Composite stirring wing production method

A technology of composite materials and production methods, applied in the direction of casting molding equipment, molds, cores, etc., to achieve the effect of uniform metallographic grains, stable cooling, and fine metallographic microscopic grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

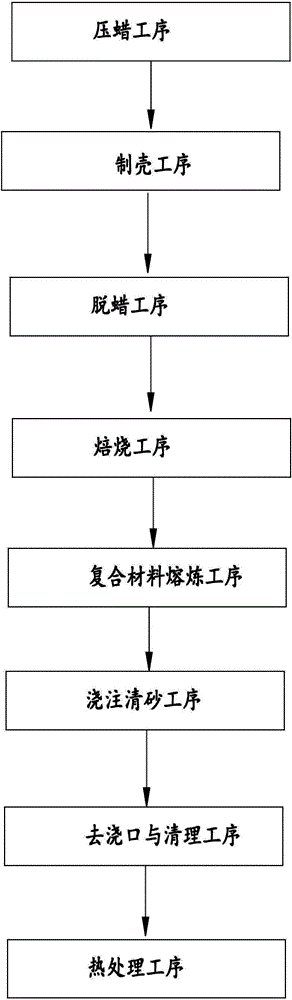

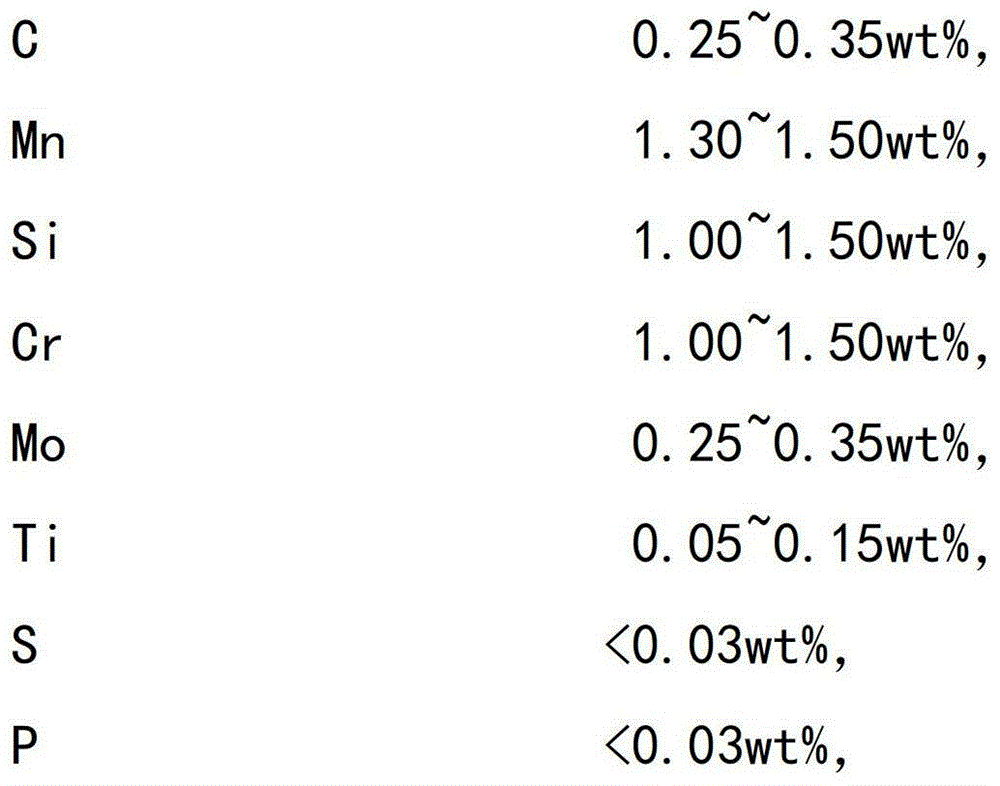

[0079] A method for producing a composite material stirring wing, comprising the following steps:

[0080] (1) Wax pressing process, using a wax pressing machine to make a wax mold, repairing the flash and burrs of the wax mold, and then assembling the wax mold to the pouring system, and welding the wax mold and the pouring system to form a wax tree;

[0081] (2) In the shell making process, the surface of the wax tree is coated with a coating with silica sol as a binder. When the coating does not flow, the upper layer of sand is sprinkled, and dried and solidified; similarly, the second layer of coating is sprinkled with the upper layer of sand; Starting from the third layer, paint with water glass as the binder, and sprinkle the upper layer of sand, and dry for 3-5 hours after each layer of paint to obtain the coated mold shell;

[0082] (3) Dewaxing process, put the coated mold shell into hot water above 95°C, and melt the wax in it to form a cavity mold shell;

[0083] (4...

