Multi-layer turning wheel structure of water turbine

A technology of water turbines and runners, applied in hydropower, mechanical equipment, machines/engines, etc., can solve the problems of difficult manufacturing and transportation, large size of key parts, and high construction costs, so as to reduce the difficulty of manufacturing and transportation and improve the cost of benefits Ratio, the effect of increasing unit capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

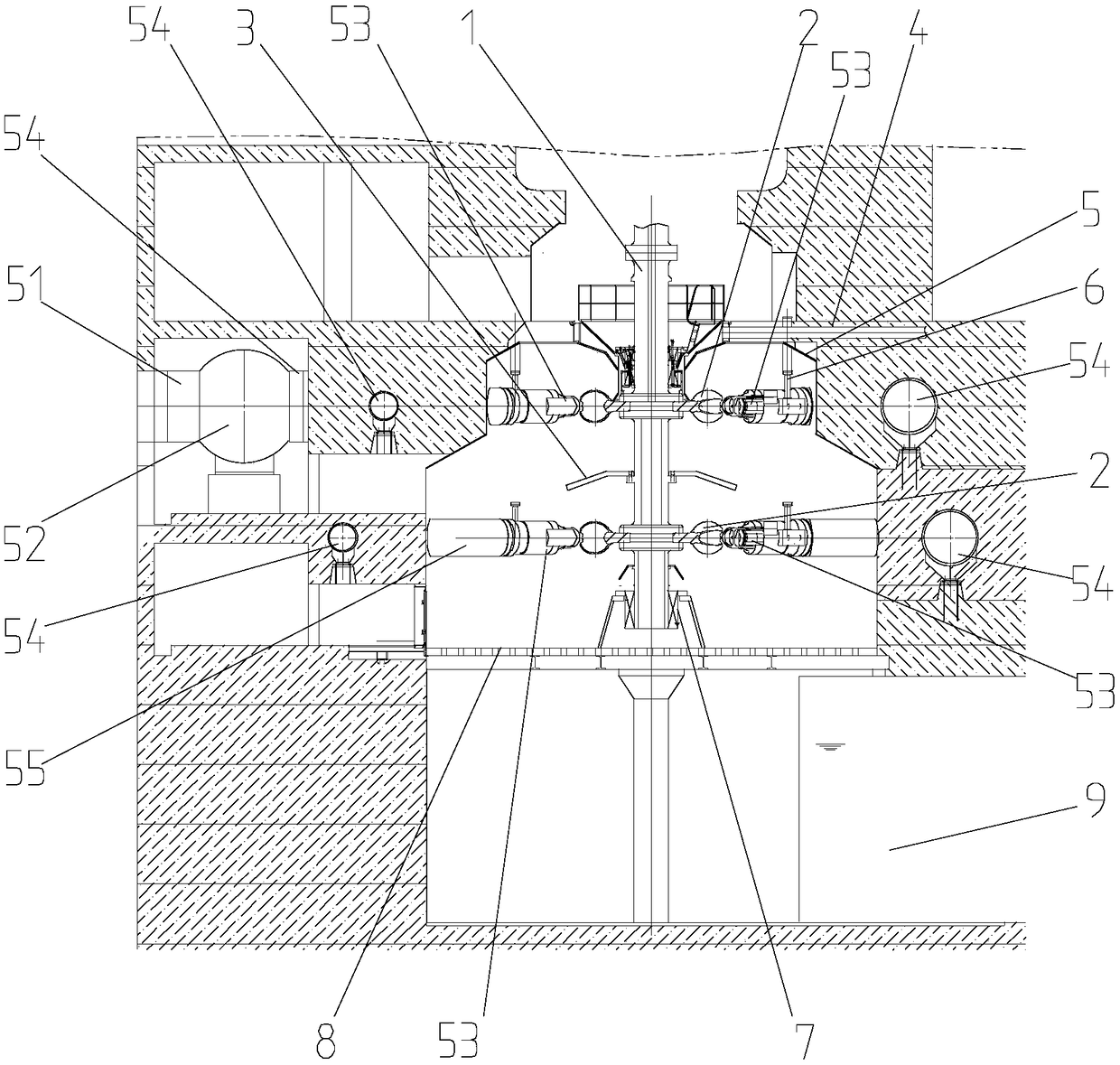

[0021] Such as figure 1 The shown embodiment 1 is a multi-layer runner structure of a water turbine. The multi-layer runner structure of the water turbine in this example is provided with a vertical main shaft 1, the generator is connected above the main shaft, and the lower end is installed in the shaft seat fixed on the maintenance platform. Two upper and lower runners 2 are installed on the main shaft. Two water inlet pipes 51 are arranged up and down to supply water to the two runners respectively.

