Patents

Literature

37results about How to "Improve the ability of continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

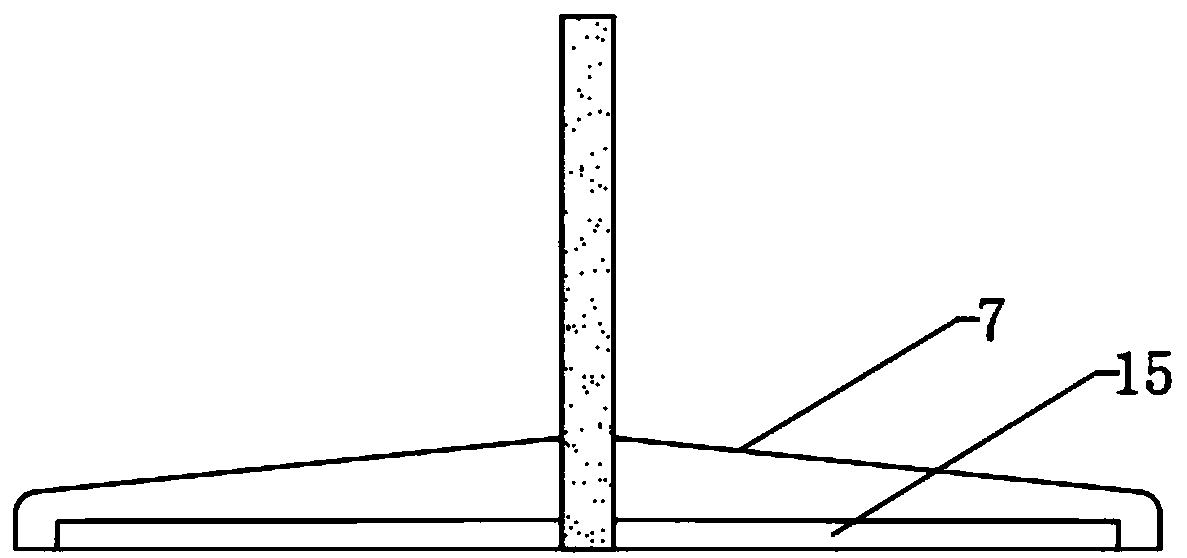

Method for preparing rotary ceramic target

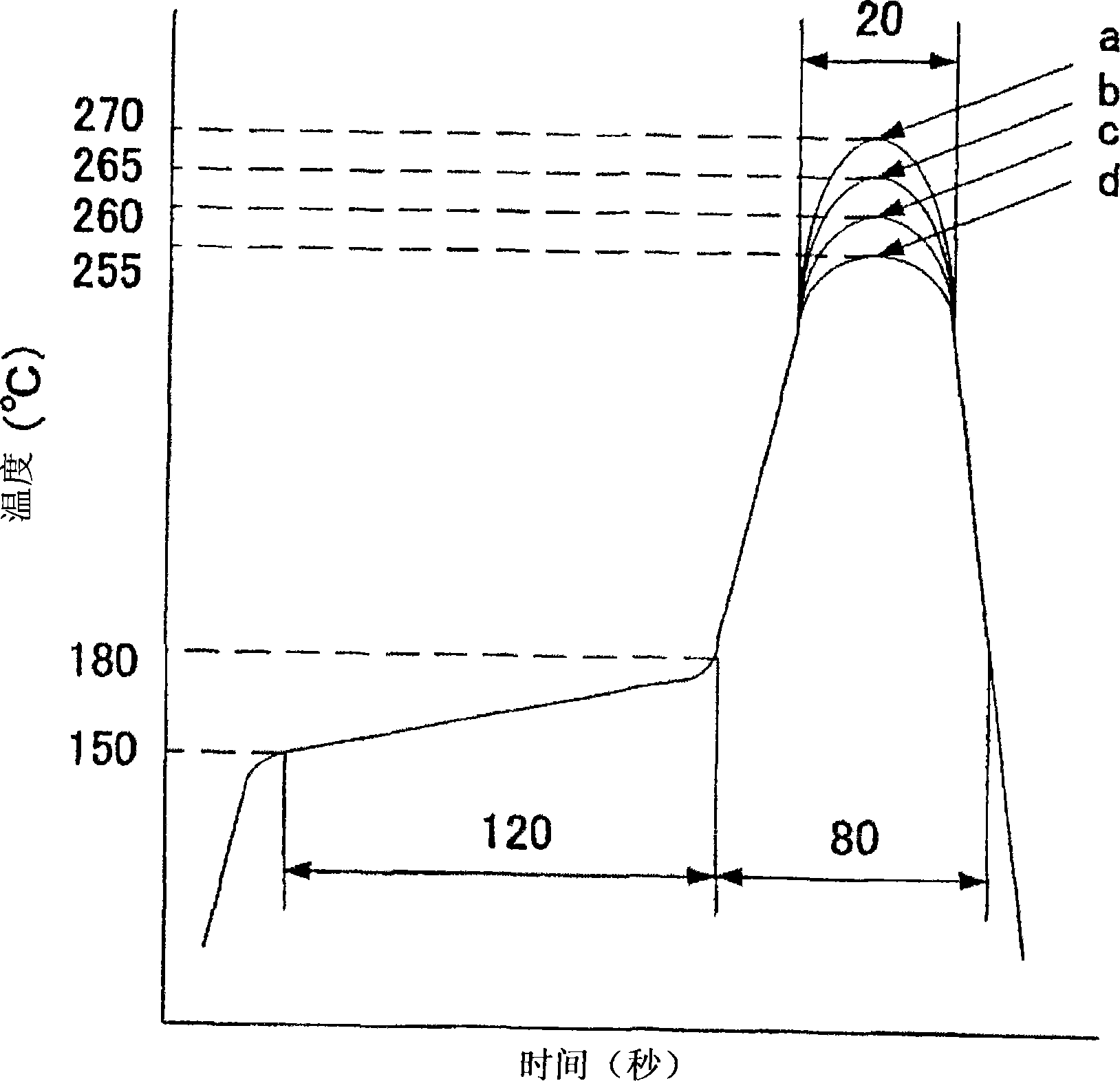

InactiveCN101705467AExtension of timeImprove the ability of continuous productionVacuum evaporation coatingSputtering coatingContinuous useTime of use

The invention relates to the technical field of films, in particular to a method for preparing a rotary ceramic target, which comprises the following steps: (1) preparing a precursor of the target, namely weighting metal oxide powder of which the purity is not less than 99 weight percent, putting the powders into a mould for cold isostatic pressing to prepare the precursor of the target, wherein the reaction pressure is between 130 and 230 MPa, and the reaction time is between 20 and 70 minutes; and (2) sintering, namely putting the precursor of the target obtained in the step (1) into a sintering furnace for sintering densification, wherein the sintering temperature is between 1,000 and 1,600 DEG C, and the sintering time is between 40 and 85 hours. The wall thickness of rotary ceramic target prepared by the method is multiple times that of a plane target, so that the time of using the target continuously by customers is prolonged, the continuous productive power is improved and the total production cost is reduced.

Owner:上海高展金属材料有限公司 +1

Flame-retardant polyamide composition and its use

Provided is a polyamide compound which is free from an environmental problem caused by an antimony compound and from a problem in a production process caused by the generation of a gas, which is a main cause of a mold deposit particularly in the case of the combination use with a flame-retardant containing bromine, and is excellent in flame-retardancy, toughness and melt fluidity, and also exhibits good heat resistance and good color stability in a reflow soldering step being required in the surface mounting, and thus is suitable for electric and electronic parts. A flame-retardant polyamide composition, characterized in that it comprises 10 to 80 mass % of a polyamide (A), 5 to 40 mass % of a flame retardant (B), 0.5 to 10 mass % of zinc borate and at least one other salt of zinc (C), 0 to 60 mass % of an inorganic reinforcing material (D) and 0 to 5 mass % of a drip preventing agent (E).

