Production line for straw weaving

A production line and straw technology, applied in mechanical equipment, sugarcane machining, etc., can solve problems such as dependence on labor, low weaving efficiency, and poor quality of straw mats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] In order for those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

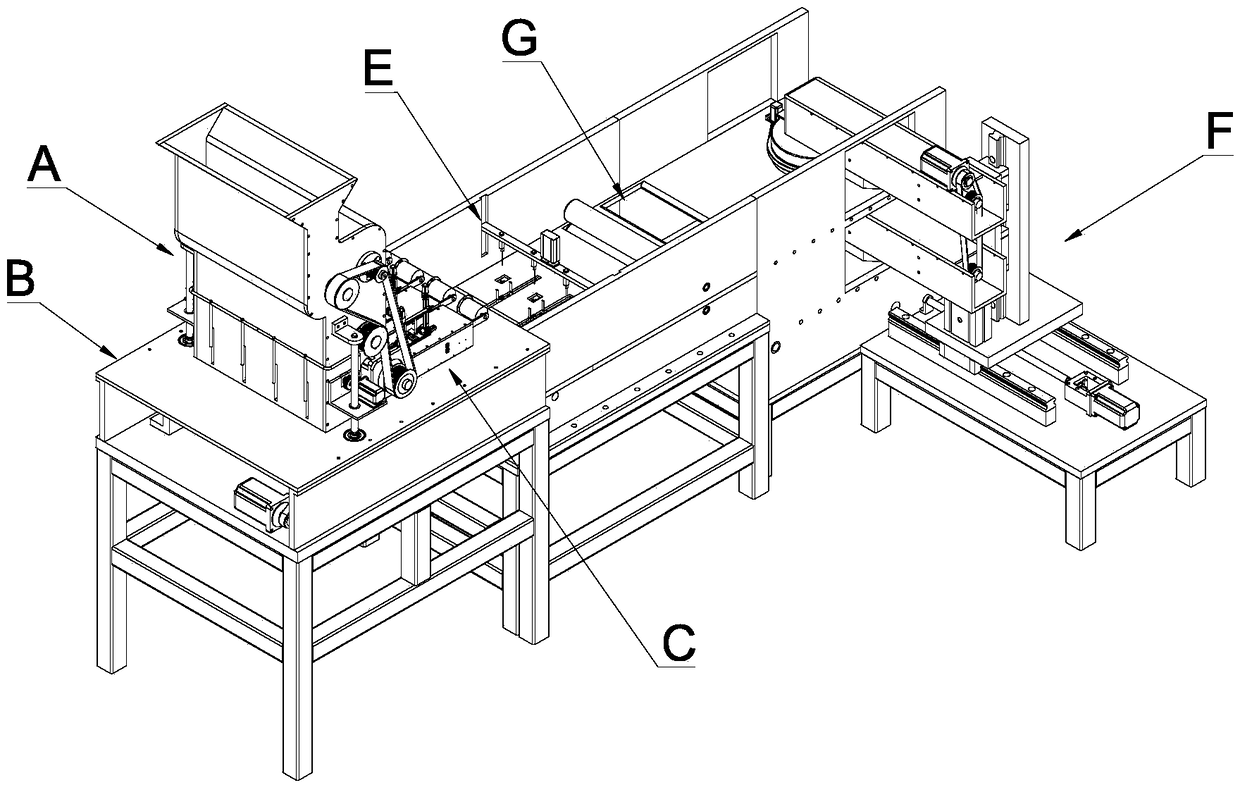

