Proton exchange composite membrane and continuous preparation method thereof

A proton exchange and composite membrane technology, applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problems of difficult lamination and large-scale production, and achieve the effect of ensuring the hydrogen and proton transport capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

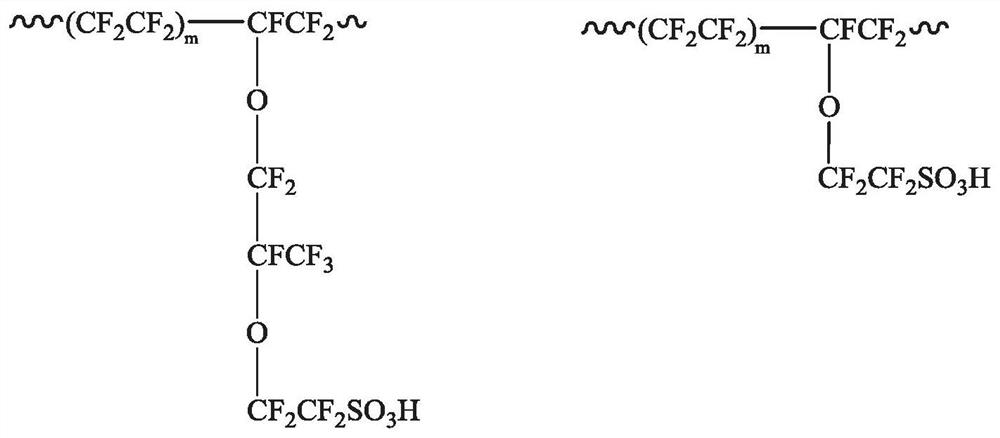

[0034] 1. Dissolve the long side chain perfluorosulfonic acid resin with an EW value of 950g / mol in a mixed solvent with a volume ratio of 1:1 between deionized water and isopropanol to form a 5% perfluorosulfonic acid resin solution , and then add 0.1% nano-SiO of long side chain perfluorosulfonic acid resin quality 2 , to form casting solution 1;

[0035] 2. Dissolve the short side chain perfluorosulfonic acid resin with an EW value of 650g / mol in a mixed solvent with a volume ratio of deionized water and isopropanol of 1:1 to form a casting solution 2 with a concentration of 10%;

[0036] 3. Using the existing technology, the microporous membrane with a thickness of 3 μm is bonded with the support base film to form a composite support, which is placed on the coating unwinding roller;

[0037] 4. Put the casting solution 1 in step 1 into the feeding system 1, and use the first process parameters of coating speed 1m / min and coating wet thickness 1000μm to coat the casting so...

Embodiment 2

[0042] 1. Dissolve the long side chain perfluorosulfonic acid resin with an EW value of 1150g / mol in a mixed solvent with a volume ratio of 1:1 between deionized water and isopropanol to form a perfluorosulfonic acid resin solution with a concentration of 15%. , then add 0.5% nano Ag of long side chain perfluorosulfonic acid resin quality 2 O, forming casting solution one;

[0043] 2. Dissolving the short side chain perfluorosulfonic acid resin with an EW value of 850g / mol in a mixed solvent with a volume ratio of deionized water and isopropanol of 1:1 to form a casting solution 2 with a concentration of 25%;

[0044] 3. Using the existing technology, the microporous membrane with a thickness of 3 μm is bonded with the support base film to form a composite support, which is placed on the coating unwinding roller;

[0045] 4. Put the casting solution 1 in step 1 into the feeding system 1, and use the first process parameters of coating speed 10m / min and coating wet thickness 1...

Embodiment 3

[0050] 1. Dissolve the long side chain perfluorosulfonic acid resin with an EW value of 1000g / mol in a mixed solvent with a volume ratio of 1:1 between deionized water and isopropanol to form a perfluorosulfonic acid resin solution with a concentration of 10%. , and then add 0.2% nano-CaO of the quality of the long side chain perfluorosulfonic acid resin to form a casting solution 1;

[0051] 2. Dissolve the short side chain perfluorosulfonic acid resin with an EW value of 750 g / mol in a mixed solvent of deionized water and isopropanol with a volume ratio of 1:1 to form a casting solution 2 with a concentration of 15%;

[0052] 3. Using the existing technology, the microporous membrane with a thickness of 5 μm is bonded with the support base film to form a composite support, which is placed on the coating unwinding roller;

[0053] 4. Put the casting solution 1 in step 1 into the feeding system 1, and use the first process parameters of coating speed 5m / min and coating wet thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com