Potassium perchlorate production technology with zero wastewater discharge and products thereof

A technology for potassium perchlorate and waste water discharge, applied in perchloric acid, perchlorate, electrolysis process and other directions, can solve the problems of high impurity content of sodium chloride, no economic value, high energy consumption, and achieve high product cost performance, avoid Anode damage, the effect of solving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

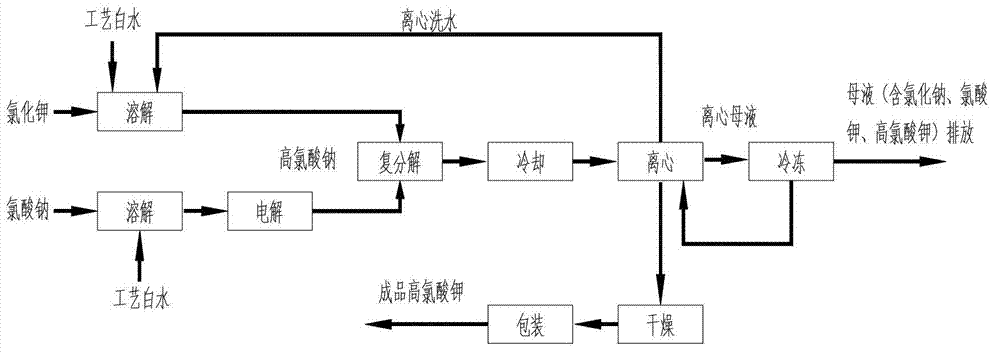

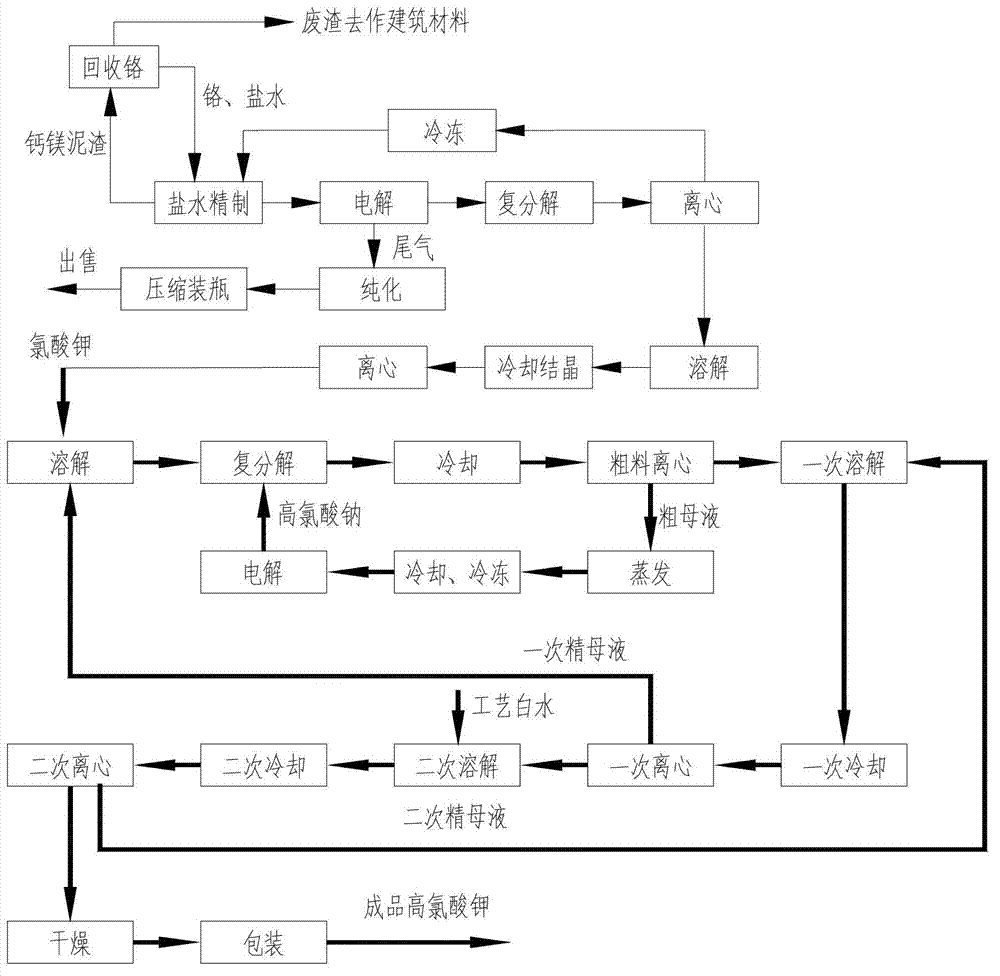

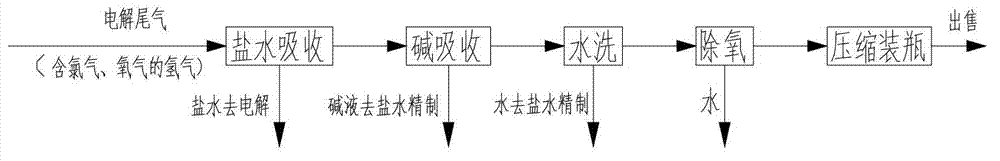

[0025] Attached below Figures 2 to 4 Preferred embodiment of the present invention is described further, the step of electrolytic metathesis process is:

[0026] ① first electrolyze sodium chlorate into sodium perchlorate;

[0027] 2. potassium chlorate is used as the metathesis raw material, and sodium perchlorate is carried out metathesis reaction generates potassium perchlorate coarse material;

[0028] ③ The potassium perchlorate crude material is purified by recrystallization to obtain the product; the metathesis mother liquor sodium chlorate is electrolyzed and recycled.

[0029] Potassium chlorate is used instead of potassium chloride as the raw material for metathesis, and the mother liquor after metathesis extracting potassium perchlorate is sodium chlorate, which can be returned to the perchlorate electrolytic cell for electrolysis.

[0030] The traditional process of producing potassium perchlorate by metathesis of potassium chloride is because the by-product sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com