Automatic cutting machine for protective film

A technology of protective film and cutting machine, which is applied in metal processing and other directions, can solve the problems of ineffective control of the cutting environment, low production efficiency, and increased production costs, so as to reduce manpower input, improve production efficiency, and maintain uniformity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

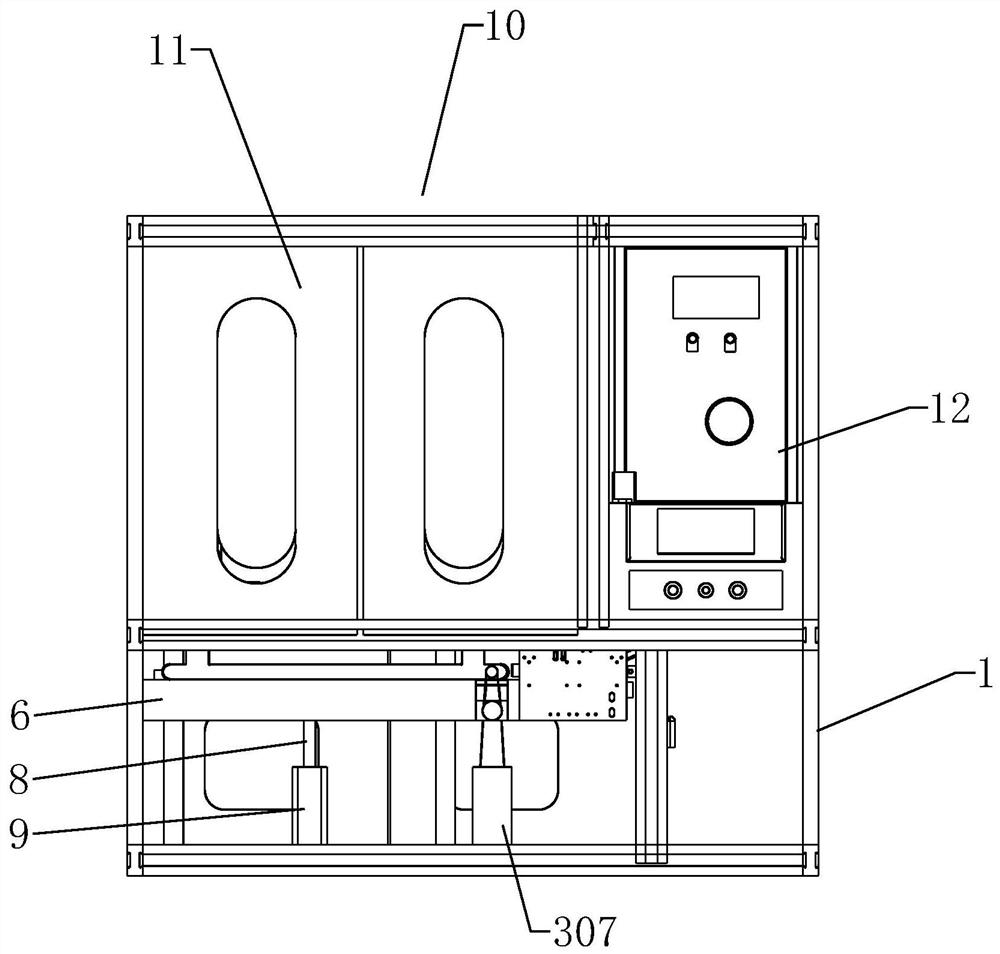

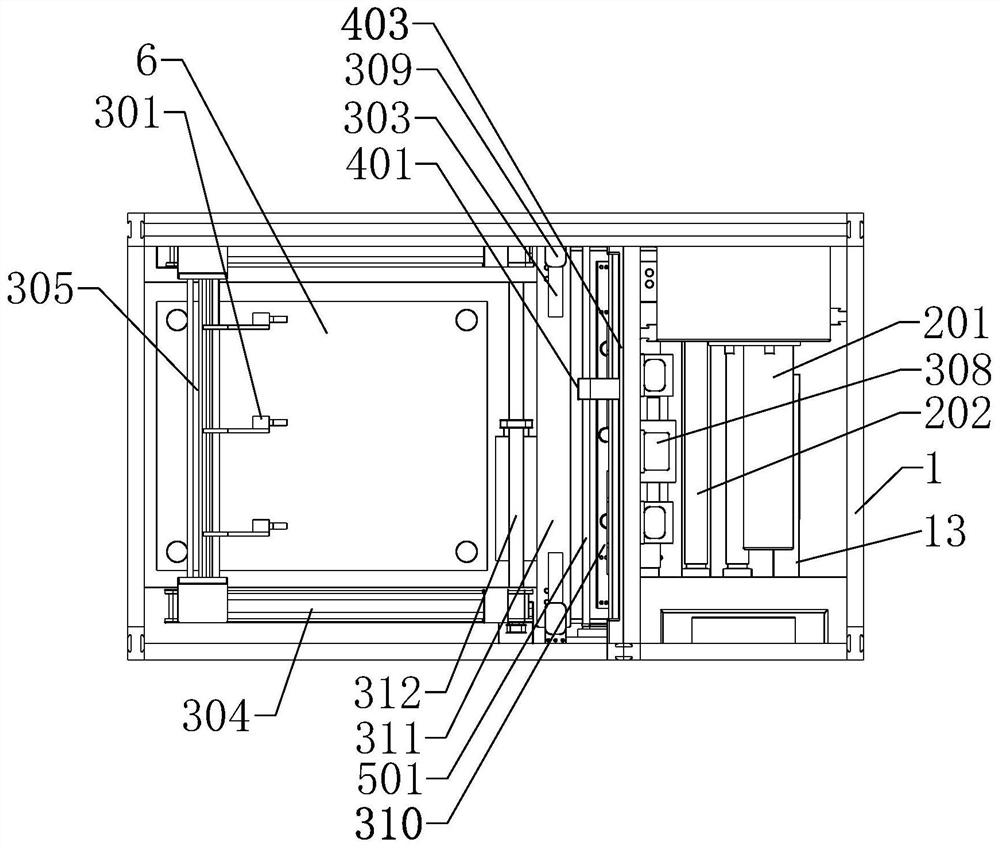

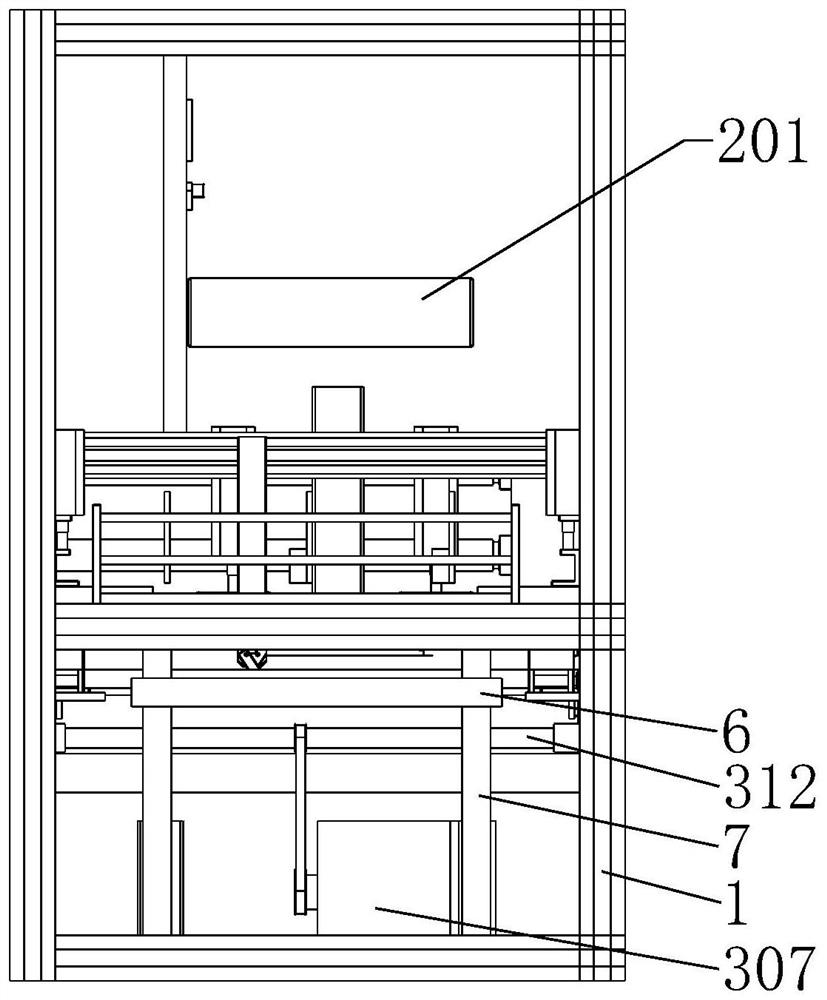

[0039] Example: Reference Figure 1-7 , an automatic protective film cutting machine, including a frame 1, and also includes a feeding mechanism, a clamping mechanism, a cutting mechanism and a bending mechanism. The feeding mechanism is used to place the protective film, the clamping mechanism is used to open and fix the rolled protective film, the cutting mechanism is used to cut the protective film, and the bending mechanism is used to bend one side of the protective film. The protective film is cut and folded after being processed by the above mechanism.

[0040] The discharge mechanism includes a discharge roller 201 and two feed rollers 202, the discharge roller 201 and the feed roller 202 are all horizontally arranged on the frame 1, and the discharge roller 201 is used to place the roll of protective film, from the roll of The protective film pulled out from the protective film stretches out between the two feed rollers 202; the discharge roller 201 and the feed rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com