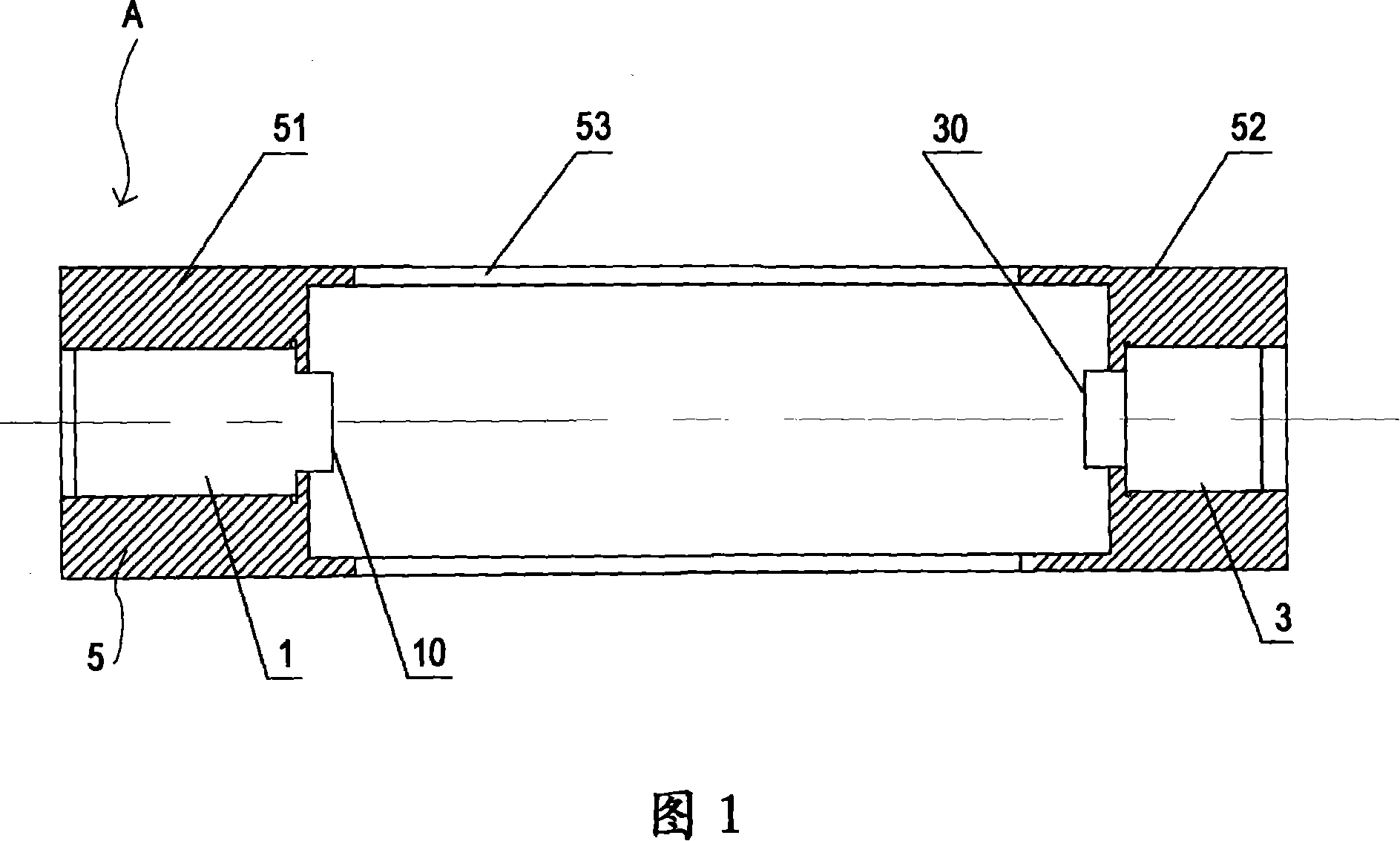

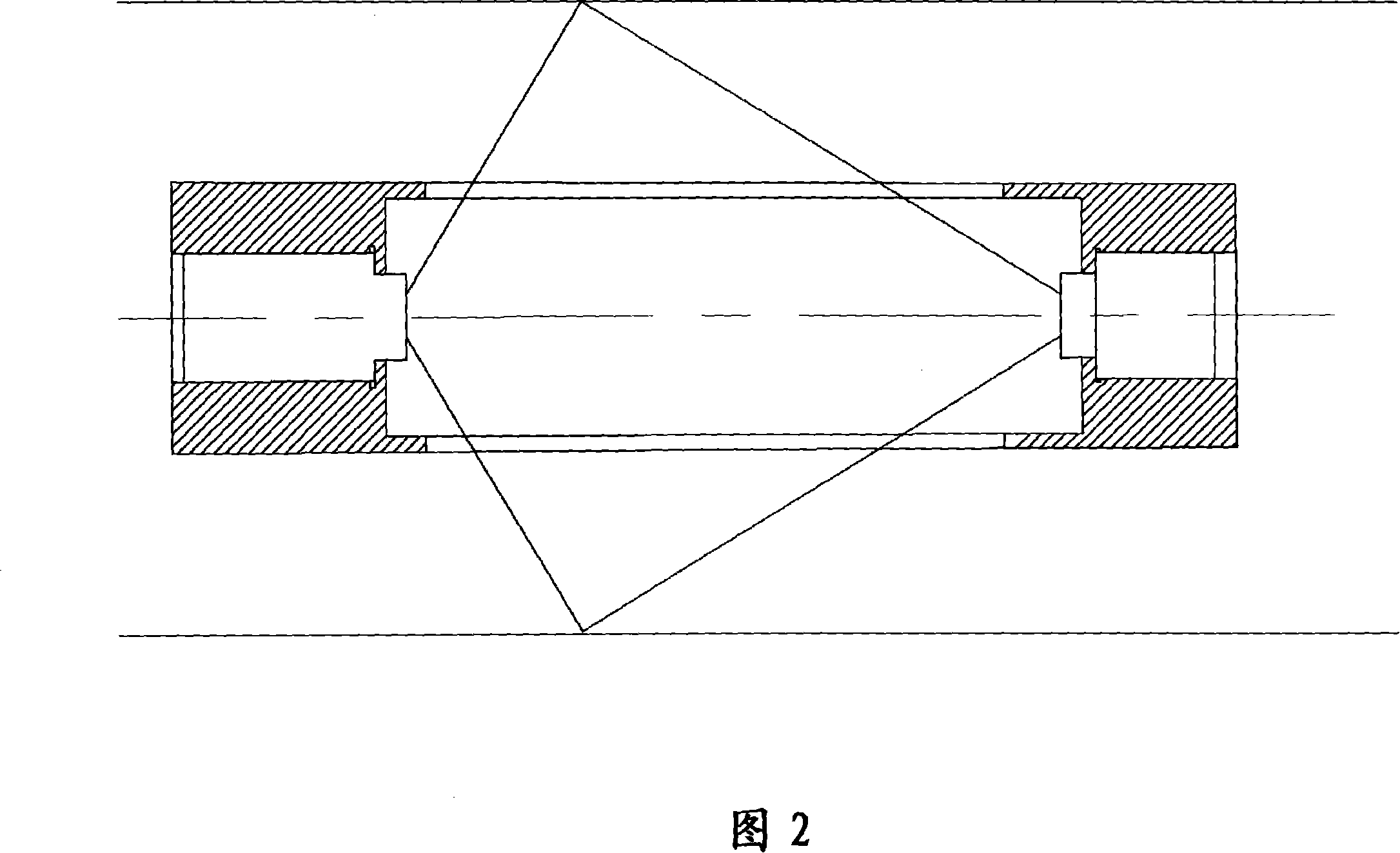

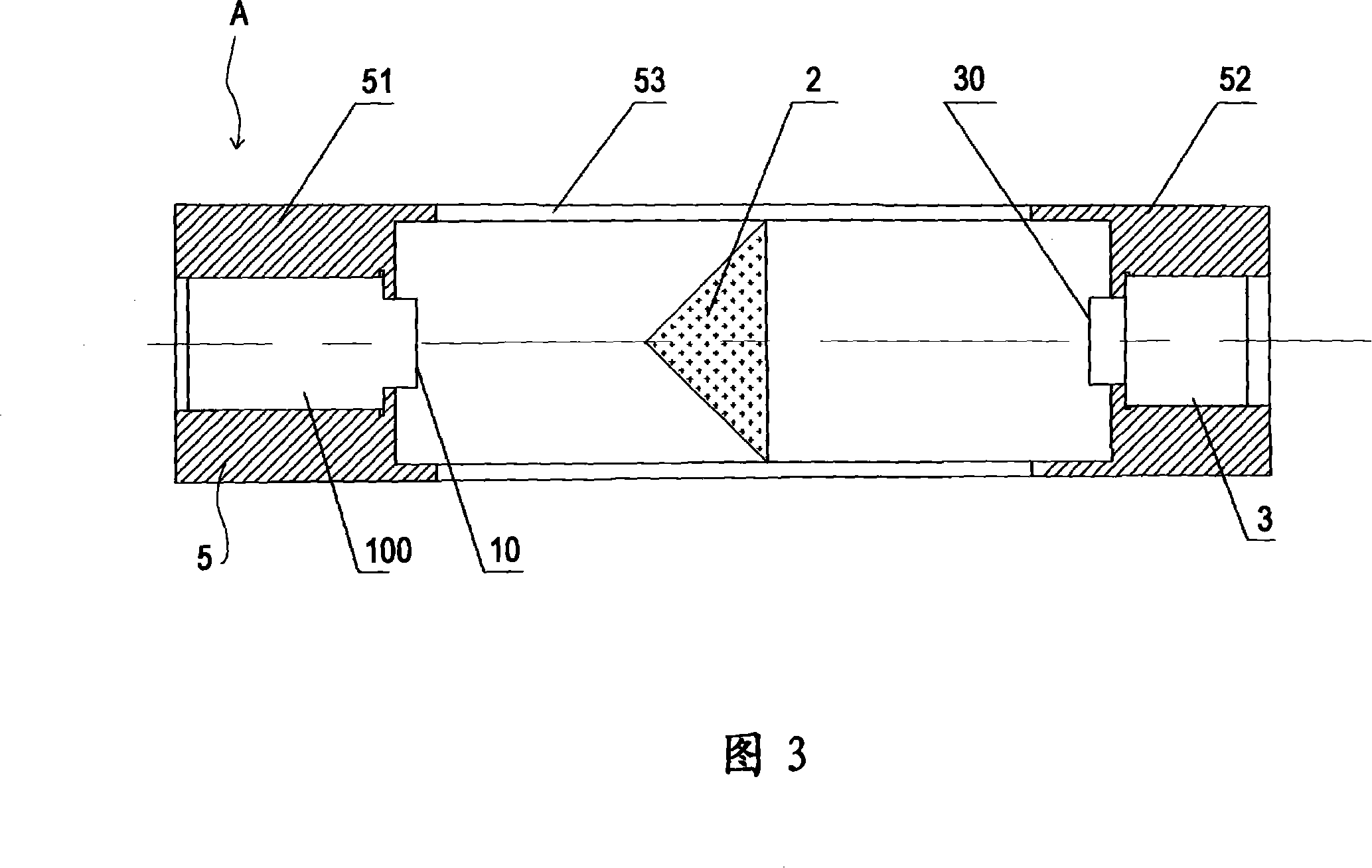

[0046] Fig. 3 is a schematic cross-sectional view of the optical hole measuring device used in Embodiment 2 of the present invention, the cross-section passing through the central axis of the device. Fig. 4 is a schematic diagram of the working principle of the optical measurement method according to Embodiment 2 of the present invention.

[0047] As shown in Figure 3 and Figure 4, the optical hole measuring device A 0 The reflective mirror 2 as a light reflective member is attached to the third frame 53 . The optical hole measuring device A 0 Among them, the laser generator 100 is different from the laser generator 1 in the above-mentioned optical hole measuring device A, and the rest of the components can refer to the optical hole measuring device A.

[0048] Optical hole measuring device A 0 Among them, the reflector 2 is a conical solid member, and the reflector 2 is used to reflect the laser beam emitted by the laser generator 100. Therefore, the cone angle of the refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com