Subcontracting device in film packaging machine

A film packaging and frame technology, applied in packaging, packaging bottles, packaging paper, etc., can solve the problems of high cost, slow speed, no more than 12 packs/minute at the fastest, inconvenient adjustment, etc., to achieve convenient and fast adjustment, distribution Package speed, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

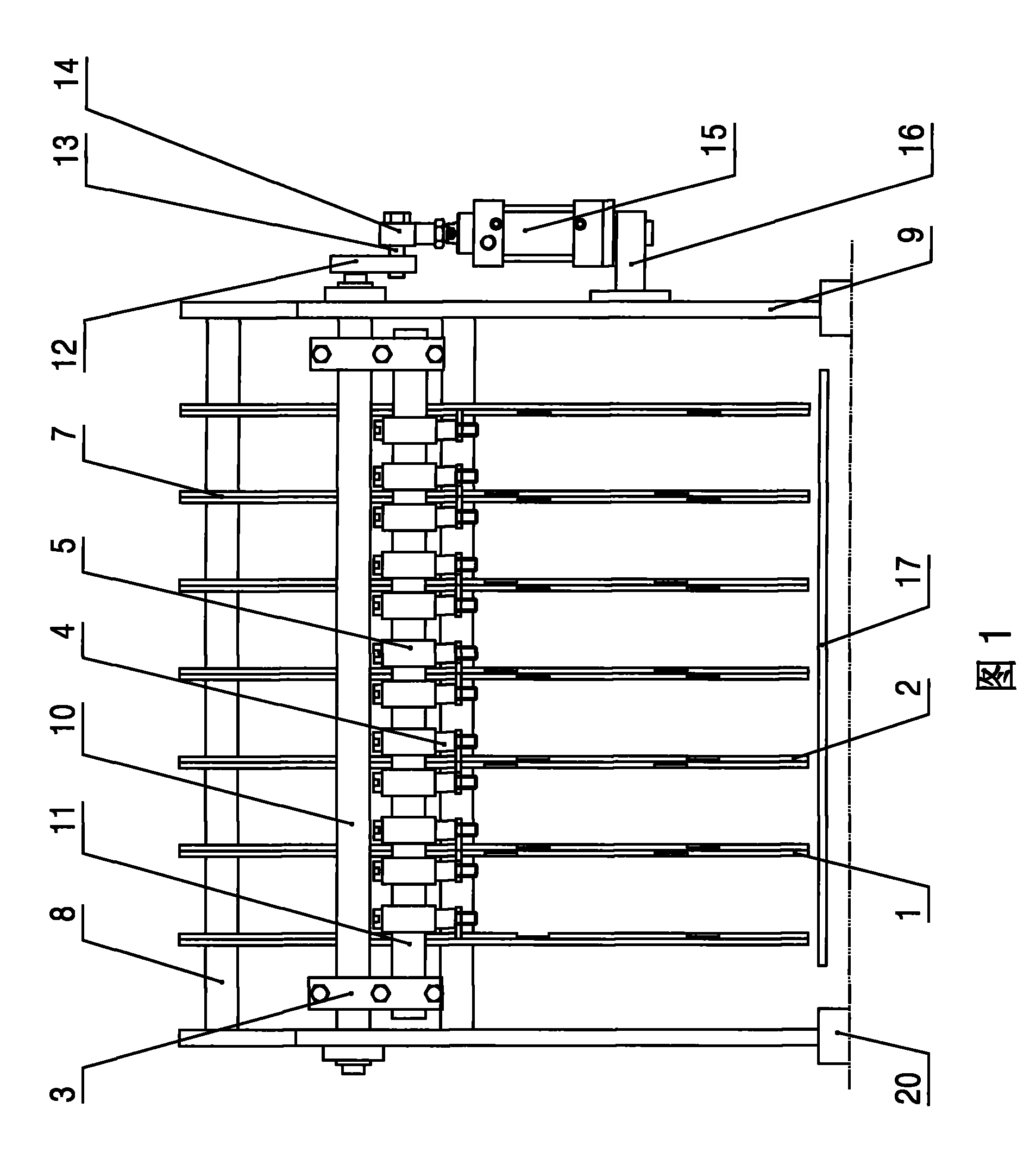

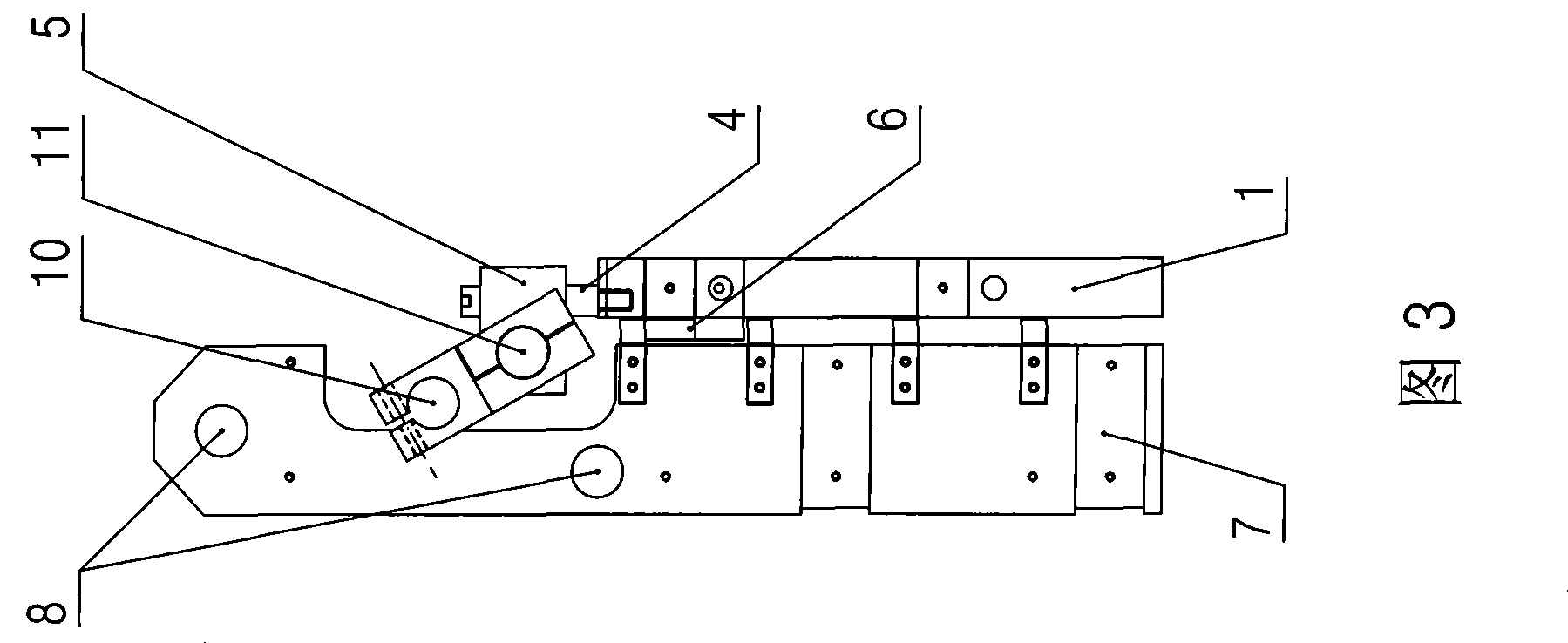

