Diameter-variable multi-gear combined equivalent gear drive type continuously variable transmission

A technology of continuously variable transmission and gear combination, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of unusable, poor manufacturability of friction transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

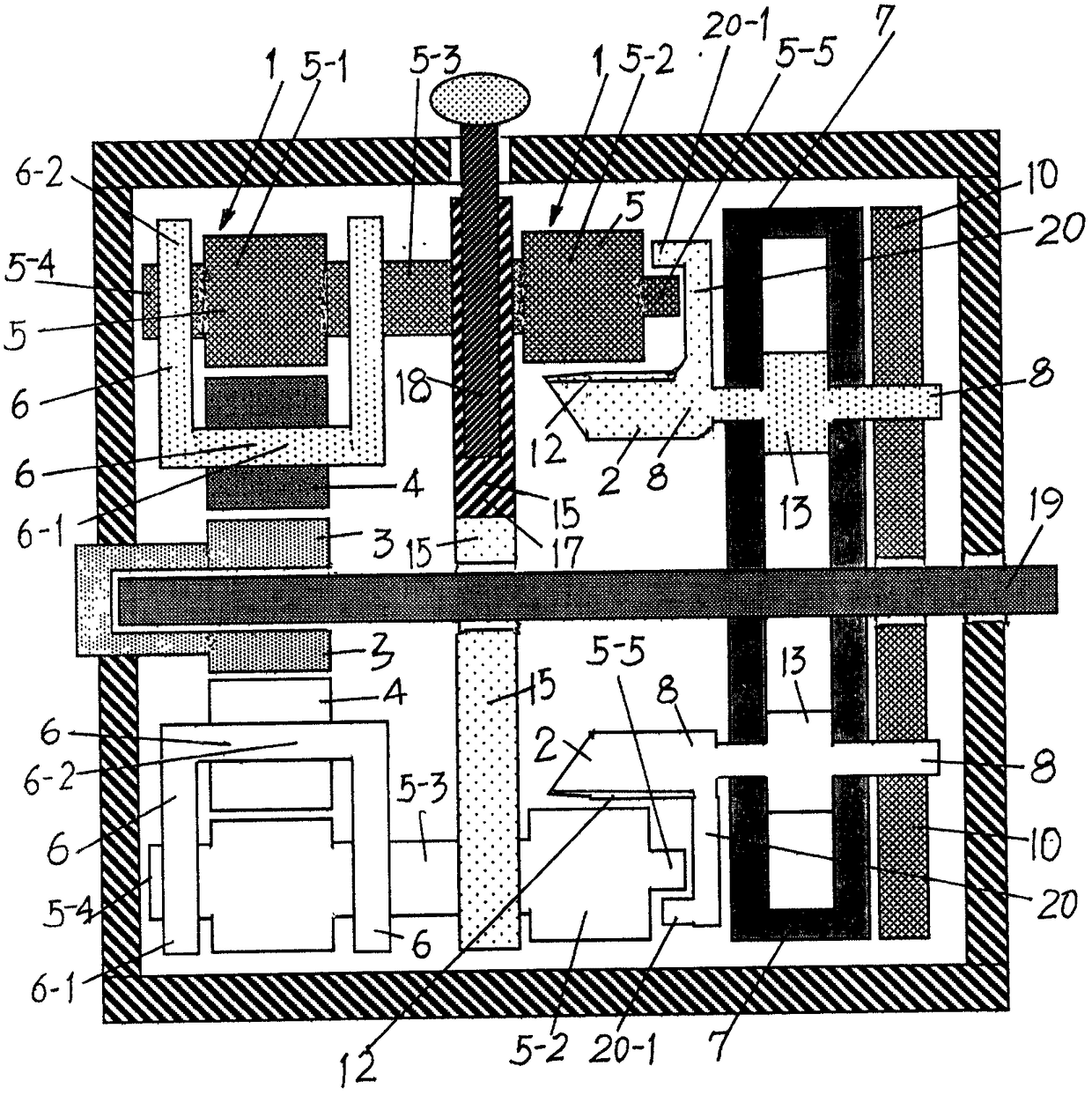

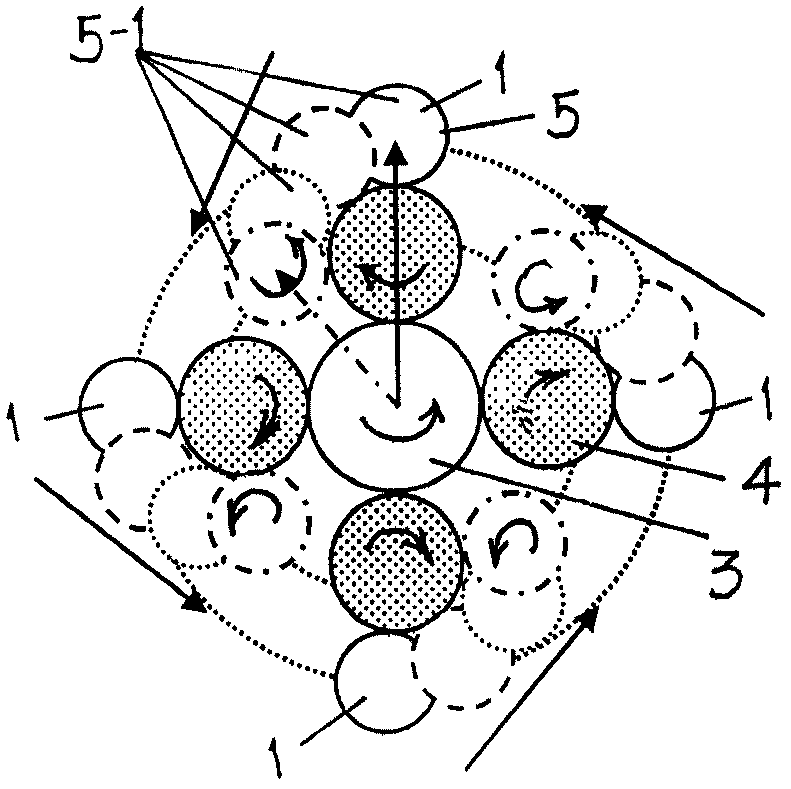

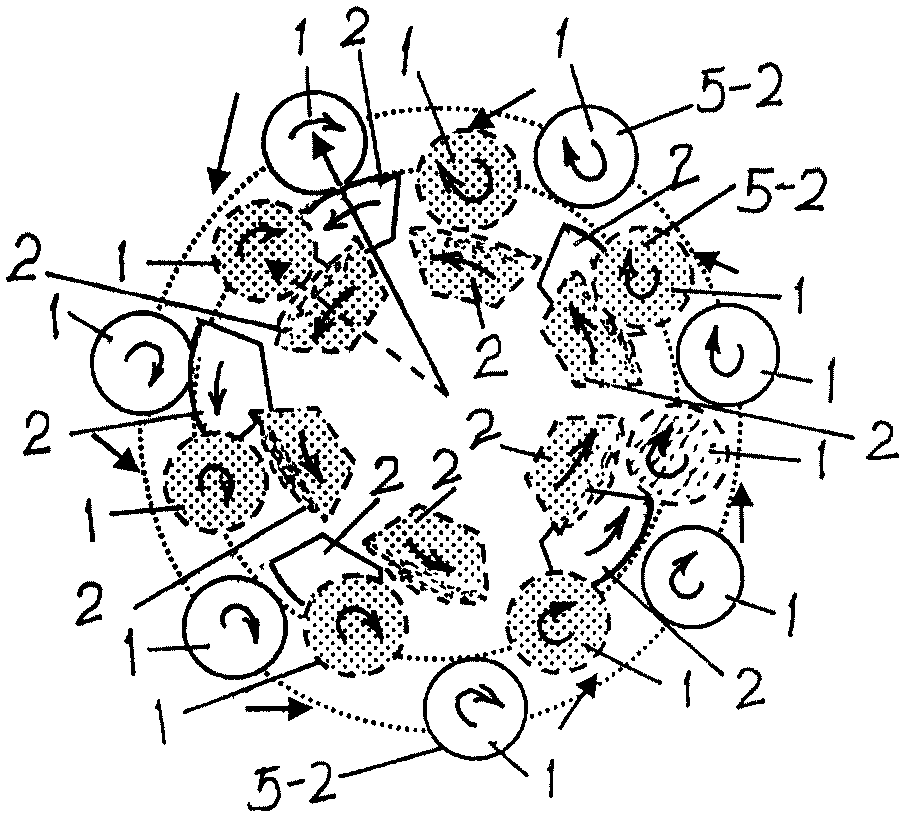

[0047] Embodiment 1, variable-diameter multi-gear combined into a continuously variable transmission of equivalent gear transmission

[0048] Such as figure 1 , 2 , 3, 4, 5, 6, 7, variable-diameter multi-gear combined into a continuously variable transmission of equivalent gear transmission, including the driving gear assembly and the driven gear assembly, the driving gear assembly and the driven gear assembly The last-stage gear of the meshed driving gear assembly is a multiple gear combination equivalent gear 1, and the first-stage gear of the driven gear assembly meshing with the driving gear assembly in the driven gear assembly is a combination of multiple tooth columns Formula equivalent gear 2, multiple gear combined equivalent gear 1 meshes with multiple tooth column combined equivalent gear 2 to transmit power, multiple gear combined equivalent gear 1 and multiple tooth column combined equivalent gear 2 Synchronous in the meshing state, and steplessly change the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com