Owner:MITSUI CHEM INC

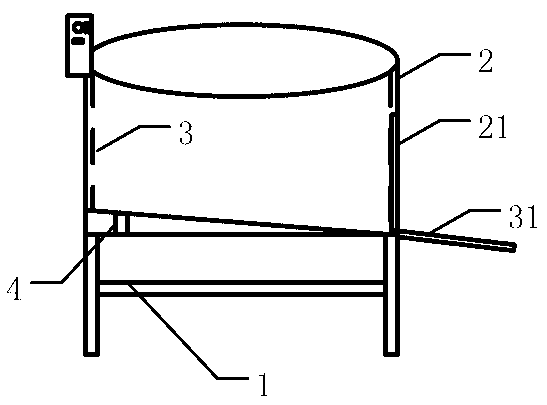

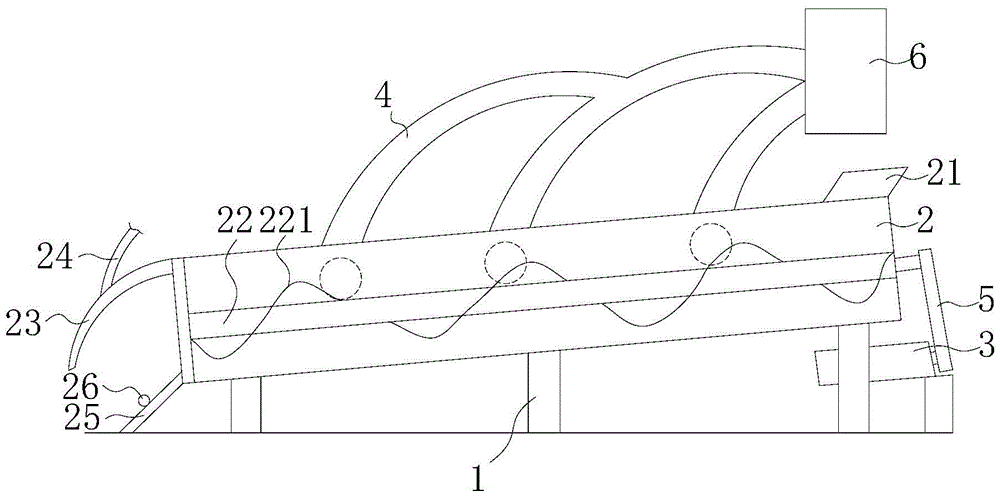

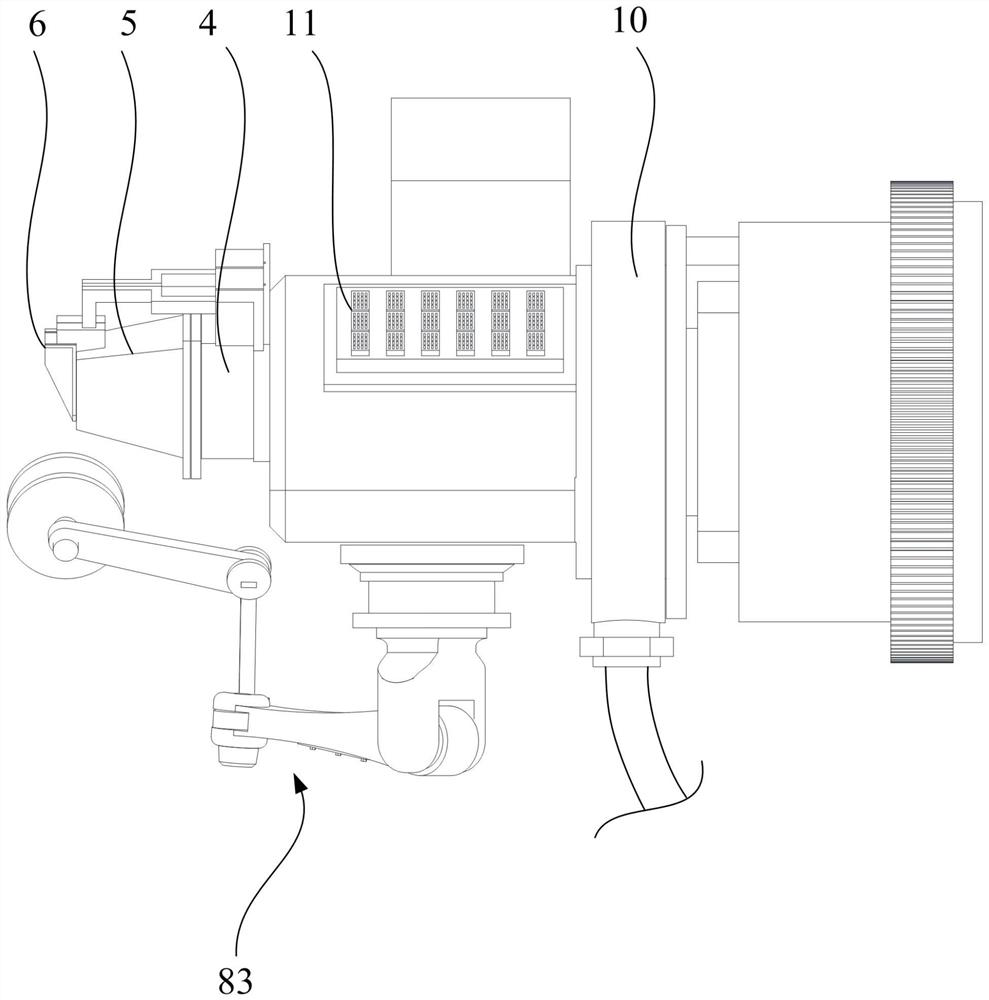

Easily discharged tea frying machine

InactiveCN103005025AImprove convenienceEasy to operatePre-extraction tea treatmentGas cylinderWork in process

The invention discloses an easily discharged tea frying machine which comprises a bracket, an outer barrel arranged on the bracket, an inner pot embedded on the outer barrel, a twisting tea stopper which is arranged on the outer barrel and is inserted into a cavity of the inner pot, and a heating device and a motor which are arranged on the outer side of the bottom of the inner pot, wherein the heating device is a gas stove; the heating device is externally connected with a gas storage cylinder; and the easily discharged tea frying machine is characterized in that partial side wall of the inner pot is provided with a discharge opening which can be turned towards the outer side of the outer barrel, wherein the outer barrel is provided with an opening through which the discharge opening can be turned outwards; and the bottom of the inner pot is provided with a jacking unit on one side away from the discharge opening. According to the tea frying machine, the discharging convenience and operability after the semi-finished tea is fried are improved, the waiting time for natural temperature reduction is reduced, and the continuous productivity of equipment in unit time is greatly improved.

