Patents

Literature

36results about How to "Keep neat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

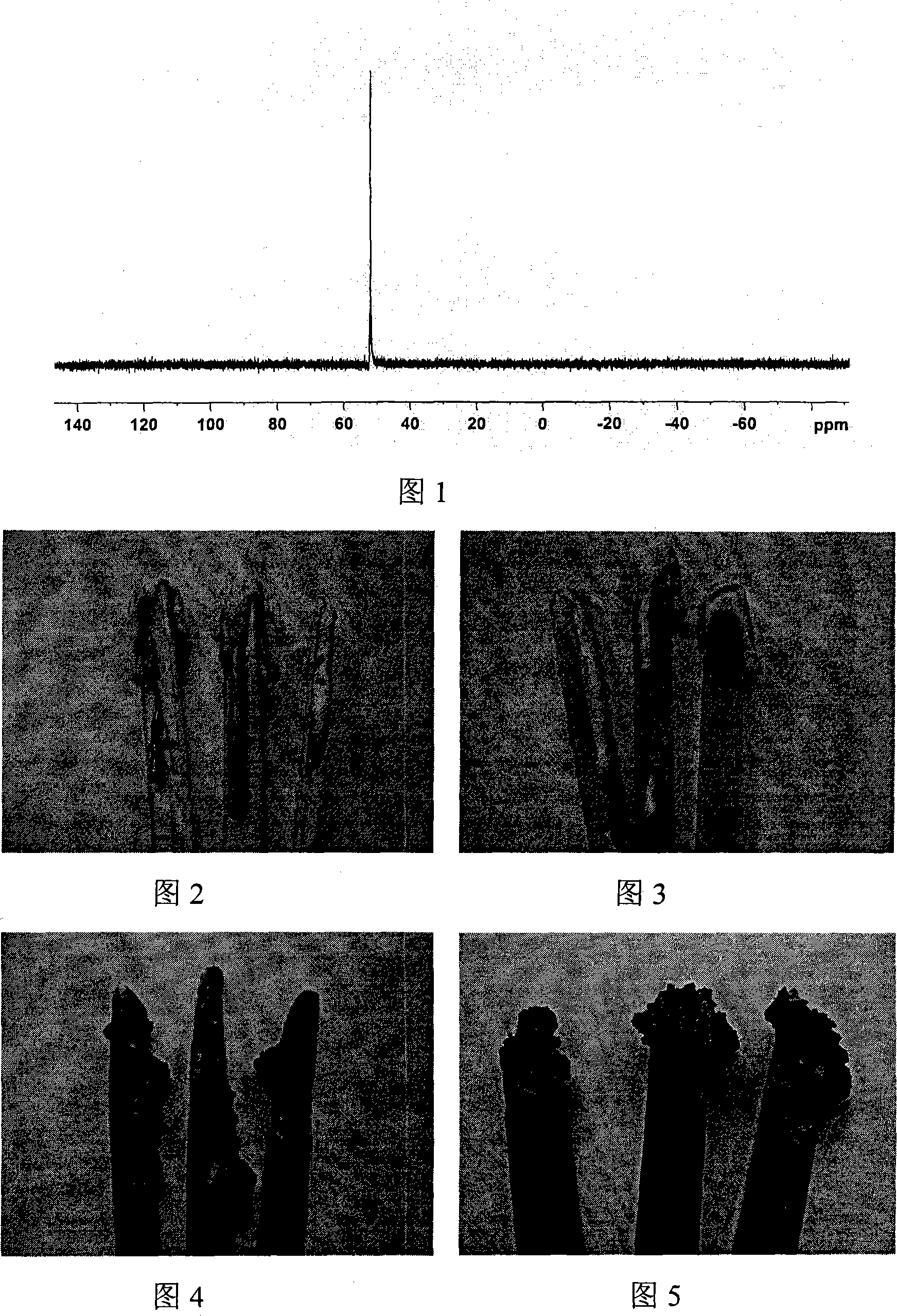

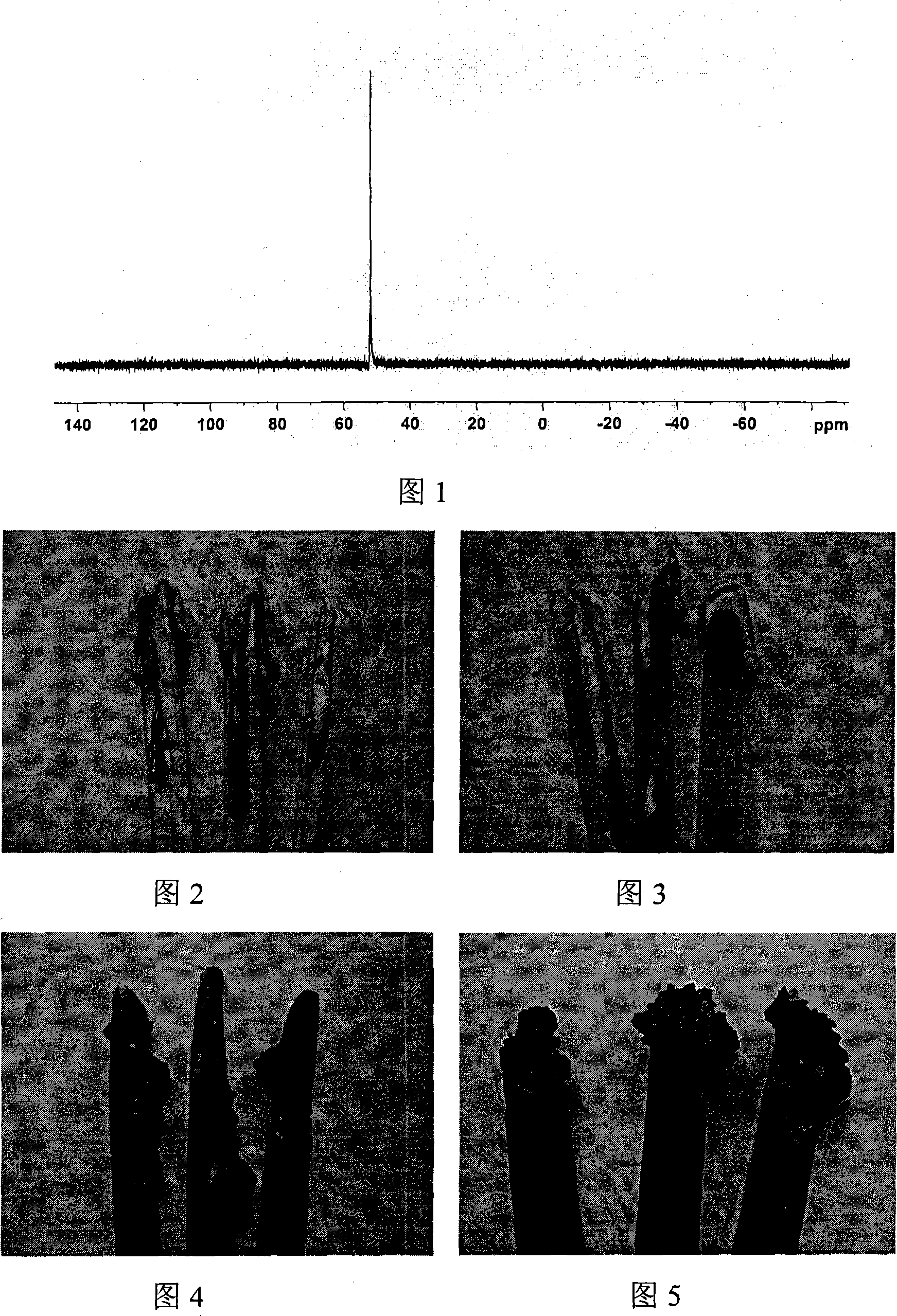

Phosphoric flame-proof copolyester ionomer and preparation method thereof

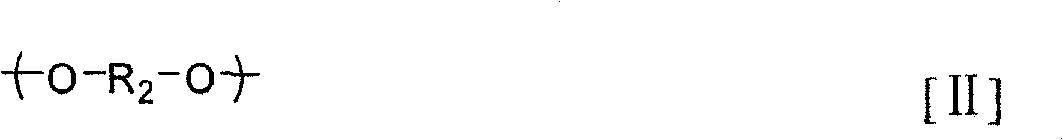

The invention discloses a phosphorus-containing flame retardant copolyester ionomer and the preparation method, which is characterized in that: based on a plurality of building units synthesizing polyester represented by I and II, a plurality building units represented by IV or a plurality building units represented by III and IV are introduced and the copolyester ionomer is prepared by random copolymerization; wherein, the number of the building units represented by III is 0 to 20 percent of the number of the building units represented by I, the number of the building units represented by IV is 0.1 to 20 percent of the number of the building units represented by I, the number of the building units represented II: the number of the building units represented by [I+III+IV] equals 1, the intrinsic viscosity of the prepared copolyester ionomer [Eta] is in the rang of 0.25 to 0.95dL / g. The phosphorus-containing flame retardant copolyester ionomer has the advantages that: because the ionic groups are phosphorus-containing groups, the flame-retardance modification and the ionization modification of polyester are realized simultaneously; meanwhile, the melt viscosity of polyester is enhanced by the incarbonization produced by the phosphorus-containing ionic groups and the ''physical crosslinking'' produced by the ''ionic aggregate'', thus, the flame retardant and anti-dripping performance is given to polyester.

Owner:SICHUAN UNIV

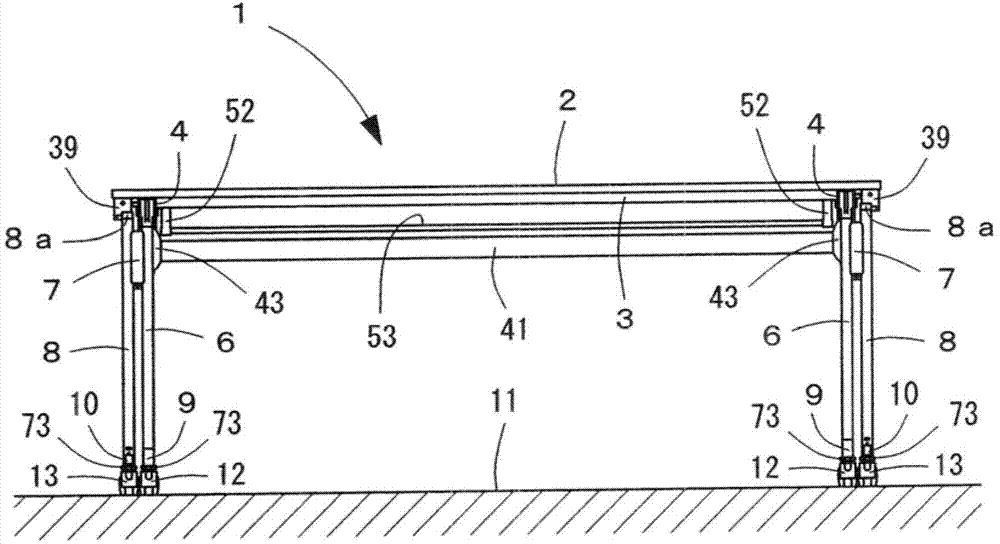

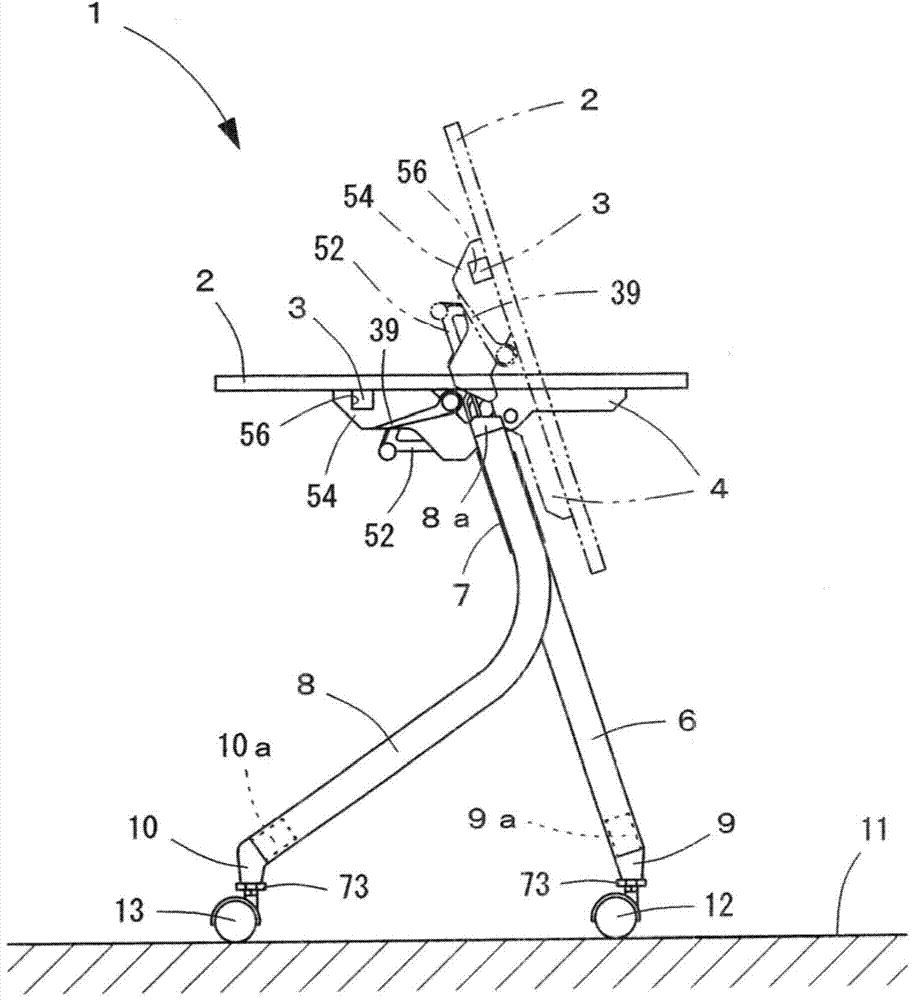

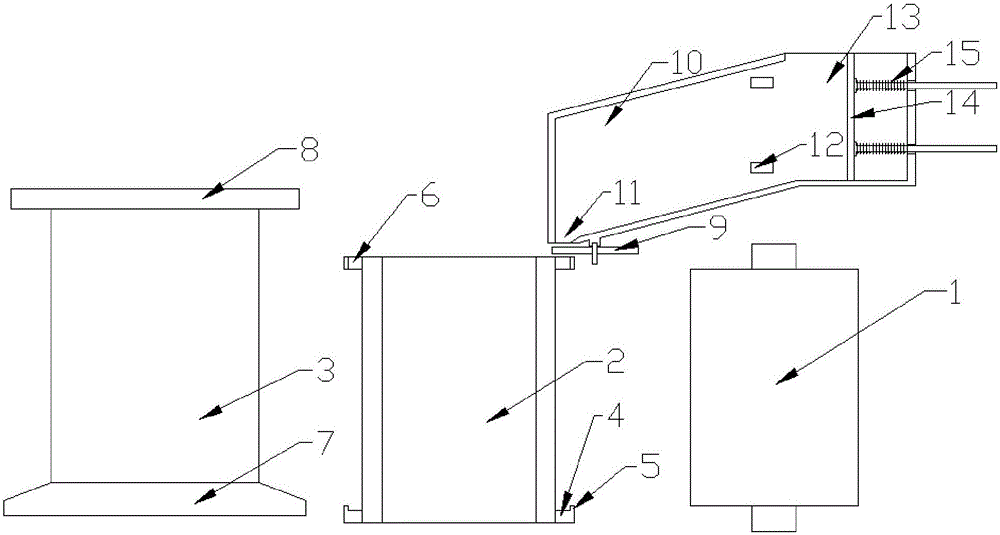

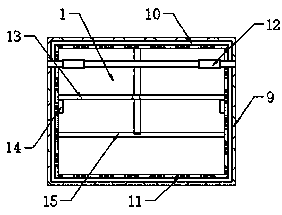

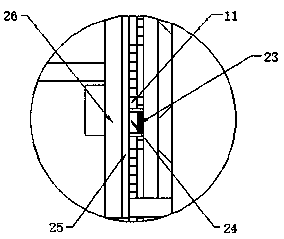

Folding table

ActiveCN103156384AAchieve compactnessConducive to lightweightFoldable tablesStowable tablesMechanical engineeringGround level

The invention provides a folding table, which comprises a height regulation device capable of easily and reliably regulating height from a leg or a top plate to the ground, while the folding table obtains reliable and stable using and folding states to the top plate. A locking connecting rod is arranged, and the locking connecting rod comprises a clamping part clamping or unclamping in a clamping groove. The clamping part of the locking connecting rod forms a plate on a same plane with the locking connecting rod. A peripheral surface on an upper end of a connection component is configured a same plane of a rotation area of the clamping part.

