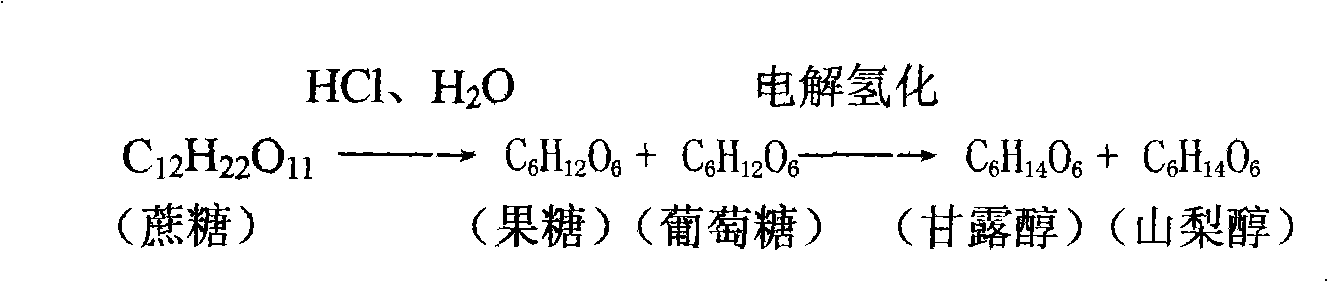

Method for preparing hexahydric alcohol by saccharose electrolytic reduction

A technology of hexahydric alcohol and sucrose, which is applied in the field of producing hexahydric alcohol, can solve the problems of high product impurities, high raw material consumption, and difficult separation, and achieve the effect of abundant power resources, good product quality, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Weigh 2000g of edible sucrose into a three-neck flask, add 2000ml of distilled water, add an appropriate amount of dilute hydrochloric acid, heat and stir in a water bath, keep the temperature at 80°C for 3 hours, naturally cool to 50-60°C, adjust the pH to neutral with NaOH, and add a small amount of activated carbon to the solution After decolorization, 3956.4 g of mother liquor was obtained after filtration, and the hydrolysis conversion rate of sucrose was analyzed to be 98.2%, and it was cooled for later use.

example 2

[0020] Take by weighing example 1 gained sucrose hydrolyzate 684.6g (equivalent to 1mol sucrose), add 400g Raney's nickel catalyst, be made into total volume and be 1000ml solution as electrolysis catholyte, the sulfuric acid solution that is 1ml / L is the electrolysis anode with 800ml concentration in addition Liquid and electrolyte are pumped into the anode chamber and cathode chamber of the electrolytic cell respectively. The anode of the electrolytic cell is made of lead and the cathode is made of stainless steel. The electrolysis conditions are: current density 3.2A / dm 2 , the electrolysis power is 140Ah, the electrolysis temperature is 35-40°C, the reaction process uses dilute NaOH solution to control the pH of the catholyte at 8-9; the hydrogenation conversion rate is 98.5% after the reaction is completed, and the catalyst is left for the next experiment for recycling.

example 3

[0022] Take by weighing example 1 gained sucrose hydrolyzate 684.6g (equivalent to 1mol sucrose), add 400g Raney's nickel catalyst, be made into total volume and be 1000ml solution as electrolysis catholyte, the sulfuric acid solution that is 1ml / L is the electrolysis anode with 800ml concentration in addition Liquid and electrolyte are pumped into the anode chamber and cathode chamber of the electrolytic cell respectively, and the anode of the electrolytic cell is made of PbO 2 / Ti, the cathode is made of stainless steel, the electrolysis conditions are: current density 3.2A / dm 2 , the electrolysis power is 140Ah, the electrolysis temperature is 45-50°C, the pH of the catholyte is controlled at 8-9 with dilute NaOH solution during the reaction; the hydrogenation conversion rate is 98.1% after the reaction is completed, and the catalyst is left for the next experiment for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com