A fully automatic tunnel bolt installation equipment

A technology for installing equipment and tunnel anchors, which is applied to mining equipment, installation of bolts, and program-controlled manipulators. It can solve problems such as failure to meet construction schedule requirements, high manual installation costs, and failure to achieve anchor protection effects, etc., to achieve applicable geological conditions. The effect of wide range, fast installation speed and reduction of equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described in conjunction with accompanying drawing and specific embodiment:

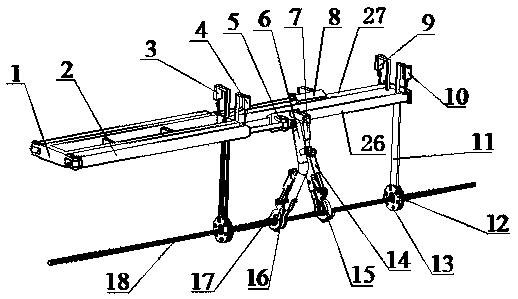

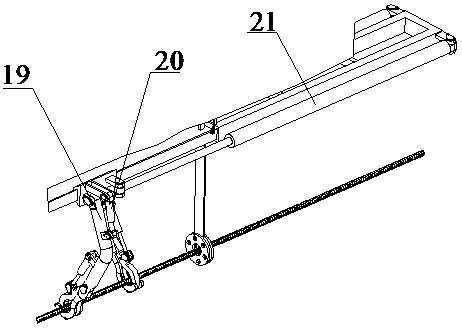

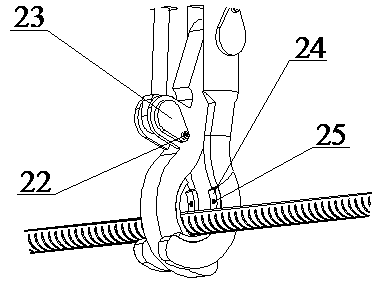

[0020] Such as Figure 1~3As shown, a fully automatic tunnel bolt installation equipment, the fully automatic tunnel bolt installation equipment has a bracket 1; the lower end of the bracket 1 is fixed with a guide rod 11 for guiding when installing the bolt; Described guide rod 11 is two that are arranged vertically to support, wherein a guide rod 11 is positioned at an end of support 1, and another guide rod 11 is fixed in the middle part of support; The lower end of described guide rod 11 is connected with detachable The guide rod wear plate 12, the middle part of the guide rod wear plate 12 has a through hole for the anchor rod 18 to pass through; the two sides of the bracket 1 are respectively provided with guide rails, namely guide rail I26 and guide rail II27; and the The above-mentioned guide rail I26 and guide rail II27 are located between the two gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com