Permanent magnet coupler with variable magnet position and variable speed

A coupling and magnet technology, applied in the field of permanent magnet couplings, can solve the problems of bloated structure, unfavorable product promotion and application, large adjustment workload, etc., and achieve the effects of being beneficial to popularization and application, convenient and quick adjustment, and strong application adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

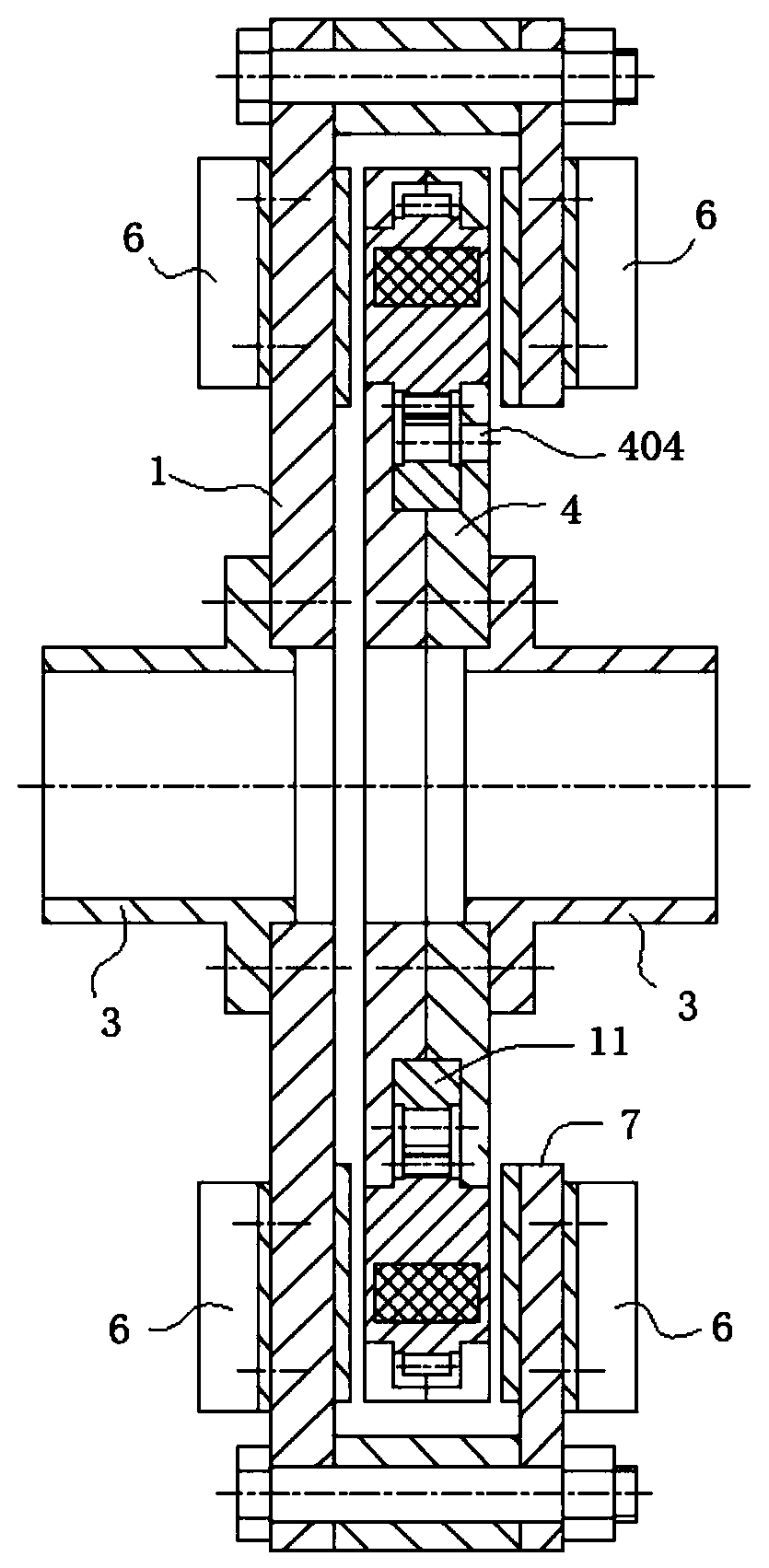

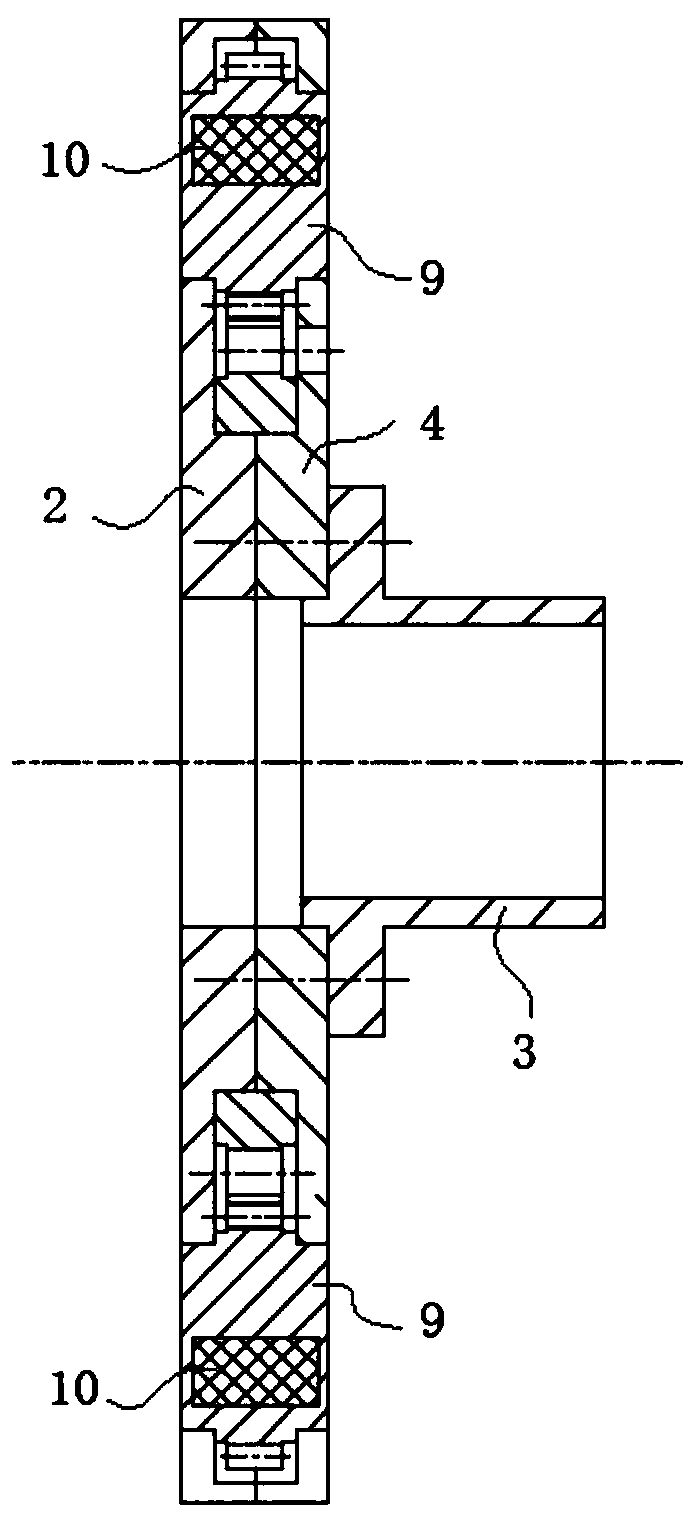

[0044] see figure 1 As shown, the present invention is a permanent magnet coupling with variable magnet position and speed, including a conductor rotor assembly installed at the drive end of the permanent magnet coupling; and a permanent magnet rotor assembly installed at the load end of the permanent magnet coupling.

