A machining tool grinding device adopting the principle of stabilizing and correcting surface

A technology of machining and knives, which is applied in the field of grinding equipment for machining knives, can solve the problems of reducing cutting life, deformation of blades, and separate classification, etc., and achieves the effects of improving stability, avoiding fluctuations in grinding stones, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

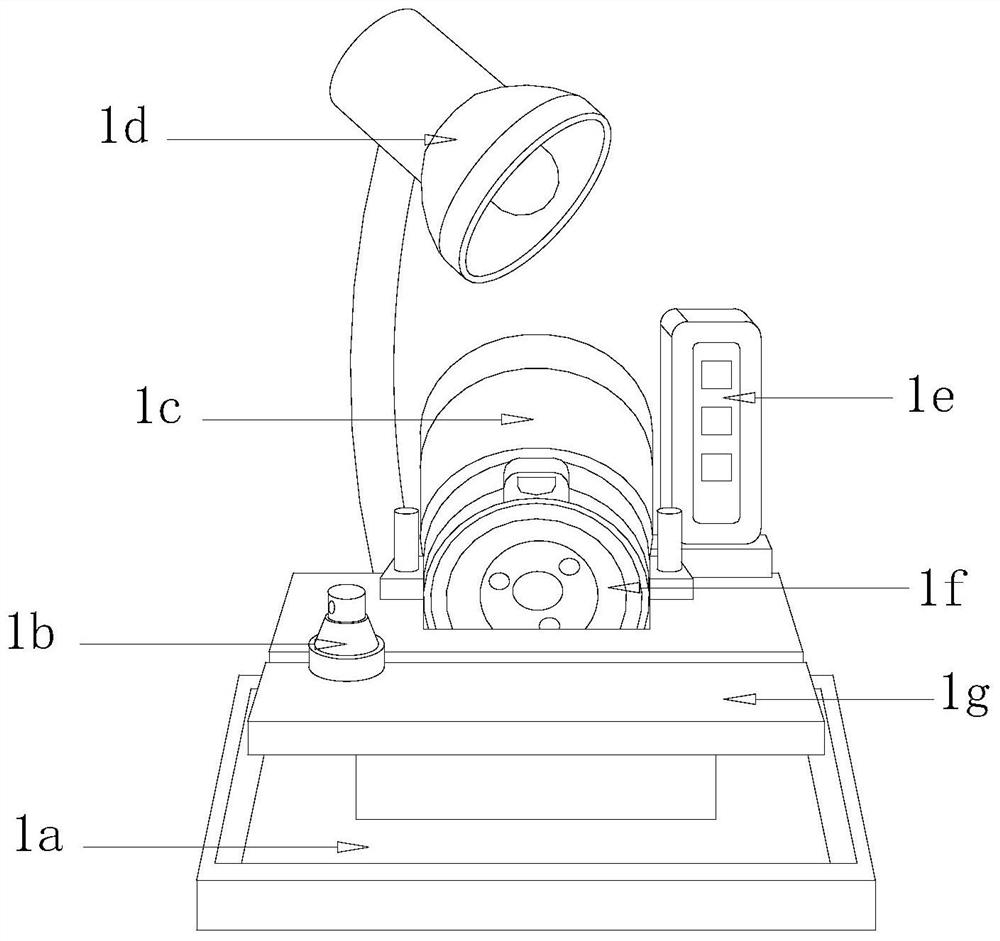

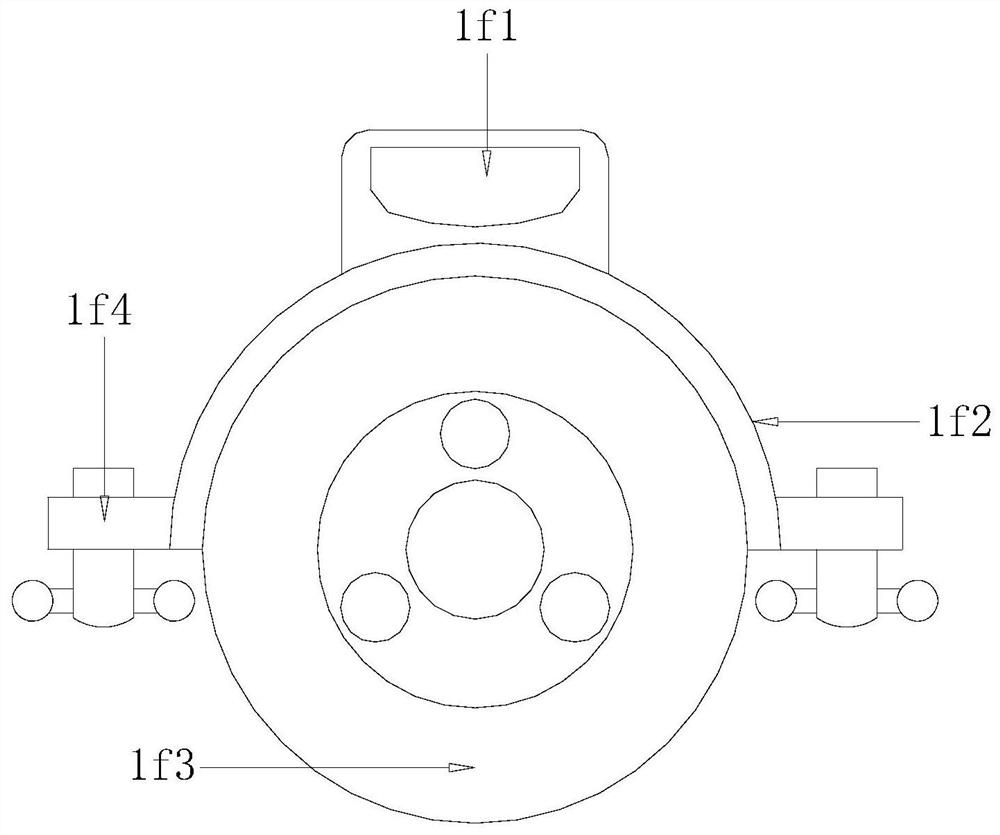

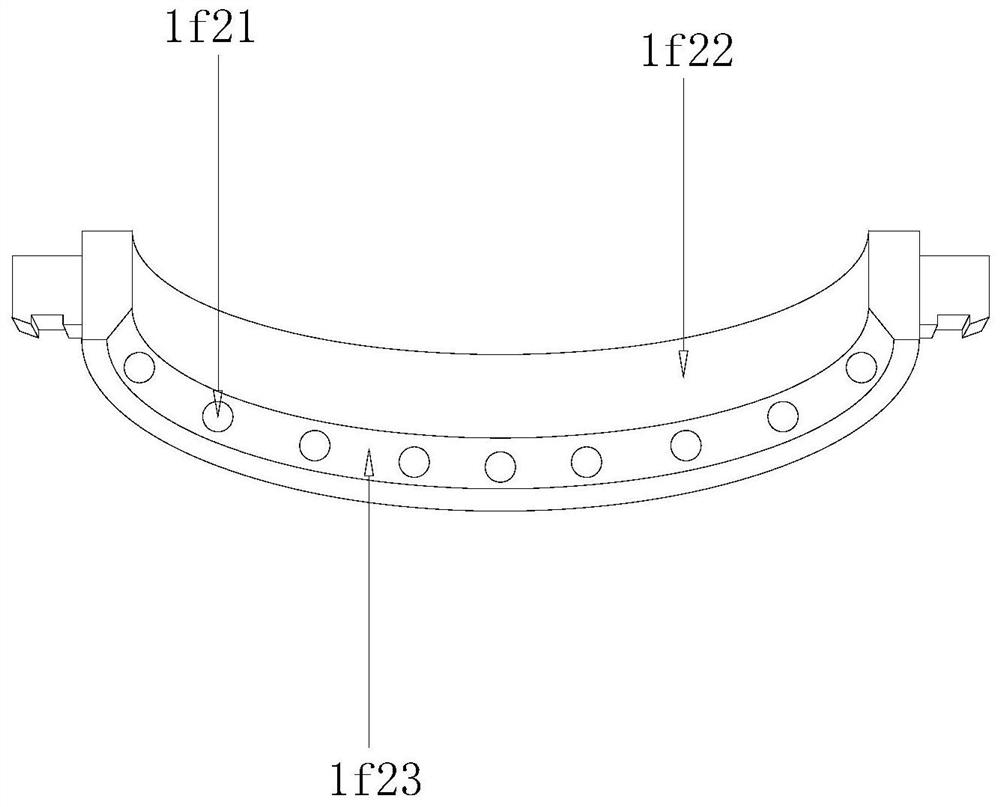

[0029] See Figure 1-Figure 6 , The present invention provides a machining tool grinding device that adopts the principle of increasing stability and leveling, and its structure includes a mounting base 1a, a tool base 1b, a drive motor 1c, a lighting lamp 1d, a control switch 1e, a grinding mechanism 1f, and a processing platform 1g The bottom of the processing platform 1g is embedded on the top of the mounting base 1a, and the drive motor 1c is mounted on the middle of the rear end of the processing platform 1g by snapping. The rear end of the processing platform 1g is provided with a lighting lamp 1d. The bottom of the control switch 1e is embedded on the right side of the rear end of the processing platform 1g, the rear end of the grinding mechanism 1f is buckled and connected with the front end of the drive motor 1c, and the bottom of the tool base 1b is installed on the processing platform 1g by fitting. At the front end, the tool to be polished is fixed on the tool base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com