Owner:HUIBIES FURNITURE

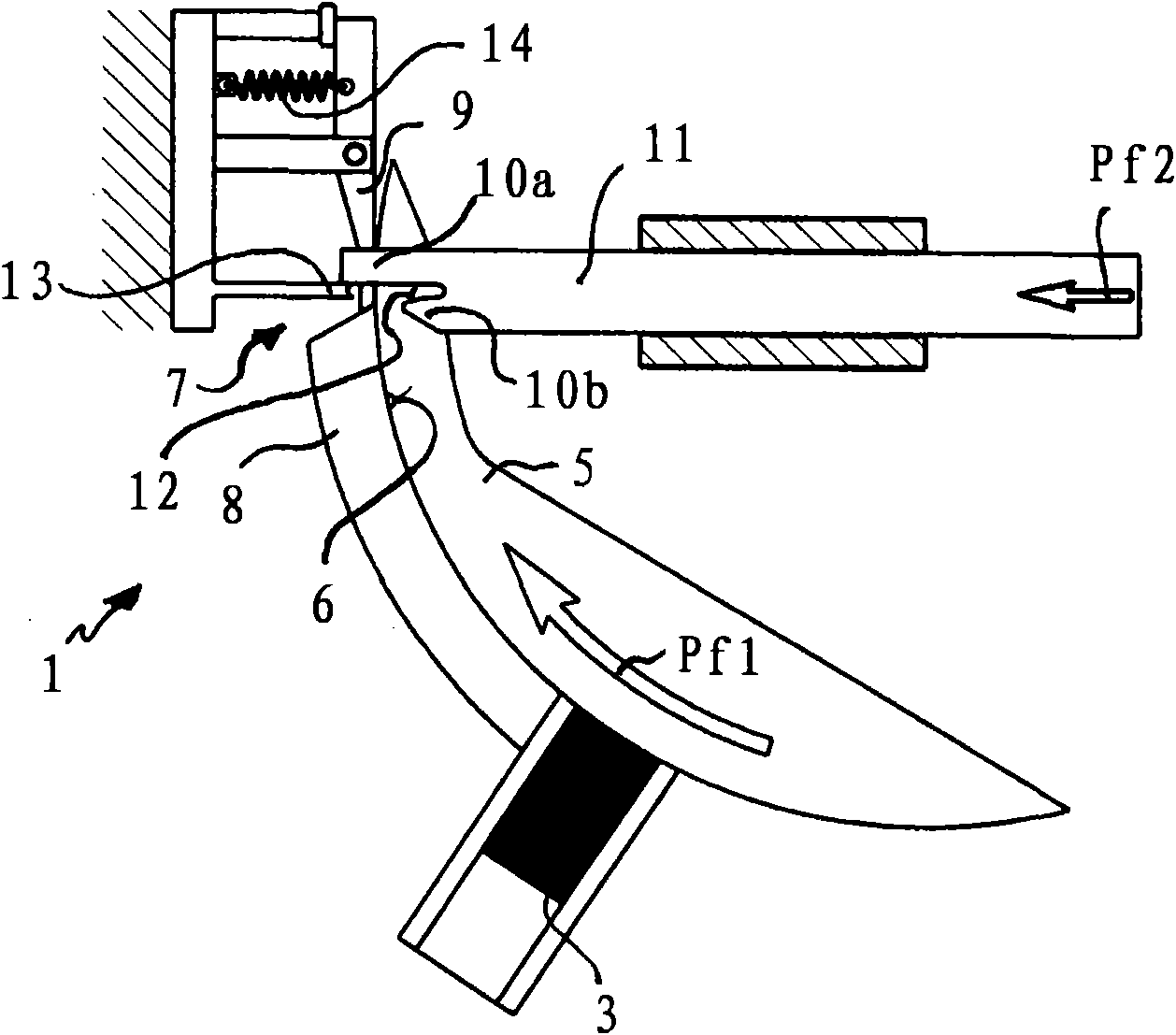

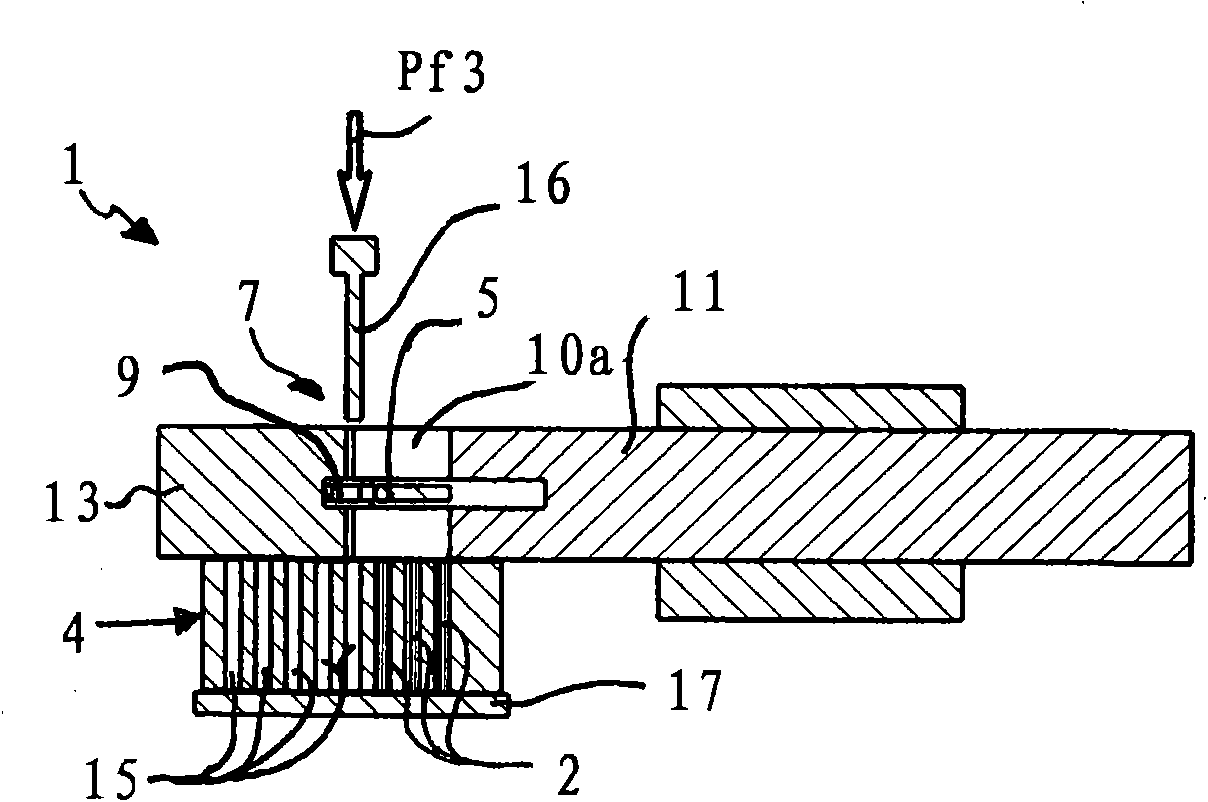

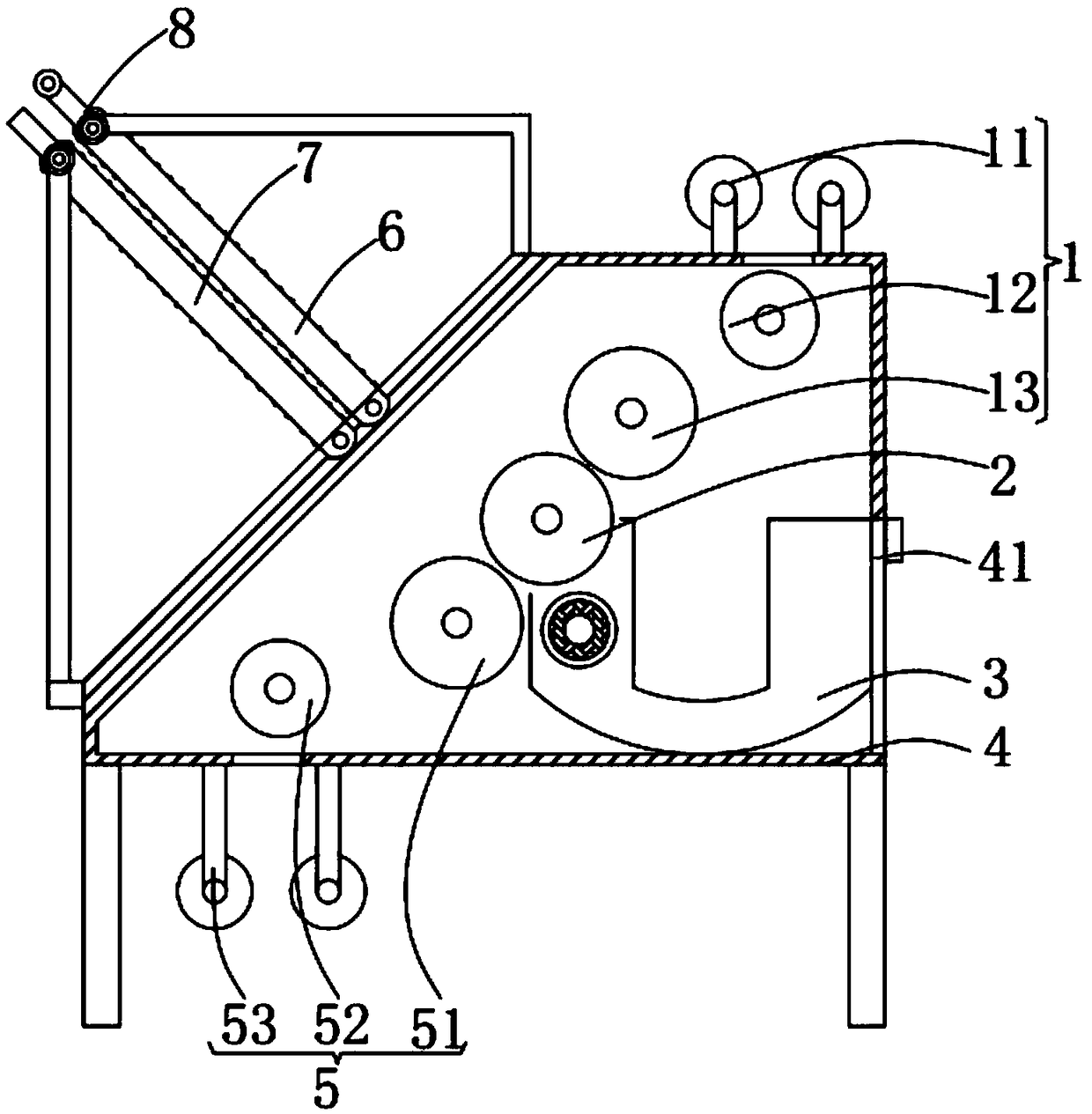

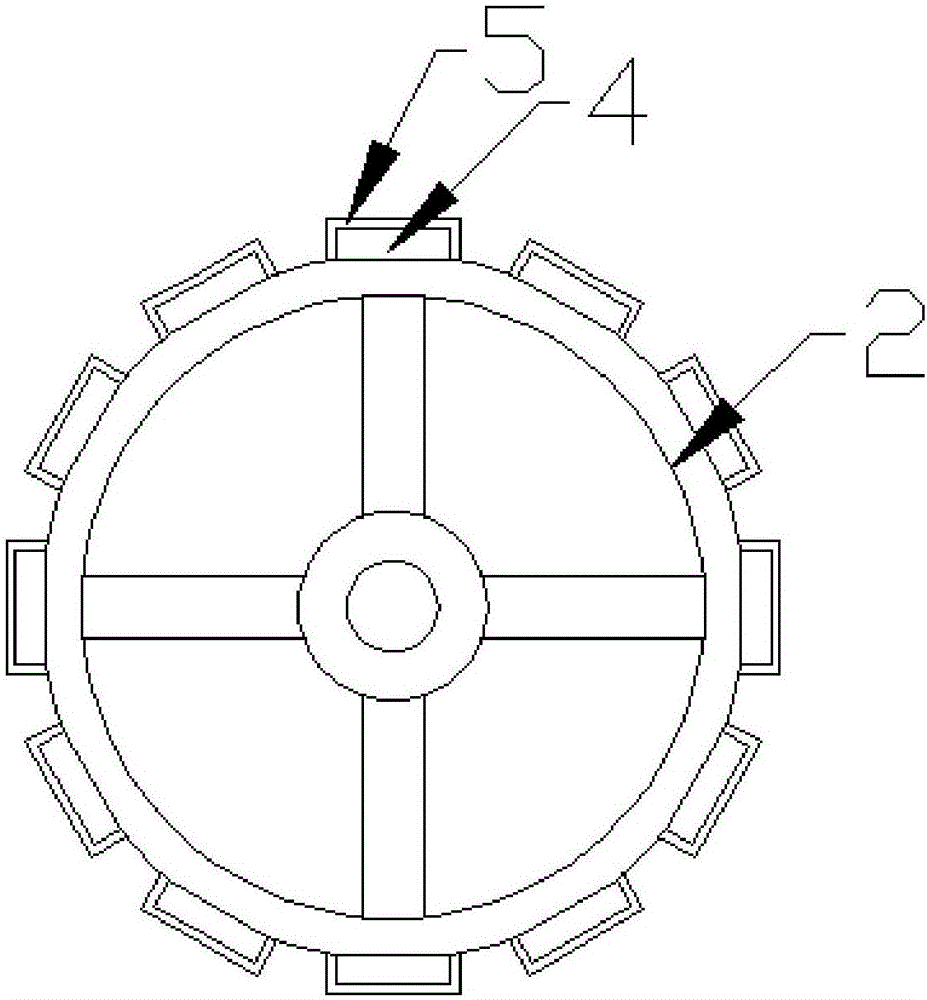

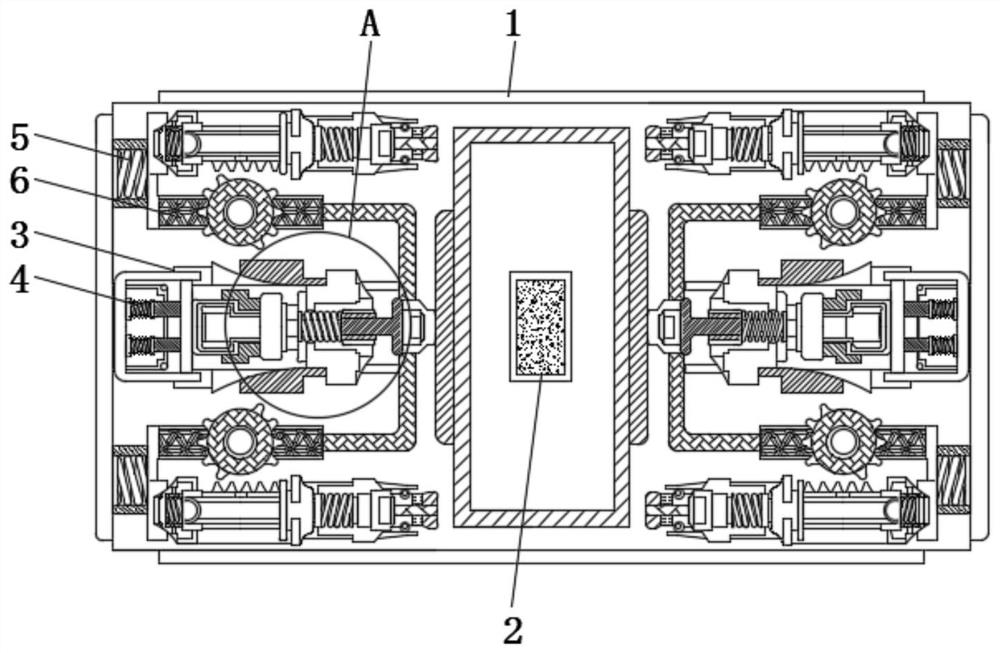

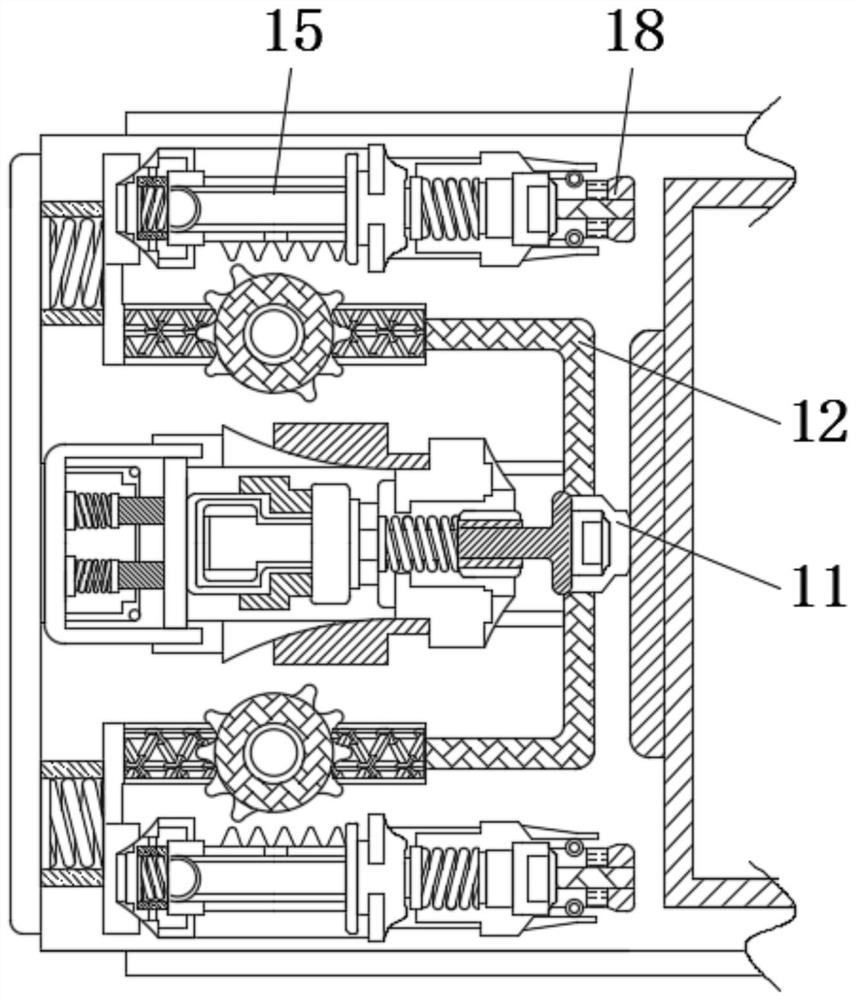

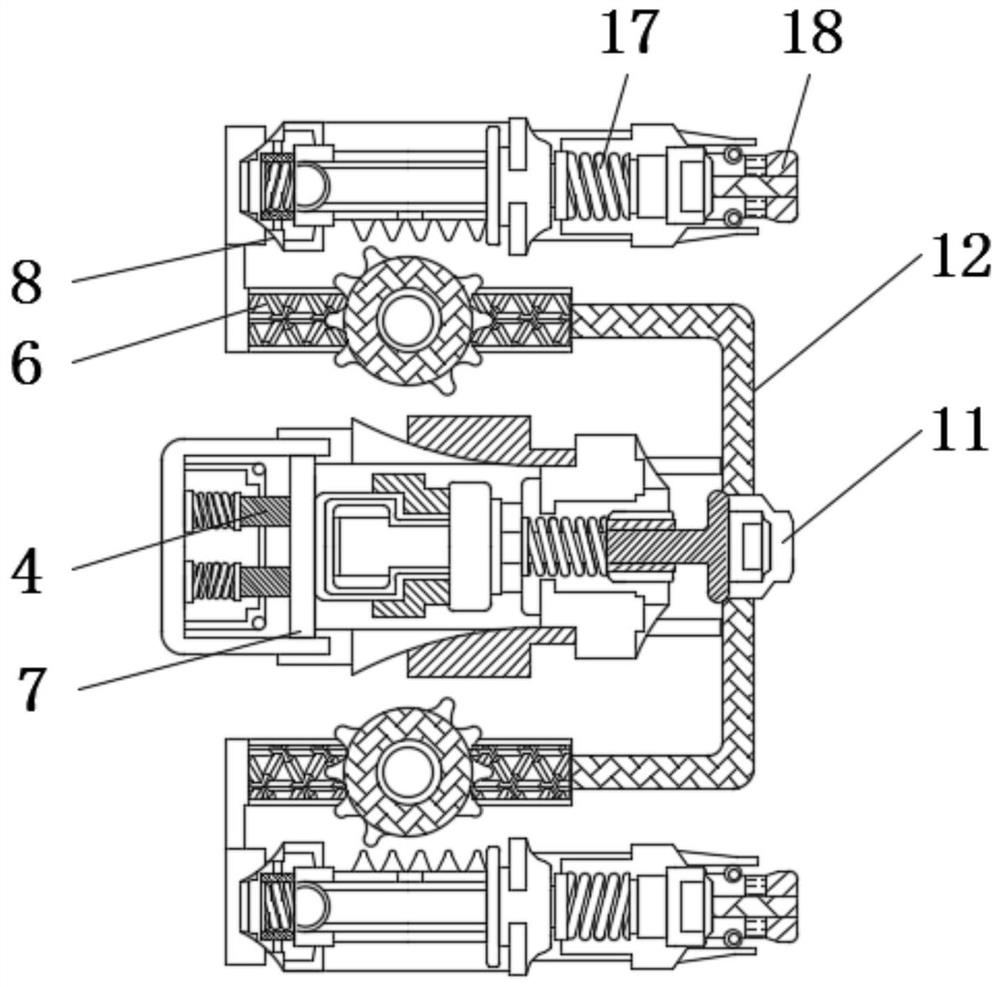

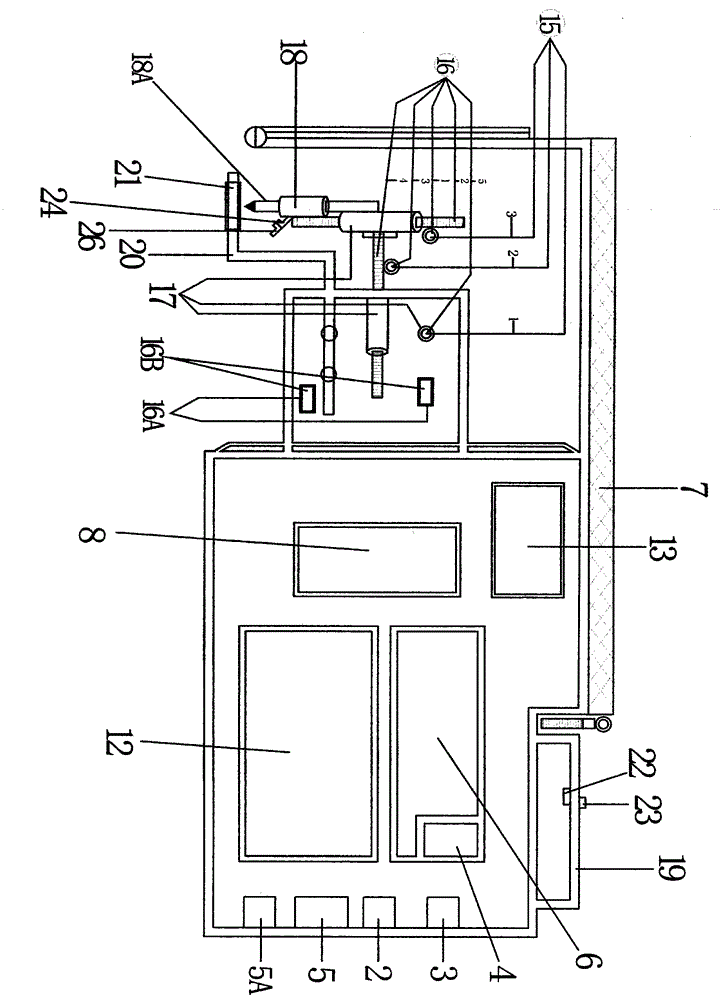

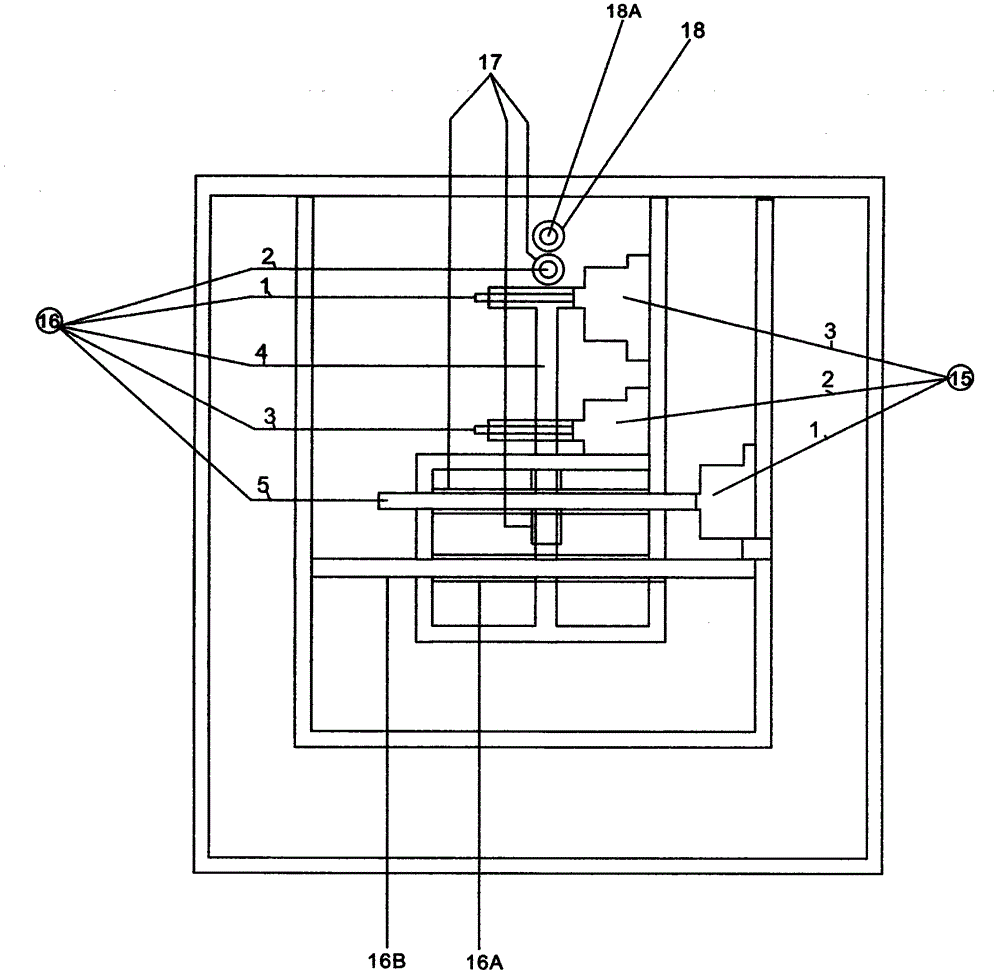

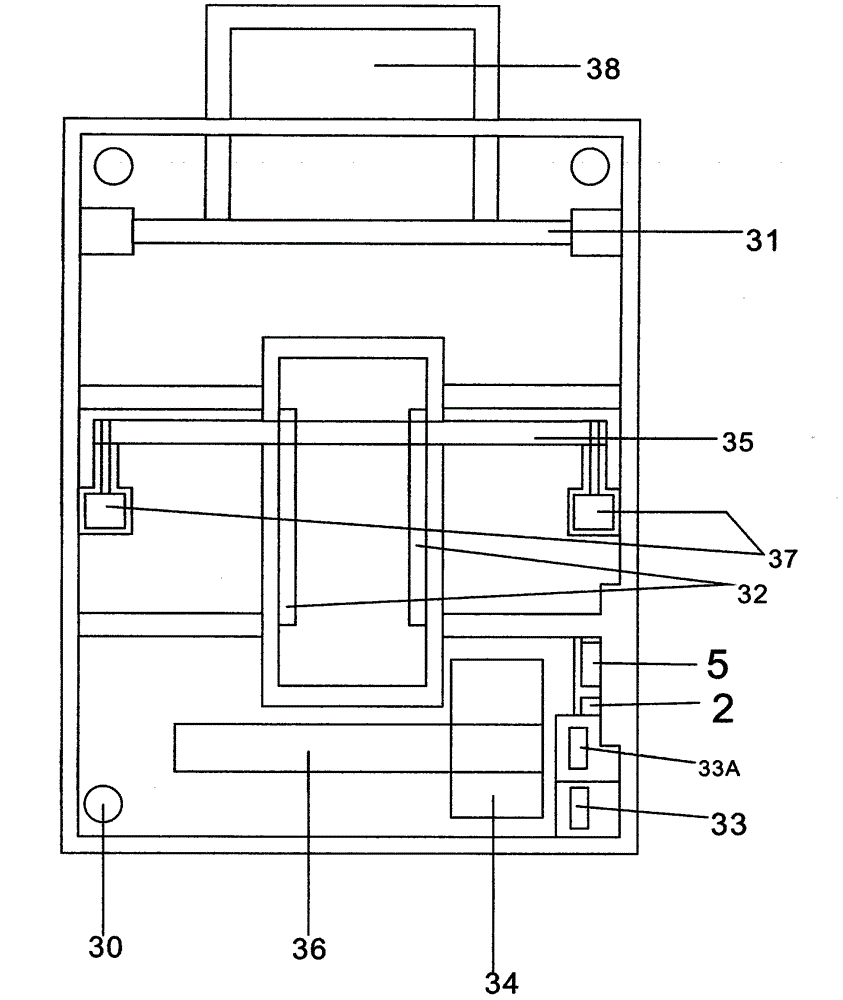

Brush manufacturing machine

The present invention relates to a brush manufacturing machine having a bristle conveying device (1) from a bristle storing device (3) to a box or a bristle receiving section (4), the bristle receiving section has a receiving opening (15) for single bristle bundle, wherein the machine has a bundle divider with a receiving notch (6) for fetching out the bristle bundle from the bristle storing device (3). In a zone with a assembly point (7), a bundle slider (11) capable of moving between a conveying position and a retaining position is provided to convey the bundle (2) from the bundle divider (5) to the bristle receiving section (4), the slider is used for removing the bristle bundle (2) from the receiving notch (6) of the bundle divider (5) and holding the bristle bundle (2) between the bundle slider (11) and a bundle holder (13). An axially adjustable ejector (16) is also provided to loading and discharging the bristle bundle (2), held between the slider (11) and the bundle holder (13), into and from the bristle receiving section (4).