Owner:苏州市瀛园农产品研发有限公司

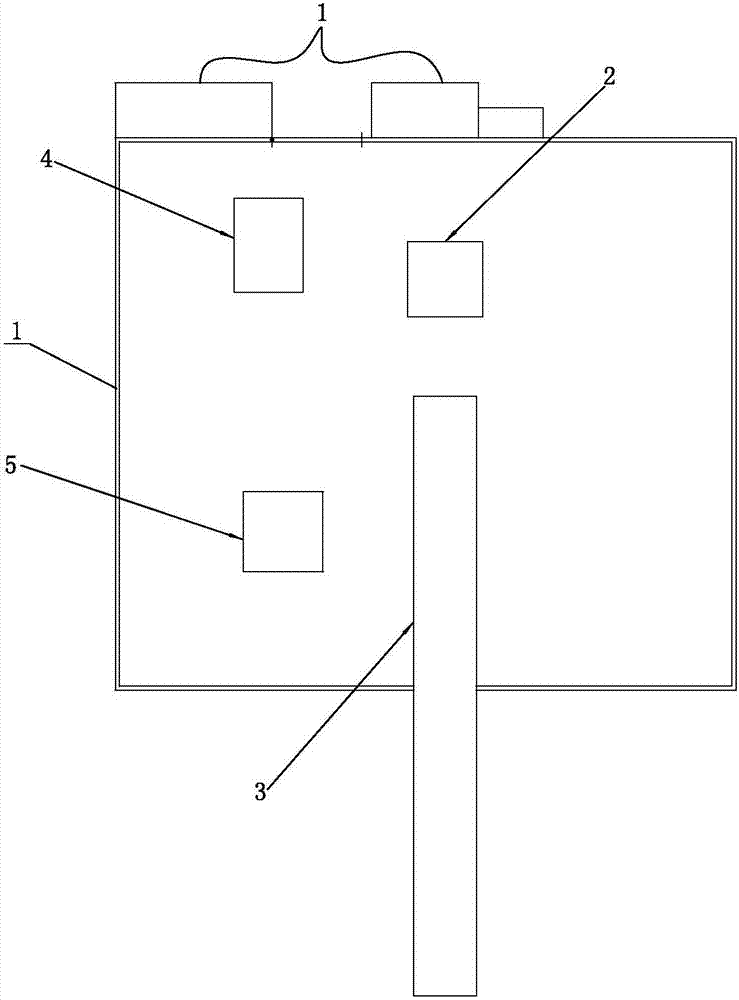

