Test bed capable of simulating cutter behaviors at various positions of cutter head

A technology for simulating knives and test benches, applied in measuring devices, testing wear resistance, testing machinability, etc., to achieve the effects of accurate test data, saving space, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

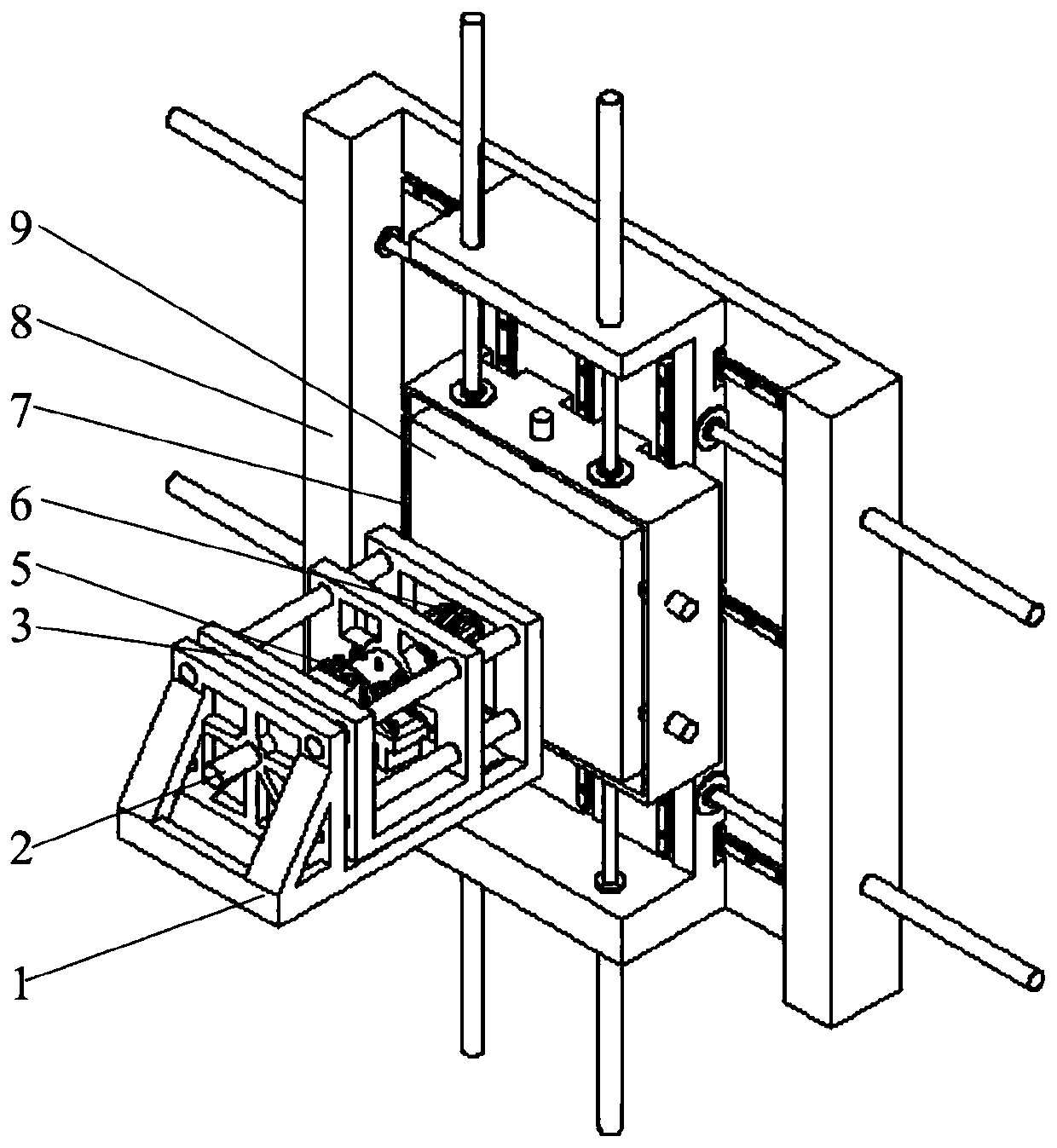

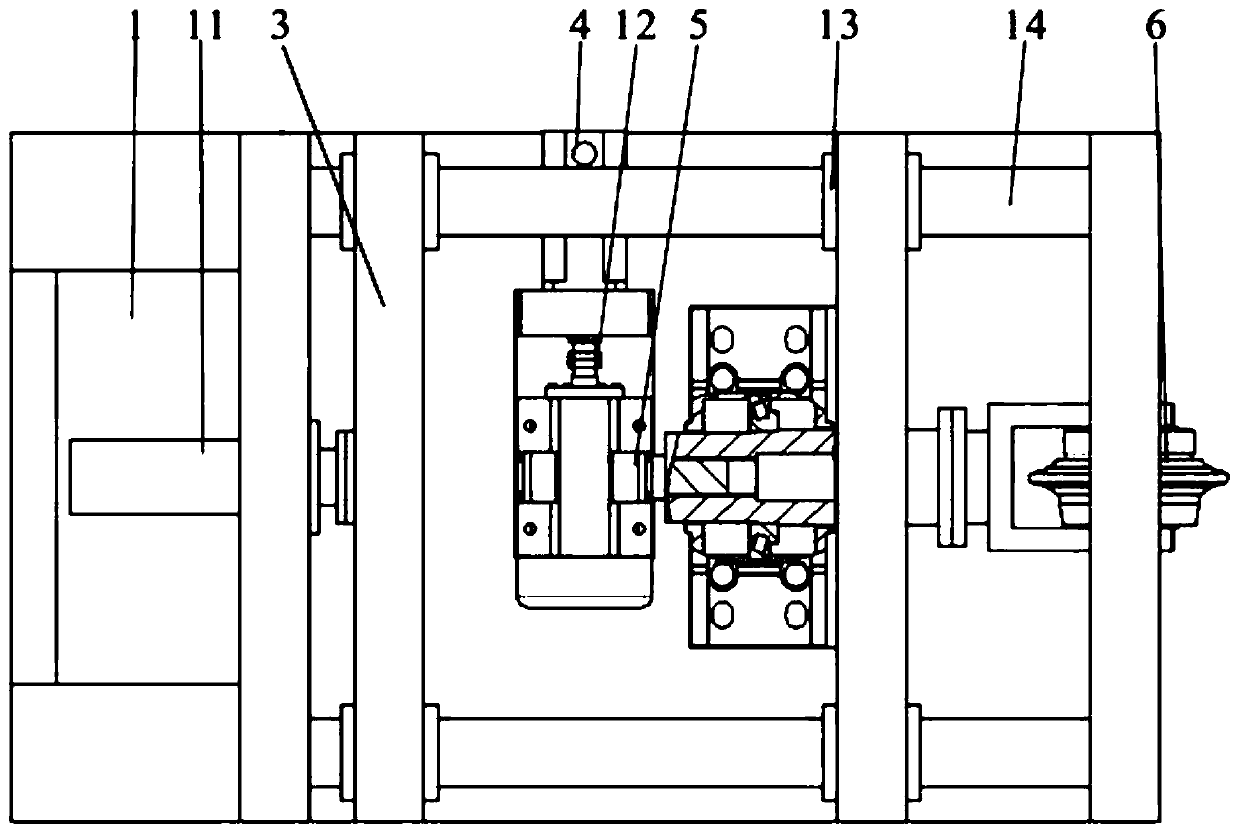

[0055] A test bench capable of simulating the behavior of cutters at various positions on a cutter head, comprising a transverse base 1 and a longitudinal base 8, the transverse base 1 is provided with a hydraulic propulsion system 2, and the hydraulic propulsion system 2 is connected with a tool box cutter System 6, a rock box moving system 7 is set on the longitudinal base 8, and a rock box system 9 is set on the rock box moving system 7. The rock box moving system 7 pushes the rock box system 9 to move according to the set path, so that the cutter breaks the rock on the rock sample according to the set path. In this embodiment, the horizontal base 1 is set horizontally, the rock box moving system 7 is set vertically, and the rock box moving system 7 is separately fixed on the foundation, and its center coincides with the center of the knife box cutter system 6, and the surface of the rock sample 904 Perpendicular to the feed direction of the tool box tool system 6 .

[005...

Embodiment 2

[0077]The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that: the tool seat 602 has an inclination angle to install a tool with an inclination angle, which is used to simulate an edge knife or an over digging knife.

[0078] This embodiment is used to simulate the edge-to-edge or over-excavation conditions of cutterheads with different diameters under confining pressure, and the specific test process is the same as that of Example 1.

