Silver nanowire-polyperfluorinated ethylene propylene super-hydrophobic porous membrane and preparation method

A polyperfluoroethylene propylene and silver nanowire technology is applied in the field of composite materials, which can solve the problems of difficult control or adjustment of membrane pore structure, poor antibacterial performance of superhydrophobic porous membrane, and lack of antibacterial function of membrane material, and achieves good superhydrophobicity. Hydrophobic properties, dynamic control or adjustment of membrane pore structure, super-hydrophobicity and strong self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

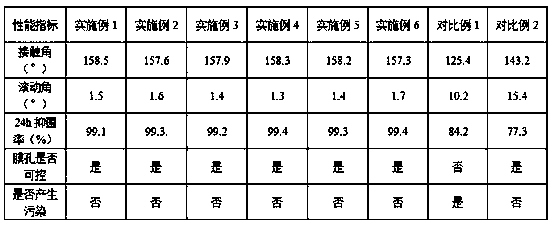

Examples

Embodiment 1

[0033] (1) Add polystyrene to a mixed solvent of dichloromethane and chloroform, add acetone, stir to completely dissolve polystyrene to obtain a casting solution, then cast the casting solution on the surface of the substrate, and immediately use the The water-saturated high-humidity air passes through the surface of the casting liquid, and the honeycomb polystyrene porous membrane is prepared through the formation of water drop templates and the volatilization of solvent and water; the relative humidity of the high-humidity air is 94%, and the flow line speed is 16L / min; In the casting solution, 17 parts by weight of polystyrene, 34 parts by weight of dichloromethane, 42 parts by weight of chloroform, and 7 parts by weight of acetone;

[0034] (2) Mix liquid tetrafluoroethylene, liquid hexafluoroethylene, organic peroxide initiator, and molecular weight regulator evenly, and defoam to obtain a reaction liquid, and then cast it on the polystyrene porous membrane prepared in s...

Embodiment 2

[0038] (1) Add polystyrene to a mixed solvent of dichloromethane and chloroform, add acetone, stir to completely dissolve polystyrene to obtain a casting solution, then cast the casting solution on the surface of the substrate, and immediately use the The water-saturated high-humidity air passes through the surface of the casting liquid, and the honeycomb polystyrene porous membrane is prepared through the formation of water drop templates and the volatilization of solvent and water; the relative humidity of the high-humidity air is 92%, and the flow line speed is 12L / min; In the casting solution, 16 parts by weight of polystyrene, 32 parts by weight of methylene chloride, 47 parts by weight of chloroform, and 5 parts by weight of acetone;

[0039] (2) Mix liquid tetrafluoroethylene, liquid hexafluoroethylene, organic peroxide initiator, and molecular weight regulator evenly, and defoam to obtain a reaction liquid, and then cast it on the polystyrene porous membrane prepared i...

Embodiment 3

[0043] (1) Add polystyrene to a mixed solvent of dichloromethane and chloroform, add acetone, stir to completely dissolve polystyrene to obtain a casting solution, then cast the casting solution on the surface of the substrate, and immediately use the The water-saturated high-humidity air passes through the surface of the casting liquid, and the honeycomb polystyrene porous membrane is prepared through the formation of water drop templates and the volatilization of solvent and water; the relative humidity of the high-humidity air is 98%, and the flow line speed is 18L / min; In the casting solution, 19 parts by weight of polystyrene, 37 parts by weight of dichloromethane, 37 parts by weight of chloroform, and 7 parts by weight of acetone;

[0044] (2) Mix liquid tetrafluoroethylene, liquid hexafluoroethylene, organic peroxide initiator, and molecular weight regulator evenly, and defoam to obtain a reaction liquid, and then cast it on the polystyrene porous membrane prepared in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com