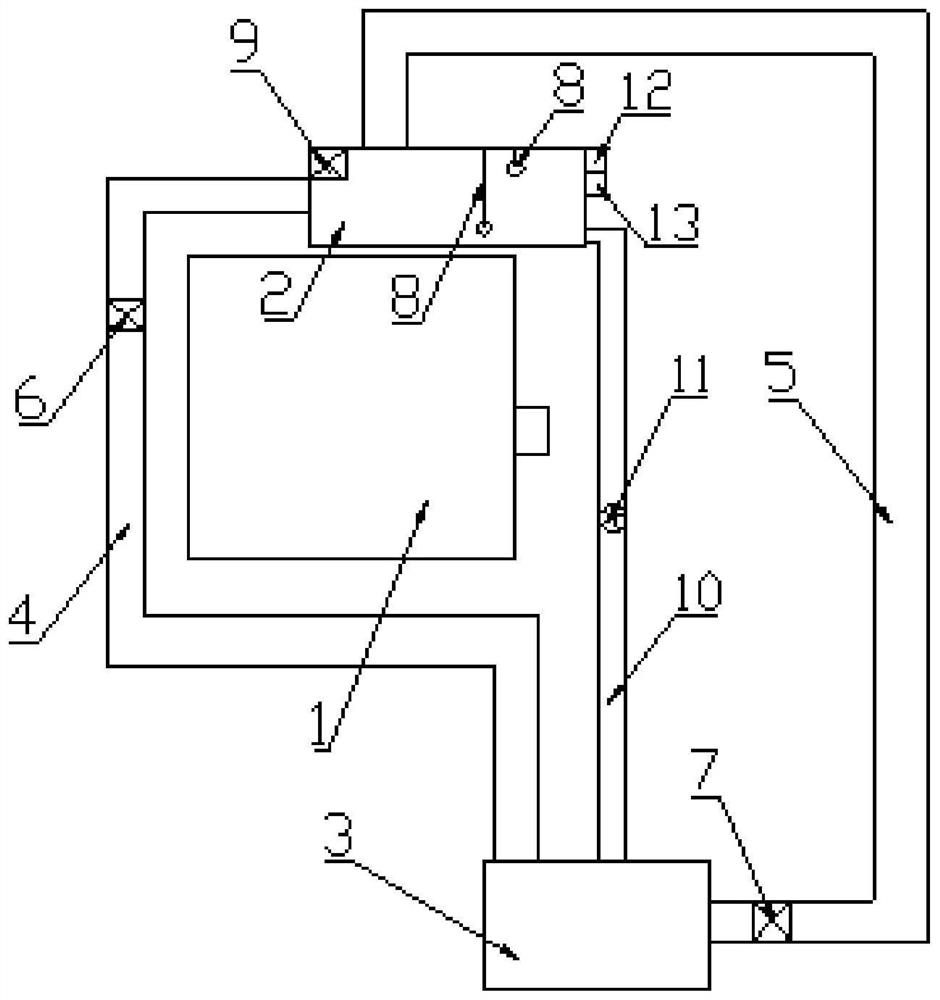

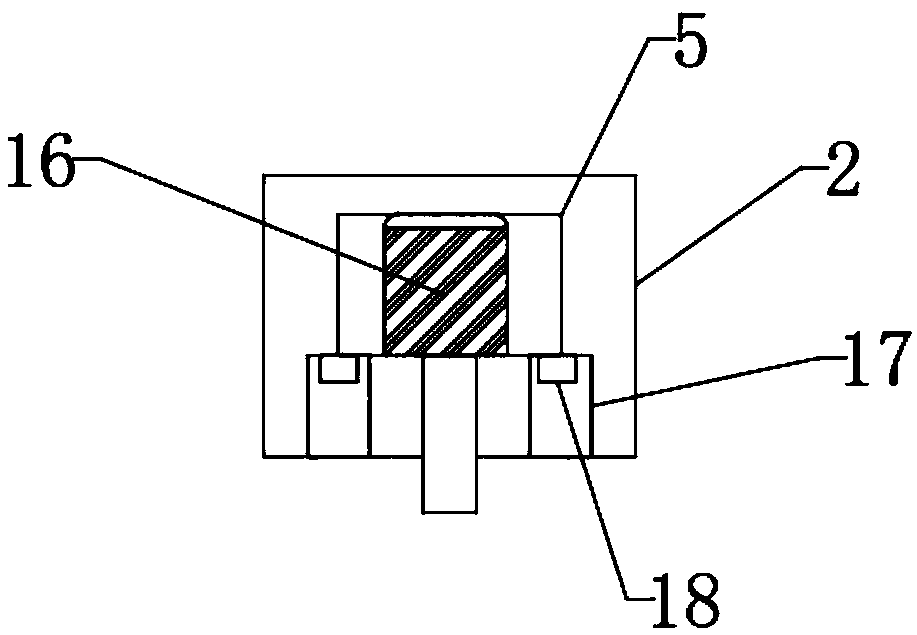

