A light-weight ball mill wear-resistant liner and its preparation method

A wear-resistant liner, ball mill technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of high energy consumption and heavy weight, and achieve the effect of reducing operating energy consumption, reducing weight, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

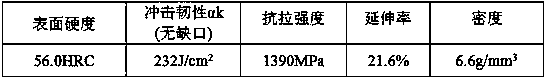

Embodiment 1

[0026] 1. The present invention provides a lightweight ball mill wear-resistant liner, which has the following chemical composition C: 1.50wt%; Si: 0.15wt%; Mn: 28.6wt%; Al10.0 wt%; S: 0.006 wt% %; P: 0.008 wt%; C+Mn: Al=2.5, the rest is Fe and unavoidable impurities.

[0027] 2. A method for preparing a lightweight ball mill wear-resistant liner, comprising the following steps: electric arc furnace smelting, LF furnace refining, VD furnace vacuum refining, die casting and heat treatment, the specific steps are:

[0028] A. Electric arc furnace smelting

[0029] According to 850kg / t 钢 The scrap steel is loaded into the ratio, and the following mass ratio high-quality scrap steel (chemical composition C 0.12wt%, Si 0.12wt%, Mn 0.35wt%, P 0.025wt%, S 0.020wt% and the rest Fe and unavoidable impurities); then 300kg / t 钢 The molten iron is loaded into the ratio, and the following mass ratio of high-quality low-sulfur molten iron (chemical composition C 4.2wt%, Si 0.40wt%, Mn 0.3...

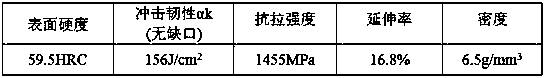

Embodiment 2

[0042] 1. The present invention provides a lightweight ball mill wear-resistant liner, which has the following chemical composition C: 1.65wt% in mass ratio; Si: 0.28wt%; Mn: 29.6wt%; Al: 11.3 wt%; S: 0.008wt% %; P: 0.012 wt%; C+Mn: Al=2.8, the rest is Fe and unavoidable impurities.

[0043] 2. A preparation method of a lightweight ball mill wear-resistant liner comprises the following steps: electric arc furnace smelting, LF furnace refining, VD furnace vacuum refining, die casting and heat treatment process composition, the specific steps are:

[0044] A. Electric arc furnace smelting

[0045] According to the scrap steel loading ratio of 850kg / t steel, add the following mass ratio high-quality scrap steel (chemical composition C 0.16wt%, Si 0.18wt%, Mn 0.42wt%, P 0.030wt%, S 0.028wt%, and the rest are Fe and unavoidable impurity); After that, the molten iron of 300kg / t steel is loaded into the proportioning ratio, and the following mass ratio of high-quality low-sulfur mol...

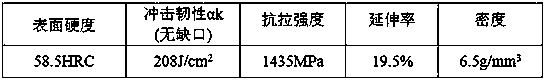

Embodiment 3

[0058] 1. The present invention provides a lightweight ball mill wear-resistant liner, which has the following chemical components in mass ratios: C: 1.80wt%; Si: 0.40wt%; Mn: 30.6wt%; Al: 12.6wt%; S: 0.010wt% %; P: 0.015 wt%; C+Mn: Al=3.0, the rest is Fe and unavoidable impurities.

[0059] 2. A preparation method for the wear-resistant liner of a lightweight ball mill according to claim 1, comprising the following steps: electric arc furnace smelting, LF furnace refining, VD furnace vacuum refining, mold casting and heat treatment, and the specific steps are:

[0060] A. Electric arc furnace smelting

[0061] According to the scrap steel loading ratio of 850kg / t steel, add the following mass ratio high-quality scrap steel (chemical composition C 0.20wt%, Si 0.25wt%, Mn 0.50wt%, P 0.035wt%, S 0.035wt%, and the rest are Fe and unavoidable impurities); after that, the molten iron of 300kg / t steel is loaded into the ratio, and the following mass ratio of high-quality low-sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com