High-temperature-resistant robot crawler and preparation method thereof

A robot and high-temperature-resistant technology, applied in the field of robot crawler and its preparation, can solve the problems that excellent performance cannot be maintained at high temperature, limit the scope of robot use, etc., and achieve the effect of reducing the weight of the crawler and improving the heat-resistant deformation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

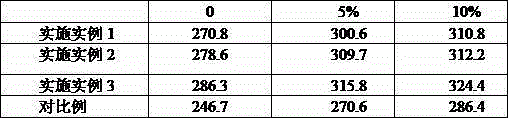

Examples

Embodiment 1

[0036] (1) Preparation of prepolymer

[0037] After drying and pulverizing 6g of methyl vinyl silicone rubber, mix it with 100g of PCL2000, add 10g of trimer isocyanurate modifier, and use a heat shearing machine at a temperature of 40-50°C at 3000-4000r / min speed heat shearing for 10-15min to form a homogeneous phase, then stir and dehydrate at 90-120°C and 0.096-0.097MPa vacuum for 2-3h, cool to about 60°C, and quickly mix with 19g of PAPI and 0.5g of triethylene glycol Mix base diamine, react for 2-3 hours under the protection of nitrogen, and obtain polyurethane prepolymer after vacuum degassing.

[0038] (2) Manufacture of heat-resistant robot crawlers

[0039] Wrap 15g of aramid fibers whose surface is activated with a silane coupling agent in the form of an endless rope and wind them on the mold, then weigh the measured prepolymer, heat it up, and vacuum defoam it for about 2 minutes. Add 5g of molybdenum disulfide treated with silane coupling agent into the prepolym...

Embodiment 2

[0041] (1) Preparation of prepolymer

[0042] After drying and pulverizing 8g of methyl vinyl silicone rubber, mix it with 100g of PCL2000, add 14g of trimer isocyanurate modifier, and use a heat shearing machine at a temperature of 40-50°C at 3000-4000r / min speed heat shearing for 10-15min to form a homogeneous phase, then stir and dehydrate at 90-120°C and 0.096-0.097MPa vacuum for 2-3h, cool to about 60°C, and quickly mix with 19g of PAPI and 0.5g of triethylene glycol Mix base diamine, react for 2-3 hours under the protection of nitrogen, and obtain polyurethane prepolymer after vacuum degassing.

[0043] (2) Manufacture of heat-resistant robot crawlers

[0044] Same as Example 1

Embodiment 3

[0046] (1) Preparation of prepolymer

[0047] After drying and pulverizing 10g of methyl vinyl silicone rubber, mix it with 100g of PCL2000, add 18g of trimer isocyanurate modifier, and use a thermal shear at 3000-4000r at a temperature of 40-50°C. / min speed heat shearing for 10-15min to form a homogeneous phase, then stir and dehydrate at 90-120°C and 0.096-0.097MPa vacuum for 2-3h, cool to about 60°C, and quickly mix with 19g of PAPI and 0.5g of triethylene glycol Mix base diamine, react for 2-3 hours under the protection of nitrogen, and obtain polyurethane prepolymer after vacuum degassing.

[0048] (2) Manufacture of heat-resistant robot crawlers

[0049] Same as Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com