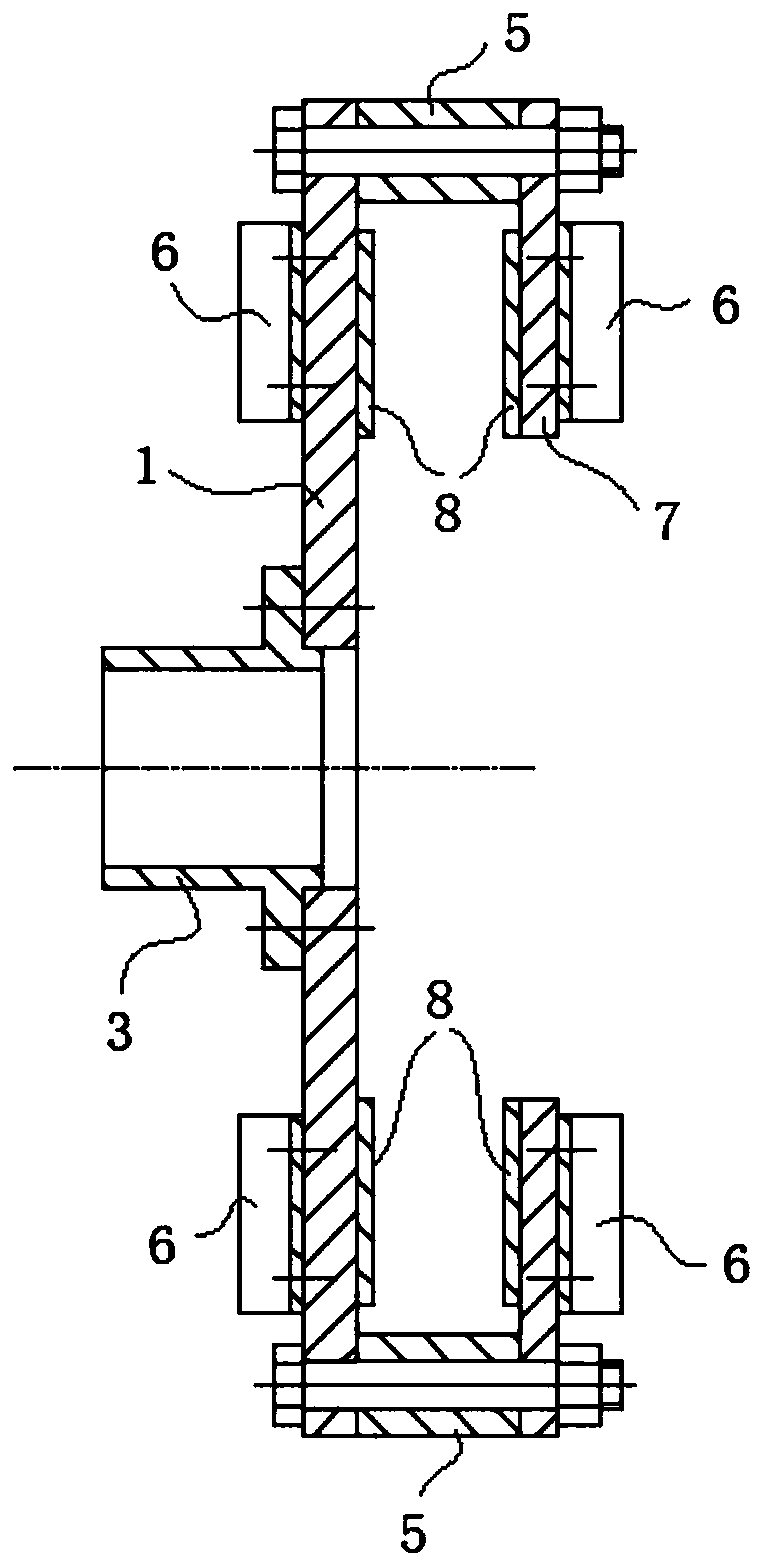

[0045] see figure 2As shown, the conductor rotor assembly includes a first conductor disk 1 and a second conductor disk 7, and the outer edge of the first conductor disk 1 is connected to the outer edge of the second conductor disk 7 through a connecting piece; the connecting piece includes a spacer 5 and a bolt assembly, and the spacer The cylinder 5 is located between the first conductor disk 1 and the second conductor disk 7, and is fixed by a bolt assembly, so that there is a certain distance between the first conductor disk 1 and the second conductor disk 7, which is used for clearance fit with the permanent magnet rotor assembly .

[0046] A fixing mem...

Embodiment 2

[0054] see figure 1 As shown, the present invention is a permanent magnet coupling with variable magnet position and speed, including a conductor rotor assembly installed at the drive end of the permanent magnet coupling; and a permanent magnet rotor assembly installed at the load end of the permanent magnet coupling.

[0055] see figure 2 As shown, the conductor rotor assembly includes a first conductor disk 1 and a second conductor disk 7, and the outer edge of the first conductor disk 1 is connected to the outer edge of the second conductor disk 7 through a connecting piece; the connecting piece includes a spacer 5 and a bolt assembly, and the spacer The cylinder 5 is located between the first conductor disk 1 and the second conductor disk 7, and is fixed by a bolt assembly, so that there is a certain distance between the first conductor disk 1 and the second conductor disk 7, which is used for clearance fit with the permanent magnet rotor assembly .

[0056] A fixing me...

Embodiment 3

[0064] see figure 1 As shown, the present invention is a permanent magnet coupling with variable magnet position and speed, including a conductor rotor assembly installed at the drive end of the permanent magnet coupling; and a permanent magnet rotor assembly installed at the load end of the permanent magnet coupling.

[0065] see figure 2 As shown, the conductor rotor assembly includes a first conductor disk 1 and a second conductor disk 7, and the outer edge of the first conductor disk 1 is connected to the outer edge of the second conductor disk 7 through a connecting piece; the connecting piece includes a spacer 5 and a bolt assembly, and the spacer The cylinder 5 is located between the first conductor disk 1 and the second conductor disk 7, and is fixed by a bolt assembly, so that there is a certain distance between the first conductor disk 1 and the second conductor disk 7, which is used for clearance fit with the permanent magnet rotor assembly .

[0066] A fixing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com