Owner:ZAHORANSKY AG

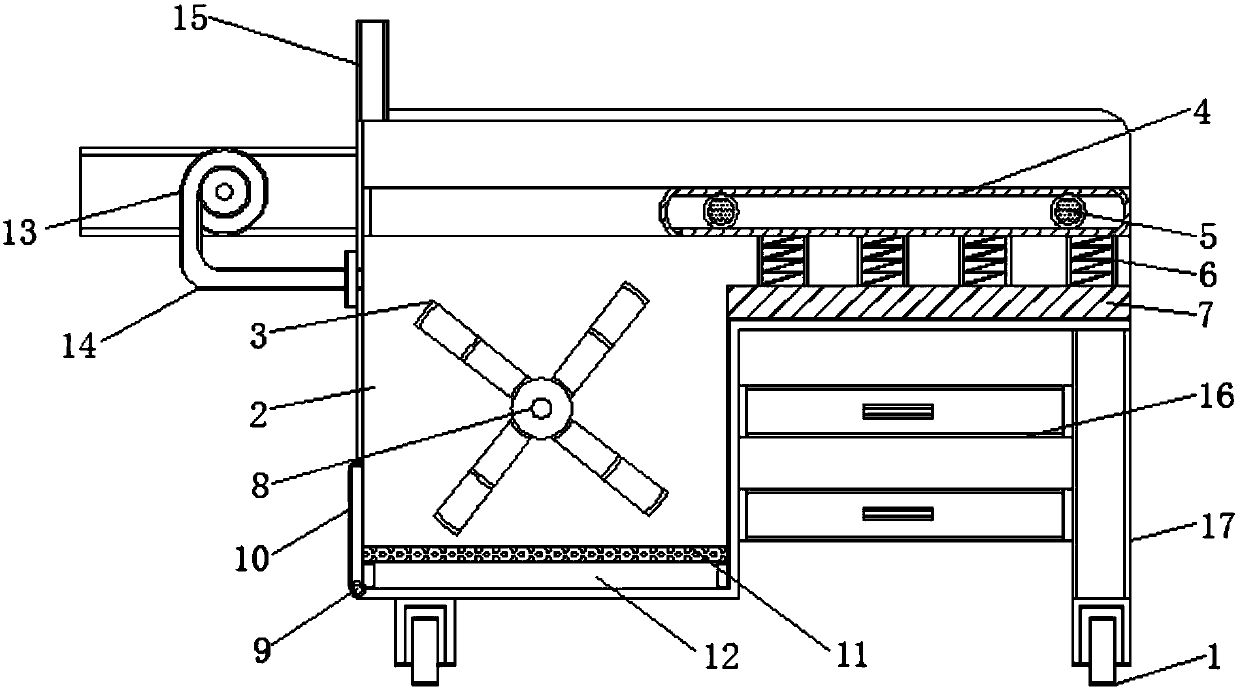

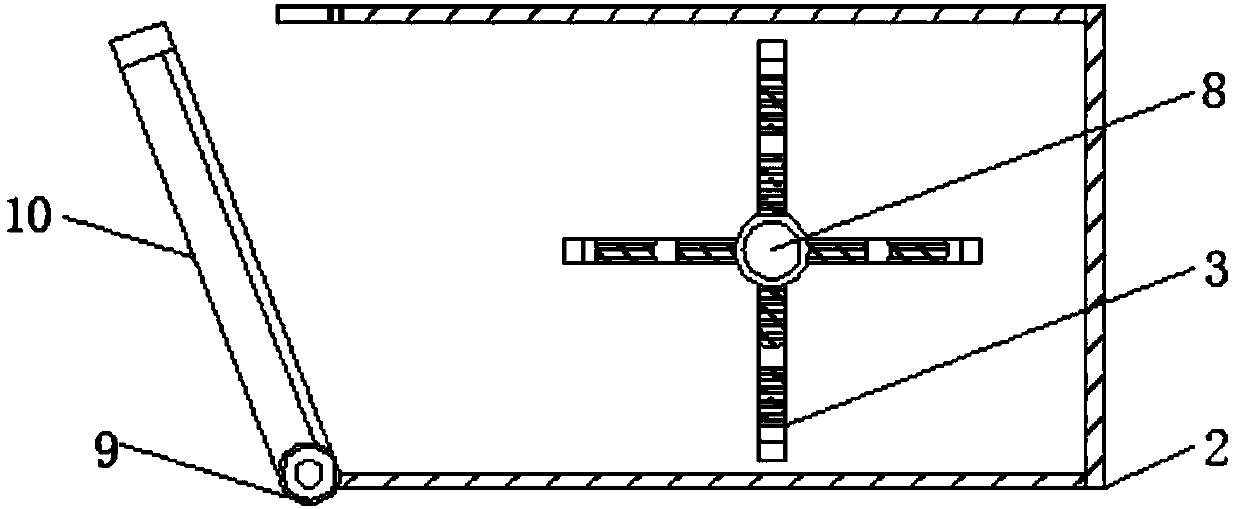

Industrial material sorting machine

InactiveCN107755296AHigh degree of cohesionObvious advantages in work efficiencyDirt cleaningSortingPulp and paper industryGuide tube

The invention discloses an industrial material sorting machine, which comprises a machine body, a sorting bin and a sorting blade, the sorting bin is located inside the machine body, the sorting blade is located inside the sorting bin, one side of the body is connected with An exhaust fan, one end of the exhaust fan is connected with an air guide pipe, the air guide pipe is connected with the sorting bin, the lower end of the sorting blade is provided with a filter screen, the lower end of the filter screen is connected with a dust collection tank, the body Guide rollers are arranged on the surface, and conveying panels are rollingly connected to both sides of the guide rollers. The present invention arranges four sets of sorting blades inside the sorting bin, which can separately undertake the materials, with high cohesion and obvious advantages in working efficiency. By connecting the exhaust fan on one side of the machine body, the dust and debris can be sucked away, keeping Higher cleanliness and use effect of industrial materials, by connecting the shock-absorbing spring at the lower end of the conveying panel, and connecting the buffer pad at the lower end of the shock-absorbing spring, the stability of its operation is improved.

Owner:WUXI IDO SCI & TECH CO LTD

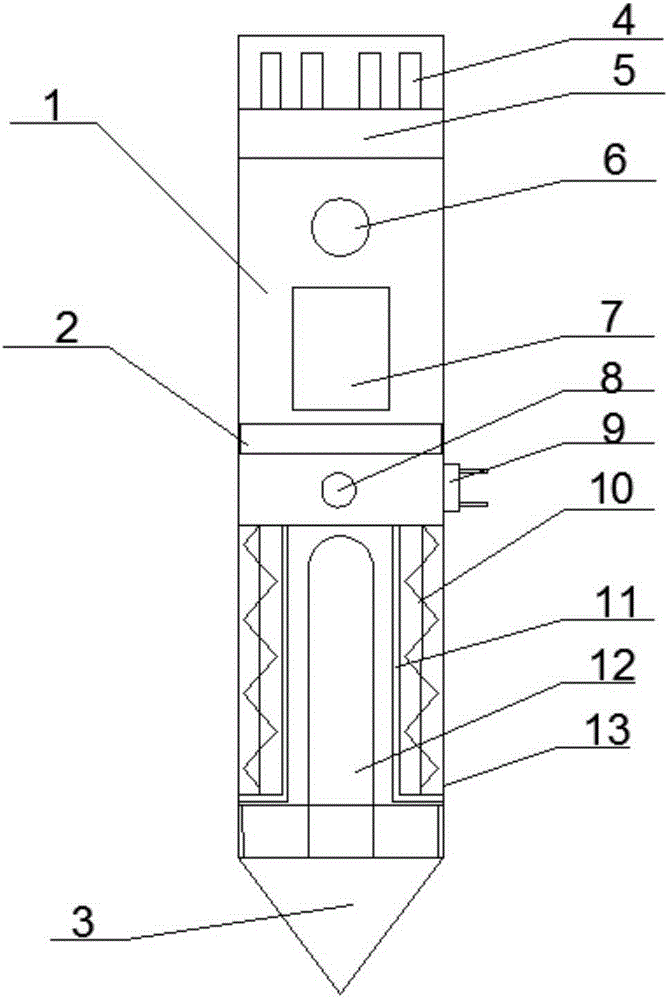

Multifunctional heating pen

InactiveCN105216487AKeep smoothKeep neatMechanical clocksWriting implementsElectrical and Electronics engineeringEngineering

The invention relates to a multifunctional heating pen which comprises an upper pen body and a low pen body. The lower end of the upper pen body is connected with the upper end of the lower pen body. The top end of the upper pen body is provided with LED electronic lamps. The LED electronic lamps are connected to a control device through a circuit. The upper pen body is provided with an LED electronic lamp switch for controlling the LED electronic lamps to be turned on or off. The lower pen body comprises a shell, a heating switch, a power device, a heating unit and a vacuum insulation plate. The power device is located on the upper portion in the shell. The outer wall of the shell is provided with the heating switch. A cavity is formed between the vacuum insulation plate and the shell. The heating unit is arranged in the cavity. A refill is arranged in the vacuum insulation plate. The upper end of a pen head is connected with the lower end of the lower pen body. The refill extends out of the lower end of the pen head. The multifunctional heating pen can emit heat automatically, is suitable for being used under the condition that the environment temperature is lower, improves the writing effect and operability and brings convenience for people writing in the cold environment.