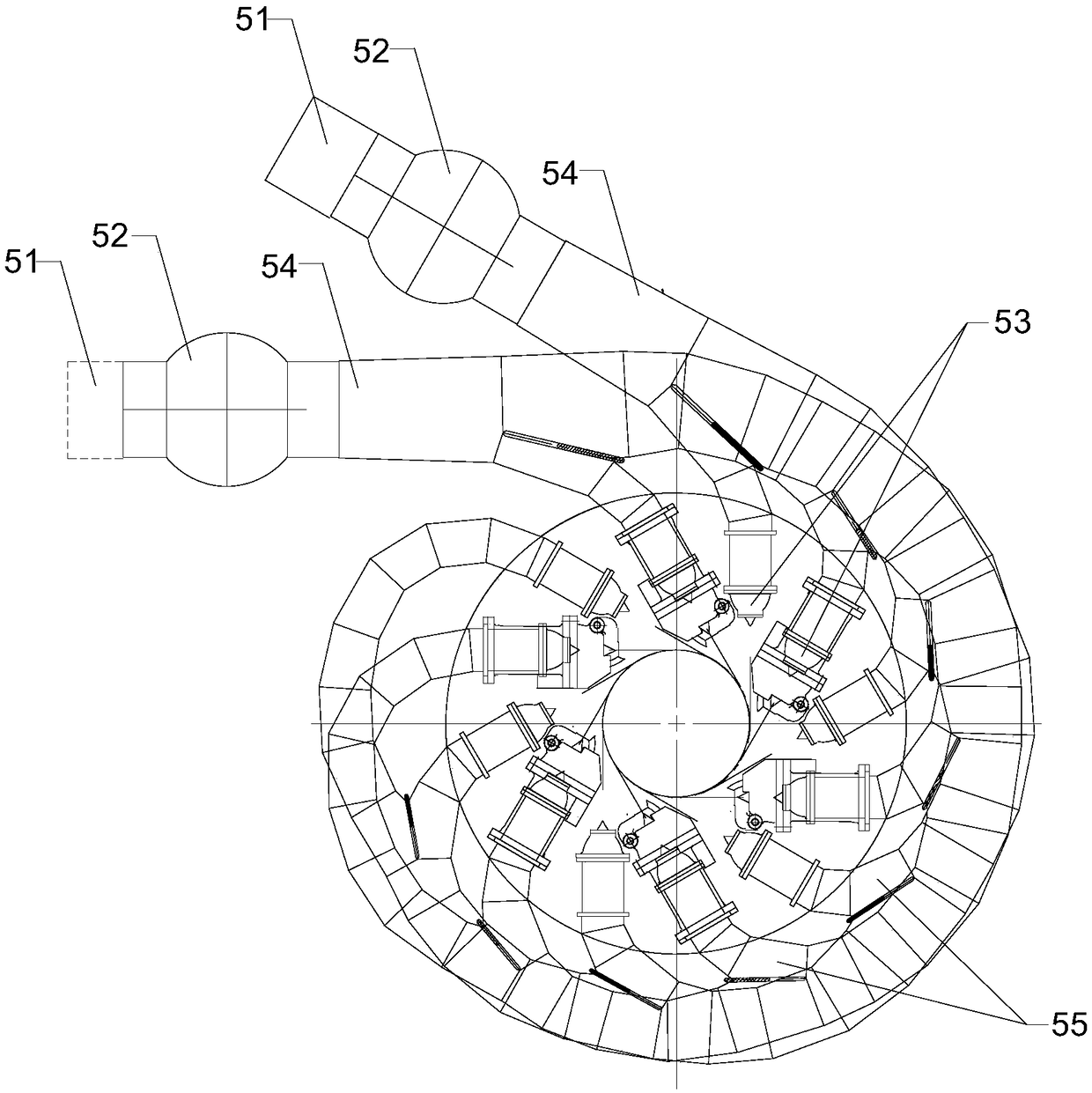

[0022] Such as image 3 , Figure 4 As shown, the upstream open end of the water inlet pipe can be independently connected to the water body of the dam, or connected to the water body of the dam after being merged upstream, a ball valve 52 is installed at the downstream end, and a water distribution pipe 54 is provided at the downstream end of the ball valve, which can independently control each Opening and closing of water distribution pipes. The height of each water dist...

