A kind of self-supporting node connection structure of concrete prefabricated member and installation method thereof

A prefabricated component and node connection technology, applied in building construction, building material processing, construction, etc., can solve the problems of low installation efficiency, complex and cumbersome assembly process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing, the present invention is described in further detail:

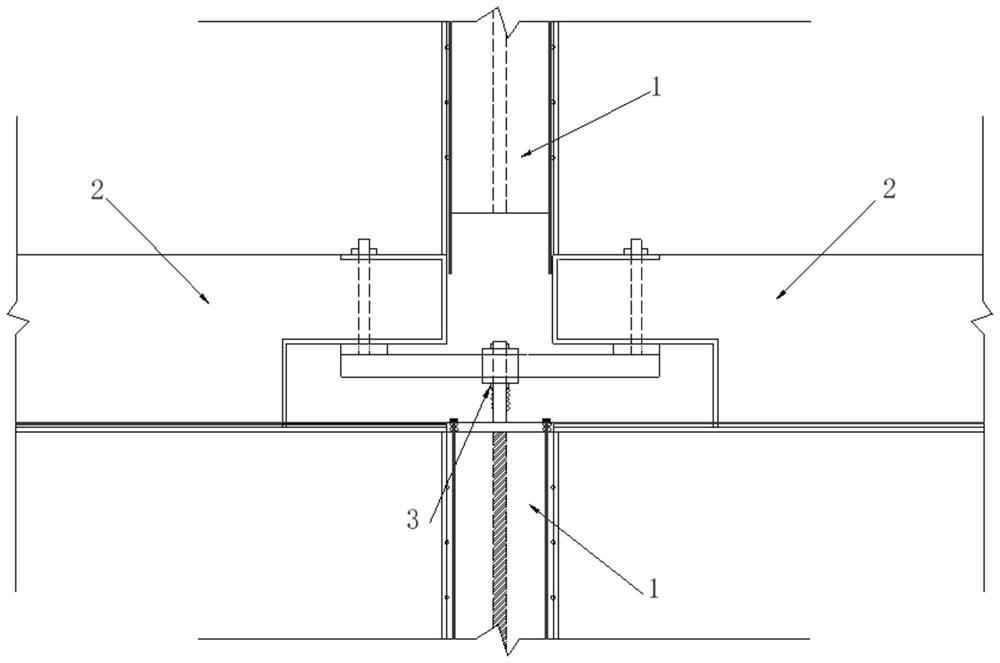

[0042] like figure 1 As shown, it is the self-supporting node connection structure of concrete prefabricated components according to the present invention, including hollow column 1 , beam 2 and I-shaped self-supporting structure 3 .