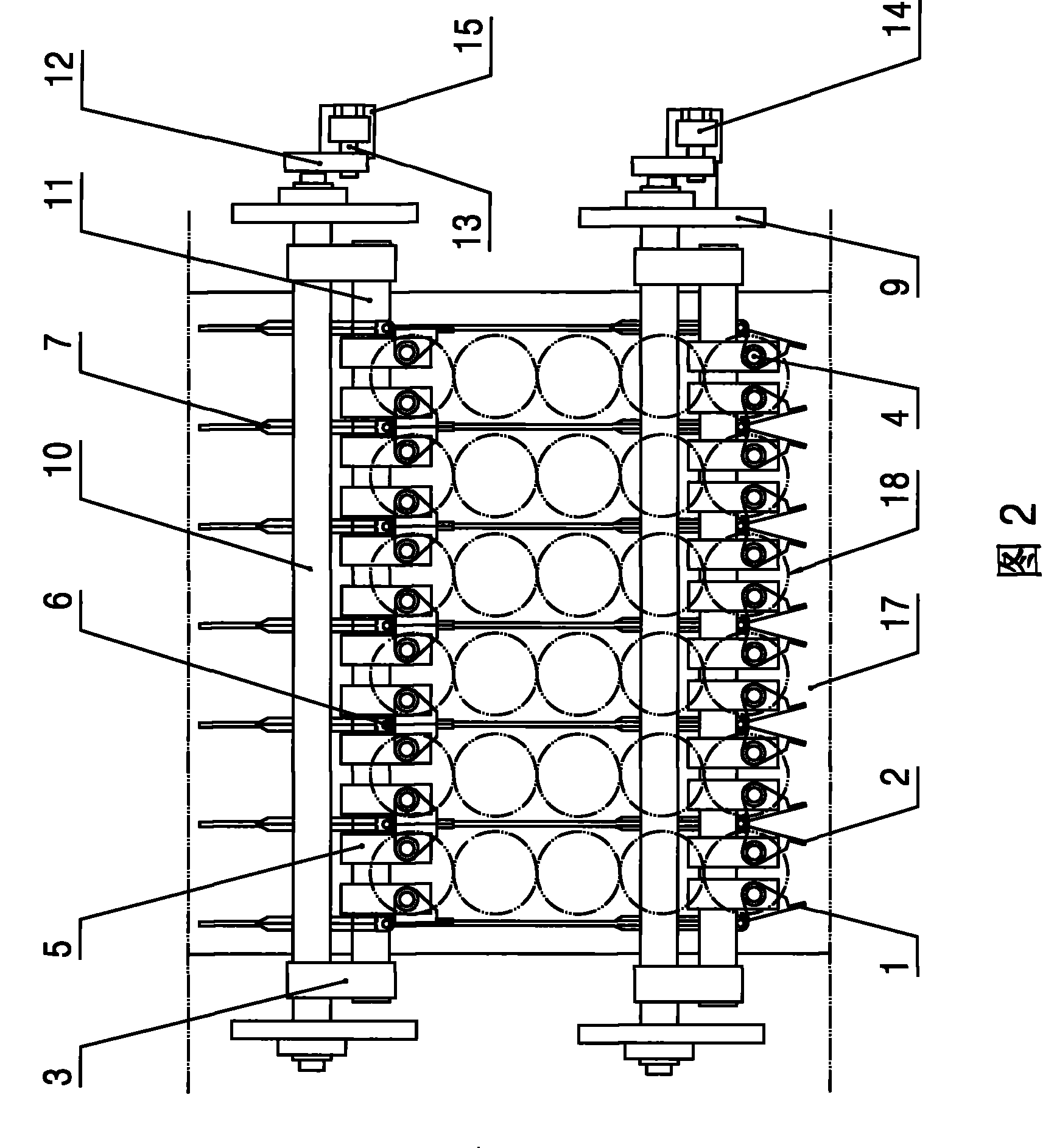

[0014] As shown in Figure 1, the subpackaging device in the film packaging machine according to the present invention includes: a frame 20 and two sets of gate opening and closing mechanisms with the same structure across the frame 20 and two sets of gate opening and closing mechanisms located in the two sets of gate openings. There are six full-arranged passages between the combined mechanisms. The specific structure of these six entire-arranged passages includes: a pair of side plates 9 arranged on both sides of the frame, and a pair of crossbeams 8 are arranged between the pair of side plates 9—see figure 2 and Figure 3, the pair of crossbeams 8 are provided with seven partitions 7 parallel to each other along their axial direction, and a whole row of passages is formed between two partitions 7; the gate opening and closing mechanism, its sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com