Flexible glass cutting device

A cutting device and glass technology, which is applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of inability to adjust the size and thickness of glass, so as to avoid hand scratches, reduce work intensity, and facilitate placement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

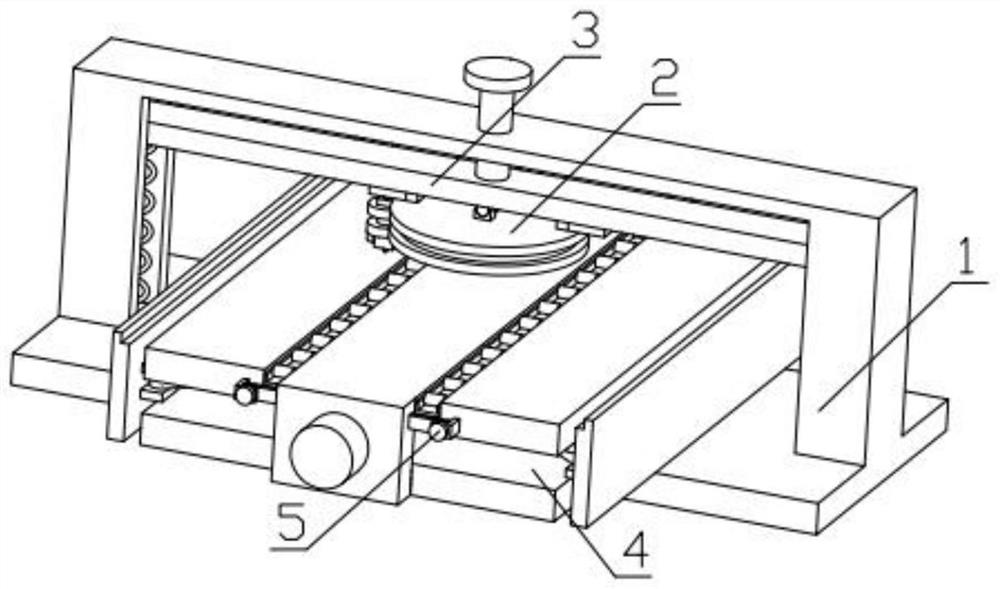

[0039] Combine below Figure 1-15Describe this embodiment, a flexible glass cutting device, including an installation frame 1, a cutting mechanism 2, an extruding mechanism 3, a glass fixing mechanism 4 and a convenient pushing mechanism 5, and the cutting mechanism 2 is slidably installed on the extruding mechanism 3 , the extrusion mechanism 3 is fixedly installed on the installation frame 1, the glass fixing mechanism 4 is fixedly installed on the installation frame 1, and the convenient pushing mechanism 5 is fixedly installed on the glass fixing mechanism 4.

