Preparation method of hydrodearomatization catalyst, hydrodearomatization catalyst and application of hydrodearomatization catalyst

A technology for hydrodearomatization and catalysts, which is applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems of increased catalyst costs, small catalyst specific surface area and pore volume, and large loss of precious metals. Improve the effective utilization rate, improve the dearomatization ability, and improve the effect of anti-carbon deposition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] (1) Preparation of A-S-1 molecular sieve:

[0077] (1) Preparation of amorphous silica-alumina dry glue A1 and slurry: sodium aluminate solution concentration 18gAl 2 o 3 / L, the concentration of sodium silicate solution is 95gSiO 2 / L, take 0.75L sodium aluminate solution and put it into the gel-forming tank, then add 0.35L sodium silicate solution, control the reaction temperature at 22°C, and feed CO with a concentration of 40v% 2 gas, CO 2 When the gas accounts for 50% of the total intake, add 0.50L sodium silicate solution while ventilating to control the pH value of the gel to 9.8, then ventilate and stabilize for 20 minutes, filter the slurry and wash it with 65°C deionized water until neutral. The filter cake was beaten with water at a solid-to-liquid volume ratio of 10:1, treated at 130°C and 3.0 MPa steam pressure for 2 hours, dried at 120°C for 6 hours, crushed and sieved to obtain the amorphous silica-alumina product A1. The prepared amorphous silica-alu...

Embodiment 2

[0082] (1) Preparation of A-S-2 molecular sieve:

[0083] (1) Preparation of amorphous silica-alumina dry glue A2 and slurry: concentration of sodium aluminate solution 23gAl 2 o 3 / L, the concentration of sodium silicate solution is 100gSiO 2 / L, take 0.78L sodium aluminate solution and put it into the gel-forming tank, then add 0.25L sodium silicate solution, control the reaction temperature at 26°C, and feed CO with a concentration of 40v% 2 gas, CO 2 When the gas accounts for 50% of the total intake, add 0.50L sodium silicate solution while ventilating to control the pH value of the gel to 9.2, then ventilate and stabilize for 20 minutes, filter the slurry and wash it with 65°C deionized water until neutral. The filter cake was beaten with water at a solid-to-liquid volume ratio of 10:1, treated at 120°C under 3.5MPa water vapor pressure for 2 hours, dried at 120°C for 6 hours, crushed and sieved to obtain the amorphous silica-alumina product A2. Mix the prepared amorp...

Embodiment 3

[0088] (1) Preparation of A-S-3 molecular sieve:

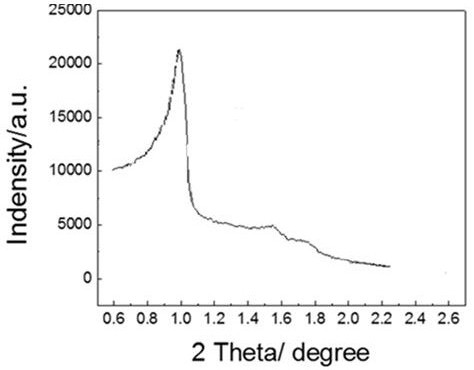

[0089] Others are the same as in Example 1, except that in step (1) when preparing amorphous silica-alumina dry gel A1, the pH value of the gel is controlled to be 11 to obtain amorphous silica-alumina product A3, and the prepared molecular sieve is A-S-3. The properties of A-S-3 are shown in Table 1. The XRD pattern of A-S-3 molecular sieve and figure 1 Similarly, the characteristic peaks of Al-SBA-15 molecular sieves are shown.

[0090] (2) Weigh tetraammine platinum acetate [Pt(NH 3 ) 4 (CH 3 COO) 2 ] solution and tetraammine palladium acetate [Pd(NH 3 ) 4 (CH 3 COO) 2] solution, the quality of the solution is calculated according to the final catalyst metal platinum and palladium content, and the solution taken by weighing is diluted to 100mL with deionized water to obtain solution A; 7 grams of ethylene glycol are weighed and diluted to 100mL with deionized water to obtain Solution B; Weigh 12g A-S-3 molecular s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com