A diameter-adjustable coiling machine

A technology of coiling machines and conduits, which is applied in the field of coiling machines, can solve the problems of high labor intensity, low efficiency, and high cost, and achieve the effects of quick and simple diameter adjustment, reduced labor intensity, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

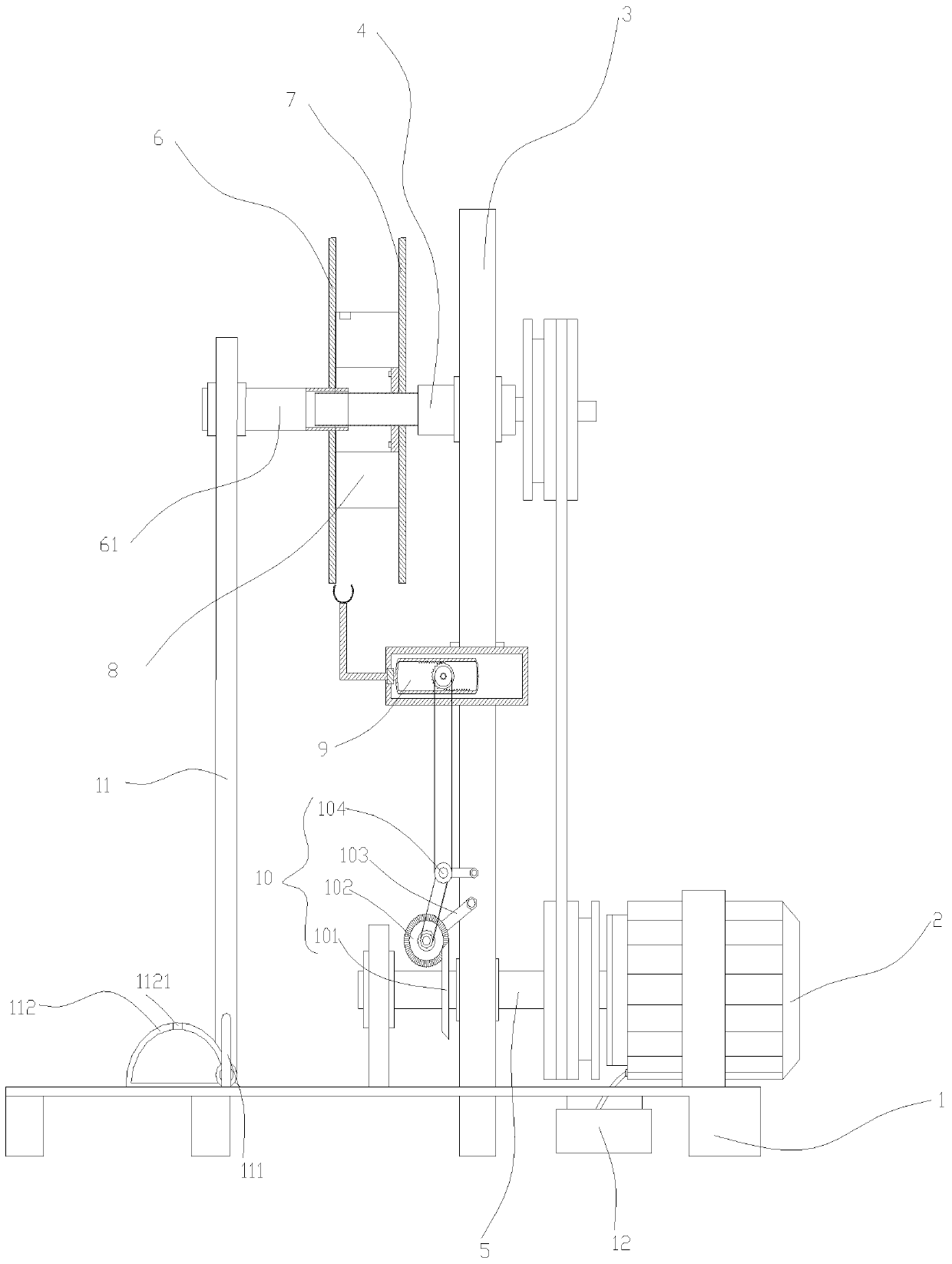

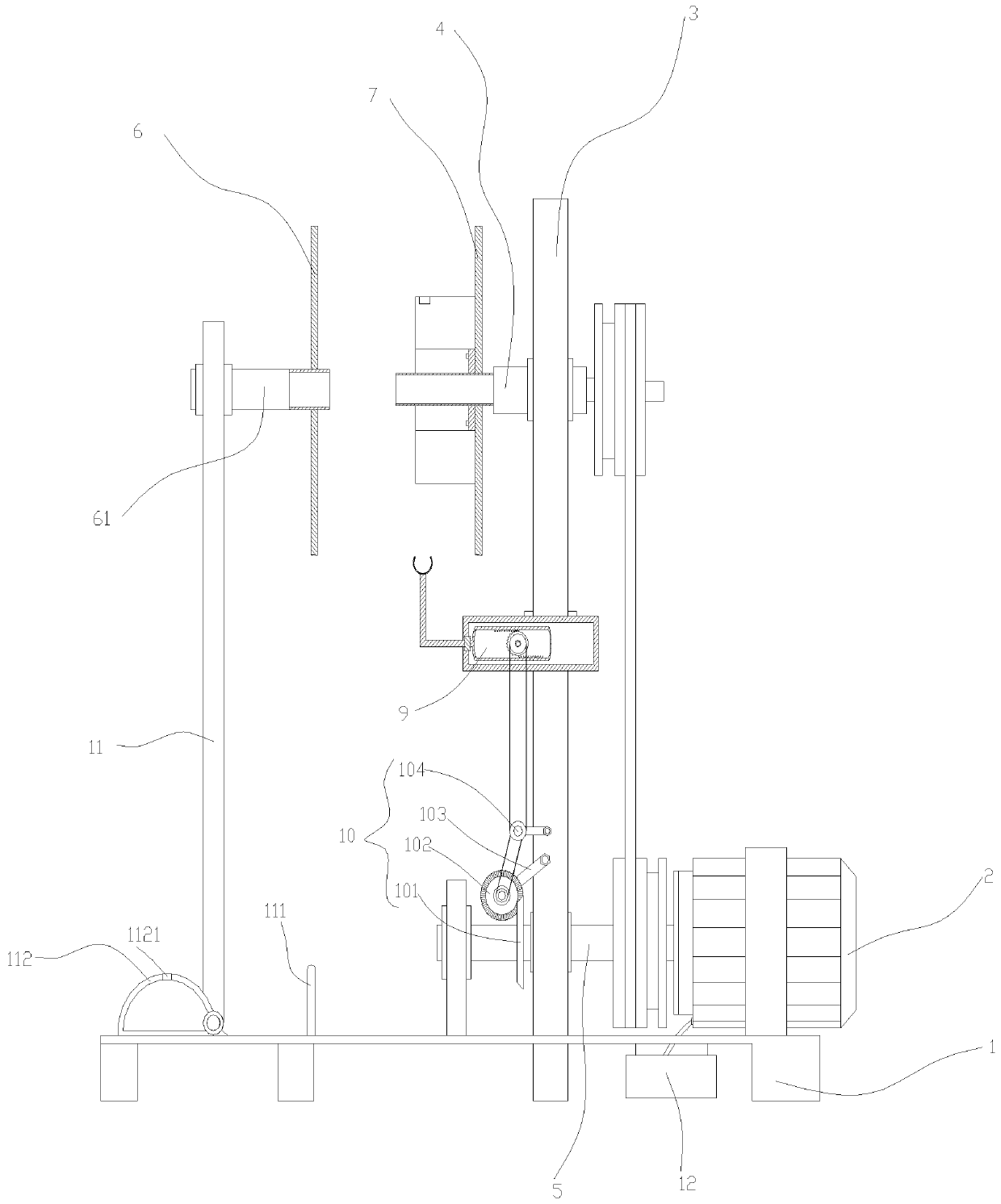

[0033] Such as figure 1 , figure 2 A diameter-adjustable pipe coiling machine, comprising a base, a motor arranged on the base, and a bracket fixed on the base, the upper end of the bracket is fixed with a secondary rotating shaft, which is connected to the main shaft of the motor through a belt; Covered with a baffle plate and a main turntable, a spline is provided at the front end of the auxiliary shaft, and a shaft sleeve is provided in the middle of the baffle plate, and a spline matched with it is formed on the inner wall of the front end of the shaft sleeve, so that the baffle plate can move The rear end of the sleeve is fixed on the sub-support through bearings. The sub-support is parallel to the support and slidably fixed on the slideway of the base. The lower end of the sub-support is hinged with a pedal, which is ring-shaped. There is a notch on the ring frame body, the opening of the notch is pear-shaped with a diameter smaller than its internal diameter, and is e...

