Hollow alkali washing aluminum aqueous protective paint and preparation method and application thereof

A protective coating and alkaline cleaning technology, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of unhealthy operators, fire hazards of volatile solvents, and inability to ensure coating resistance. and other problems, to achieve the effects of safety and environmental protection in the preparation process, accelerated curing speed, and strong alkali corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

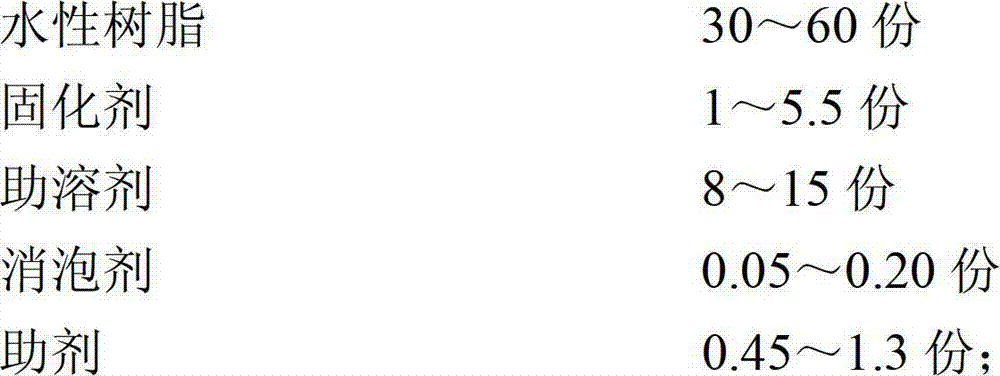

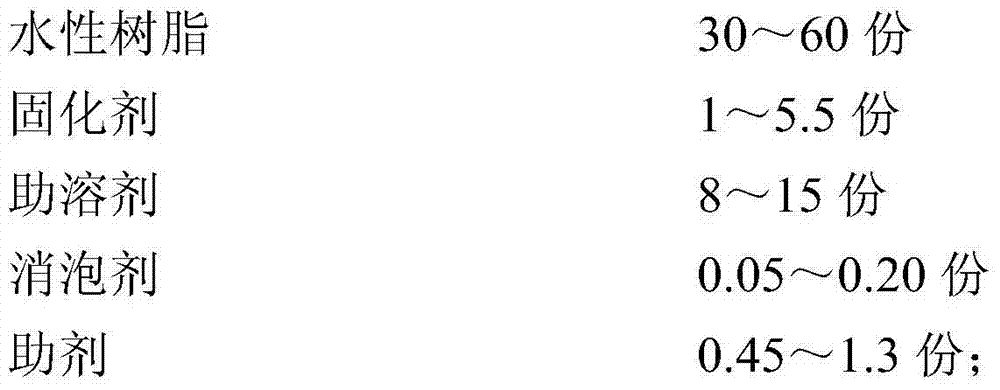

Method used

Image

Examples

Embodiment 1

[0055] (1) Mix the co-solvent (4.5kg ethanol, 2kg butanol, 1.5kg propylene glycol methyl ether) in a 200L stainless steel reaction kettle, start the disperser and adjust the dispersion speed to 500r / min to mix the components of the co-solvent evenly, and then Put in 0.15kg leveling agent silok-8000 (Silok Chemical Co., Ltd., polyether modified polyorganosiloxane, which belongs to silicone modified polyether leveling agent), 0.5kg water-based cobalt metal drier (Shanghai Ou Anji Trading Company) was dispersed and dissolved in the reactor, then 60.3kg of deionized water was added, stirred for 10 minutes, and then dispersed into a uniform liquid phase to obtain a mixed solution.

[0056] Increase the dispersion speed to 800r / min, add 1kg of water-dispersible amino curing agent cymel-303 (American Cytec, full methyl etherified amino curing agent, belongs to amino resin, effective part 98%) into the reaction kettle, stir to dissolve, and get Dispersion system 1.

[0057] (2) Put 3...

Embodiment 2

[0061] (1) In a 200L stainless steel reaction kettle, mix the cosolvents (5.5kg ethanol, 3kg isopropanol, 3.5kg propylene glycol methyl ether) evenly, start the disperser at 200r / min to disperse, and put in 0.2kg leveling agent BYK333 (German BYK chemical, silicone modified polyether leveling agent), 0.2kg non-ionic high-efficiency leveling agent Dynol 607 (American gas chemical, non-ionic surfactant), 200r / min stirring for 10min to dissolve, then add 22kg deionized water and dispersed into a homogeneous liquid phase to obtain a mixed solution.

[0062] Increase the dispersion speed to 800r / min, add 5.5kg of blocked water-based isocyanate curing agent BayerBayhydrol BL 5140 (Bayer Chemical, polyisocyanate curing agent, 40%) into the reaction kettle, stir and dissolve for 20 minutes to obtain dispersion system 1.

[0063] (2) Select solid acrylic resin SR625 (DIRANSA Argentina Dilansa Chemical) and water-based aliphatic anionic polyurethane dispersion UH 2606 (Bayer Chemical,...

Embodiment 3

[0068] (1) In a 200L stainless steel reaction kettle, mix the co-solvents (5kg ethanol, 3kg butanol, 3kg propylene glycol methyl ether, 4kg ethylene glycol butyl ether) evenly, start the disperser at 500r / min to disperse at a medium speed, and put in 0.5 kg BYK-361N (German BYK chemical, acrylic leveling agent) and 0.1kg fluorocarbon surfactant FS-610 (DuPont, organic fluorocarbon leveling agent) were stirred and dissolved to obtain a mixed solution.

[0069] Then add 4kg of butylated melamine resin CYMEL 688 (Cytec, butylated melamine resin, amino resin curing agent, 70%) and 0.5kg of dodecylbenzenesulfonic acid to the reaction kettle, fully stir and dissolve into a uniform liquid phase, continue to add 46.2kg of deionized water, and disperse for 20 minutes to obtain a uniform dispersion system 1.

[0070](2) Add 33.6kg of water-based self-drying acrylic modified epoxy ester resin HD-EA605 (Beijing Jinhuili Applied Chemical Industry, 75% solid content, which belongs to modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com