Owner:桂林风范装饰工程有限公司

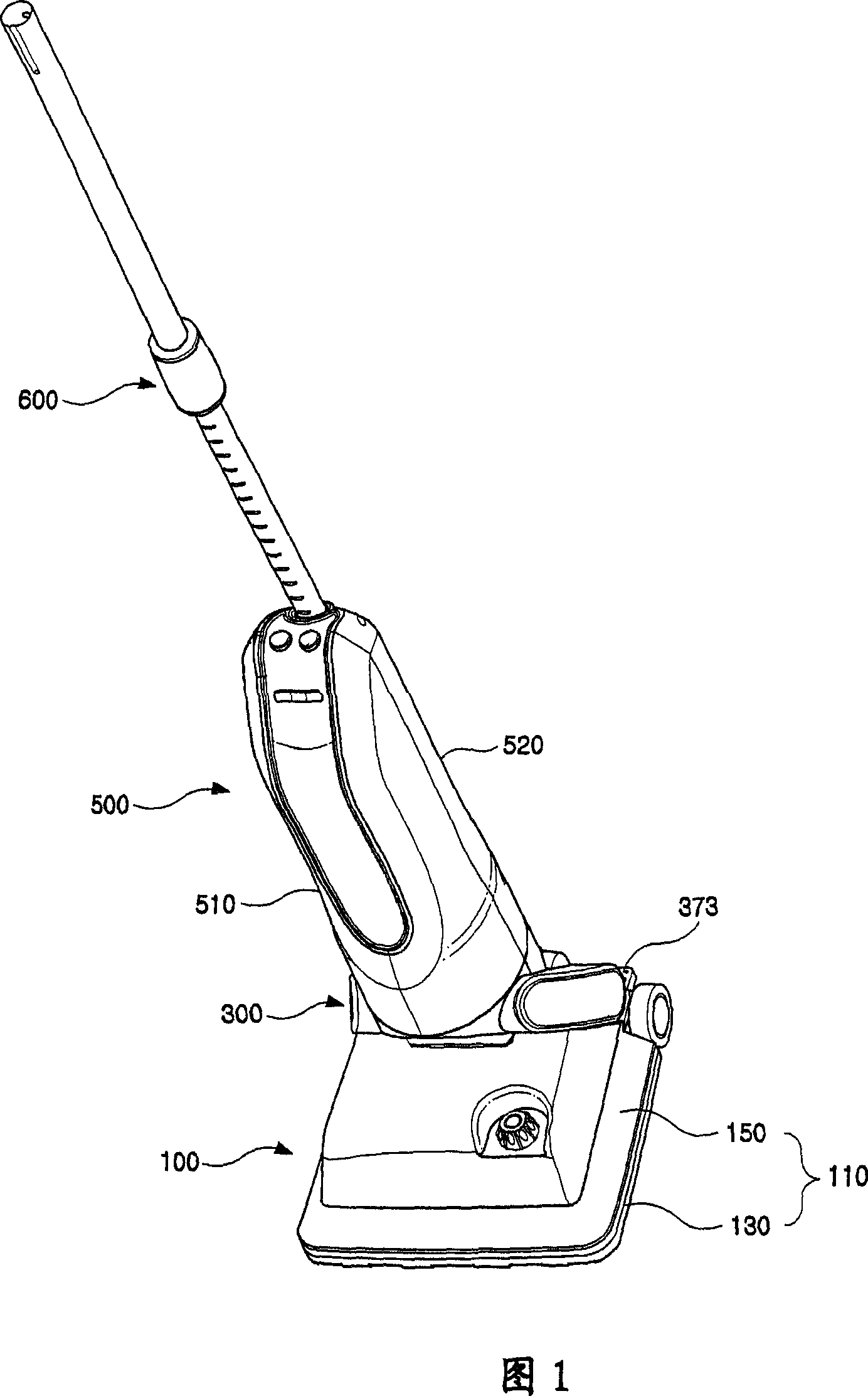

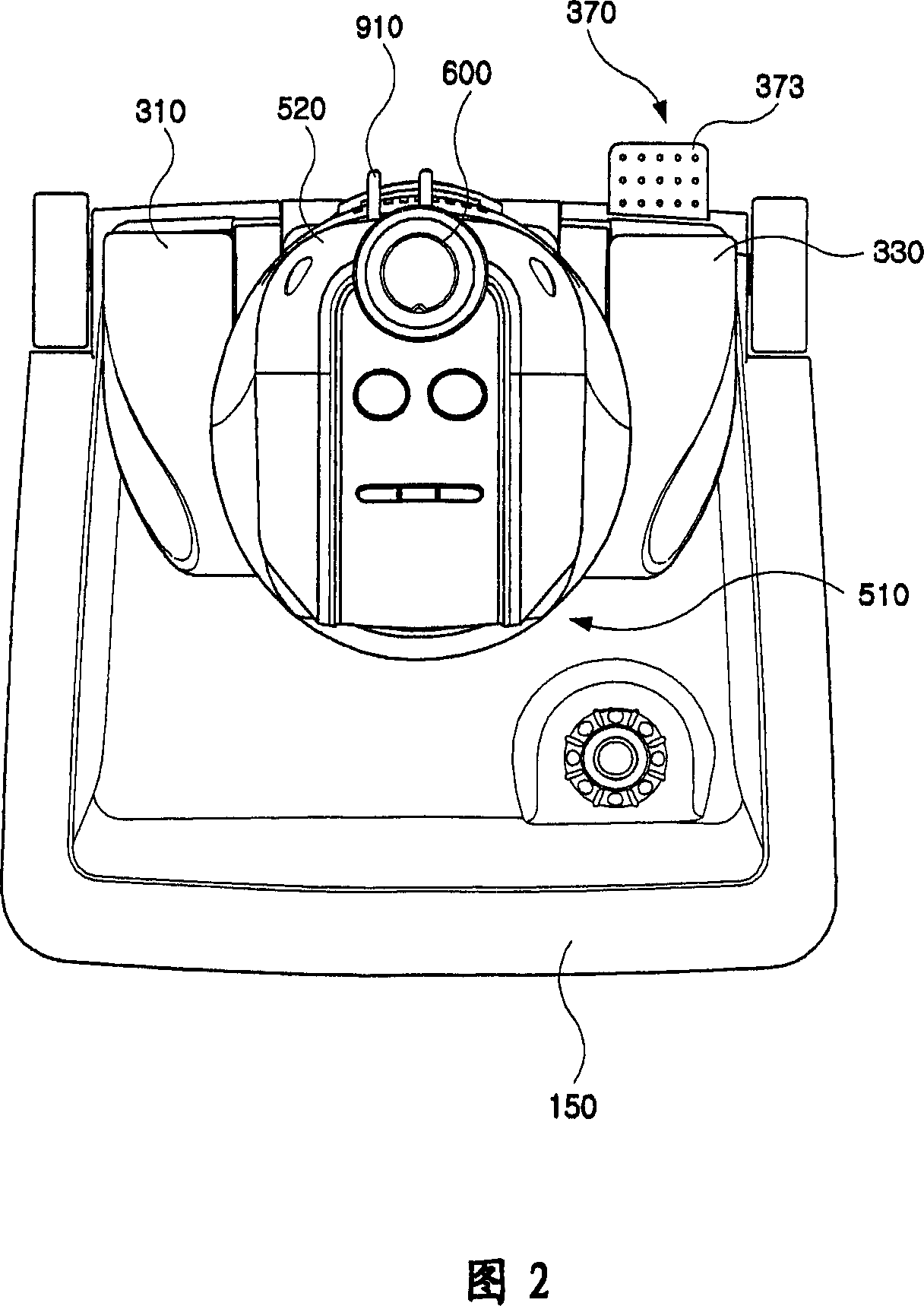

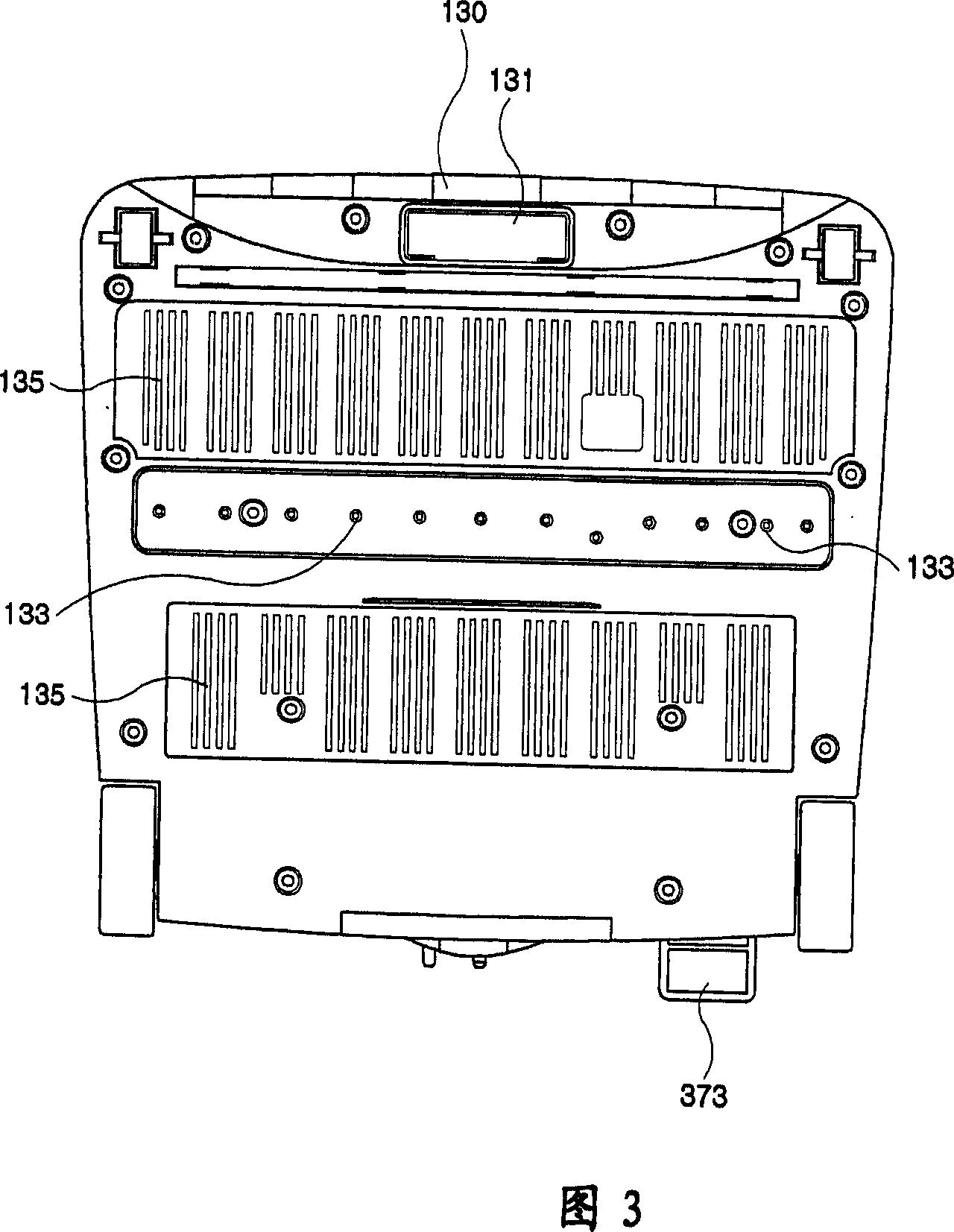

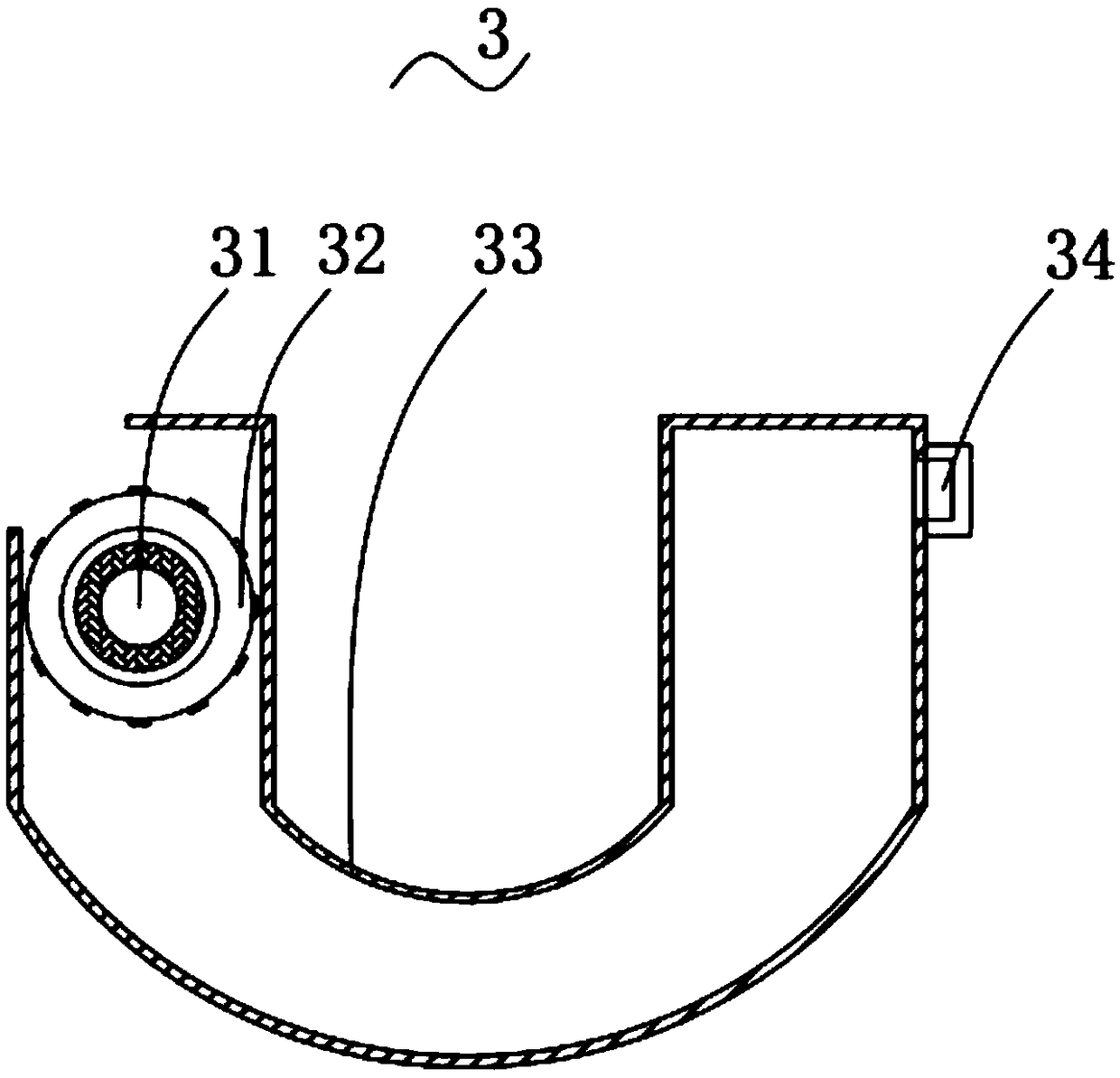

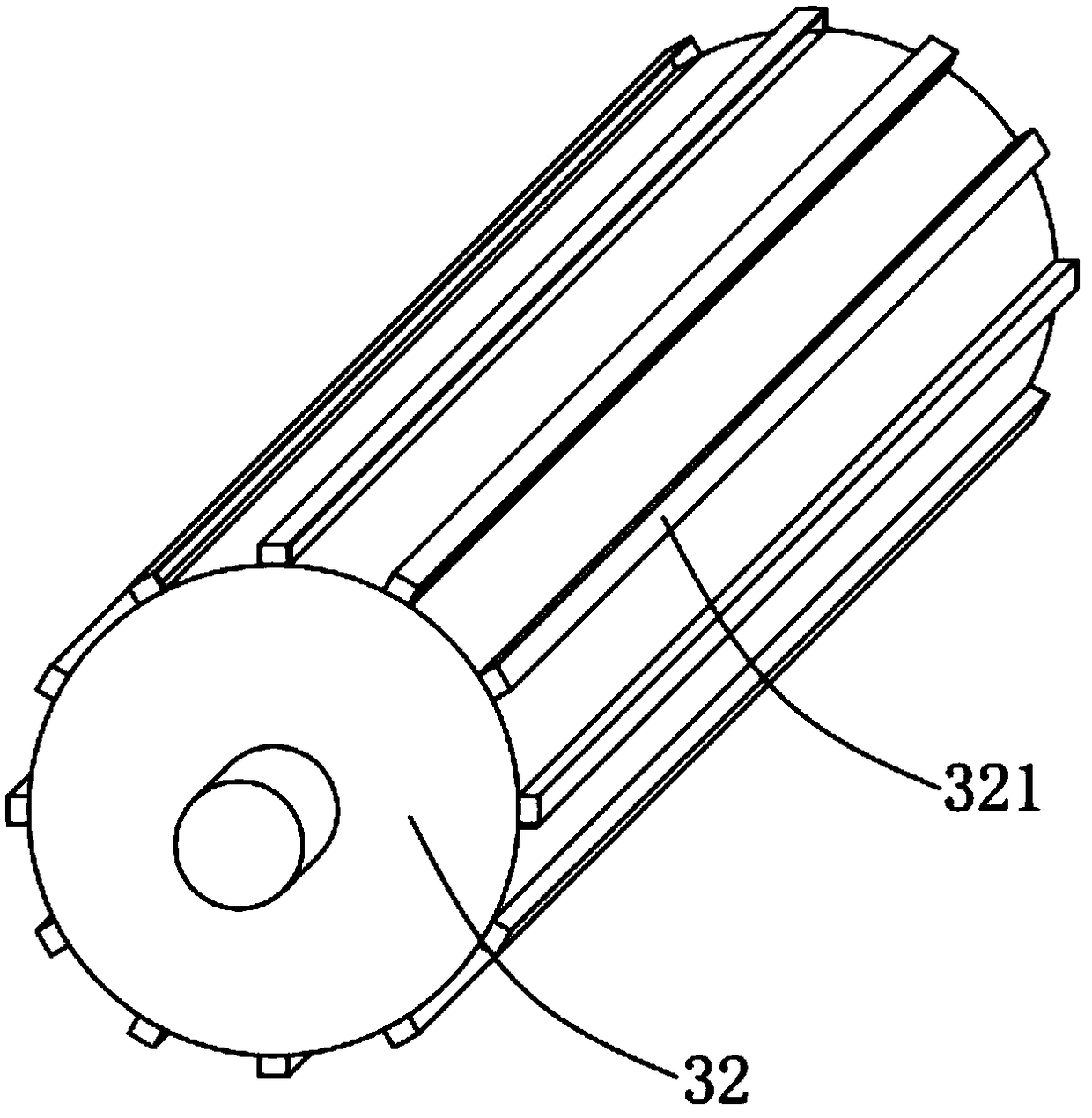

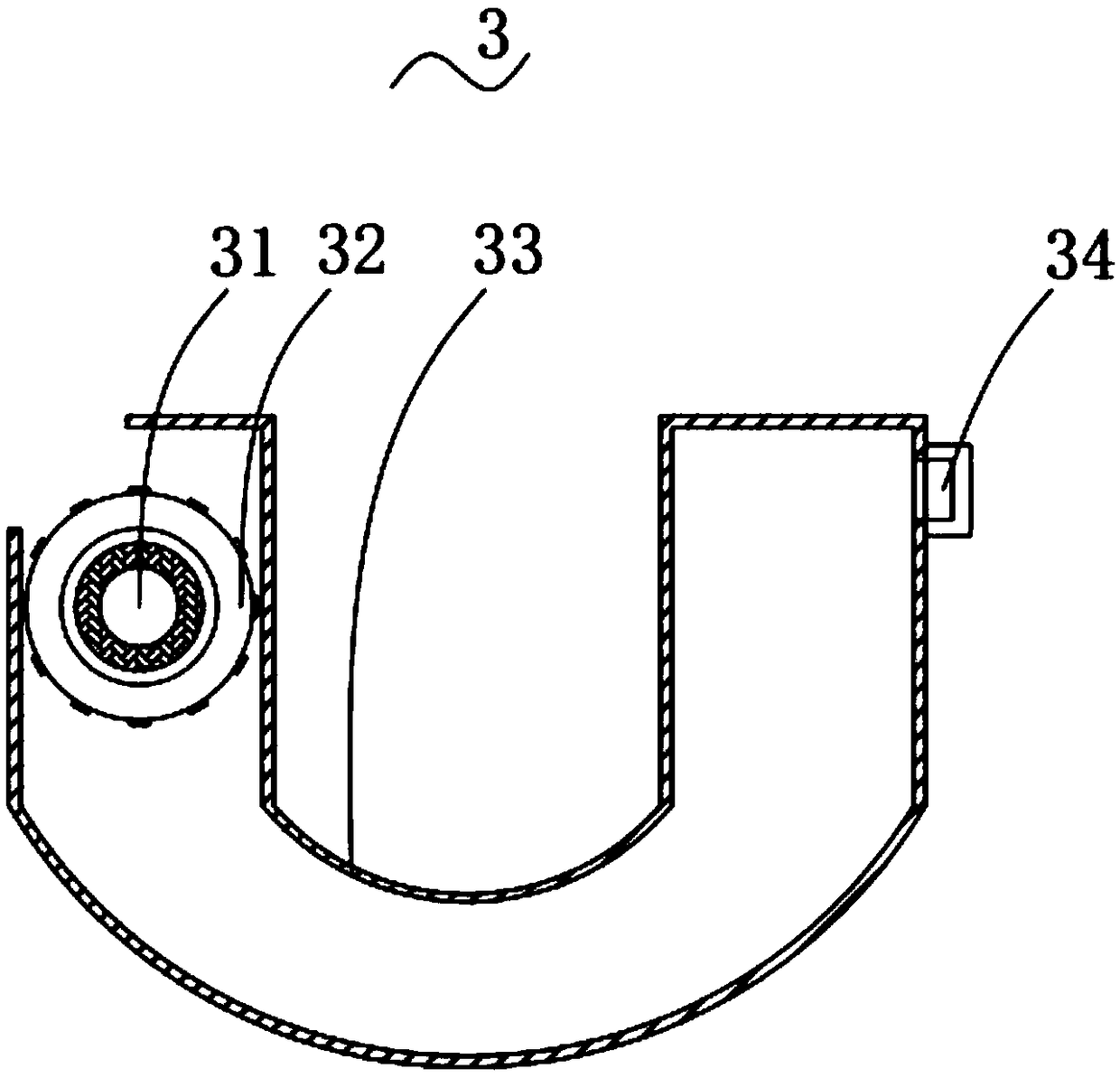

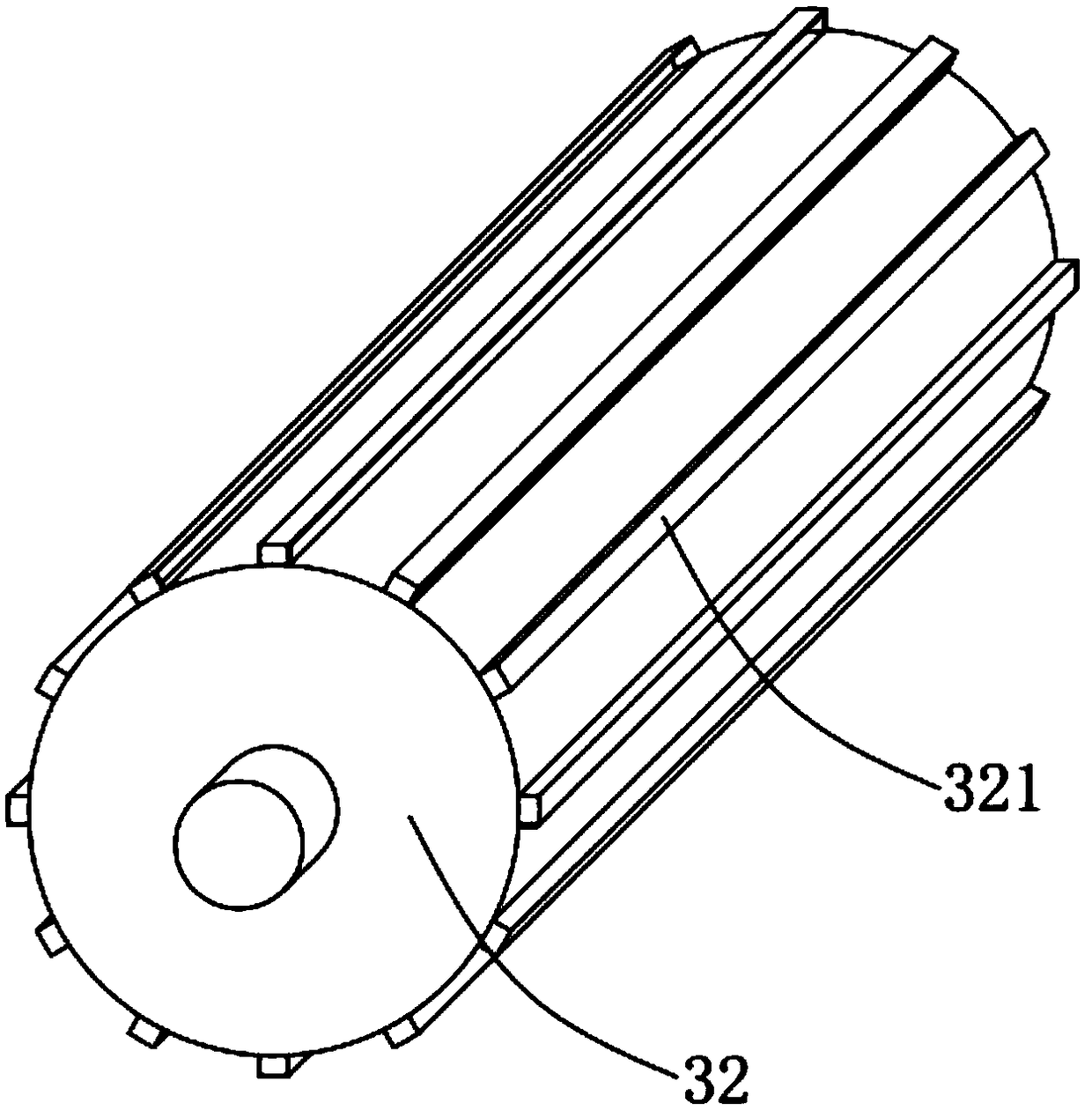

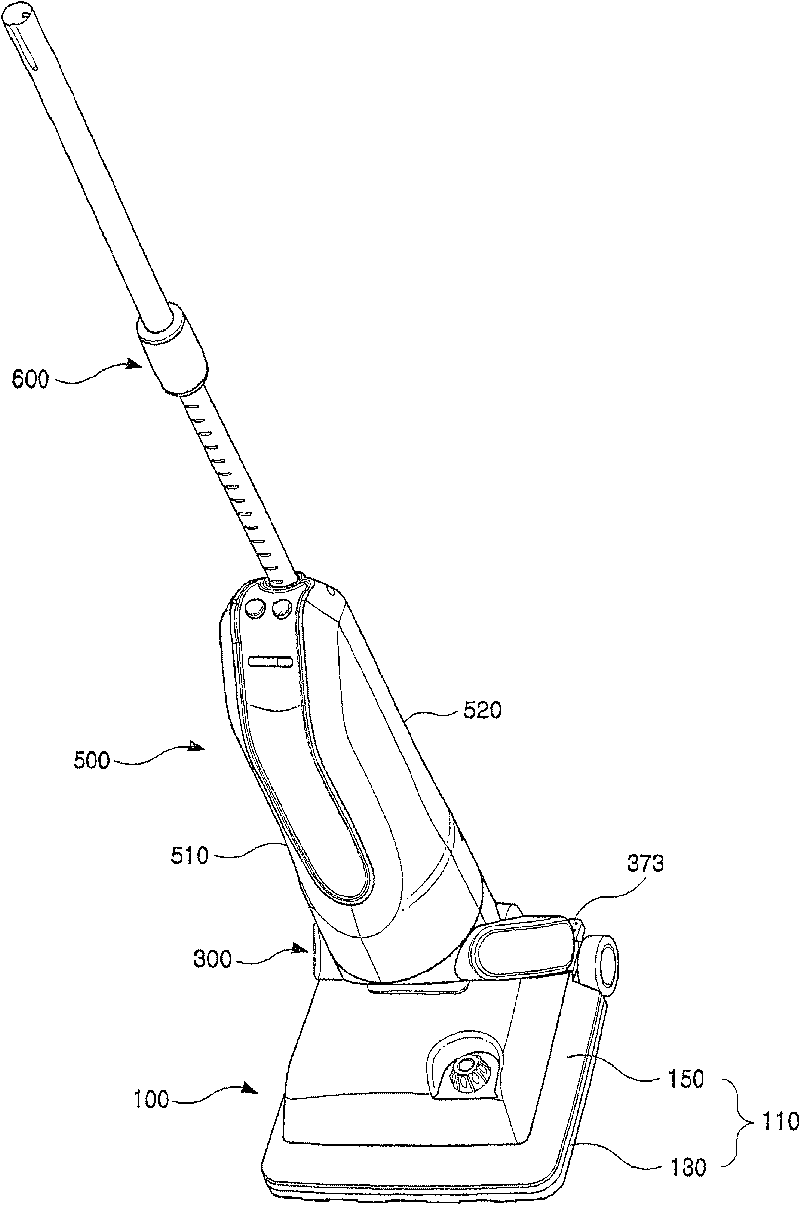

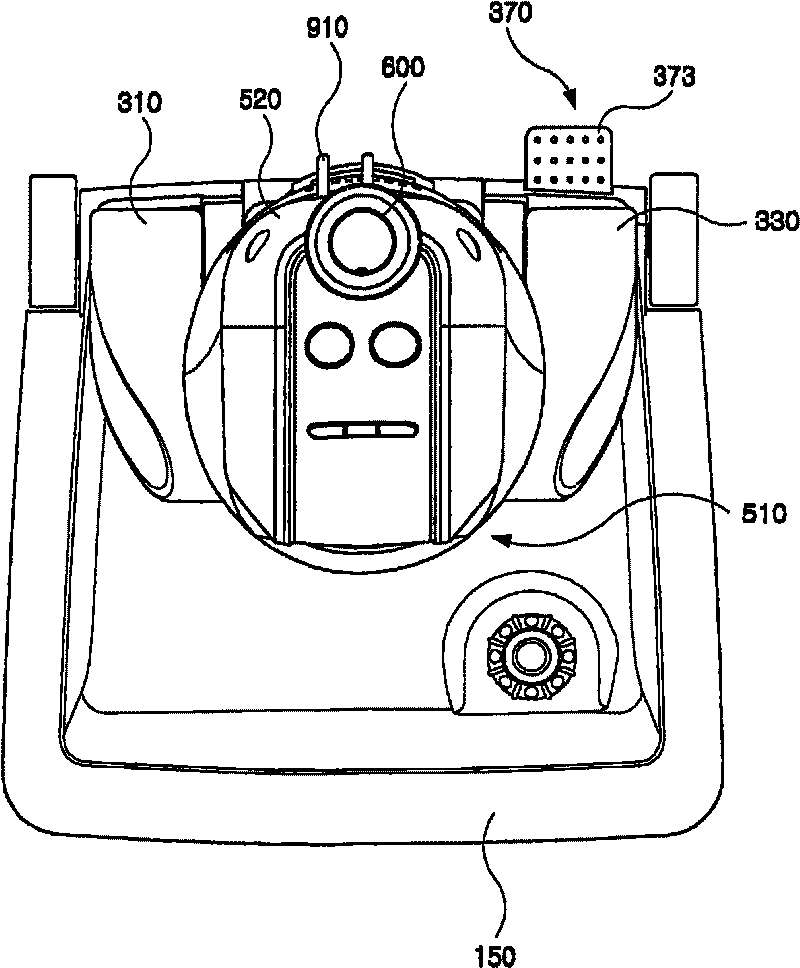

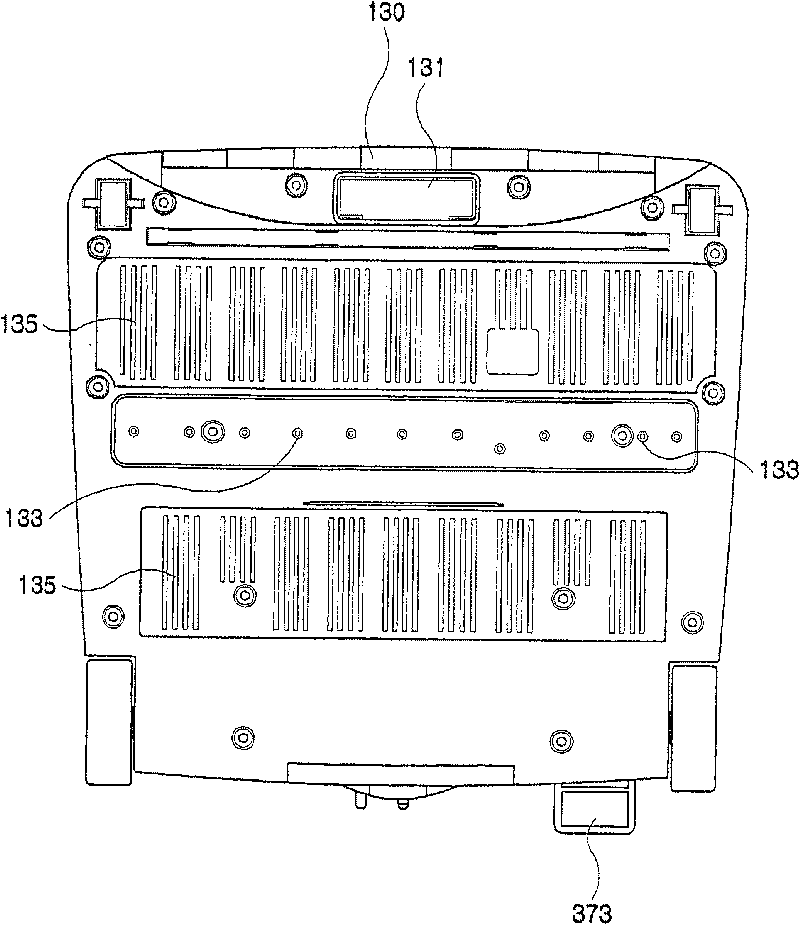

Steam and vacuum cleaner

InactiveCN101028180ADoes not affect altitudeImprove cleanlinessCarpet cleanersFloor cleanersElectric machineryEngineering

A steam type vacuum sweeper comprises a foundation bed connected respectively with a dust arrest box and a vapor generation part, a manipulation body, and a body recess for connecting the manipulation body rotatablely to the foundation bed, wherein said foundation bed is equipped with a suction nozzle and a steam jet hole thereon, the manipulation body is equipped with an electrical machine for intaking air, said body recess includes a first arm and second arm with one end rotatablely connected to the foundation bed and a connection part for connecting the other end of the first arm and second arm, said connection part is also connected with the manipulation body, an air oilchannel intercommunicating pore is provided between the first arm and the connection part. Through such a structure, a dust arrest passage way is constituted at the body recess to simplify the base construction. An electrical machine is mounted at the manipulation body to ensure that the height of the foundation bed will not be affected even if the volume becomes larger when the electrical machine capacity is improved, capable of cleaning-up floor below fleabags, desks and sofas.