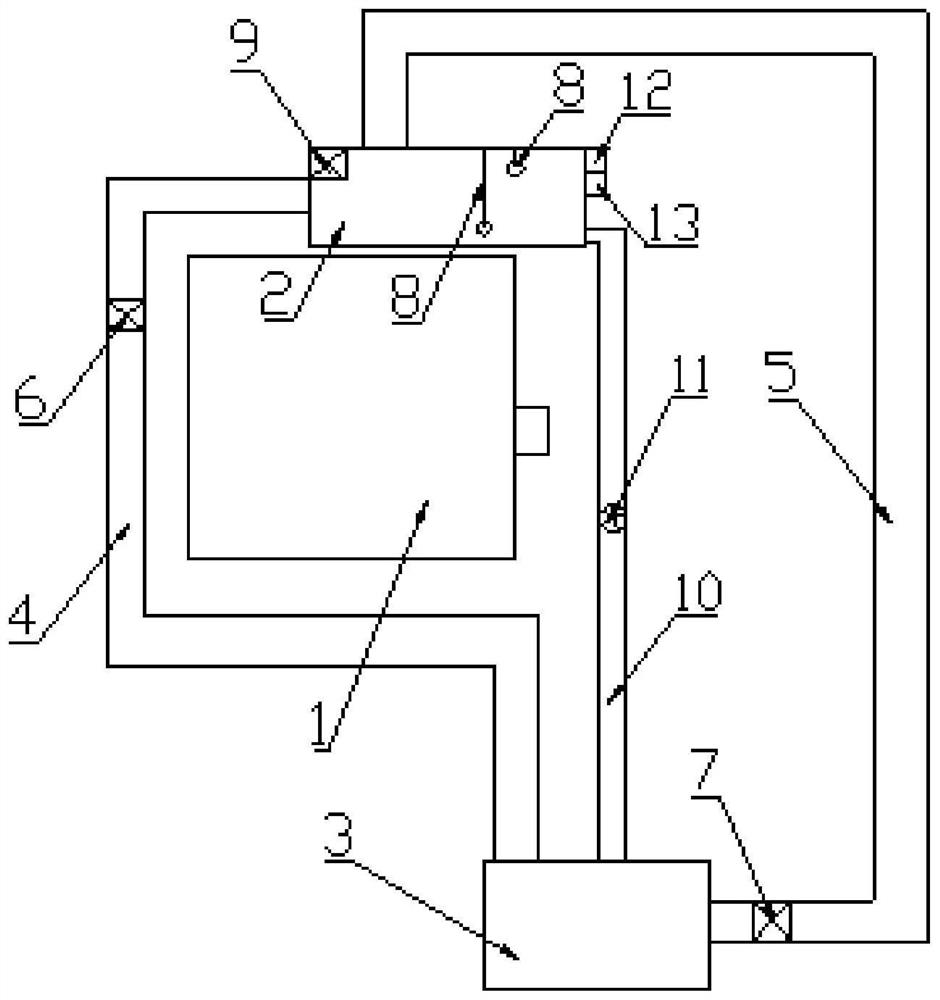