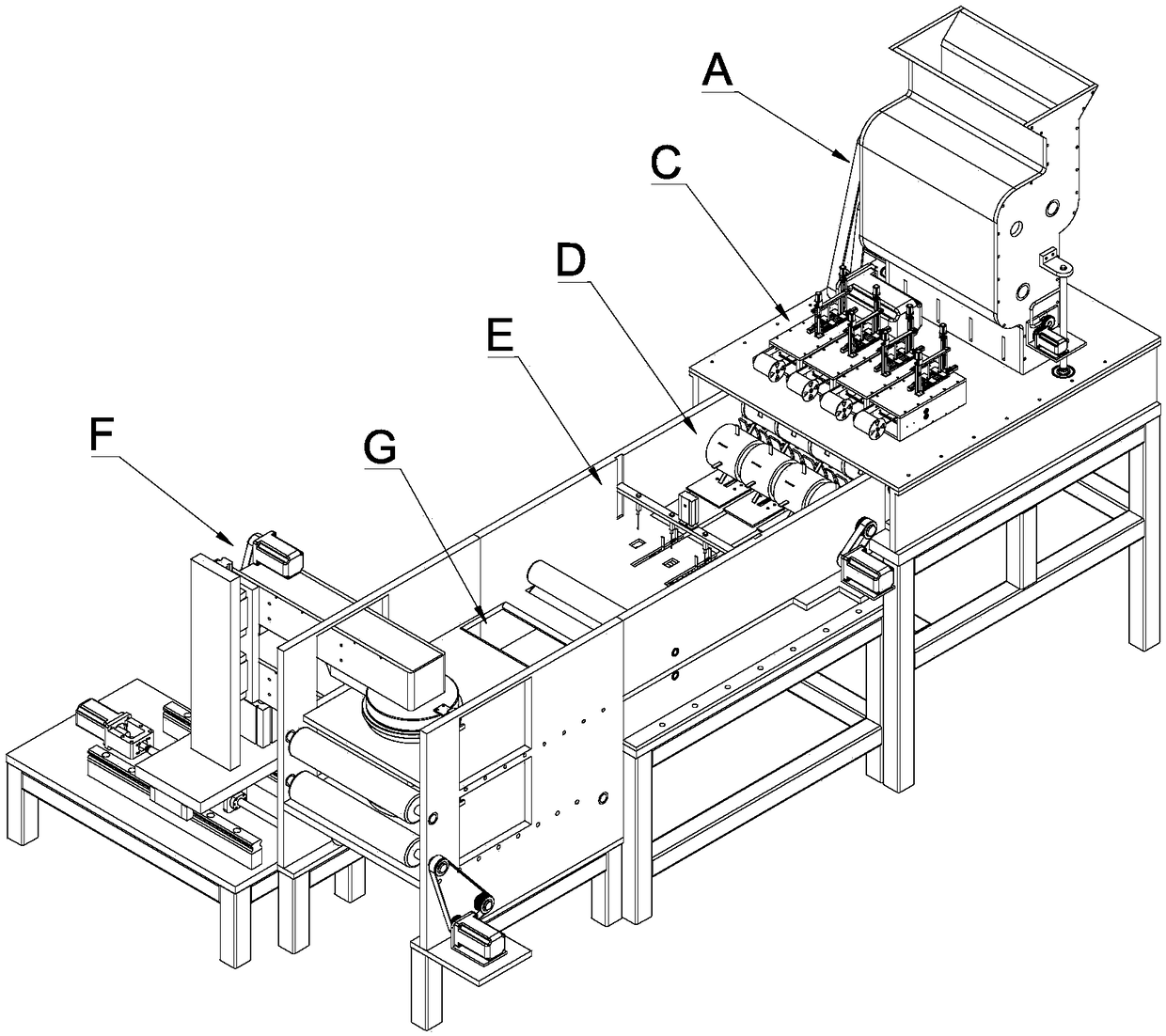

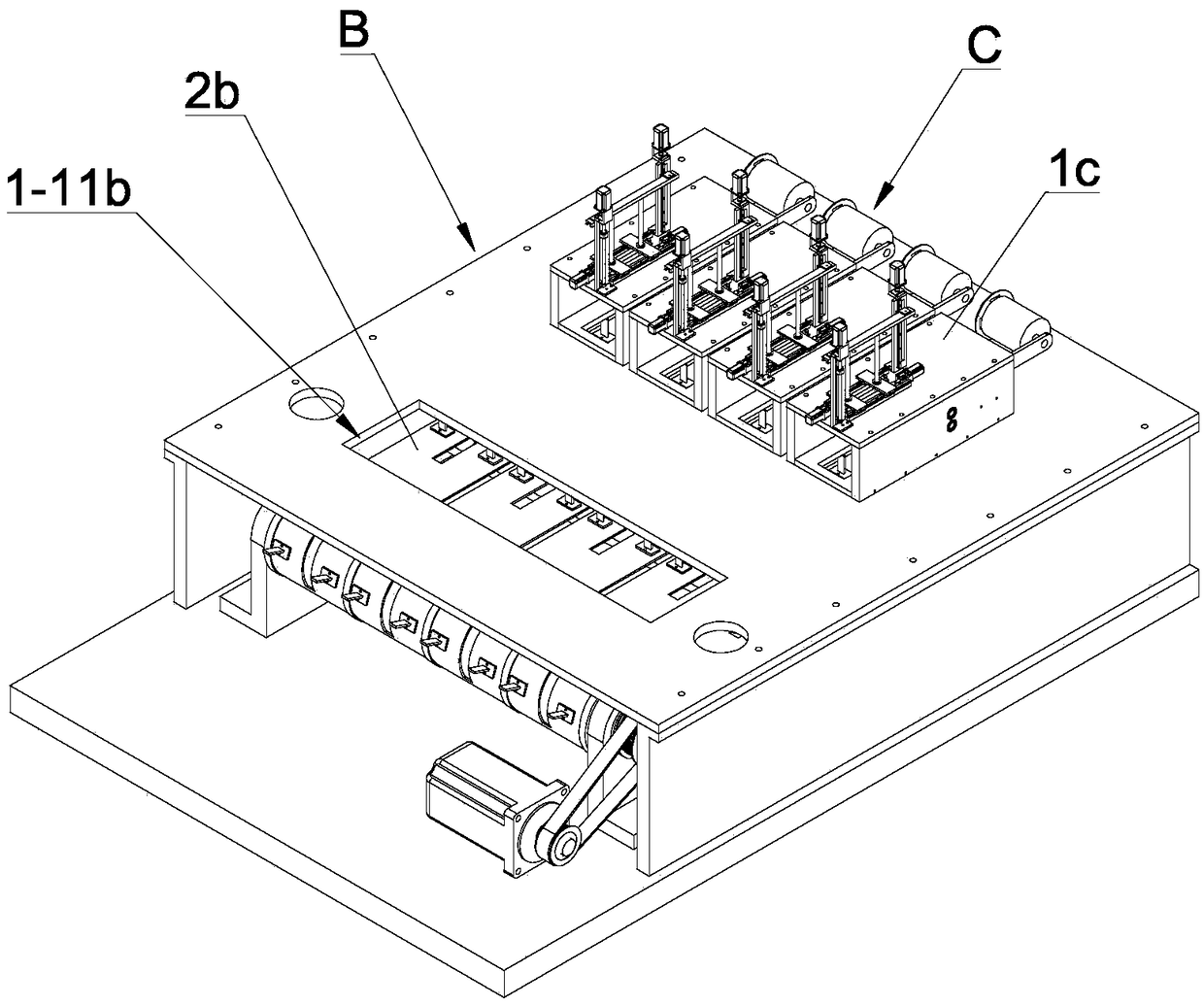

[0094] see Figure 1-5 , the straw weaving production line in this embodiment includes a feeding module A, a conveying module B for forwarding the straw in the feeding module A, a bundling module C for bundling quantitatively separated straws, A shaping module D for shaping the bundled straw bundles, a weaving module E for weaving the shaped straw bundles, and a receiving module F for collecting the woven straw mats.

[0095] see Figure 6-12 , the feeding module A includes a hopper 1a for loading straw and a breaking mechanism for breaking up the straw; wherein, the inner cavity of the hopper 1a is a three-stage structure, and the upper section is the feeding section 1- 1a, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com