Owner:韩京姬

S-shaped stainless steel cabinet suspension

Owner:SICHUAN SHIYANG ELECTRICAL & MECHANICAL EQUIP CO LTD

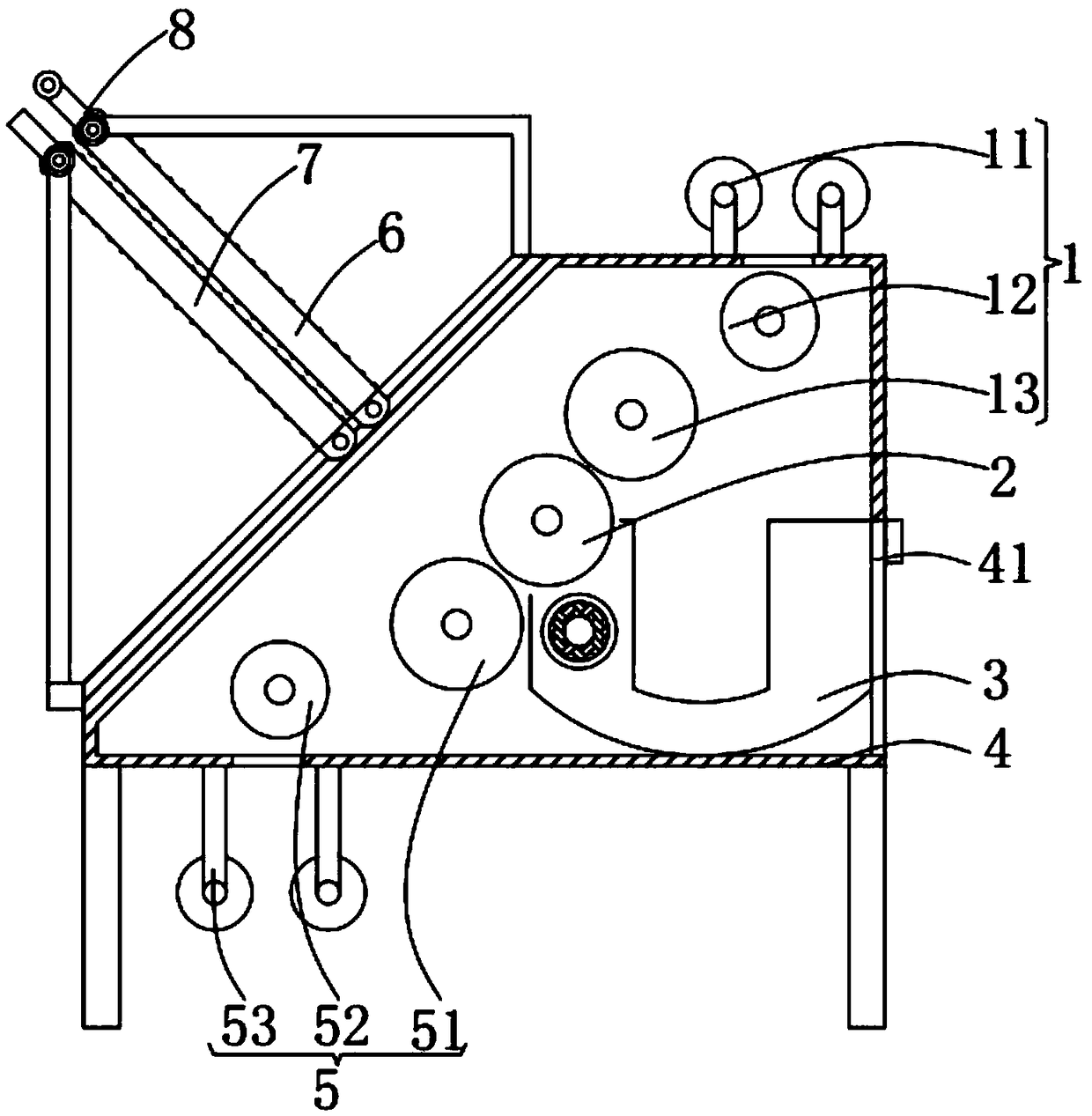

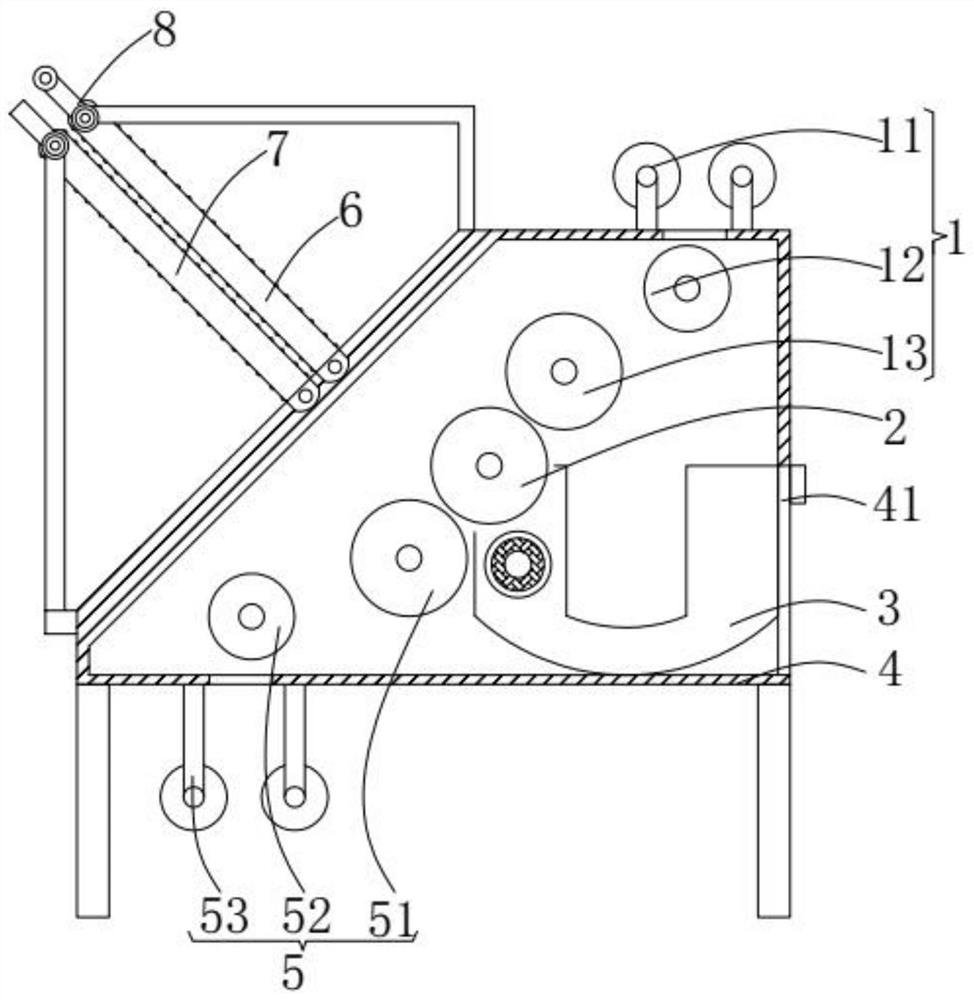

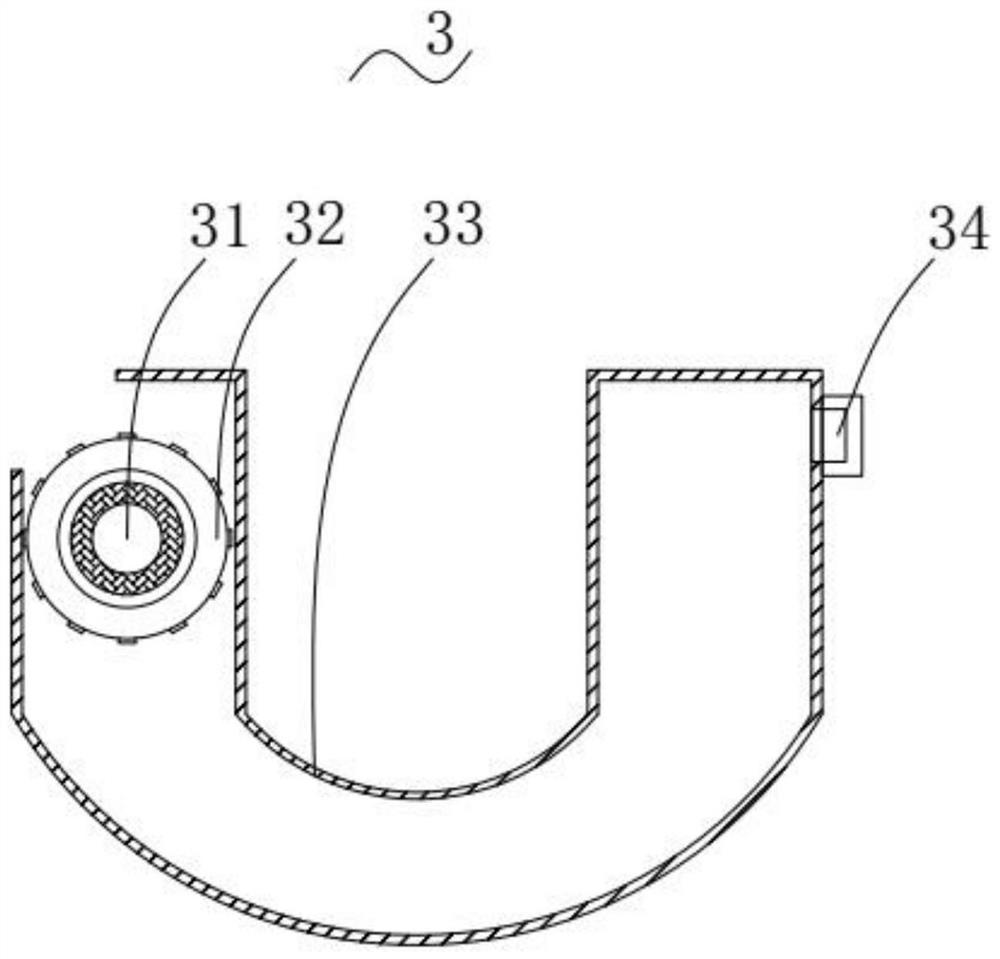

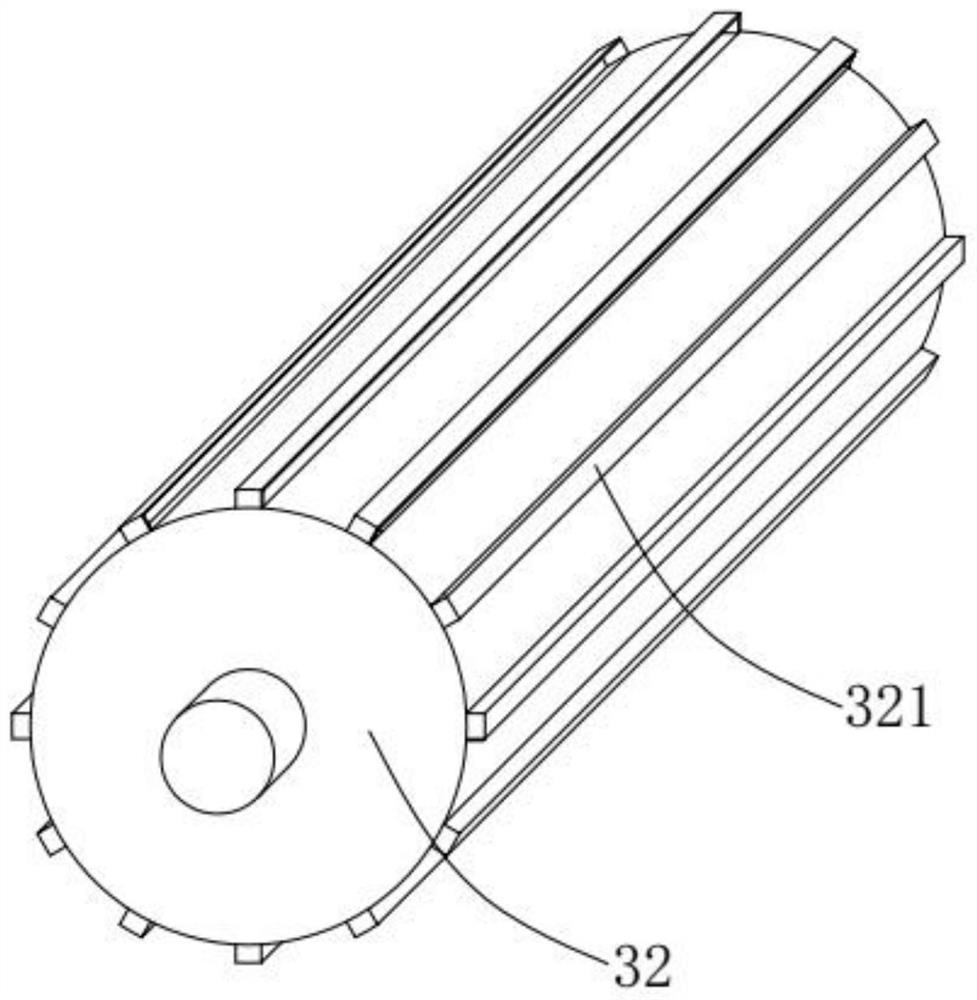

Corrugated paper making equipment

ActiveCN108790358ADoes not affect the processingKeep neatLamination ancillary operationsLaminationAdhesiveEngineering

The invention relates to the field of corrugated paper making and in particular relates to corrugated paper making equipment which comprises a first conveying mechanism, a core wheel, a coating collection mechanism, a shell, a second conveying mechanism, a first pressing moving mechanism, a second pressing moving mechanism and an edge cutting mechanism, wherein core paper to be bonded is conveyedthrough the first conveying mechanism and the second conveying mechanism; coating and bonding are carried out on the core paper by using the core wheel through the coating collection mechanism; the first pressing moving mechanism and the second pressing moving mechanism are adopted for pressing the bonded core paper; the edge cutting mechanism is used for cutting side edges. Due to a special structure of a containing box of the equipment, when a coating inside is used, the residual amount of the coating can be accurately observed through an observation window; after being bonded, the core paper is pressed through a rotating conveying belt under heating, then rapid curing of an adhesive can be promoted, both sides of a cutting blade are pressed through sponge pads, and then excessive partson both sides can be rapidly cut by using the rotating cutting blade according to demands.

Owner:淮北鸣朋环保科技有限公司

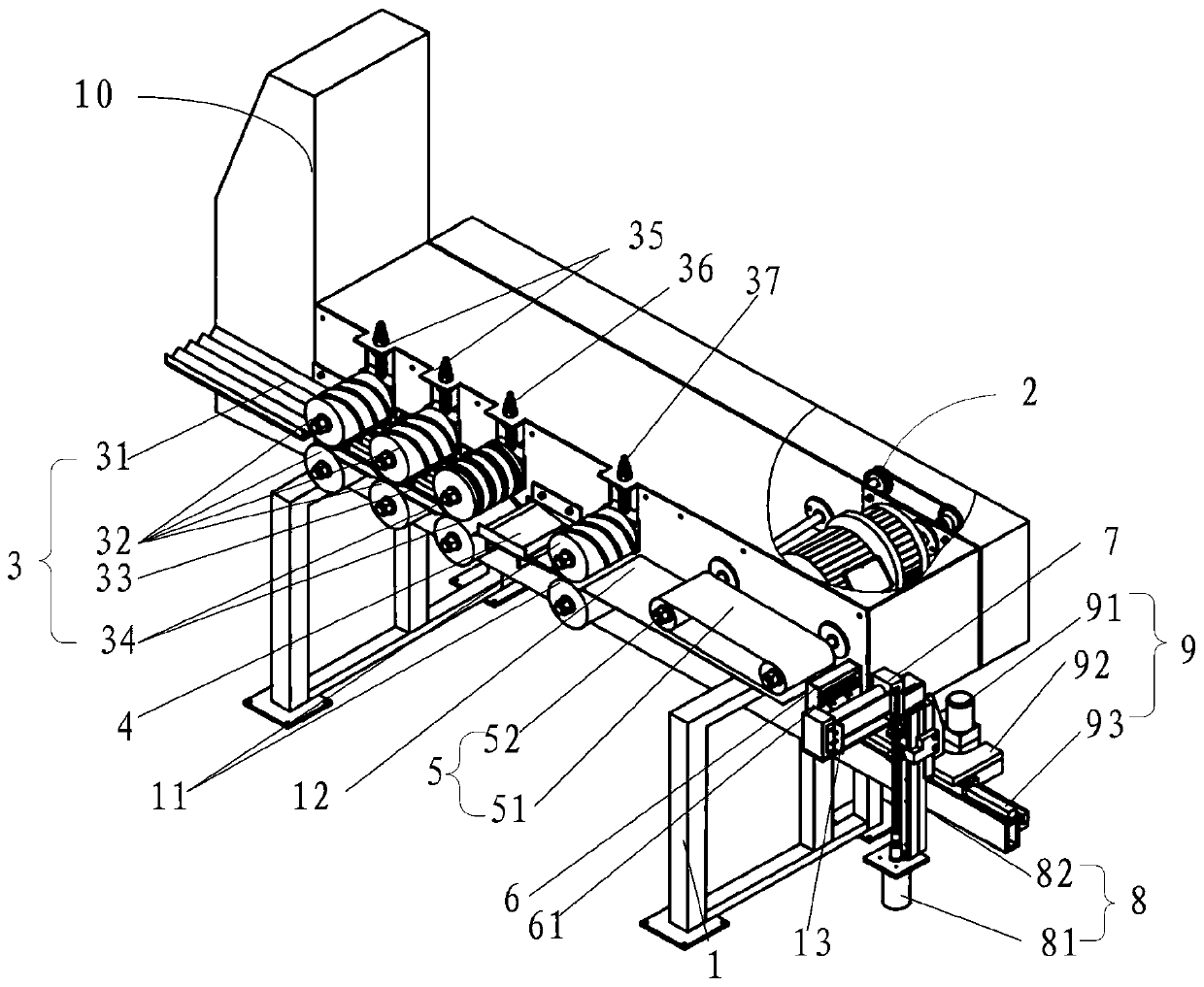

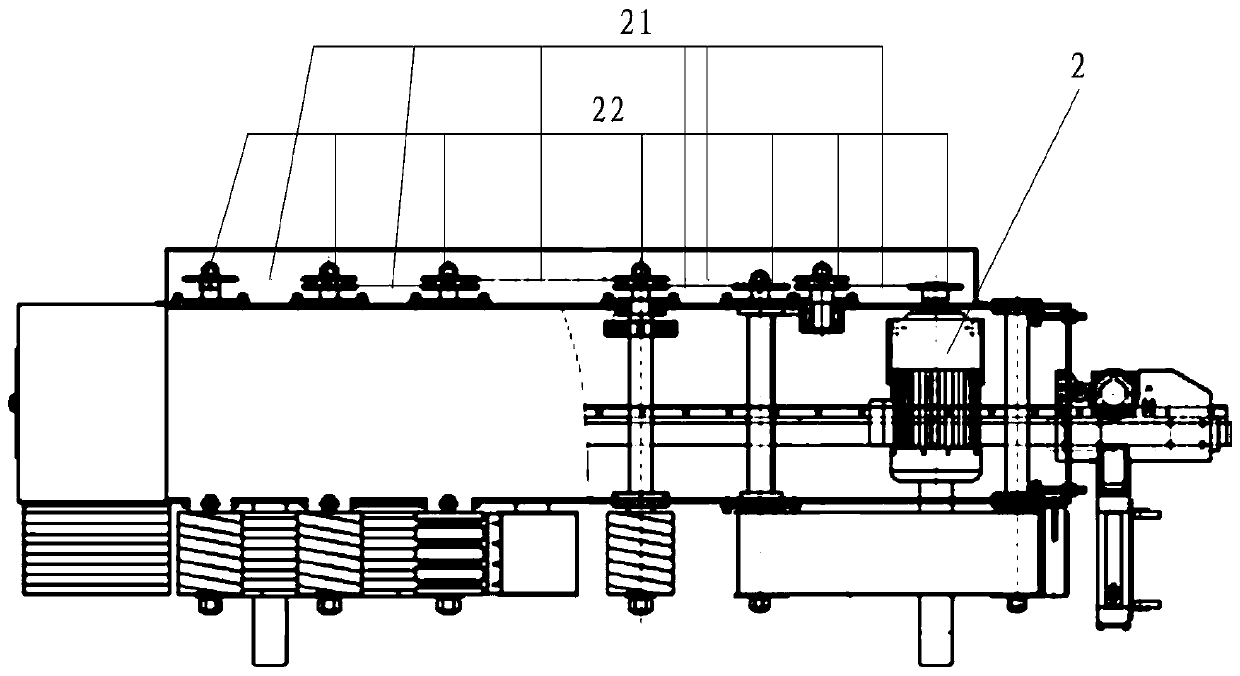

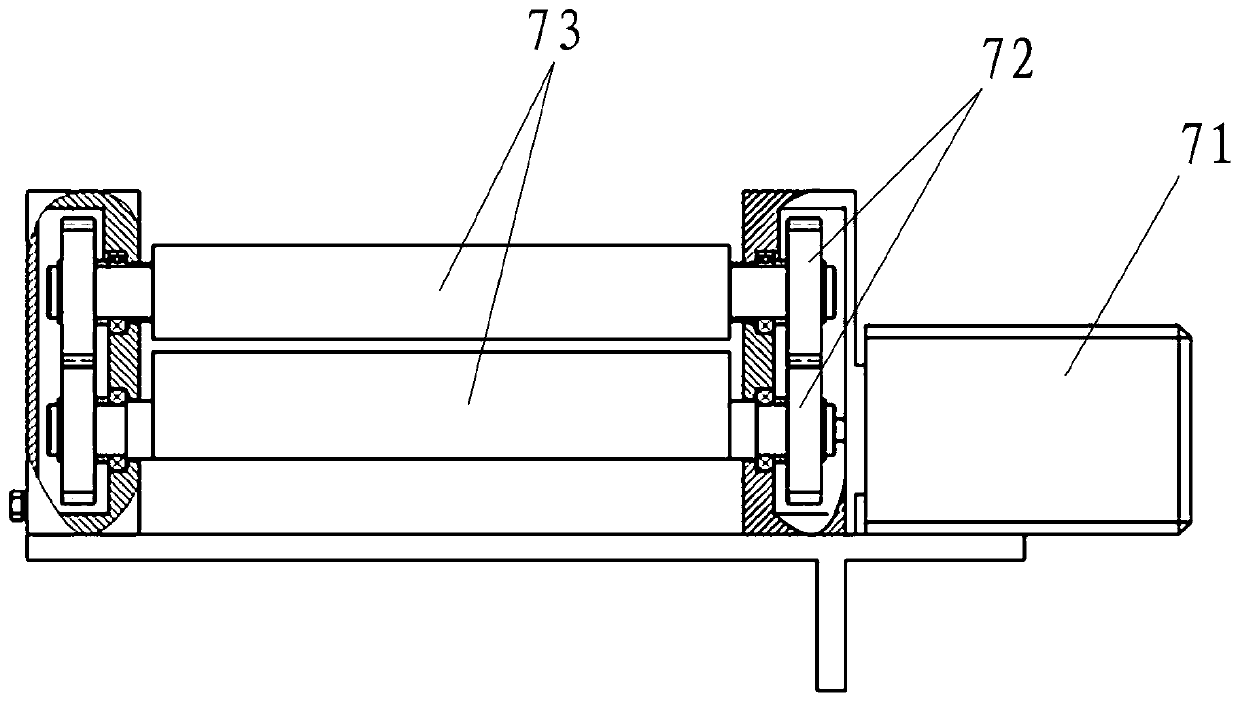

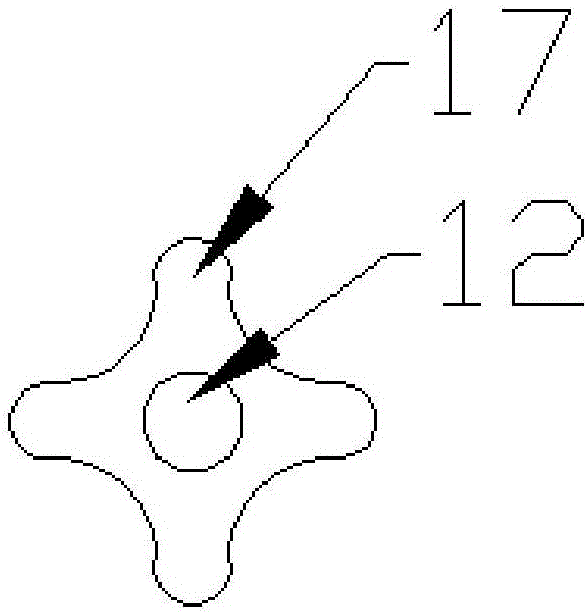

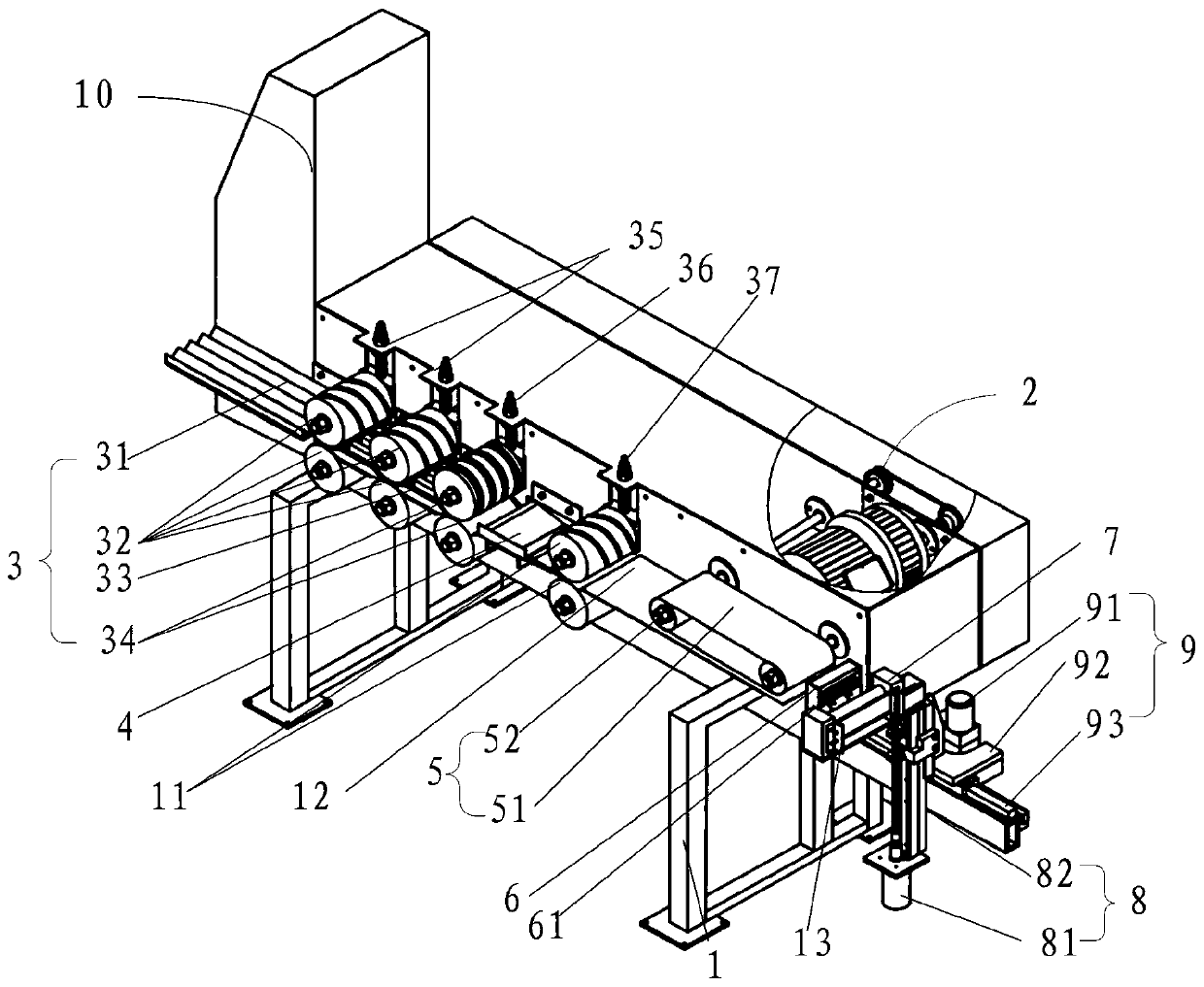

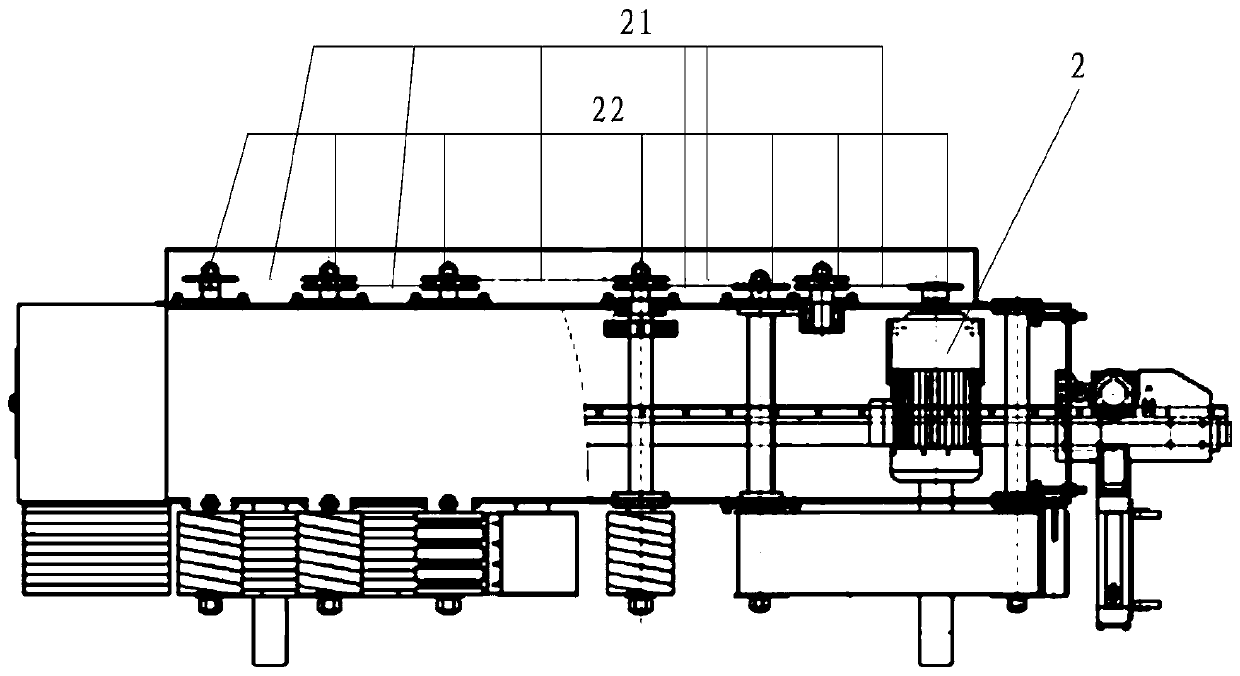

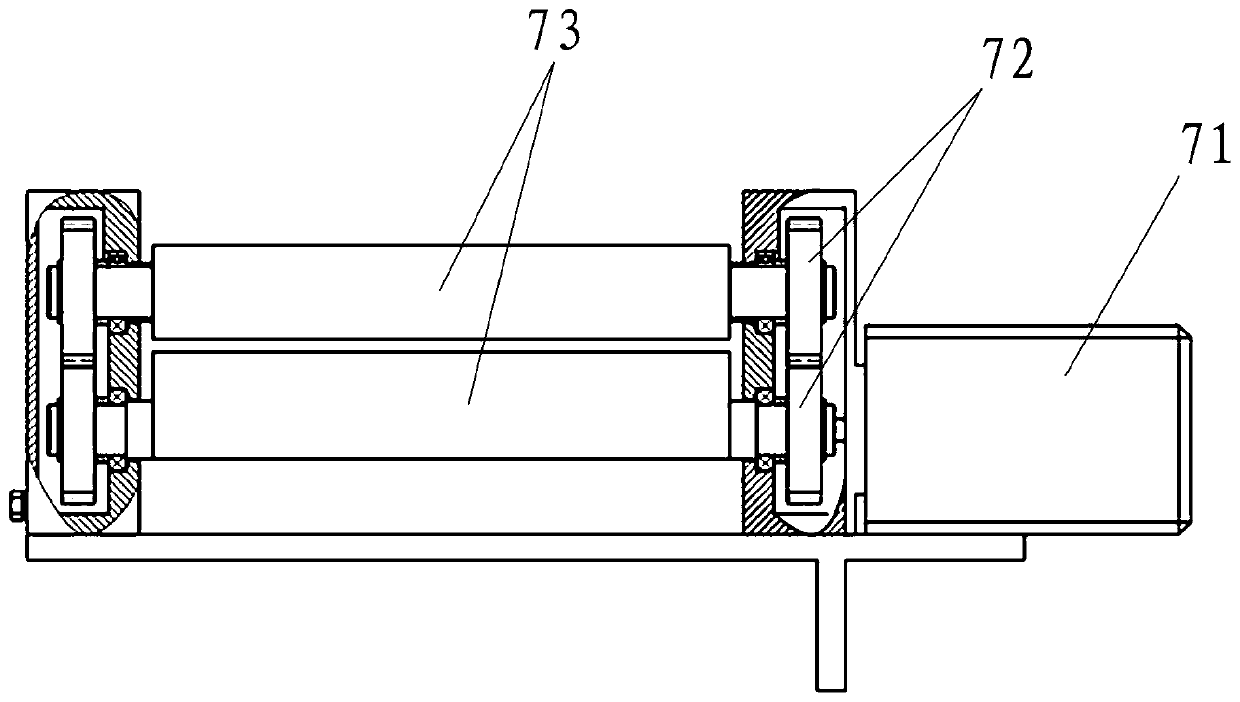

Automatic-ramie-splitting reverse pull type ramie decortication machine

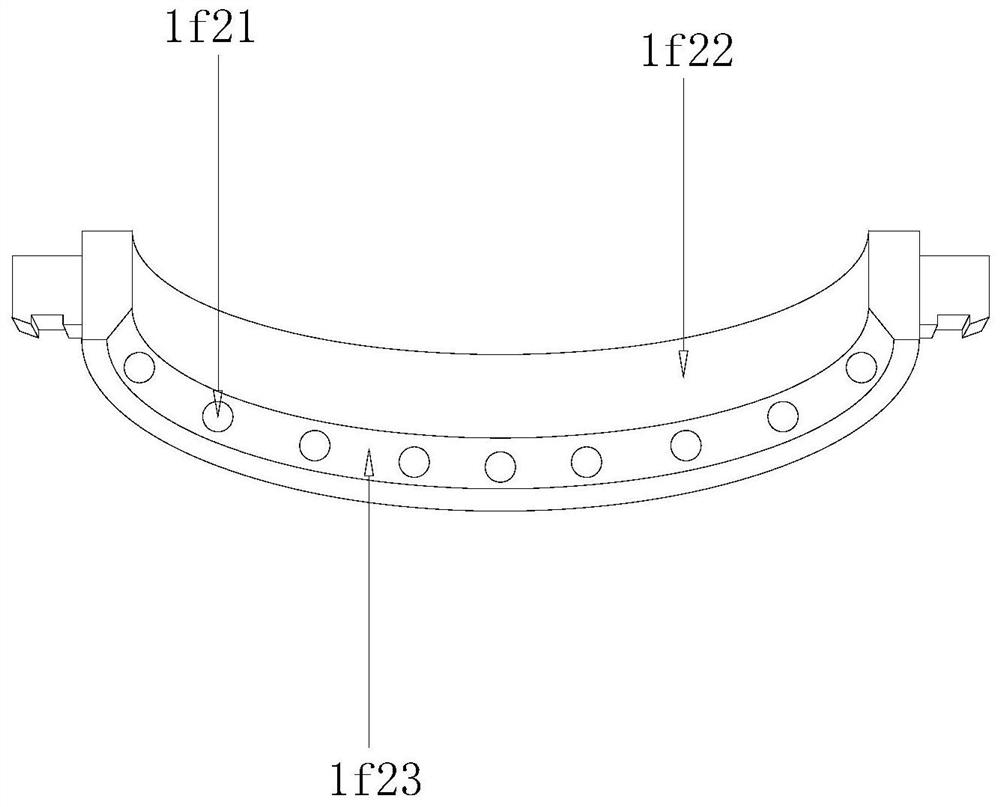

InactiveCN110820052AEliminate hard-to-remove problemsMeet the actual needs of stripping hempMechanical fibre separationFiberEngineering