Embodiment 3

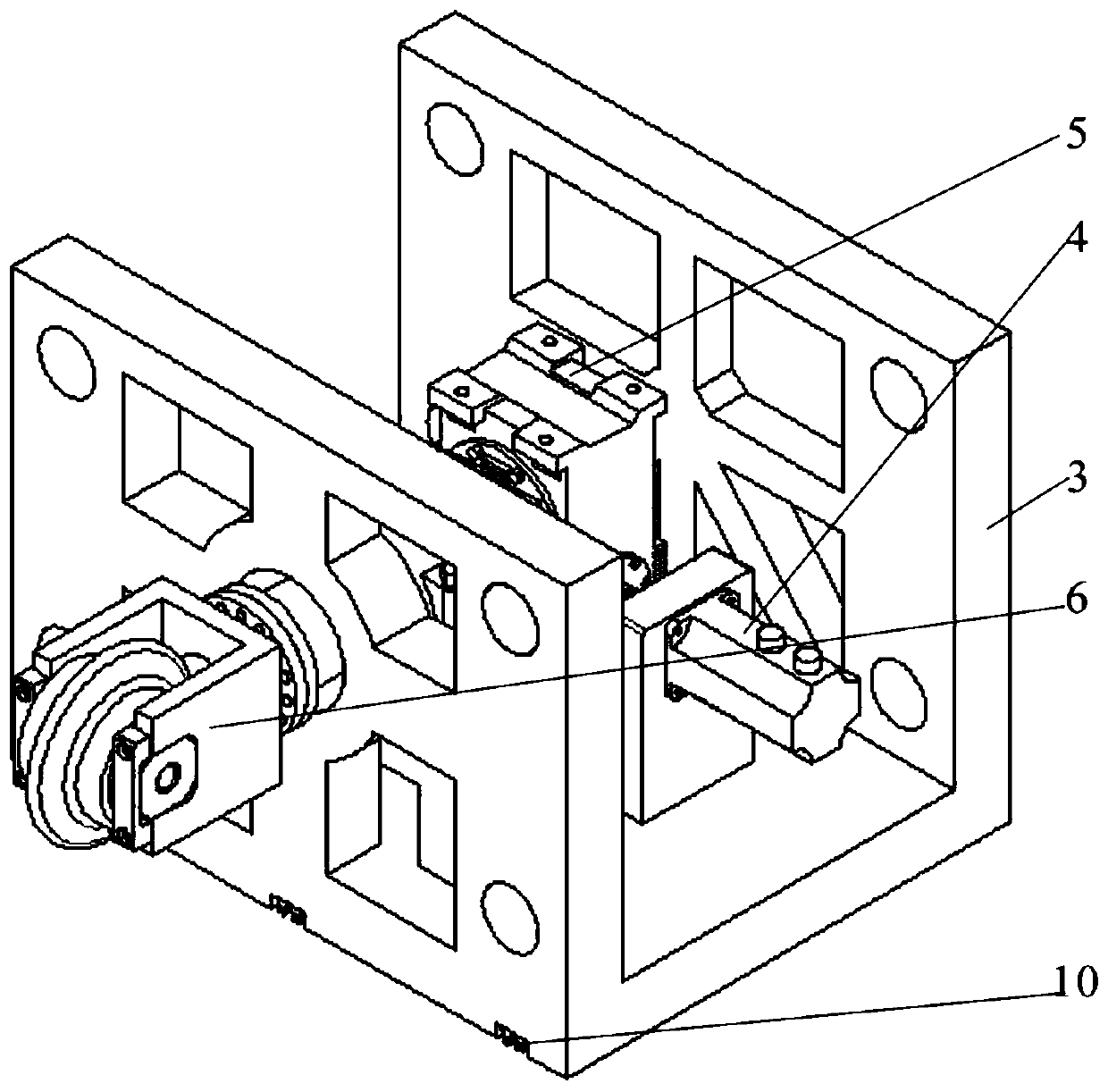

[0080] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that: the tool box tool system 6 includes a total three-way force sensor 606, and the total three-way force sensor 606 is connected to a multi-knife mounting plate 605, so The multi-knife mounting plate 605 is connected with several three-way force sensors 601, the three-way force sensor 601 is connected with a knife seat 602, and the knife seat 602 is connected with a bead 603 by bolts, between the knife seat 602 and the bead 603 There are cutters 604 .

[0081] In this embodiment, a T-shaped slot is opened on the multi-knife mounting plate 605, and the three-way force sensor 601 is slidably connected to the T-shaped slot and fixed by T-shaped bolts. The tool spacing can be adjusted according to experimental requirements. Stepless adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com