Method for preparing monodisperse cadium sulfide-silicon dioxide nucleo capsid structure

A technology of silica, core-shell structure, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of impurity condensation, uneven surface coating, uncontrollable shell wall thickness, etc. Achieve the effect of less absorption, enhanced photonic band gap characteristics, and low cost of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

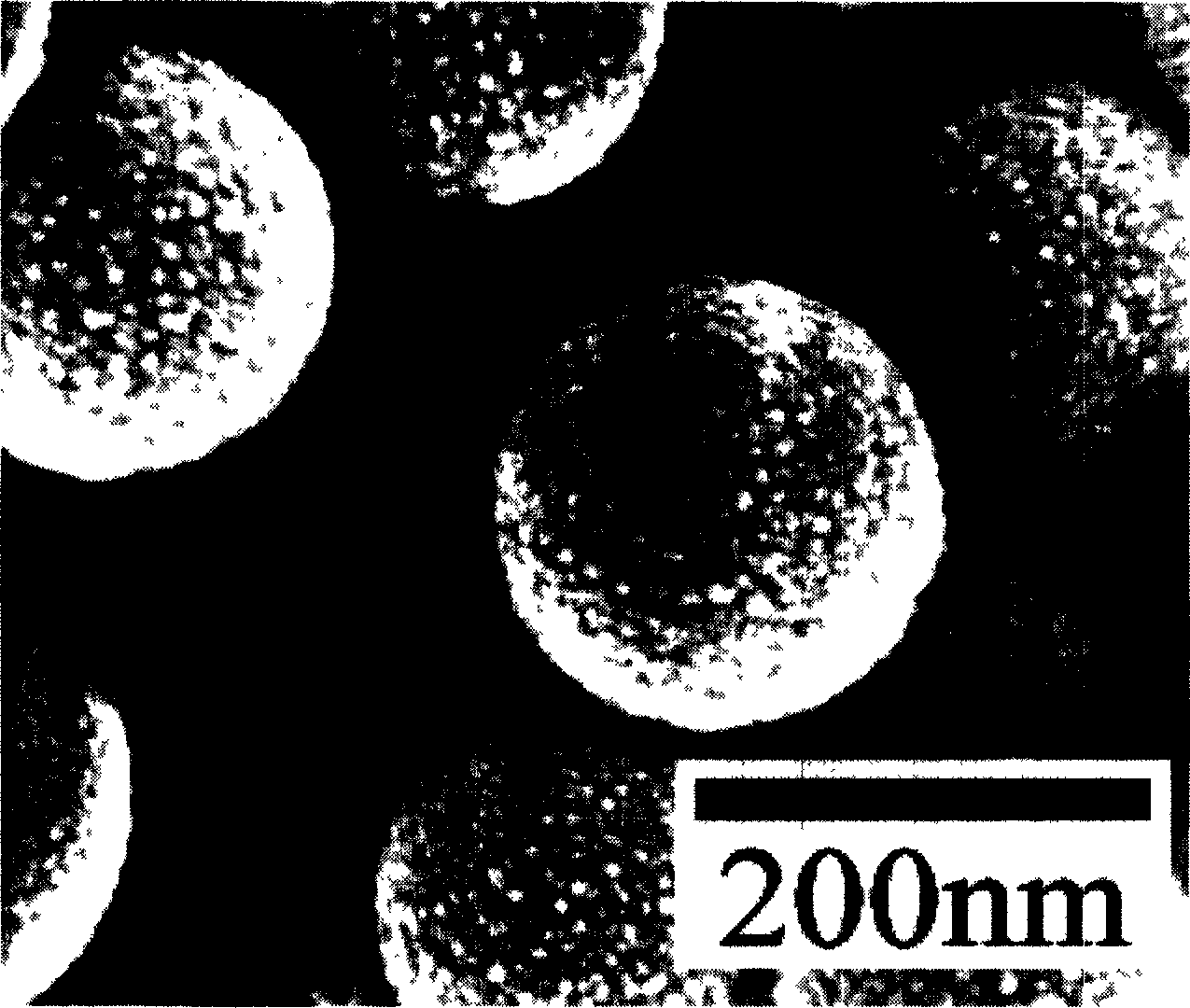

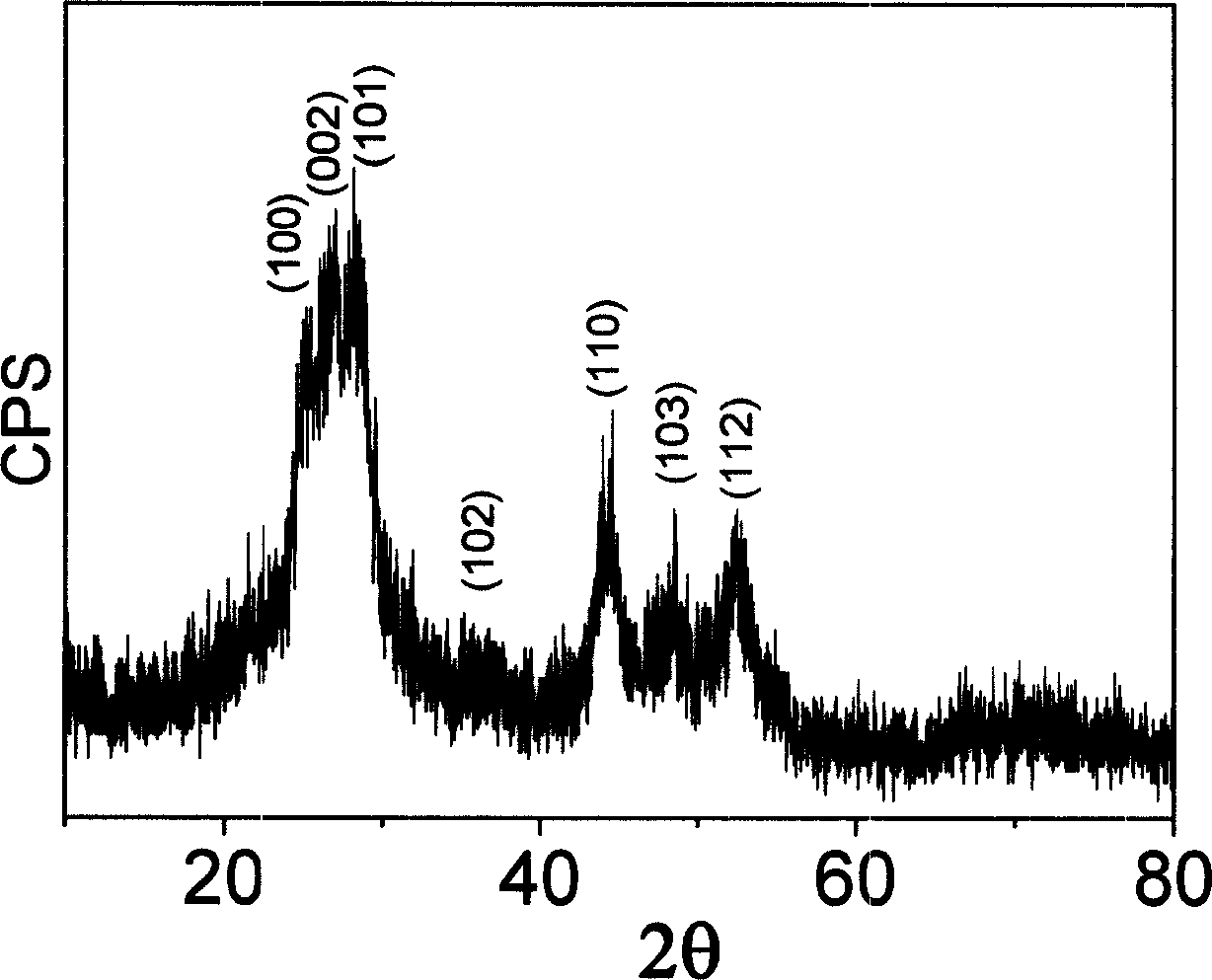

[0015] 1) Disperse 300 mg of monodisperse silica spheres with a particle size of 200 nm in 250 ml of deionized aqueous solution by ultrasonic oscillation, add 10 ml of 0.1 mol / L sodium citrate as a complexing agent, and add 15 μl of triethanolamine As a surfactant, and adjust the pH to 11 with ammonia water. Stir at a constant temperature of 60°C with magnetic force, then drop 10 ml of 0.1 mol / L cadmium chloride and 50 ml of 0.04 mol / L sulfur urine, and react for 2 hours to obtain a suspension of core-shell structure of cadmium sulfide-coated silica spheres , use deionized water and absolute ethanol to adopt centrifugal deposition and ultrasonic dispersion cycle cleaning to remove reaction residues, and dry at 60°C to obtain a monodisperse cadmium sulfide-silica core-shell structure (such as figure 1 ), it can be seen from the figure that the cadmium sulfide is evenly wrapped on the surface of the silica, there are no redundant cadmium sulfide particles and impurities agglomer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com