The invention provides an automatic-ramie-splitting reverse pull type ramie decortication machine. The automatic-ramie-splitting reverse pull type ramie decortication machine comprises a frame, a transmission mechanism, a ramie splitting and decorticating mechanism and a controller and is characterized in that ramie stalks are conveyed through a feeding device in the ramie splitting and decorticating mechanism, a self-centering ramie splitting combined tool splits the single sides of the ramie stalks, a ramie pressing device spreads and flattens the split ramie stalks in a unified manner, theflattened ramie stalks are conveyed to a ramie clamping and decorticating device and an eccentric ramie clamping device, a ramie breaking and lifting device breaks ramie sticks at the ends of the ramie stalks clamped by the eccentric ramie clamping device, and a reserve pull device reversely pulls the ramie stalks to complete ramie decortication and ramie stick removing. The automatic-ramie-splitting reverse pull type ramie decortication machine has the advantages that the whole process including one-step ramie splitting, ramie clamping and ramie breaking, reverse pull ramie stick removing andthe like can be completed, the ramie sticks are in an elongated and complete state in the whole ramie decortication process, the problem that crushed ramie sticks attached into fiber layers are hardto remove, the actual ramie decortication requirements of ramie farmers can be satisfied, and the automatic-ramie-splitting reverse pull type ramie decortication machine is promising in market popularization prospect.

Owner:HARBIN FORESTRY MASCH RES INST STATE FORESTRY & GRASSLAND ADMINISTRATION +1

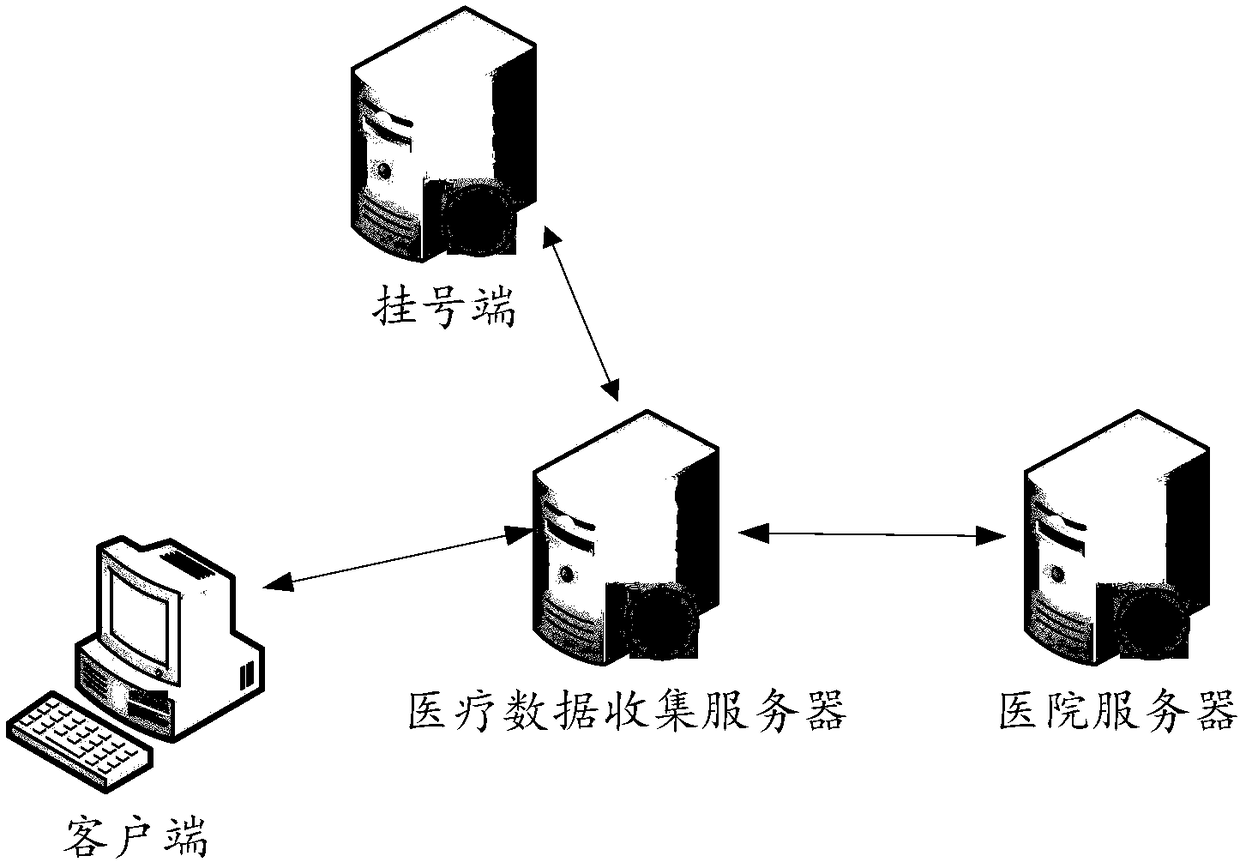

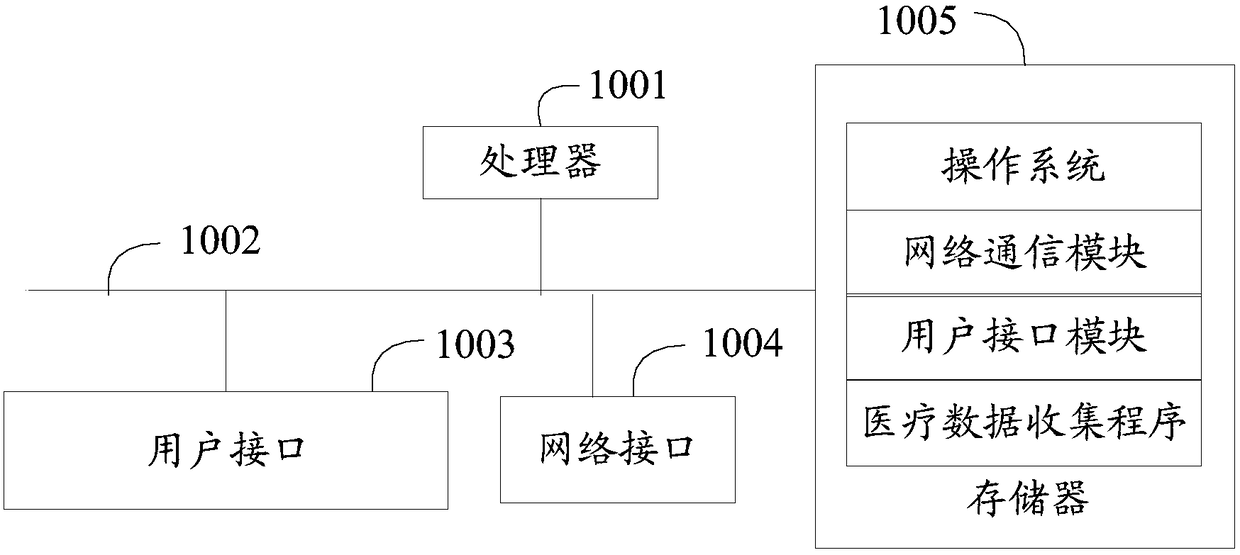

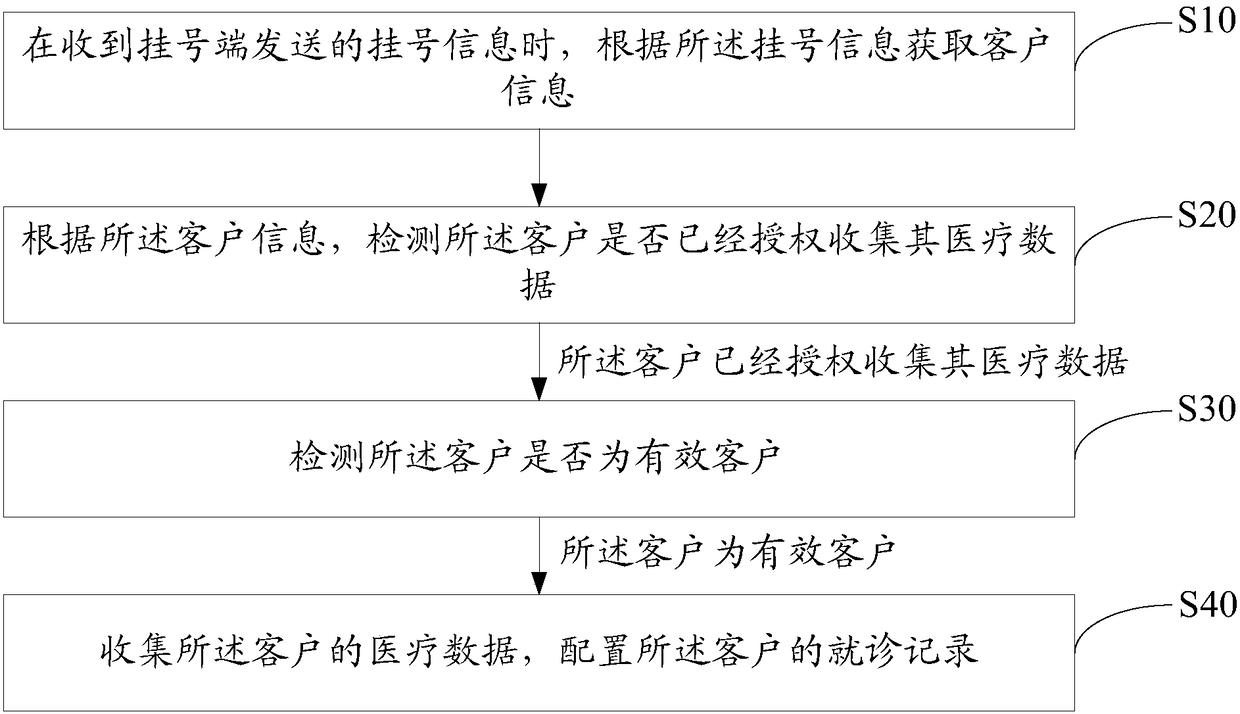

Medical data collection method, server and computer readable storage medium

InactiveCN108346459AReduce workloadIntegrity guaranteedHealthcare resources and facilitiesInstrumentsCollections dataCustomer information

The invention discloses a medical data collection method. The method comprises the steps of receiving registration information transmitted by a registration terminal, and obtaining customer information according to the registration information; detecting whether the customer is authorized or not to collect the medical data thereof according to the customer information; if the customer has authorized to collect the medical data thereof, detecting whether the customer is a valid customer or not; and if the customer is a valid customer, collecting the medical data of the customer, and configuringa doctor seeing record of the customer. The invention further discloses a medical data collection server and a computer readable storage medium. Automatic collection of the medical data of customersis realized according to the invention.

Owner:PING AN TECH (SHENZHEN) CO LTD

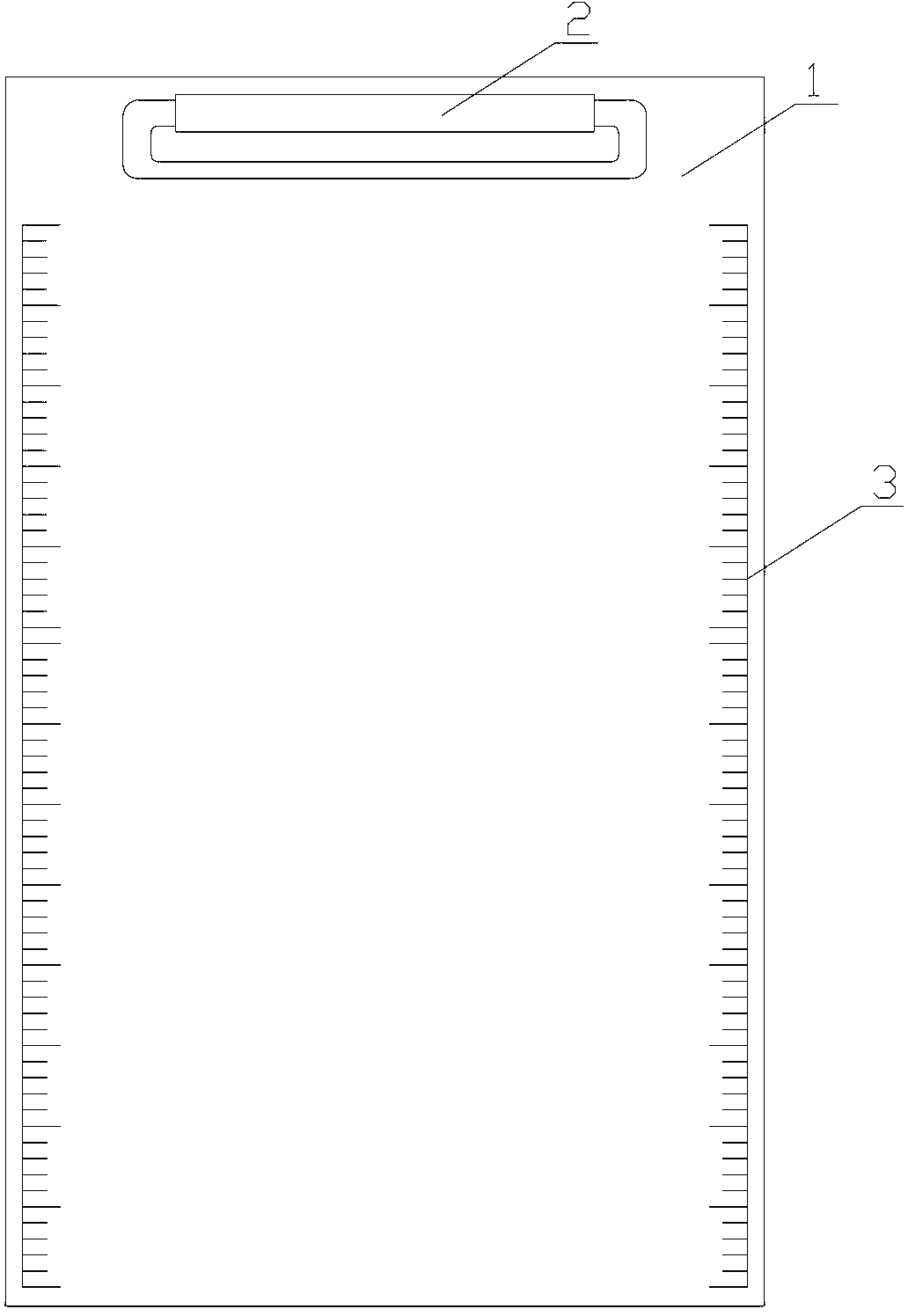

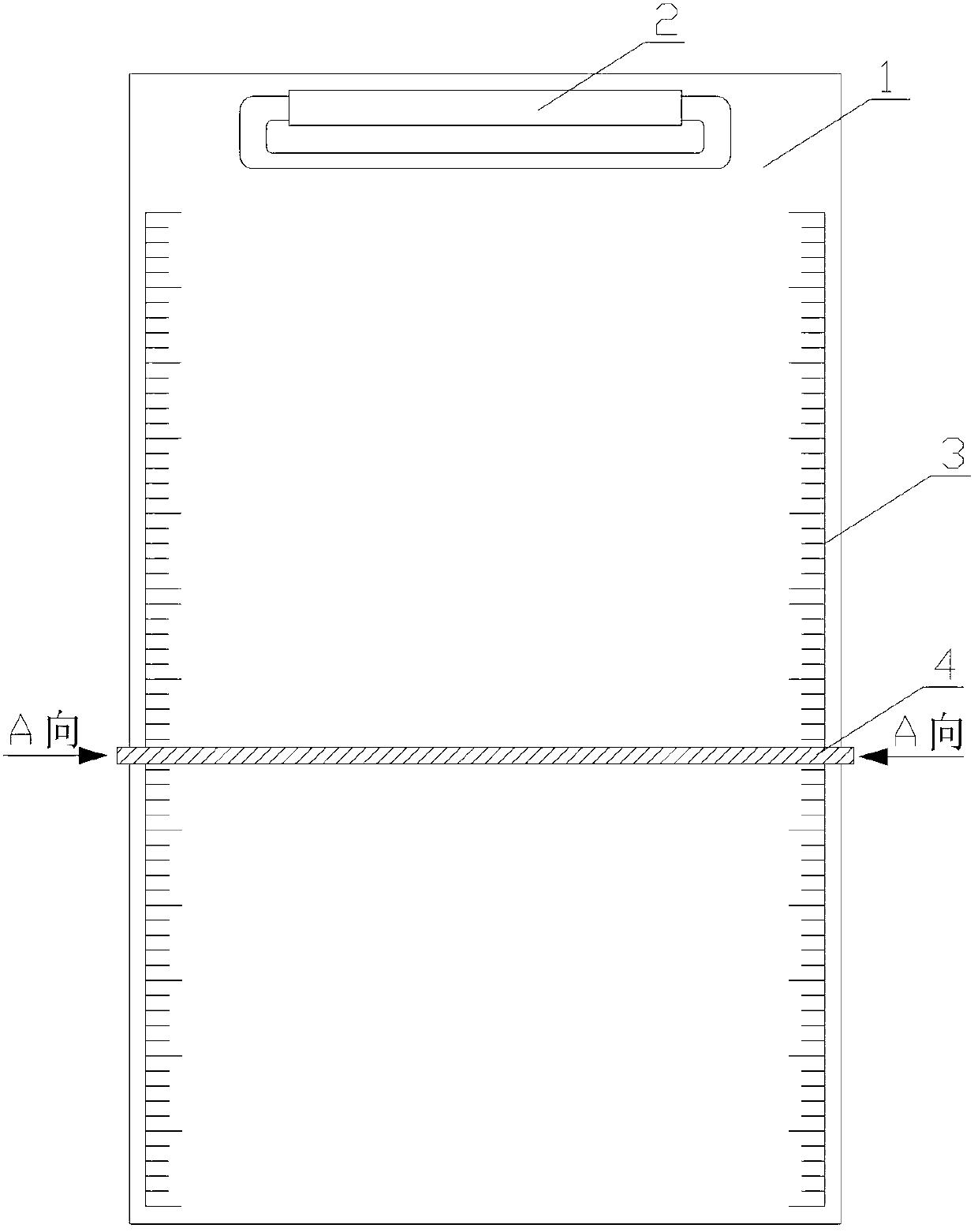

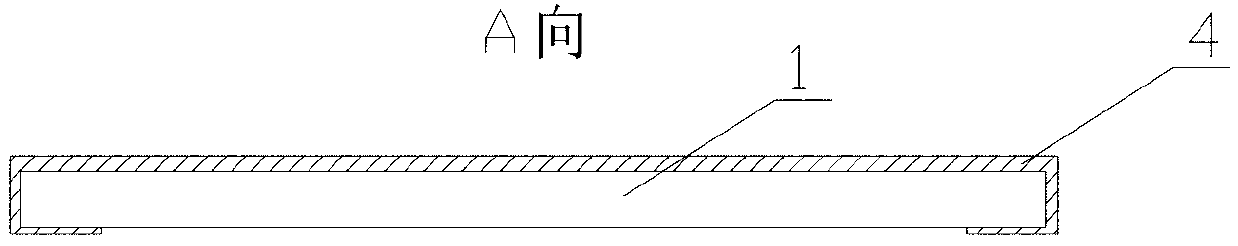

Convenient writing paper board clamp

A convenient writing paper board clamp comprises a base plate and a clamping structure, wherein the clamping structure is fixed at the upper end of the base plate. Two sides of the base plate are provided with scale marks. The convenient writing paper board clamp further comprises a ruler capable of vertically moving along the base plate. The bottom end of the base plate is provided with a ruler fixing structure for preventing the ruler from falling off the base plate. By means of the technical scheme, the convenient writing paper board clamp can ensures neat handwriting well and facilitate reading and preservation of important written records. The convenient writing paper board clamp is simple in structure, convenient to manufacture and strong in practical applicability and has wide application prospect.

Owner:大连奥林匹克电子城利辉通讯器材商行

Corrugated paper production process

ActiveCN108608683ADoes not affect the processingFit tightlyMechanical working/deformationPaper productionPulp and paper industry

The invention relates to the field of corrugated paper manufacturing, in particular to a corrugated paper production process. The coating pressing equipment adopted by the method comprises a first conveying mechanism and a second conveying mechanism to convey core paper to be bonded, a core wheel is used for carrying out coating and adhesion on the core paper through a coating collecting mechanism; a first pressing mechanism, and a second pressing mechanism are used for pressing the adhered core paper, and an edge cutting mechanism is used for cutting side edges. According to the corrugated paper production process, a special structure is adopted by a packaging box, and when the coating inside the packaging box is used, the residual quantity of the coating can be accurately observed through an observation window; after the core paper is adhered by the coating, pressing is carried out under the condition that a rotating conveying belt is matched with heating, and glue is promoted to berapidly solidified; and the two sides of the cutting blade are pressed by a sponge cushion block, so that the rotary cutting blade can quickly cut parts on the two sides according to requirements.