Embodiment 2

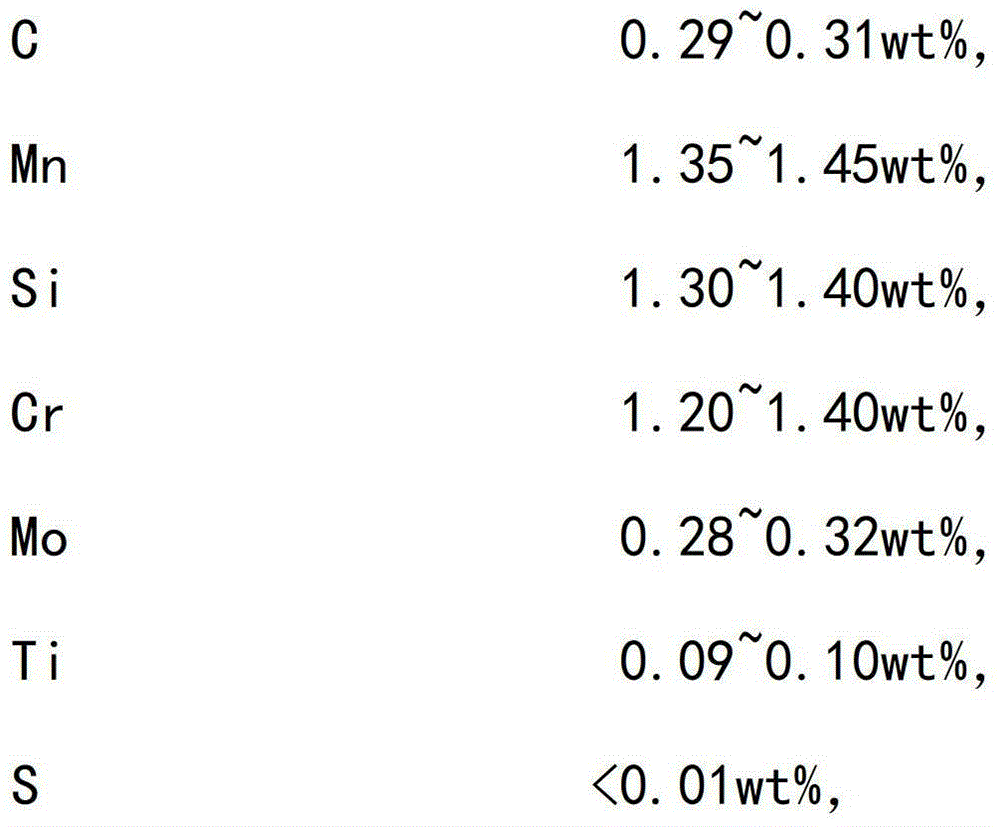

[0094] A method for producing a composite material stirring wing, comprising the following steps:

[0095] (1) In the process of wax pressing, the prepared wax paste is injected into the wax press machine, and the wax mold is prepared by using the mold; at the same time, the wax mold is prepared with the wax paste to prepare the wax mold of the pouring system. The wax mold is repaired with burrs, and then the wax mold is assembled on the pouring system, and the wax mold and the pouring system are welded to form a wax tree;

[0096] (2) In the shell making process, the surface of the wax tree is coated with a coating with silica sol as a binder. When the coating does not flow, the upper layer of sand is sprinkled, and dried and solidified; similarly, the second layer of coating is sprinkled with the upper layer of sand; From the third layer, paint with water glass as a binder, and sprinkle the upper layer of sand, and dry for 3 hours after each coat of paint to obtain a coated ...

Embodiment 3

[0109] A method for producing a composite material stirring wing, comprising the following steps:

[0110] (1) In the process of wax pressing, the prepared wax paste is injected into the wax press machine, and the wax mold is prepared by using the mold; at the same time, the wax mold is prepared with the wax paste to prepare the wax mold of the pouring system. The wax mold is repaired with burrs, and then the wax mold is assembled on the pouring system, and the wax mold and the pouring system are welded to form a wax tree;

[0111] (2) In the shell making process, the surface of the wax tree is coated with a coating with silica sol as a binder. When the coating does not flow, the upper layer of sand is sprinkled, and dried and solidified; similarly, the second layer of coating is sprinkled with the upper layer of sand; From the third layer, paint with water glass as a binder, and sprinkle the upper layer of sand, and dry for 4 hours after each layer of paint to obtain a coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com