Embodiment 2

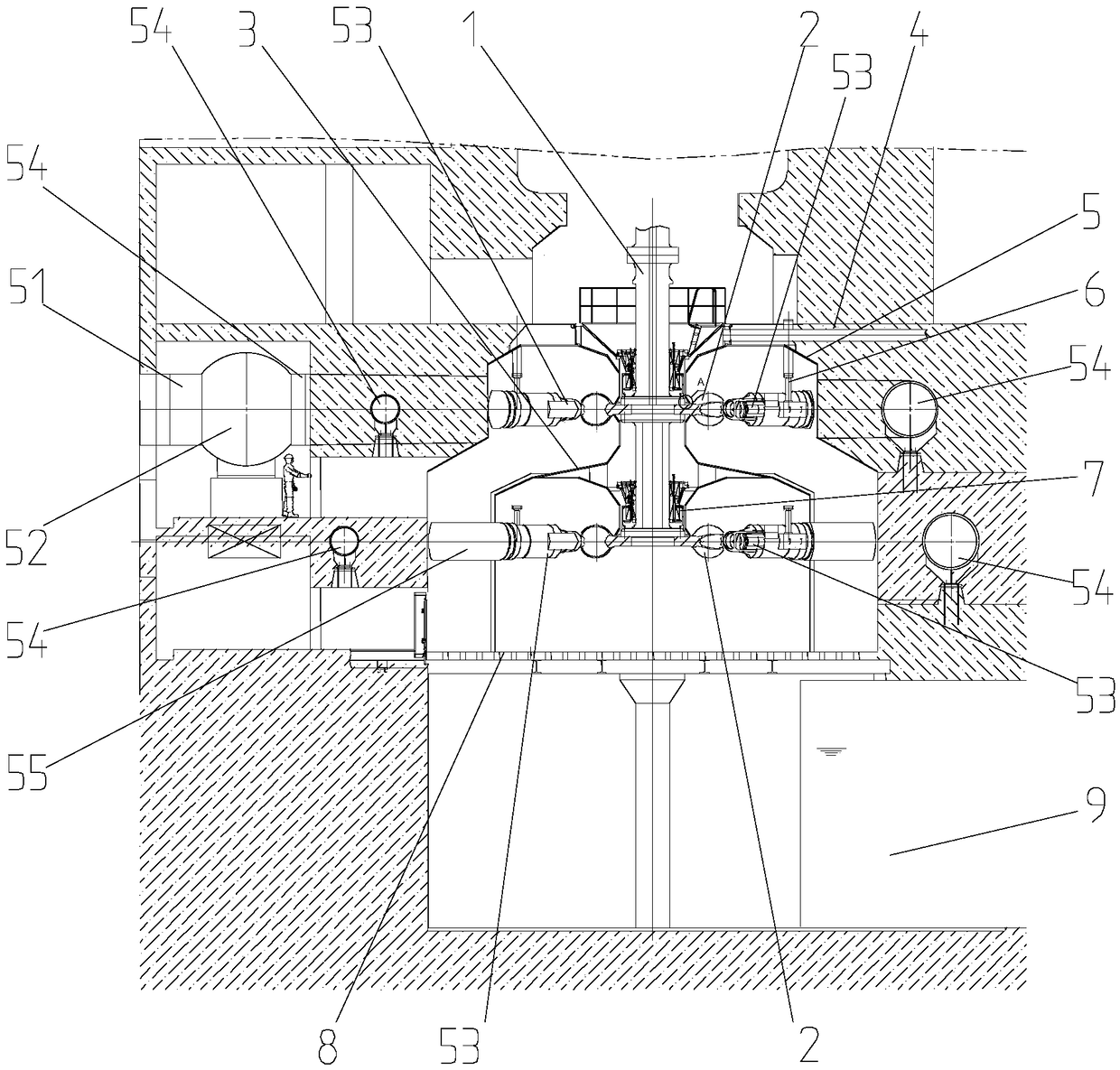

[0027] Such as figure 2 The shown embodiment 2 is another multi-layer runner structure of a water turbine. What the water isolation device selected in this structure is a closed isolation cover, which seals the lower runner and each nozzle. The isolation cover can also be called an inner casing, corresponding to the outer casing.

[0028] The lower end of the main shaft of this example is suspended, and the bearing is installed in the inner casing between the two runners. The bearing can also be arranged on the maintenance platform in the manner of embodiment 1.

[0029] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com