Owner:东莞市东创纸品制造有限公司

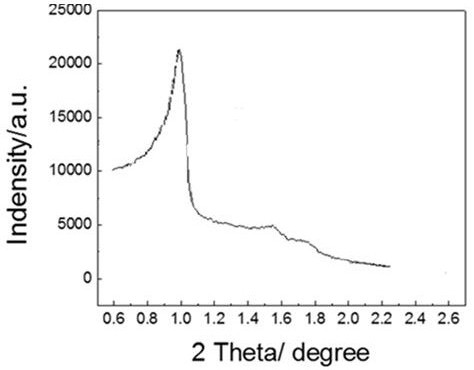

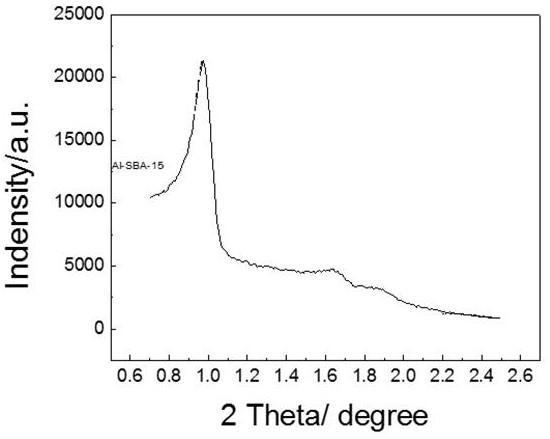

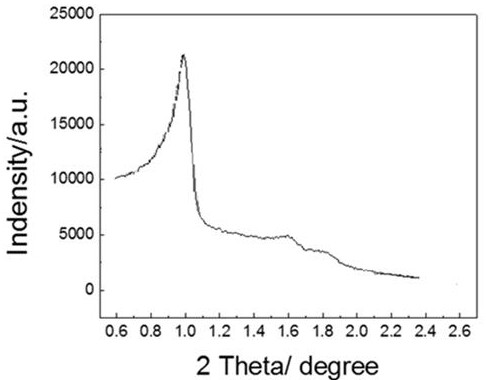

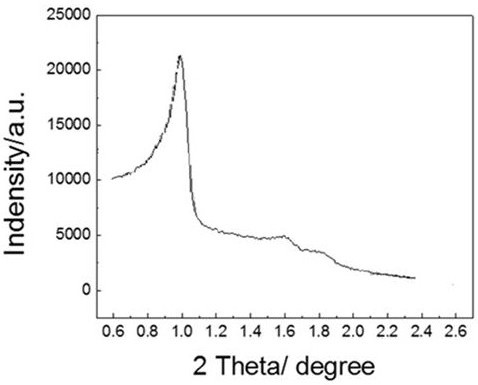

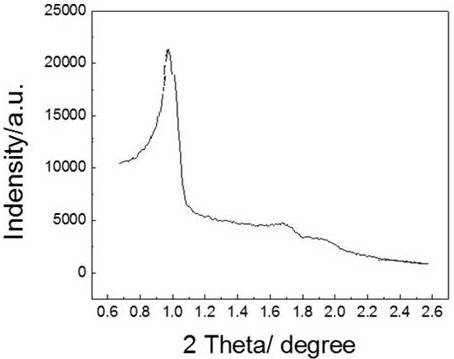

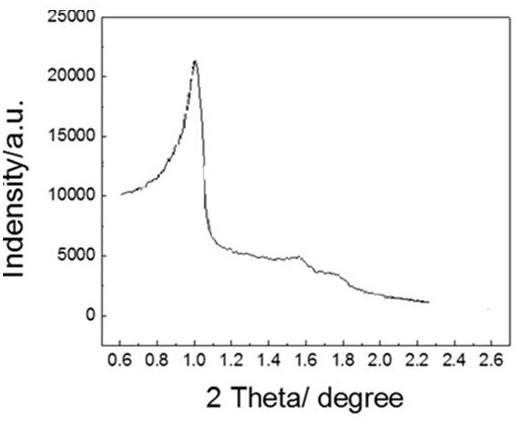

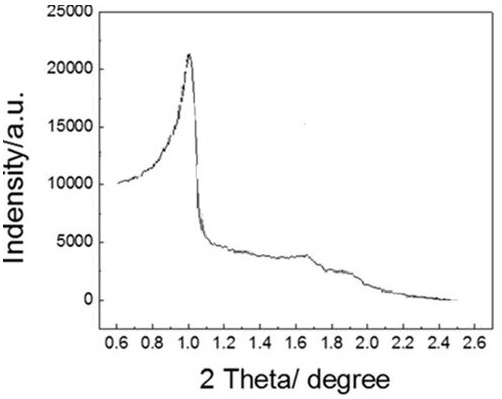

Preparation method of hydrodearomatization catalyst, hydrodearomatization catalyst and application of hydrodearomatization catalyst

PendingCN114453013AImproved dearomatization capabilityFacilitated DiffusionMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveGlycol synthesis

The invention discloses a preparation method of a hydrodearomatization catalyst, the hydrodearomatization catalyst and application of the hydrodearomatization catalyst. The preparation method of the hydrodearomatization catalyst comprises the following steps: (I) preparing an Al-SBA-15 molecular sieve, and then mixing the Al-SBA-15 molecular sieve with a modified Y molecular sieve, aluminum oxide and water to prepare slurry; (II) adding a solution containing active metal components and an aqueous solution of ethylene glycol into the slurry prepared in the step (I) to obtain a mixed slurry; (III) filtering, washing and drying the mixed slurry prepared in the step (II) to obtain a catalyst precursor; and (IV) crushing the catalyst precursor prepared in the step (III), mixing and kneading, forming, drying and roasting to obtain the hydrodearomatization catalyst. The hydrodearomatization catalyst prepared by the method has the characteristics of high hydrodearomatization activity, good selectivity, excellent product quality and the like. The hydrodearomatization catalyst is especially suitable for hydrodearomatization processes in which naphthenic oil with high heavy aromatics content is subjected to hydro-upgrading and isomerization and then is subjected to hydrorefining.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst carrier, hydrocracking catalyst and preparation method and application thereof

ActiveCN114453010AIncrease acidityImprove pore structureCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a hydrocracking catalyst carrier, a hydrocracking catalyst and a preparation method and application thereof. The carrier comprises an Al-SBA-15 mesoporous molecular sieve, a beta molecular sieve, aluminum oxide and nano silicon dioxide, and the pore distribution of the Al-SBA-15 mesoporous molecular sieve comprises: the pore diameter lt; the pore volume of 4 nm pores accounts for 20% or less of the total pore volume, preferably 15% or less; in the Al-SBA-15 mesoporous molecular sieve, the ratio of acid B to acid L is 1 or below. The hydrocracking catalyst prepared by adopting the hydrocracking catalyst carrier has excellent comprehensive performance, is especially used in the hydrocracking reaction process of shale oil with a complex raw material structure, and has excellent product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrofining catalyst as well as preparation method and application thereof

ActiveCN114453005AImprove acid propertiesReduce strong acid contentMolecular sieve catalystsHydrocarbon oils refiningMolecular sievePtru catalyst

The invention discloses a hydrofining catalyst as well as a preparation method and application thereof. The hydrofining catalyst comprises a carrier, an active metal component, nano magnesium oxide and an organic auxiliary agent, wherein the carrier comprises an Al-SBA-15 molecular sieve and aluminum oxide. The hydrofining catalyst can deeply remove nitrogen-containing compounds in shale oil, is good in hydrogenation performance, meets the quality requirements of subsequent process production, and ensures that the use performance of a cracking catalyst is fully exerted.

Owner:CHINA PETROLEUM & CHEM CORP +1

Insulating paper support wood piece adhesion equipment

InactiveCN106829613AImplement automatic placementAchieving adhesionArticle deliveryDrive wheelPaper recycling

The invention relates to an insulating paper supporting wood chip bonding equipment, which comprises an insulating paper winding roller, a supporting wood chip placing roller, and an insulating paper recovery roller; the upper part of the supporting wood chip placing roller is provided with a supporting wood chip placing mechanism; The limit ring is concentrically fixed, and the outer edge of the limit ring is vertically provided with an annular retaining ring, and a number of support wood chip placement sleeves are arranged in an annular array on the top outer wall of the support wood chip placement roller; the support wood chip placement mechanism includes a flat support The wood chip placement groove is provided with a support wood chip discharge hole at one end of the support wood chip placement groove, and the support wood chip discharge hole is located at the upper position of the support wood chip placement sleeve. The upper part is synchronously fixed with an exciting motor; the bottom of the insulating paper recovery roller is provided with a circular truncated guide block, and the upper bottom of the guide block is fixedly connected with the bottom of the insulating paper recovery roller.

Owner:NANTONG ZHONGLING INSULATION MATERIALS

Auxiliary equipment suitable for prefabricated part production molds with different sizes

The invention relates to the technical field of prefabricated part production equipment, in particular to auxiliary equipment suitable for prefabricated part production molds of different sizes. The auxiliary equipment comprises an equipment body, a photoresistor is fixedly connected to the center of the interior of the equipment body, and a fixing frame is fixedly connected to the front surface of the equipment body; reset springs are fixedly connected to the left side face of the interior of the fixing frame, reset frames are fixedly connected to the positions, located on the upper side and the lower side of the fixing frame, of the front surface of the equipment body, and positioning frames are fixedly connected to the right side faces of the reset frames. Due to the force is mutual, the molds are limited, so that the auxiliary equipment can be well suitable for positioning the molds of different sizes, the application range of the auxiliary equipment can be well widened, neatness of prefabricated part production is guaranteed, the production quality of the auxiliary equipment is improved, bubbles in the molds are affected by impact to disappear, meanwhile, concrete in the molds is tighter, and therefore the working efficiency of the equipment is ensured.

Owner:邓伟强

Hydrotreating catalyst as well as preparation method and application thereof

ActiveCN114452965AImprove acid structureIntrinsic activity is fully reflectedMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

The invention discloses a hydrotreating catalyst as well as a preparation method and application thereof. The hydrotreating catalyst comprises a carrier, an active metal component and nano titanium dioxide, and the carrier comprises an Al-SBA-15 mesoporous molecular sieve and aluminum oxide. When the hydrotreating catalyst is used for hydrotreating shale oil distillate oil, the denitrification capacity is high, the operation period of a device can be prolonged, and the operation cost of a refinery plant is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

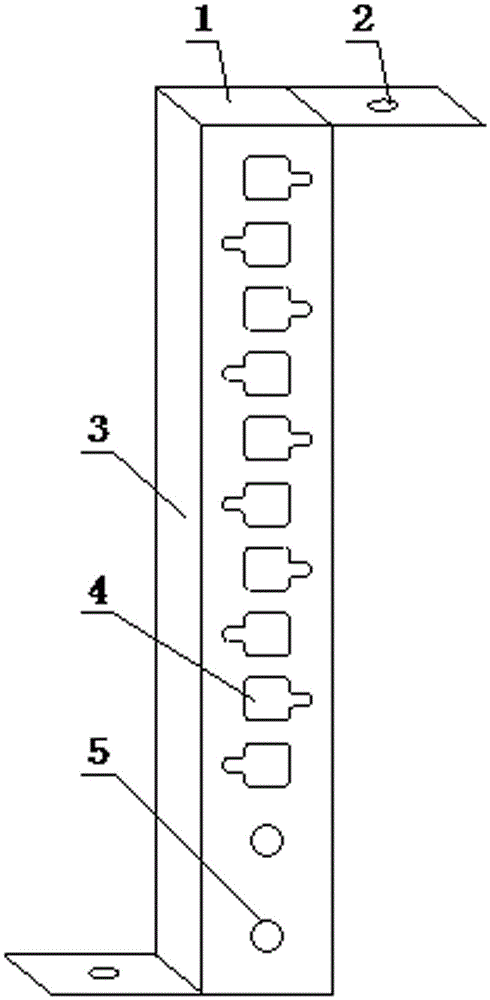

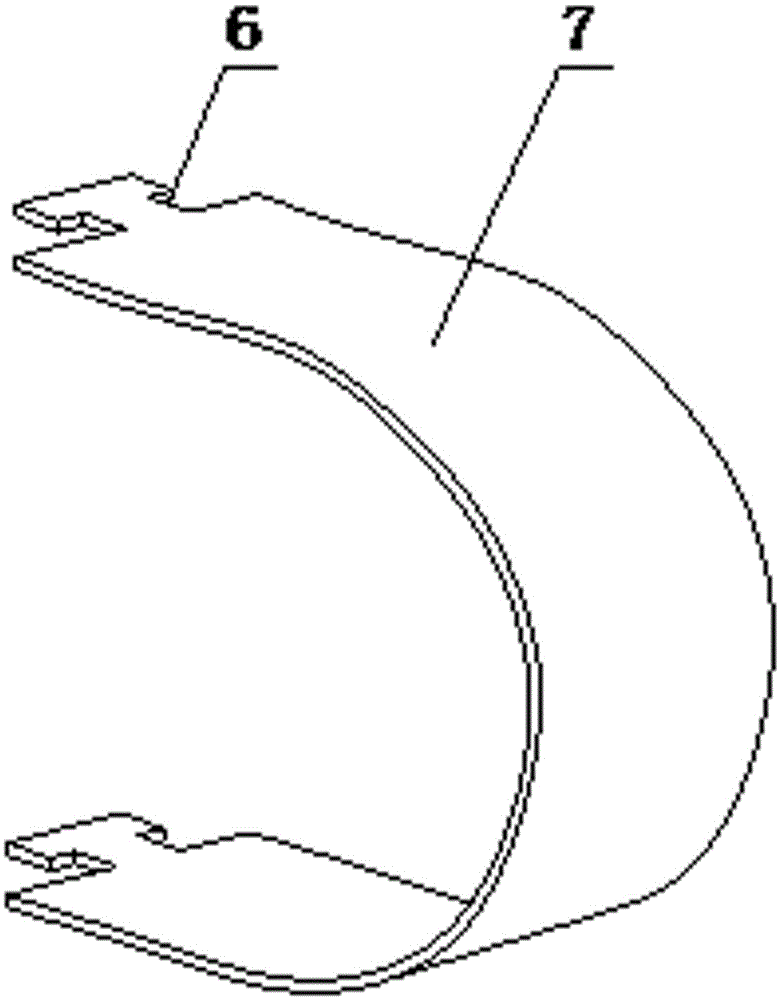

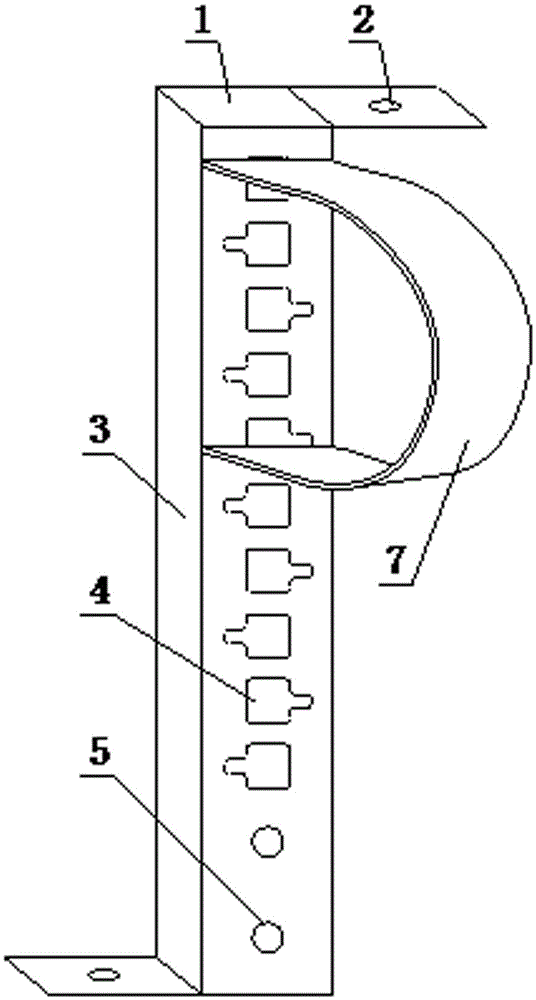

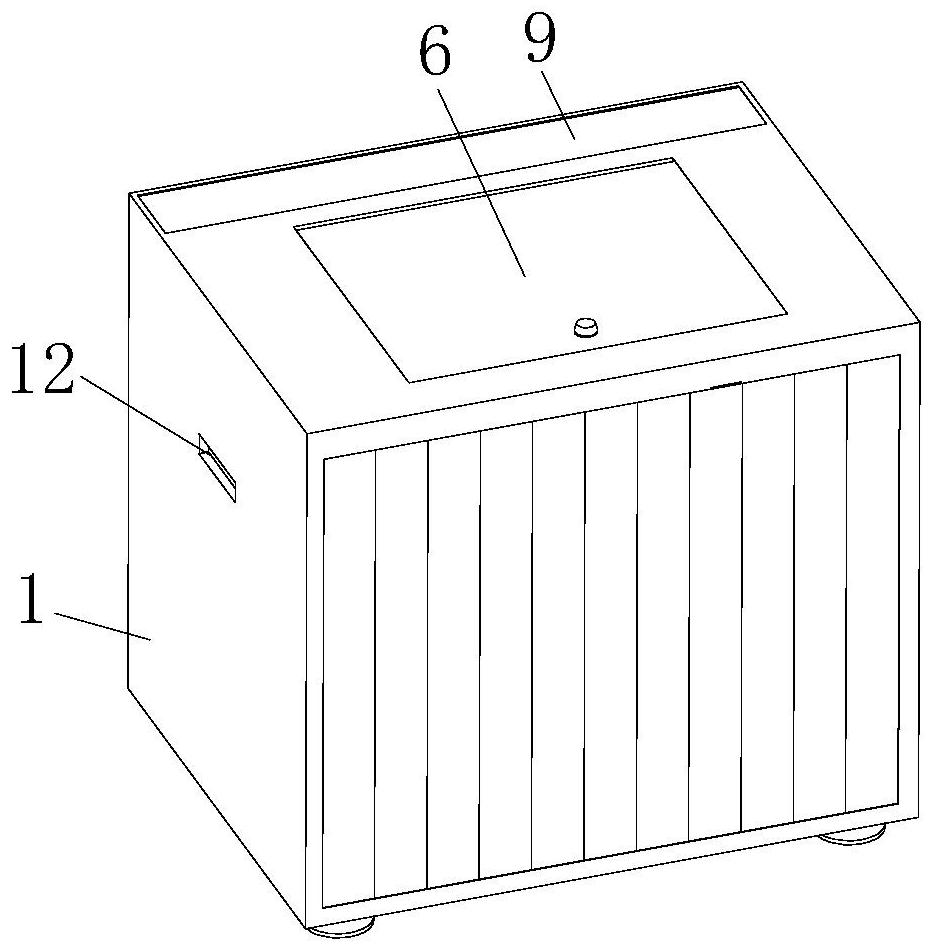

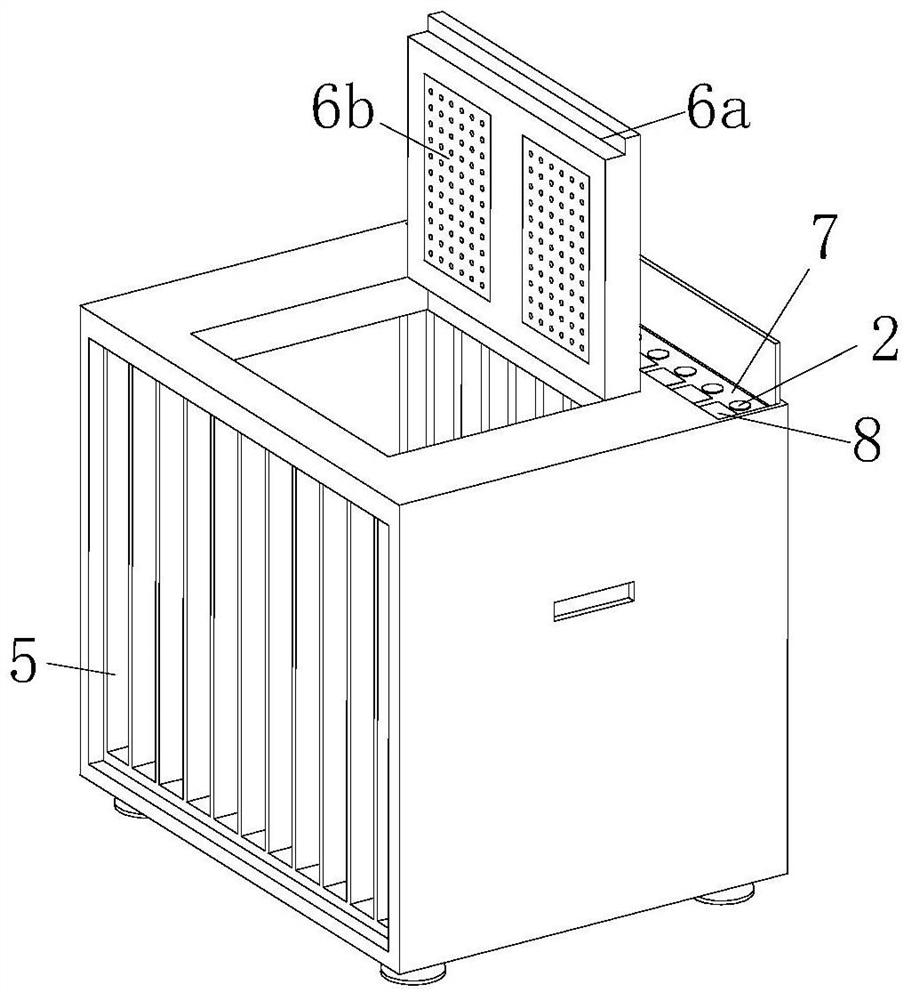

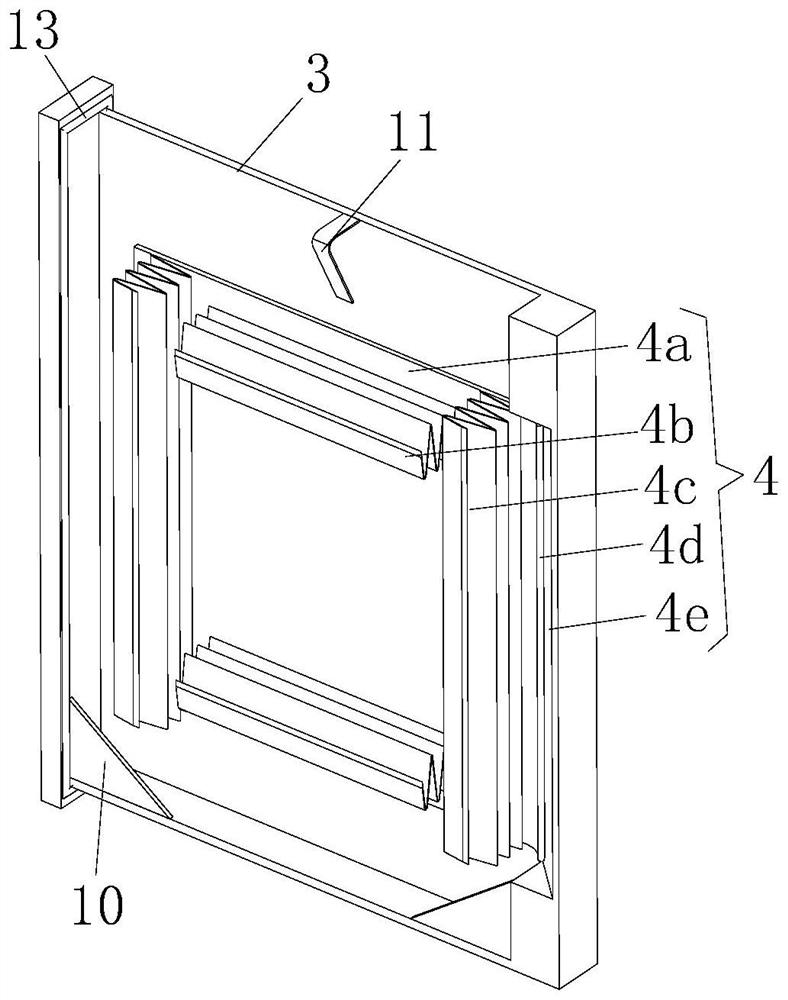

Filebox for quick access to files

ActiveCN109866522BAvoid loose or even bent situationsKeep neatFiling appliancesComputer hardwareEngineering

The invention discloses a file box capable of achieving rapid file taking and belongs to the technical field of file boxes. The file box comprises a box body, a plurality of file pop-up mechanisms, aplurality of file supporting frames and a plurality of file compressing mechanisms, the box body is internally provided with a plurality of file grooves, the multiple file pop-up mechanisms are in one-to-one correspondence with the multiple file supporting frames, each file pop-up mechanism comprises a driving assembly, a clamping assembly and an elastic assembly, the multiple file compressing mechanisms are in one-to-one correspondence with the multiple file supporting frames, and a drying assembly is arranged at the top of the file box. Through the file compressing mechanisms, files in the file supporting frames can be prevented from being loosened and bent, through arrangement of the file pop-up mechanisms, the speed of external damp air entering the box body can be decreased while thefiles are rapidly taken conveniently, the airtightness of the file box is improved, and thus the file keeping effect is improved.

