Brush manufacturing machine

A brush making machine and brush bristles technology, which is applied in the direction of brushes, brush bodies, household appliances, etc., to achieve the effect of reducing space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

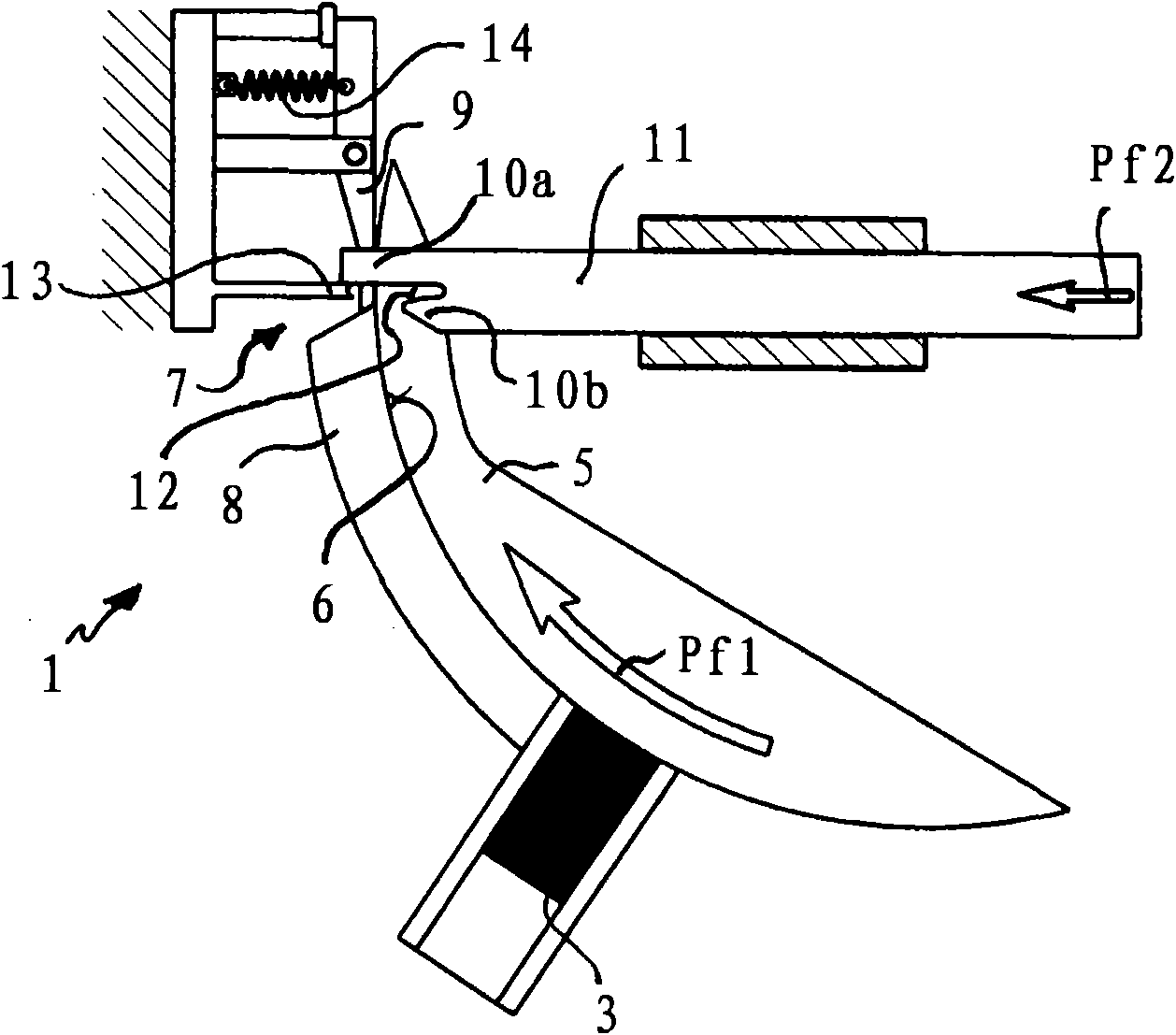

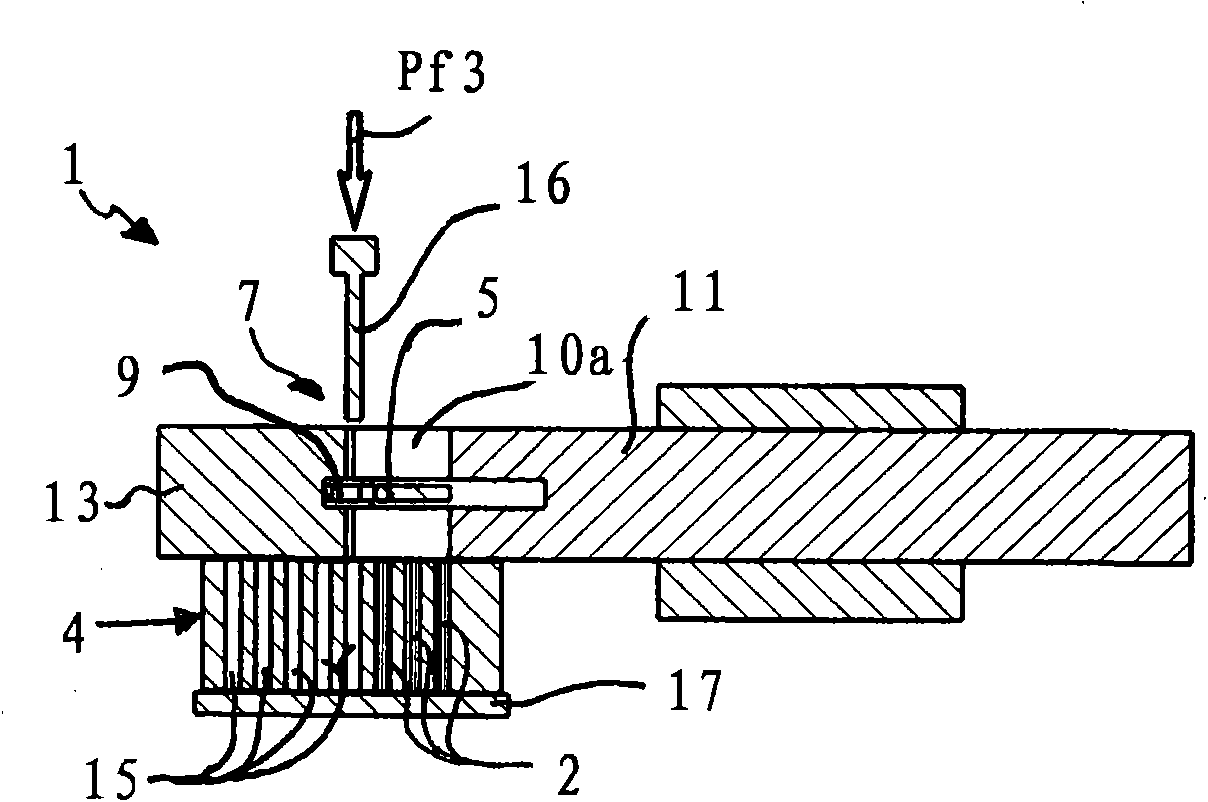

[0020] According to the accompanying drawings, the brush making machine has a device for removing the bristle bundle 2 from the bristle storage device 3 ( figure 1 ) to a box in the form of ( figure 2 ) of the bristle receiving portion 4 of the bristle delivery device 1 . Such as figure 1 As shown, the bristle delivery device 1 comprises a beam splitter 5 with a receiving groove 6 for removing bristle bundles from the bristle storage device 3 . To this end, the beam splitter 5 can be pivoted between a beam receiving position in which the receiving groove 6 is arranged in the region of the bristle storage device 3 and a bundle output position in which the receiving groove 6 is arranged in the region of the loading position 7 (arrow Pf1 ).

[0021] The beam splitter 5 is guided on an edge cover 8 which covers the receiving groove 6 during transport of the bristle bundles and thus holds the bristle bundles in the receiving groove 6 . In the region of the loading point 7 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com