specific Embodiment approach 2

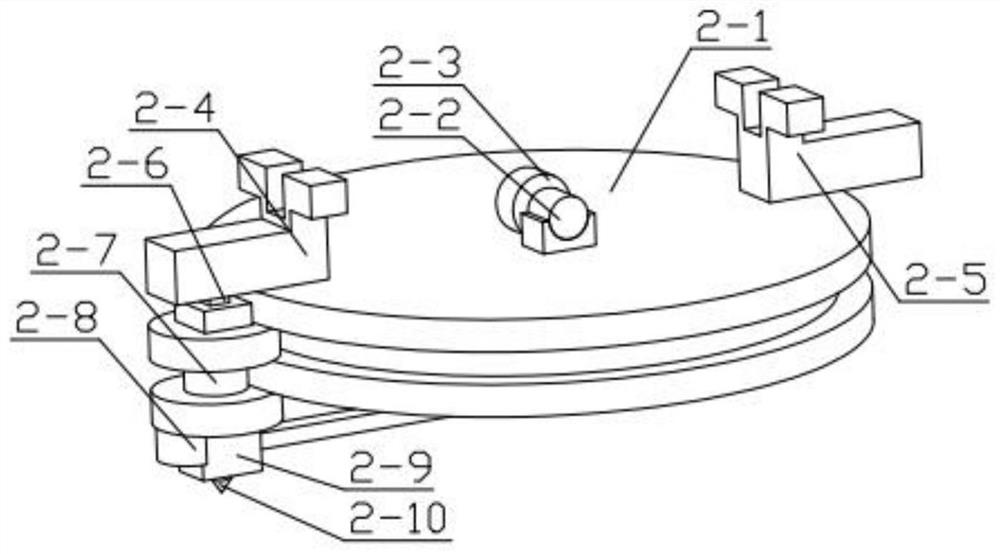

[0041] Combine below Figure 1-15 Describe this embodiment, this embodiment will further explain Embodiment 1, the described cutting mechanism 2 includes a grooved disc 2-1, a moving motor 2-2, a motor gear 2-3, a sliding foot 2-4, a sliding Foot two 2-5, triangular plug-in 2-6, limit piece 2-7, track rod 2-8, ring slide 2-9, diamond 2-10, set screw 2-11, support spring 2-12, belt The two ends of the grooved disc 2-1 are respectively fixedly equipped with a sliding foot one 2-4 and a sliding foot two 2-5, the mobile motor 2-2 is fixedly installed on the grooved disc 2-1, and the motor gear 2-3 is fixed Installed on the output end of the mobile motor 2-2, the limiter 2-7 is slidably installed in the groove provided on the grooved disc 2-1, and the limiter 2-7 is fixedly installed on one end of the track rod 2-8 , the other end of the track bar 2-8 is rotatably installed in the groove provided on the grooved disc 2-1, the ring slider 2-9 is slidably installed on the track bar 2...

specific Embodiment approach 3

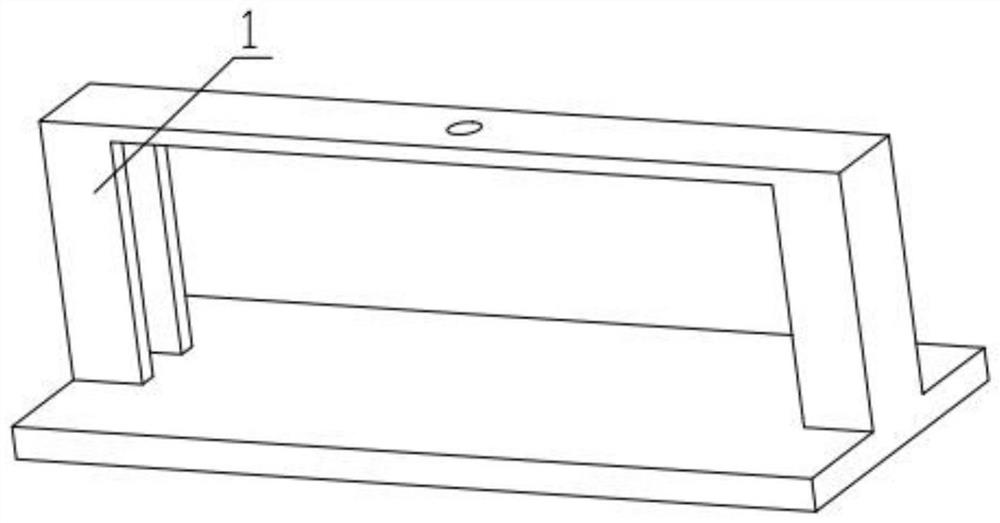

[0043] Combine below Figure 1-15 This embodiment will be described. This embodiment will further describe the second embodiment. The extrusion mechanism 3 includes an extrusion screw 3-1, a beam 3-2, a tooth strip 3-3, a side spring 3-4, and a tooth Stripes 3-3 are fixedly installed on the crossbeam 3-2, and the crossbeam 3-2 is respectively slidably installed with sliding foot 1 2-4 and sliding foot 2 2-5, and the two ends of the crossbeam 3-2 are respectively fixedly installed with side springs 3-4, the other end of the side spring 3-4 is fixedly installed on the installation frame 1, the beam 3-2 is slidably installed in the groove provided on the installation frame 1, and the extrusion screw 3-1 is threadedly connected with the installation frame 1, The extruding screw 3-1 passes through the mounting frame 1 and is in contact with the beam 3-2, and the motor gear 2-3 is meshed with the toothed strip 3-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com