Owner:SHANDONG INST OF BUSINESS & TECH

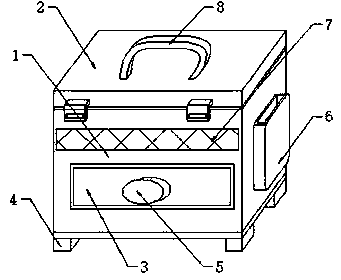

Multifunctional office storage box and using method thereof

InactiveCN108820472AEasy accessAvoid clutterContainers preventing decayInternal fittingsSteel platesElectrical battery

The invention provides a multifunctional office storage box and a using method thereof. The ankle fixing support comprises a fixing support main body, wherein a fixed shell is arranged on the fixing support main body, a protective opening is formed in the top of the fixed shell body, and a shoe sole is arranged at the bottom of the fixed shell body; a gear control button is arranged on one side ofthe shoe sole, a filling layer is arranged in the shoe sole, and a battery groove is formed in the filling layer; a heating sheet is arranged on one side of a wire, an inner sleeve is arranged in thefixed shell body, and a plurality of hook-and-loop fasteners are arranged on the inner sleeve; an air inflation-deflation hole is formed in the inner sleeve, and a tightening drawstring is formed inone end of the inner sleeve; and a fixing steel plate is arranged on the fixed shell body, and an air inflation preformed hole is formed in one side of the fixing steel plate. According to the ankle fixing support, the inner sleeve of the ankle fixing support is made of pure silver mixed fiber materials, and therefore, the effective dryness and peculiar smell protection can be provided, and foot odor and peculiar smell caused by long-term wearing can be effectively solved; and the heating sheet arranged on the shoe sole can play a role in keeping warm and promoting the blood circulation of a foot sole, and the situation that the blood flow is not smooth due to the fact that movement cannot be achieved for a long time is relieved.

Owner:广州嘉美云联科技有限公司

Mobile computer writing machine

The invention discloses a mobile computer writing machine, and the machine comprises system software, a USB line jack, a charging hole, a flat cable jack, a battery, a touch display screen, a short message receiving function, a USB line input function, and a USB line output function. The machine consists of a main body and system software. The charging hole is connected with a charger, and a built-in battery of the machine is charged fully, and then a file or data to be written is inputted into the software through the touch display screen. The machine is simple in use, and can be used for writing only if a camera of the machine is turned on and then a switch on a handle is switched on. If the moving speed of writing on the display screen in a writing process needs to be seen, certain operation skills are needed in order to guarantee the order of characters and the stable moving speed.

Owner:王安兵

Preparation method of hydrocracking catalyst, hydrocracking catalyst and application of hydrocracking catalyst

ActiveCN114453015AHigh yieldAcidity flexible regulationMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a preparation method of a hydrocracking catalyst, the hydrocracking catalyst and application of the hydrocracking catalyst. The preparation method of the hydrocracking catalyst comprises the following steps: (i) preparing a Y / Al-SBA-15 composite molecular sieve; (ii) adding the Y / Al-SBA-15 composite molecular sieve prepared in the step (i), a modified beta molecular sieve and alumina dry glue powder into an acidic solution, molding, drying and roasting to obtain a hydrocracking catalyst carrier; and (iii) impregnating the hydrocracking catalyst carrier obtained in the step (ii) with a solution containing an active metal component, and then drying and roasting to obtain the hydrocracking catalyst. The hydrocracking catalyst prepared by the method provided by the invention has excellent comprehensive performance, is used in a coal tar hydrocracking reaction process, and has excellent product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst carrier, hydrocracking catalyst and preparation methods of hydrocracking catalyst carrier and hydrocracking catalyst

ActiveCN114453018AImprove nitrogen resistanceAdjustable acidityMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

The invention discloses a hydrocracking catalyst carrier, a hydrocracking catalyst and a preparation method thereof. The hydrocracking catalyst carrier comprises a Beta / Al-SBA-15 composite molecular sieve, amorphous silica-alumina I and alumina, the acid content of medium and strong acids in the Beta / Al-SBA-15 composite molecular sieve is 0.6-1.2 mL / g, and the ratio of the acid B to the acid L is less than 0.80. The hydrocracking catalyst prepared by adopting the hydrocracking catalyst carrier has excellent comprehensive performance, is especially used in the hydrocracking reaction process of shale oil with a complex raw material structure, and has excellent product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

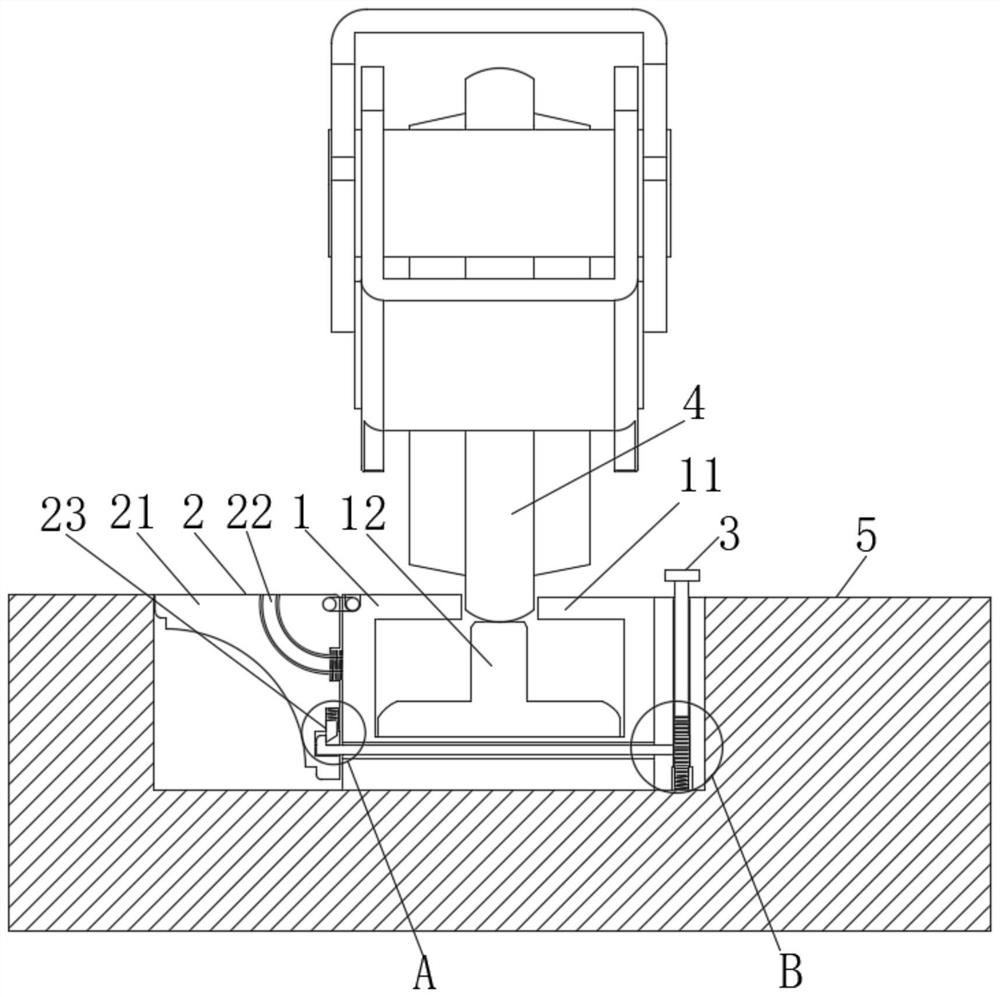

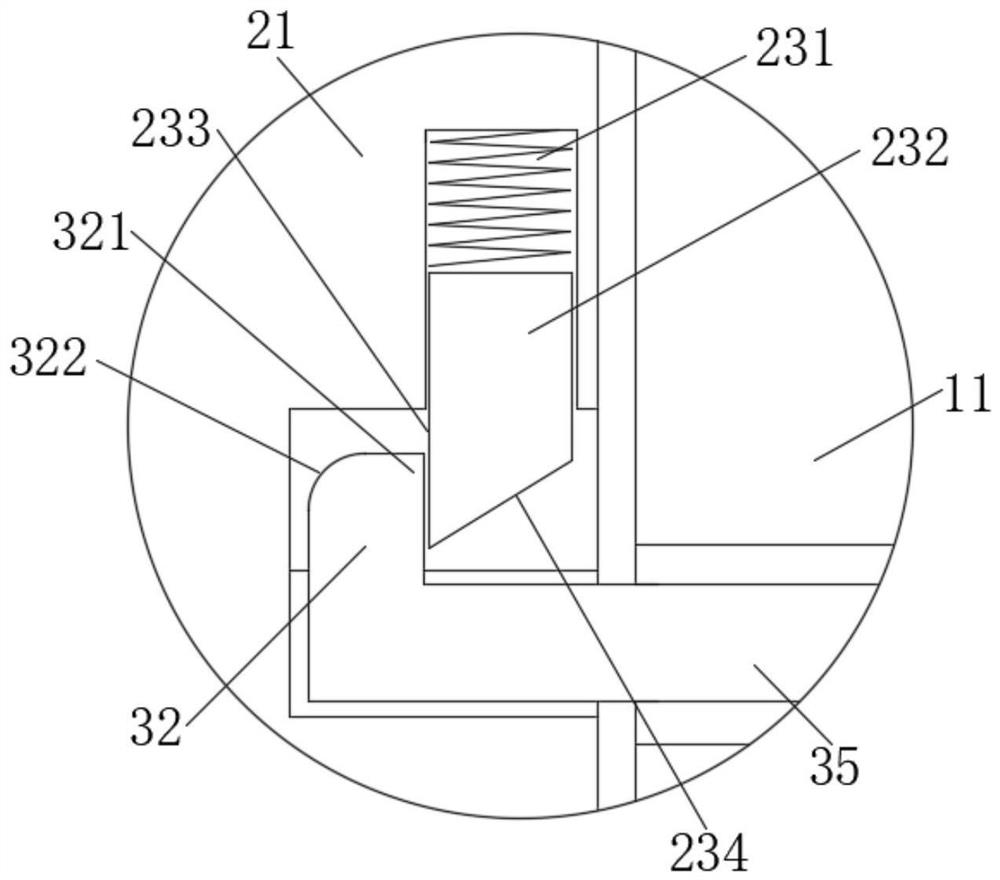

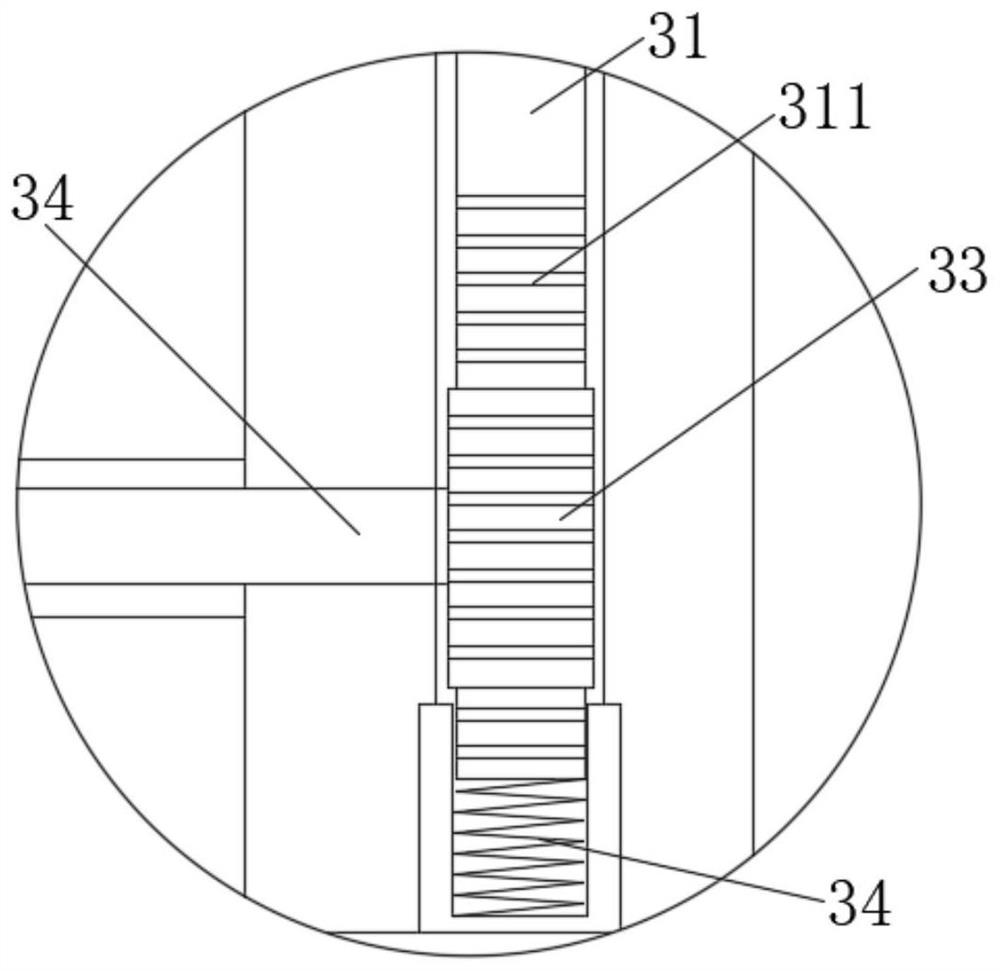

Water retaining hanging sliding door seat

ActiveCN113756670AKeep neatPreserve aestheticsRain/draught deflectorsWing suspension devicesArchitectural engineeringWater flow

The invention discloses a water retaining hanging sliding door seat. The water retaining hanging sliding door seat comprises a lower rail assembly, a water retaining assembly and a starting assembly, the lower rail assembly comprises a seat body and a supporting rod, the supporting rod is located in the seat body, the top end of the supporting rod can support a lower rolling wheel, the upper surface of the seat body is flush with the ground, the water retaining assembly comprises a water retaining block and a pop-up mechanism, one end of the water retaining block is hinged to one end of the seat body, the water retaining block is installed under the ground and is flush with the ground, and the water retaining block can be popped out and protrude out of the ground under the driving of the popping mechanism. By the adoption of the water retaining hanging sliding door seat, the water retaining hanging sliding door seat can be installed under the ground in a concealed mode at ordinary times, the neat and flush appearance is kept, meanwhile, when necessary, the water retaining assembly can be popped up to block water flow, the water retaining function is achieved, and the water retaining hanging sliding door seat is attractive and practical.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

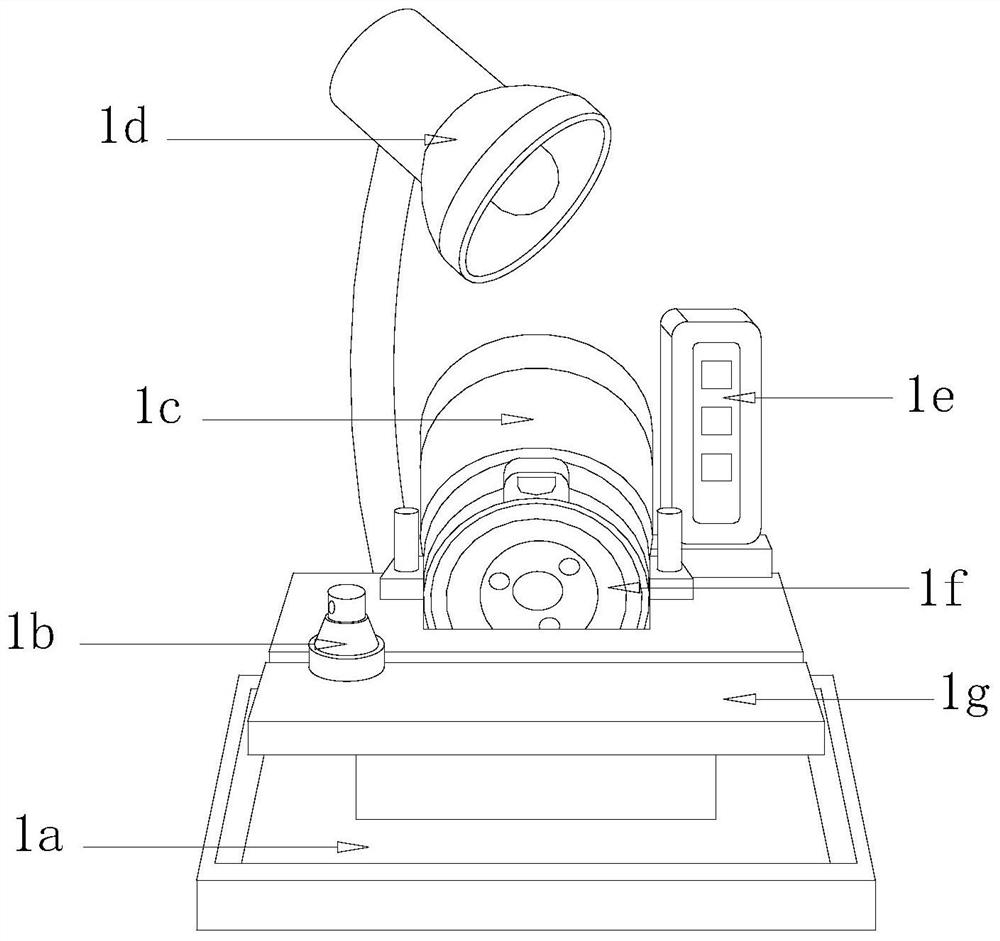

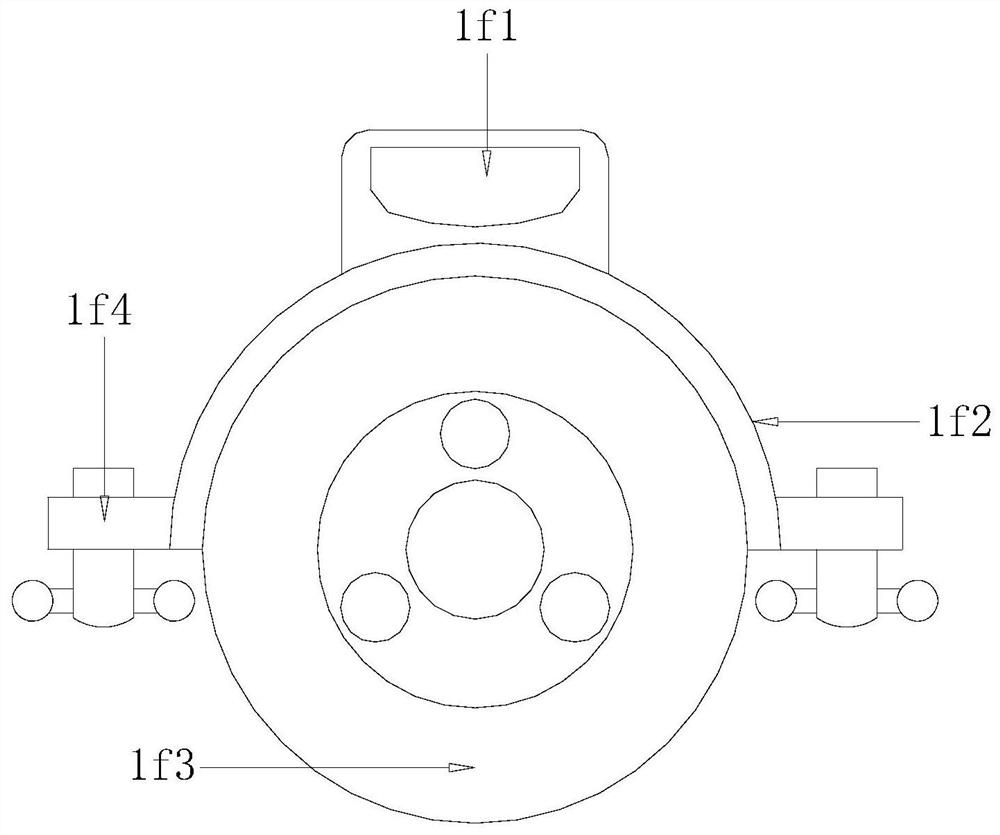

A machining tool grinding device adopting the principle of stabilizing and correcting surface

ActiveCN110509125BAvoid volatile situationsReduce frictionGrinding carriagesOther manufacturing equipments/toolsElectric machineryEngineering

The invention discloses a grinding device for machining tools by adopting a principle of stability increasing and surface correcting. The grinding device structurally includes a mounting base, a toolbase, a drive motor, a head lamp, a control switch, a grinding mechanism and a processing platform. According to the grinding device, when the surface of a grinding wheel is uneven and needs to be repaired, a surface repairing supporting block in a surface correcting assembly is taken out and adjusted to move grinding stone downwards and then move by returning the position, it is ensured that thegrinding stone fits the surface of the grinding wheel, when the grinding wheel rotates, the plane of the grinding stone is repaired, a limiting mechanism is used for limiting control of a built-in push rod at certain strength, staff flexibly take and put conveniently, during overall use, the plane of the grinding wheel can be quickly and conveniently processed, the smoothness is guaranteed in theprocess of tool grinding, the quality of the tools after grinding is effectively improved, the neat blade surface is ensured, and the cutting efficiency is improved.

Owner:东阳市智享机械科技有限公司

A corrugated paper production process

ActiveCN108608683BDoes not affect the processingFit tightlyMechanical working/deformationAdhesive gluePaper production

The invention relates to the field of corrugated paper manufacturing, in particular to a corrugated paper production process. The gluing and pressing equipment used in the method transports the core paper to be bonded by including a first conveying mechanism and a second conveying mechanism, and the core wheel realizes The coating is applied and stuck to the core paper through the coating assembly mechanism, the first pressing mechanism and the second pressing mechanism press the stuck core paper, and the edge trimming mechanism realizes cutting the side. The container provided by the present invention adopts a special structure. When the paint inside is in use, the remaining amount of paint can be accurately observed through the observation window; after the core paper sticks, use the rotating conveyor belt to cooperate with heating Press down to promote the rapid solidification of the glue, and use the sponge pad to press the two sides of the cutting blade, so that the rotating cutting blade can quickly cut the corresponding parts on both sides according to the demand.

Owner:东莞市东创纸品制造有限公司

An automatic splitting and back pulling type ramie peeling machine

InactiveCN110820052BEliminate hard-to-remove problemsMeet the actual needs of stripping hempMechanical fibre separationFiberEngineering

The invention provides an automatic-ramie-splitting reverse pull type ramie decortication machine. The automatic-ramie-splitting reverse pull type ramie decortication machine comprises a frame, a transmission mechanism, a ramie splitting and decorticating mechanism and a controller and is characterized in that ramie stalks are conveyed through a feeding device in the ramie splitting and decorticating mechanism, a self-centering ramie splitting combined tool splits the single sides of the ramie stalks, a ramie pressing device spreads and flattens the split ramie stalks in a unified manner, theflattened ramie stalks are conveyed to a ramie clamping and decorticating device and an eccentric ramie clamping device, a ramie breaking and lifting device breaks ramie sticks at the ends of the ramie stalks clamped by the eccentric ramie clamping device, and a reserve pull device reversely pulls the ramie stalks to complete ramie decortication and ramie stick removing. The automatic-ramie-splitting reverse pull type ramie decortication machine has the advantages that the whole process including one-step ramie splitting, ramie clamping and ramie breaking, reverse pull ramie stick removing andthe like can be completed, the ramie sticks are in an elongated and complete state in the whole ramie decortication process, the problem that crushed ramie sticks attached into fiber layers are hardto remove, the actual ramie decortication requirements of ramie farmers can be satisfied, and the automatic-ramie-splitting reverse pull type ramie decortication machine is promising in market popularization prospect.

Owner:HARBIN FORESTRY MASCH RES INST STATE FORESTRY & GRASSLAND ADMINISTRATION +1

Preparation method of hydrocracking catalyst, hydrocracking catalyst and application

ActiveCN114453011AEvenly distributedAvoid reunionCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a preparation method of a hydrocracking catalyst, the hydrocracking catalyst and application of the hydrocracking catalyst. The preparation method of the hydrocracking catalyst comprises the following steps: (i) preparing a Beta / Al-SBA-15 composite molecular sieve; (ii) mixing, kneading and molding the Beta / Al-SBA-15 composite molecular sieve prepared in the step (i), a Y molecular sieve and aluminum oxide to obtain a carrier precursor; (iii) impregnating the carrier precursor obtained in the step (ii) with a nano silicon dioxide dispersion liquid, and then drying to obtain a hydrocracking catalyst carrier; and (iv) dipping the carrier obtained in the step (iii) in a solution containing an active metal component, and drying and roasting to obtain the hydrocracking catalyst. The hydrocracking catalyst prepared by the method is used for hydrocracking of coal tar, and the cetane number and condensation point of diesel oil can be greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam and vacuum cleaner

InactiveCN101028180BDoes not affect altitudeImprove cleanlinessCarpet cleanersFloor cleanersElectric machineryEngineering

A steam type vacuum sweeper comprises a foundation bed connected respectively with a dust arrest box and a vapor generation part, a manipulation body, and a body recess for connecting the manipulationbody rotatablely to the foundation bed, wherein said foundation bed is equipped with a suction nozzle and a steam jet hole thereon, the manipulation body is equipped with an electrical machine for intaking air, said body recess includes a first arm and second arm with one end rotatablely connected to the foundation bed and a connection part for connecting the other end of the first arm and secondarm, said connection part is also connected with the manipulation body, an air oilchannel intercommunicating pore is provided between the first arm and the connection part. Through such a structure,a dust arrest passage way is constituted at the body recess to simplify the base construction. An electrical machine is mounted at the manipulation body to ensure that the height of the foundation bedwill not be affected even if the volume becomes larger when the electrical machine capacity is improved, capable of cleaning-up floor below fleabags, desks and sofas.

Owner:韩京姬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com