Plate cutting section deburring device

A technology for cutting sections and deburring, which is applied in the direction of grinding drive devices, grinding slides, grinding machines, etc., and can solve problems such as time-consuming, labor-intensive, safety hazards, and poor grinding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

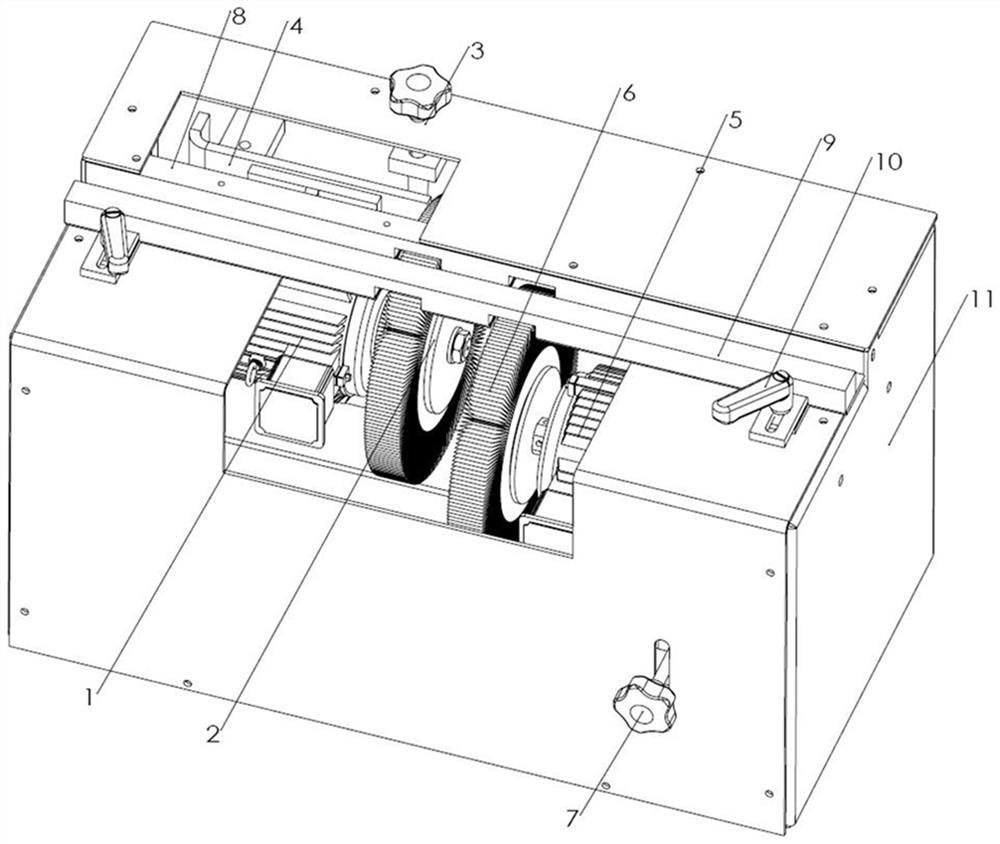

[0016] refer to figure 1 , the left motor 1 is fixed on the mounting bracket 4, and the left motor 1 is connected with the left disc brush device 2. After the left motor 1 is energized, the left motor 1 starts to rotate, and the left motor 1 can rotate together with the left disc brush device 2. The right motor 5 is installed on the horizontal adjustment mechanism 7, and the horizontal adjustment mechanism 7 is fixed on the mounting frame 4. The right motor 5 is connected with the right disc brush device 6. After the right motor 5 is energized, the right motor 5 begins to rotate, and the right motor 5 Can rotate together with right disc brush device 6. The left disk brush device 2 and the right disk brush device 6 can rotate in the same direction or rotate in the opposite direction. The horizontal adjustment mechanism 7 can adjust the distance between the left disk brush device 2 and the right disk brush device 6, so as to achieve the purpose of improving the deburring effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com