Comprehensive utilization method of heat energy in potassium perchlorate production process

A technology of potassium perchlorate and production process, which is applied in the direction of perchloric acid, perchlorate, electrolysis process, etc., to achieve the effect of abundant power resources, large floor area and cheap electricity price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

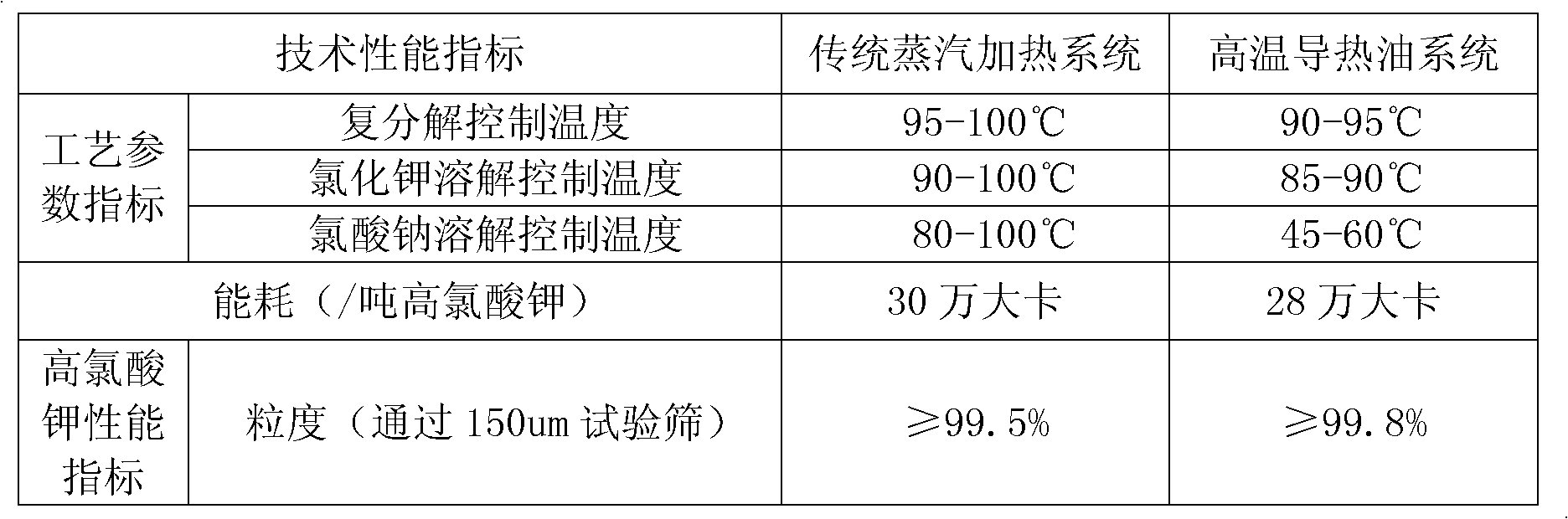

[0040] Embodiment 1 adopts the heat-giving method of the present invention to produce potassium perchlorate

[0041] Heat transfer oil medium conveying material: 304 stainless steel with a thickness of 6 mm is selected as the heat transfer oil conveying material.