Embodiment 2

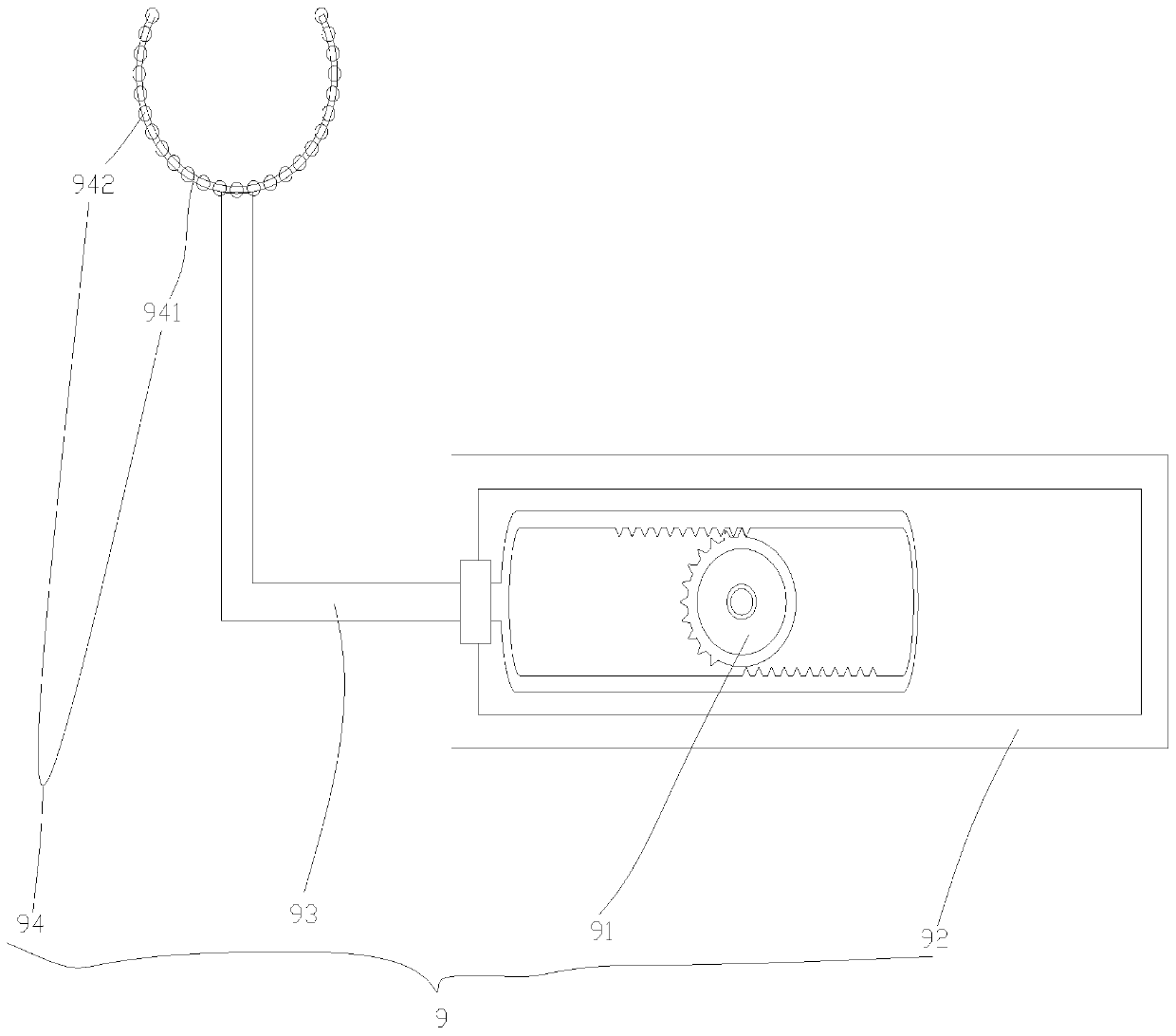

[0036] Such as figure 1 , figure 2 , image 3As shown, in this embodiment, a catheter mechanism is added to the device. The catheter mechanism includes a runner, and the runner is connected to the motor shaft through a direction-changing mechanism. The left side along the vertical centerline of the runner is set as a gear structure. Cut to the running wheel, a walking moving frame is provided, a rack structure meshing with the gear structure of the running wheel is arranged on the moving frame, a swing arm is arranged on one side of the moving frame, and a guide guide mechanism is arranged on the swing arm. The guide wheel mechanism includes an arc-shaped guide shaft on which a plurality of guide wheels are arranged.

[0037] The direction-changing mechanism includes a pair of intermeshing bevel gears. The intermeshing bevel gears include a main bevel gear fixed on the motor shaft and an auxiliary bevel gear fixed on the bracket through a pole. The auxiliary bevel gear is c...

Embodiment 3

[0040] Such as Figure 4 , Figure 5 As shown, different from the above-mentioned embodiment, in this embodiment the structure of the main turntable is the same as that of the baffle plate. The plate is an arc plate, and a raised limit block is arranged on one side of the baffle plate, and the limit block is engaged in the track of the main turntable.

[0041] The coiled catheter needs to be bundled. There is a binding groove on the main turntable, and the binding wire is embedded. After the coiling is completed, the binding wire is manually wound, and the continuity of the coiling tube is continuous without reducing the processing efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com