Vertical pulling type single crystal growth furnace

A technology of Czochralski and growth furnace, which is applied in the direction of single crystal growth, crystal growth, and self-melting liquid pulling method, etc. It can solve the problems of large flow rate of argon gas, corrosion, and high production cost, so as to reduce the space in the furnace, The effect of ensuring the service life and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

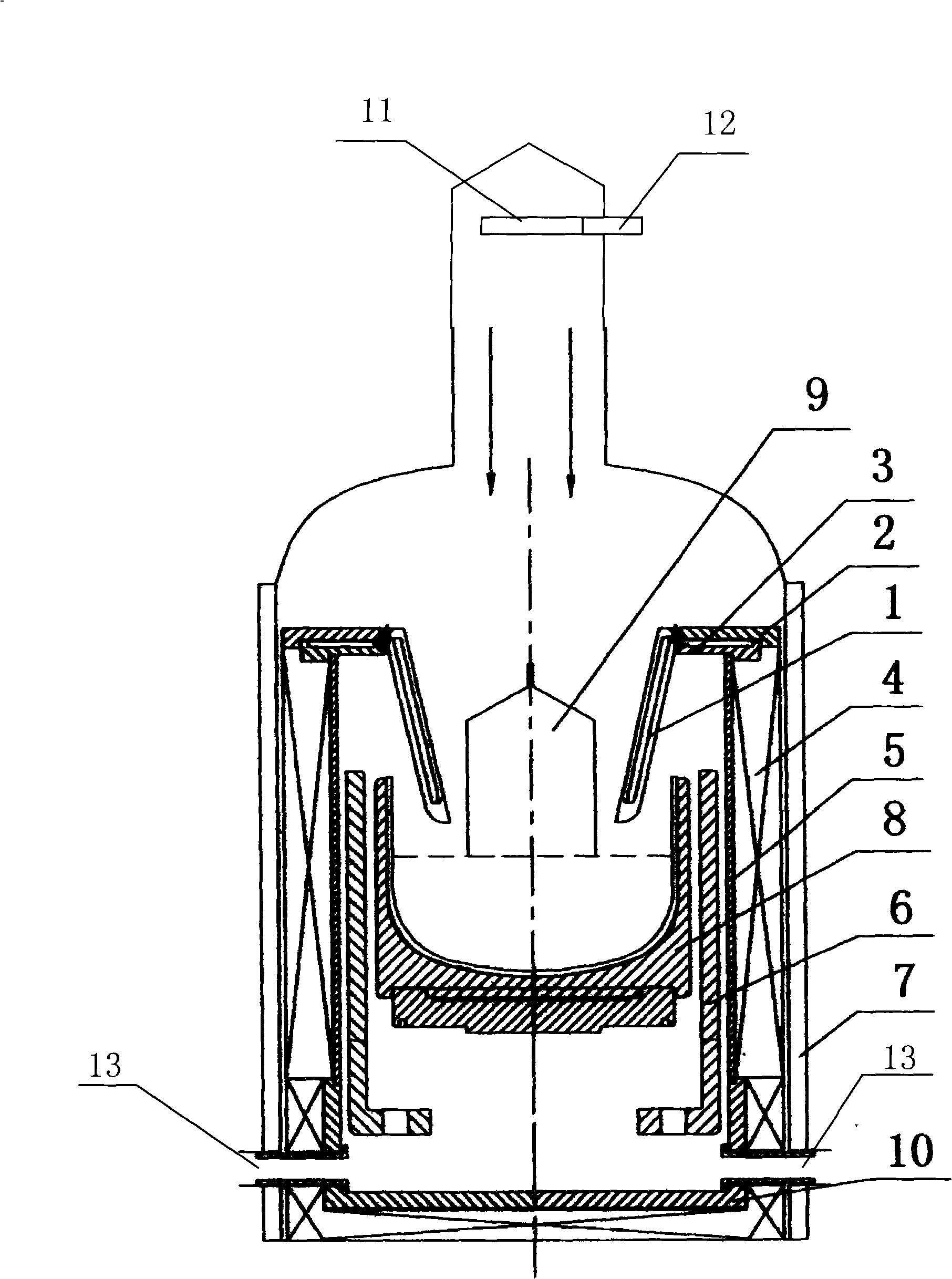

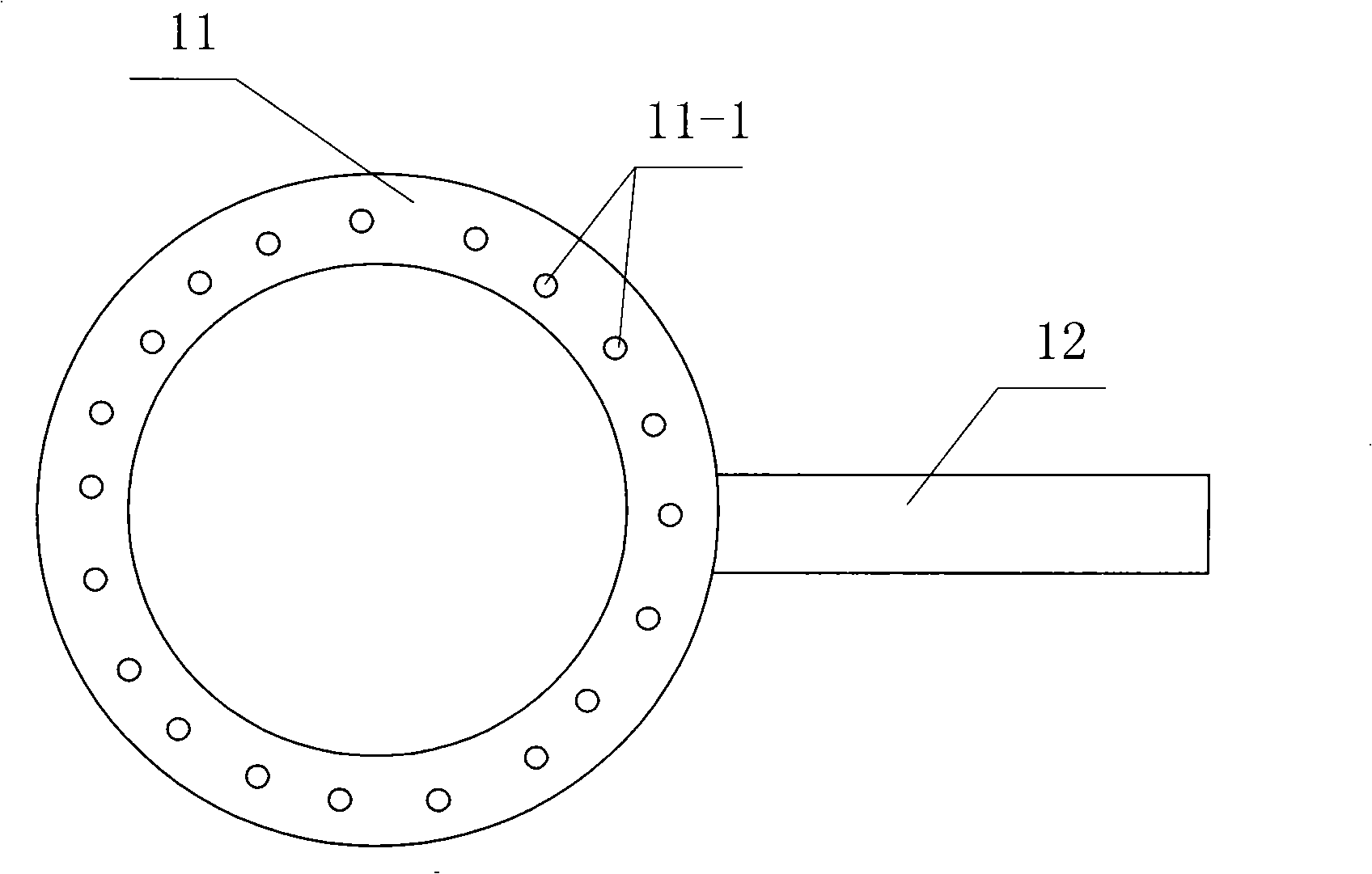

[0024] See Figure 2-7 , the Czochralski single crystal growth furnace of the present embodiment comprises: an argon gas input pipe 12, an annular gas distributor 11 communicated with the argon gas input pipe 12; 0.8×10 3 Pa to 0.9×10 3 Pa, the flow rate of argon gas is 30L / min.

