Double-layer concrete ecological slope protection and laying method thereof

A double-layer concrete, ecological slope protection technology, applied in the fields of botanical equipment and methods, excavation, coastline protection, etc., can solve the problems of harsh ecological environment of animals and plants, poor overall appearance, unfavorable plant growth, etc. , avoid soil erosion, avoid the effect of slope protection collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

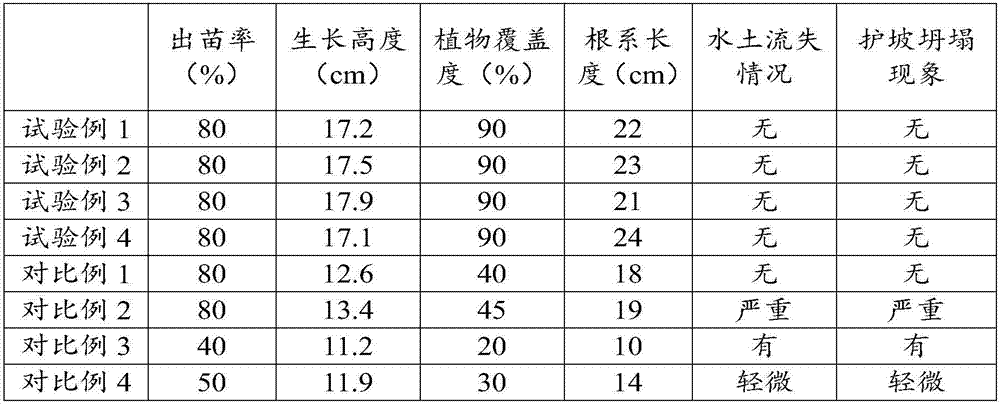

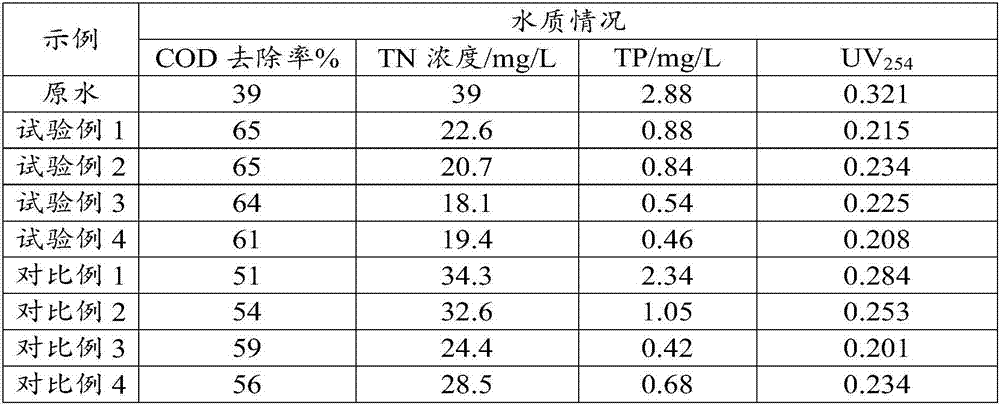

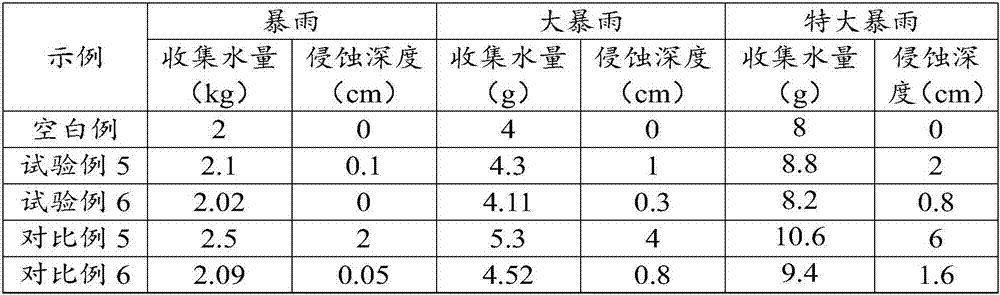

Examples

Embodiment 1

[0051] This embodiment provides a double-layer concrete ecological slope protection, which includes a first concrete layer and a second concrete layer.

[0052] Wherein, the first concrete layer is made of the first material, and the first material includes 1000 parts of the first aggregate, 150 parts of the first binder and 66 parts of the first aqueous solution. In addition, the weight ratio of the first binder to the first aqueous solution is 1:0.44. The particle diameter of the first aggregate is 20mm, and the average pore diameter is 4mm. The second concrete layer is made of the second material, and the second material includes 1000 parts of the second aggregate, 120 parts of the second adhesive material and 45 parts of the second aqueous solution. The particle diameter of the second aggregate is 5mm, and the average pore diameter is 0.001mm. That is to say, the first concrete layer is made of coarser first aggregate, while the second concrete layer is made of finer sec...

Embodiment 2

[0055] A double-layer concrete ecological slope protection provided in this embodiment includes a first concrete layer, a second concrete layer and a nutrient substrate poured into the first concrete layer.

[0056] Wherein, the first concrete layer is made of the first material, and the components of the first material include 800 parts of the first aggregate, 100 parts of the first adhesive material and 44 parts of the first aqueous solution. In addition, the weight ratio of the first binder to the first aqueous solution is 1:0.44. The particle diameter of the first aggregate is 40mm, and the average pore diameter is 6mm. The second concrete layer is made of the second material, and the components of the second material include 800 parts of the second aggregate, 100 parts of the second adhesive material and 24 parts of the second aqueous solution. The particle diameter of the second aggregate is 13 mm, and the average pore diameter is 0.01 mm. Since the first concrete laye...

Embodiment 3

[0059] A double-layer concrete ecological slope protection provided in this embodiment includes a first concrete layer, a second concrete layer, a first wire mesh layer and a second wire mesh layer.

[0060] Wherein, the first concrete layer is made of the first material, and the components of the first material include 800 parts of the first aggregate, 100 parts of the first adhesive material and 44 parts of the first aqueous solution. In addition, the weight ratio of the first binder to the first aqueous solution is 1:0.44. The particle diameter of the first aggregate is 30 mm, and the average pore diameter is 5 mm; the components of the second material include 800 parts of the second aggregate, 100 parts of the second binder and 24 parts of the second aqueous solution. The first screen layer is installed at 1 / 2 of the height of the first concrete layer. The second concrete layer is made of a second material, the particle size of the second aggregate is 8 mm, and the averag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com