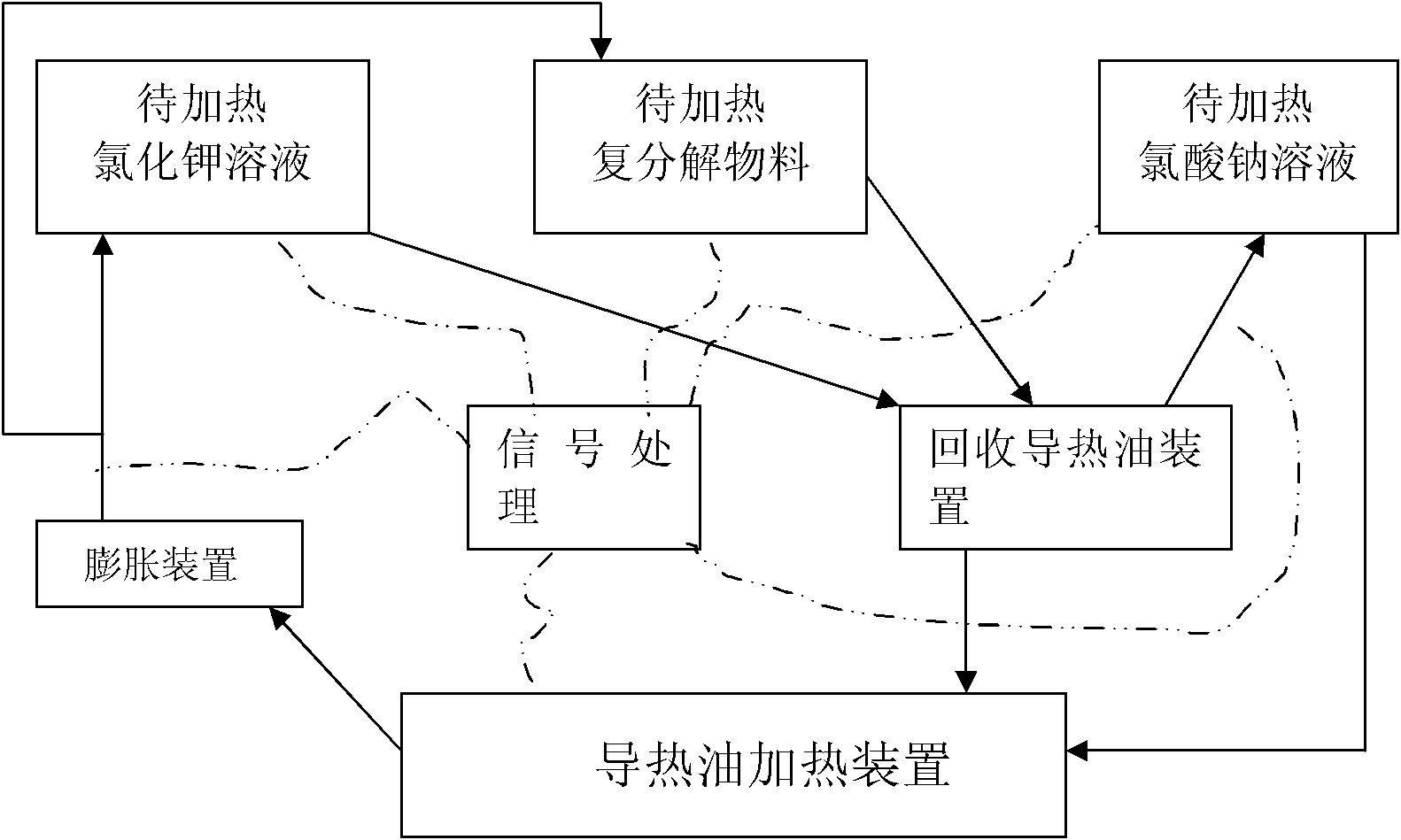

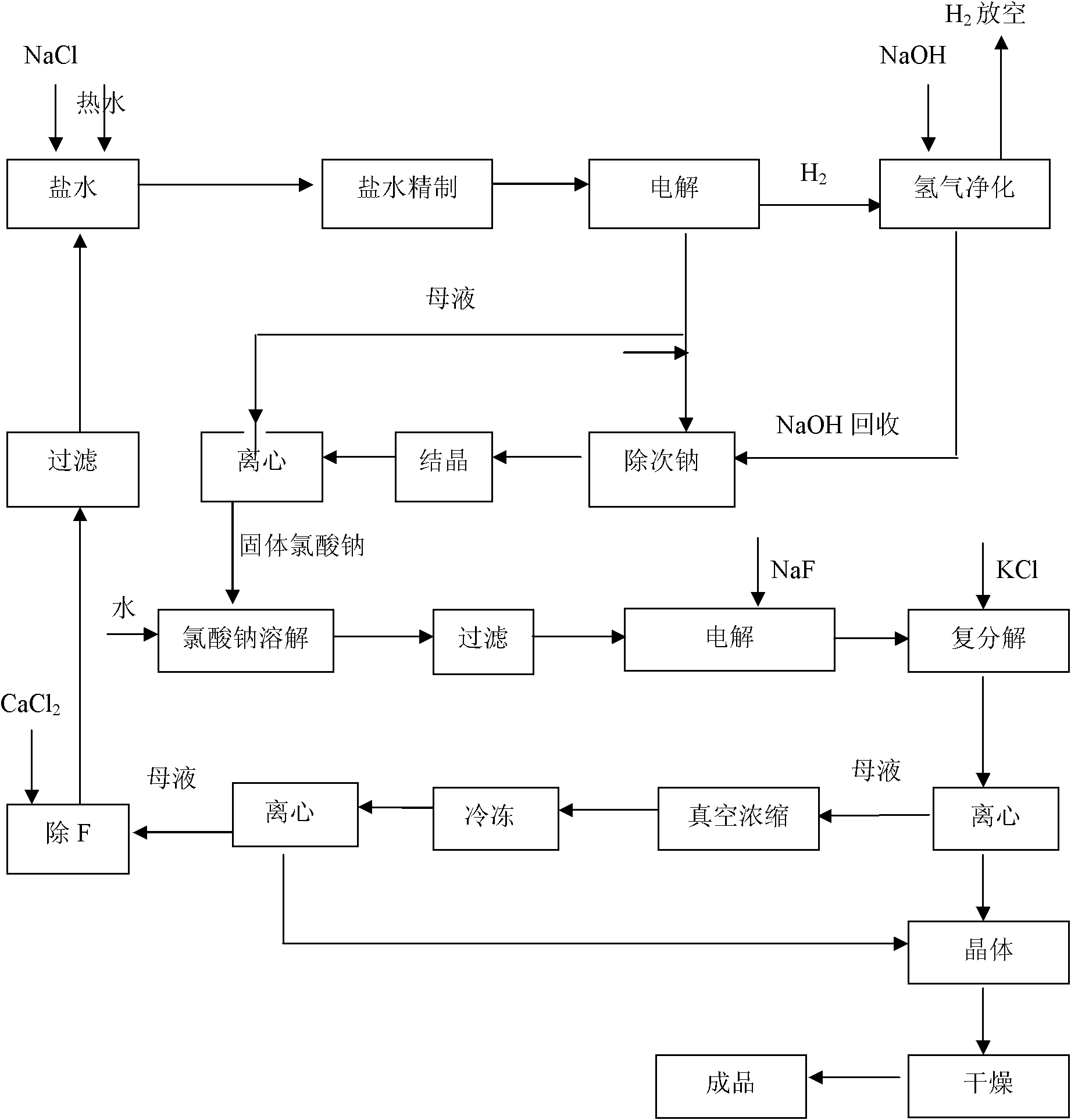

[0042] Potassium perchlorate production process roadmap is as follows figure 2 shown. Flow chart of heat transfer oil see figure 1 .

[0043] The heat-conducting oil is heated to 150°C from the heat-conducting oil heating device and then sent to the expansion device. The heat-conducting oil after heat exchange in the expansion device is sent to the potassium chloride solution to be heated or the metathesis material to be heated (a mixture of potassium chloride and sodium perchlorate) After heat transfer, the heat transfer oil returns to the heat transfer oil recovery device (temperature is about 100°C), and is sent to the heat transfer oil heating device for heating. After the heat transfer oil is heated to 150°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com