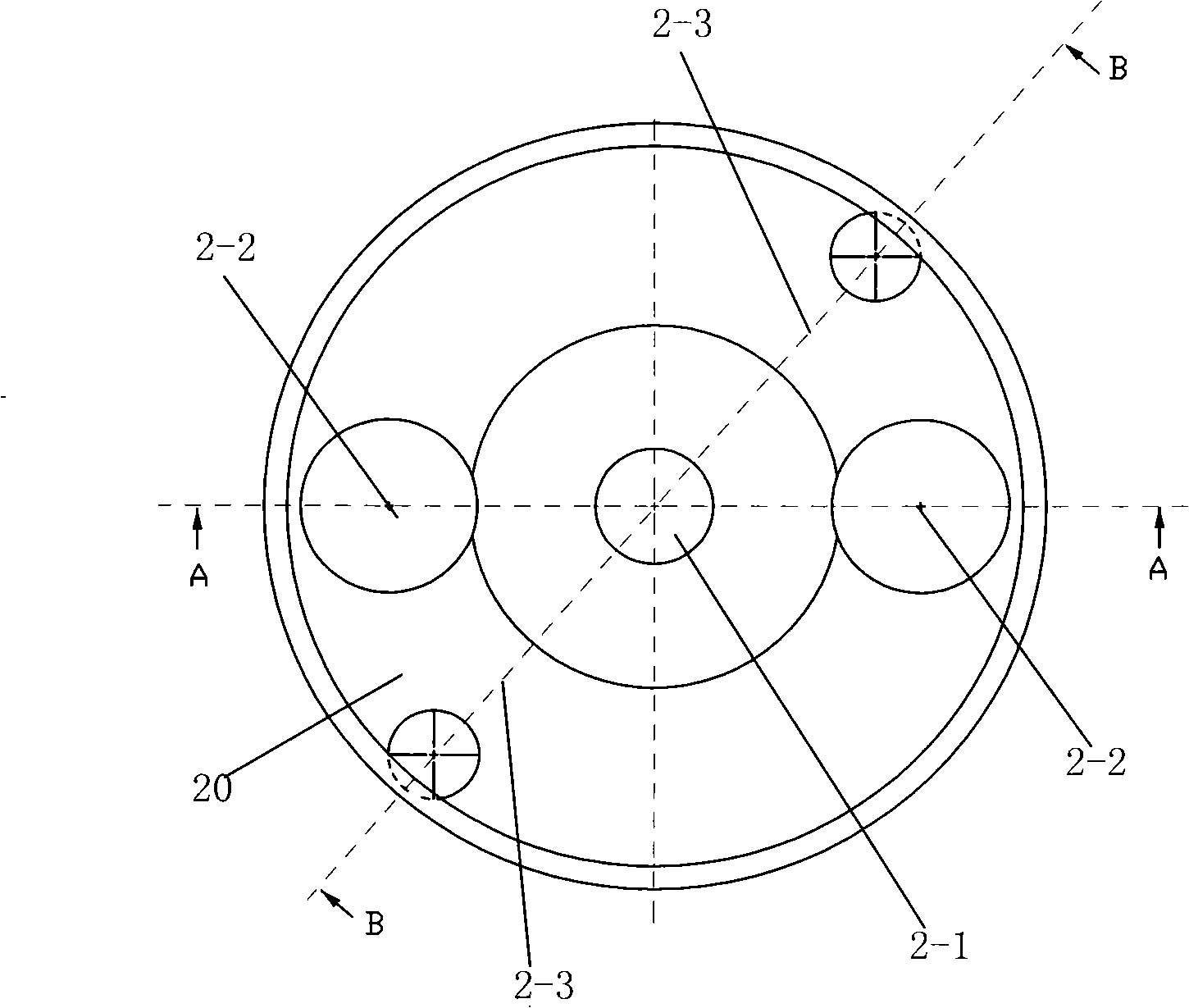

[0025] It also includes: a bowl-shaped airflow guiding device 20 located between the crucible holder 14 of the furnace and the exhaust port 13 at the bottom of the furnace; it includes: a central axis hole 2- 1. A pair of electrode holes 2-2 arranged on both sides of the central axis hole 2-1, and a vent hole 2 arranged on both sides of the central axis hole 2-1 and opposite to the exhaust port 13 of the furnace -3; the graphite axis 21 of the furnace passes through the axis hole 2-1 of the airflow guiding device 20, a pair of electrode posts 15 of the furnace pass through the electrode hole 2-2 respectively, and the exhaust gas of the furnace Port 13 communicates with each vent hole 2-3 of airfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com