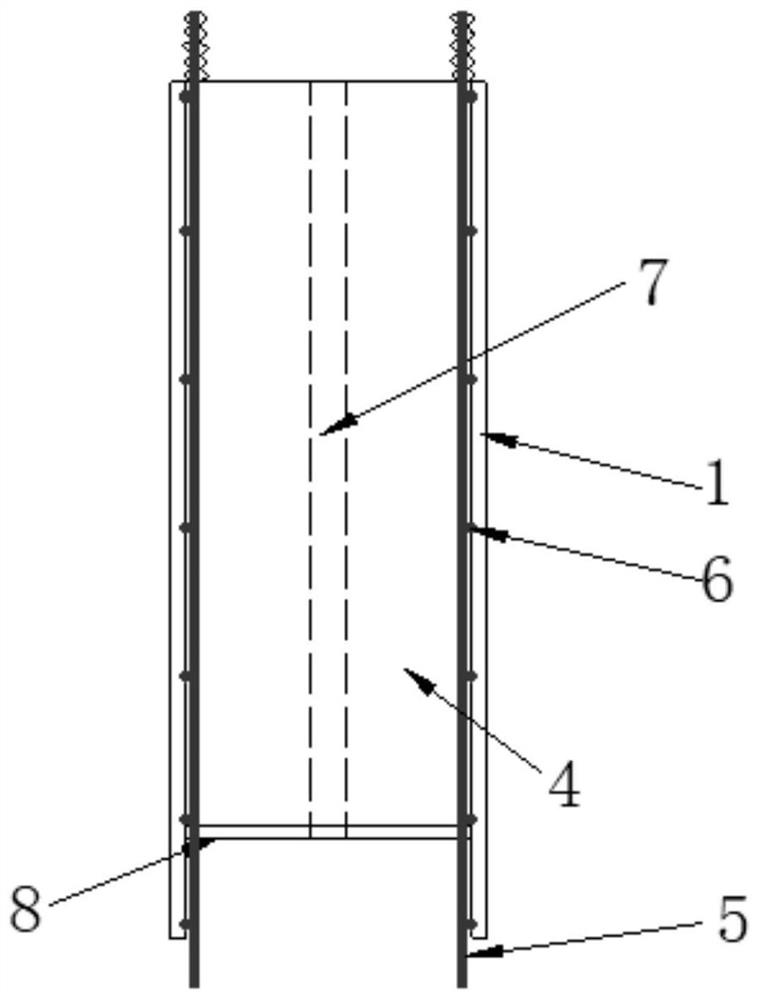

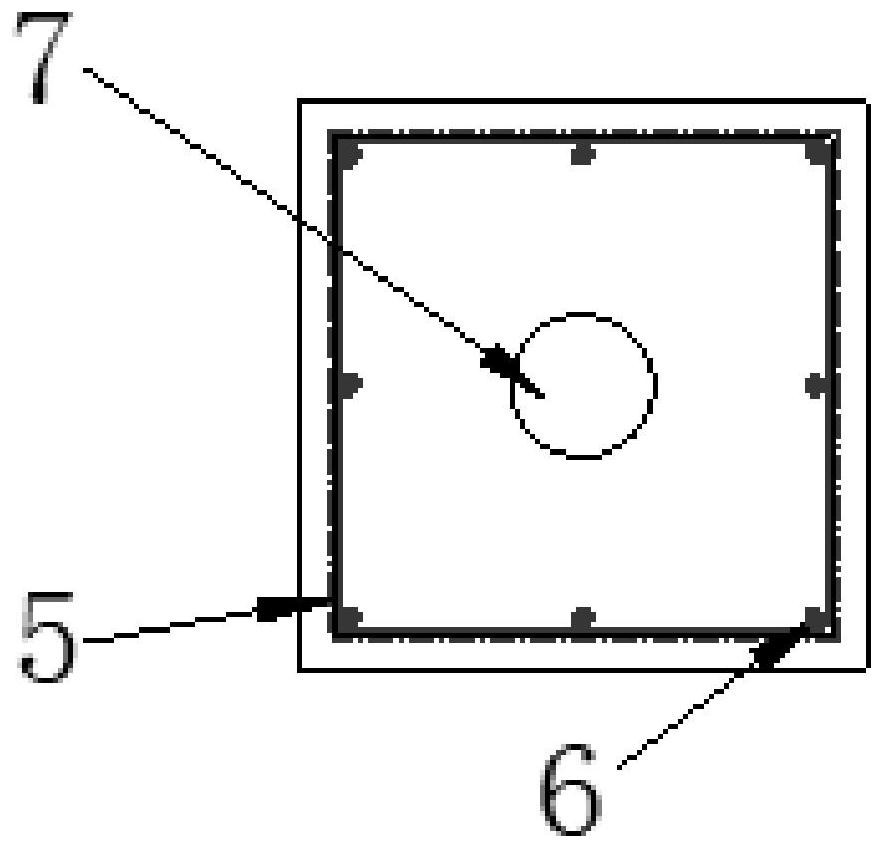

[0043] like figure 2 and image 3 As shown, the hollow column 1 can be a cylinder or a square column. In this embodiment, a square column is used. The wall thickness of the hollow column is 20-30 mm. Fixed on the inner wall, 1 / 2 of the cross section of the column continuous stirrup 5 is embedded in the inner wall, and 1 / 2 protrudes from its inner surface.

[0044] The hollow column 1 is provided with a first reinforcing bar 6, and the first reinforcing bar 6 is arranged along the length direction of the hollow column 1. In this embodiment, the number of the first reinforcing bar 6 is eight, which are respectively located in the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com