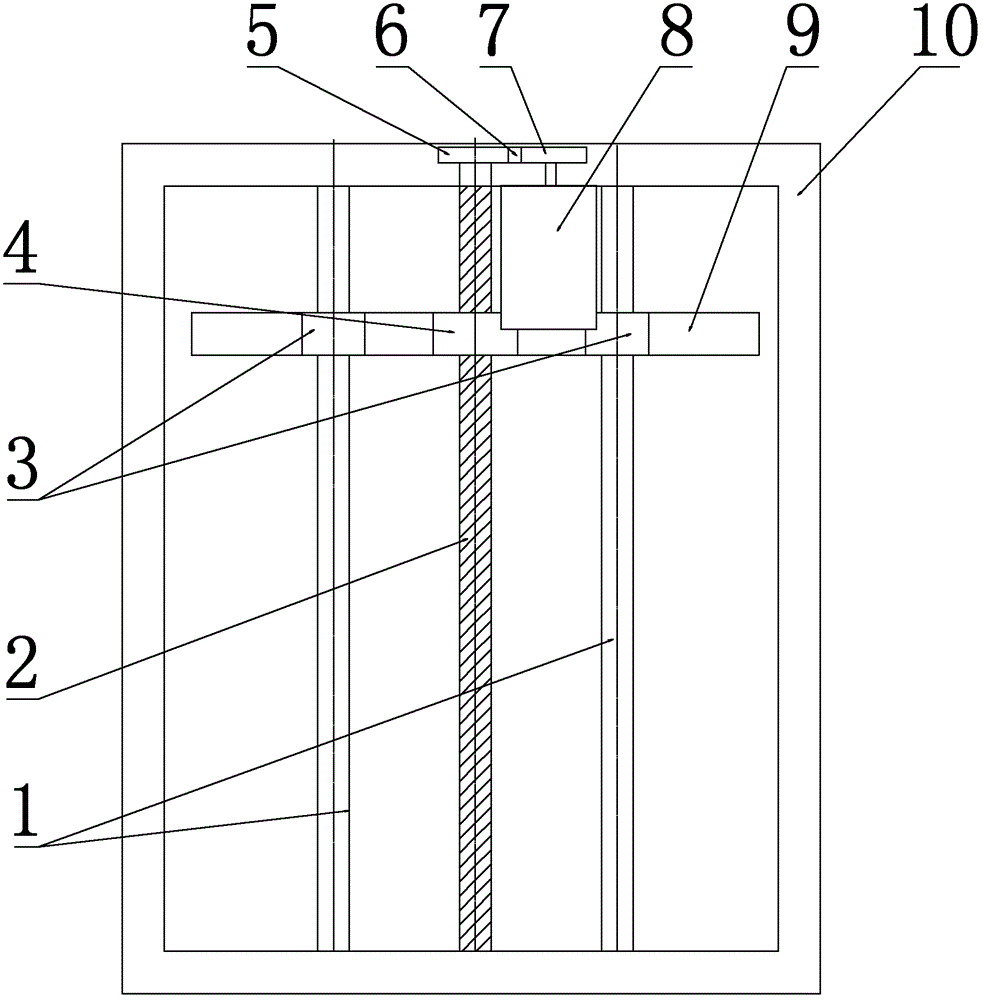

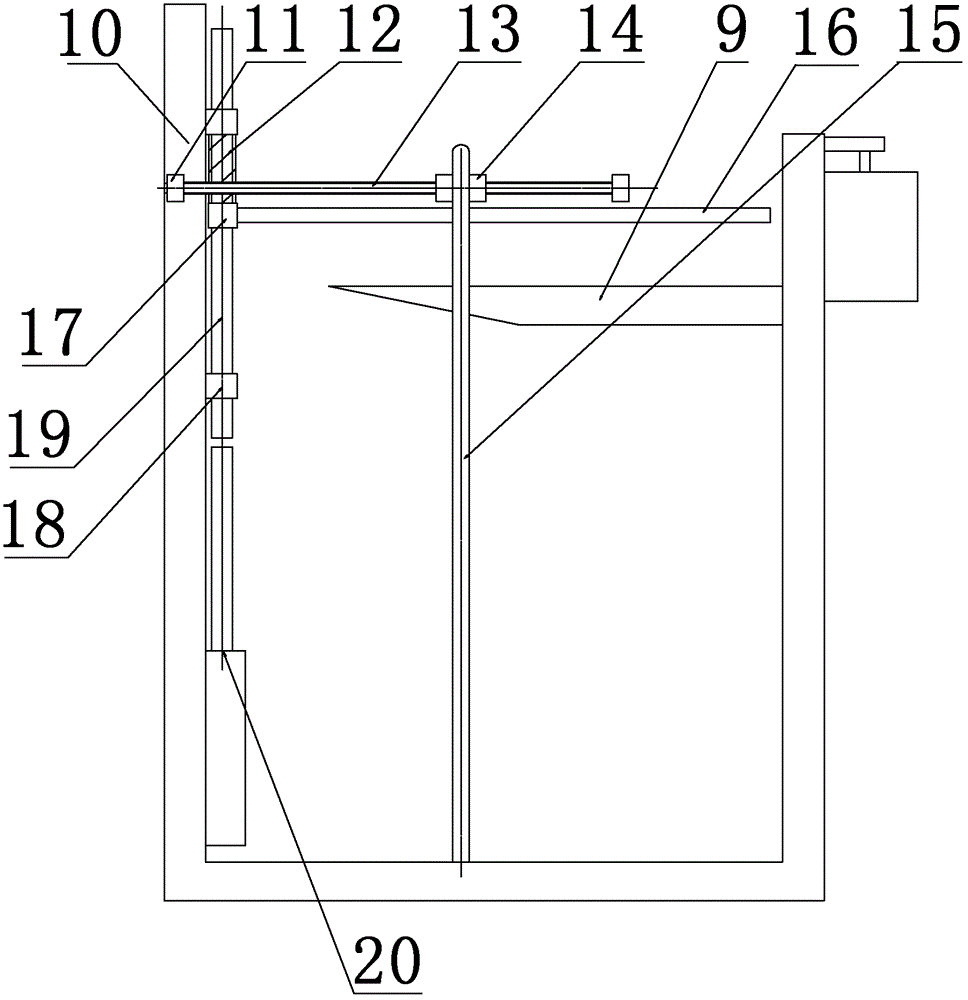

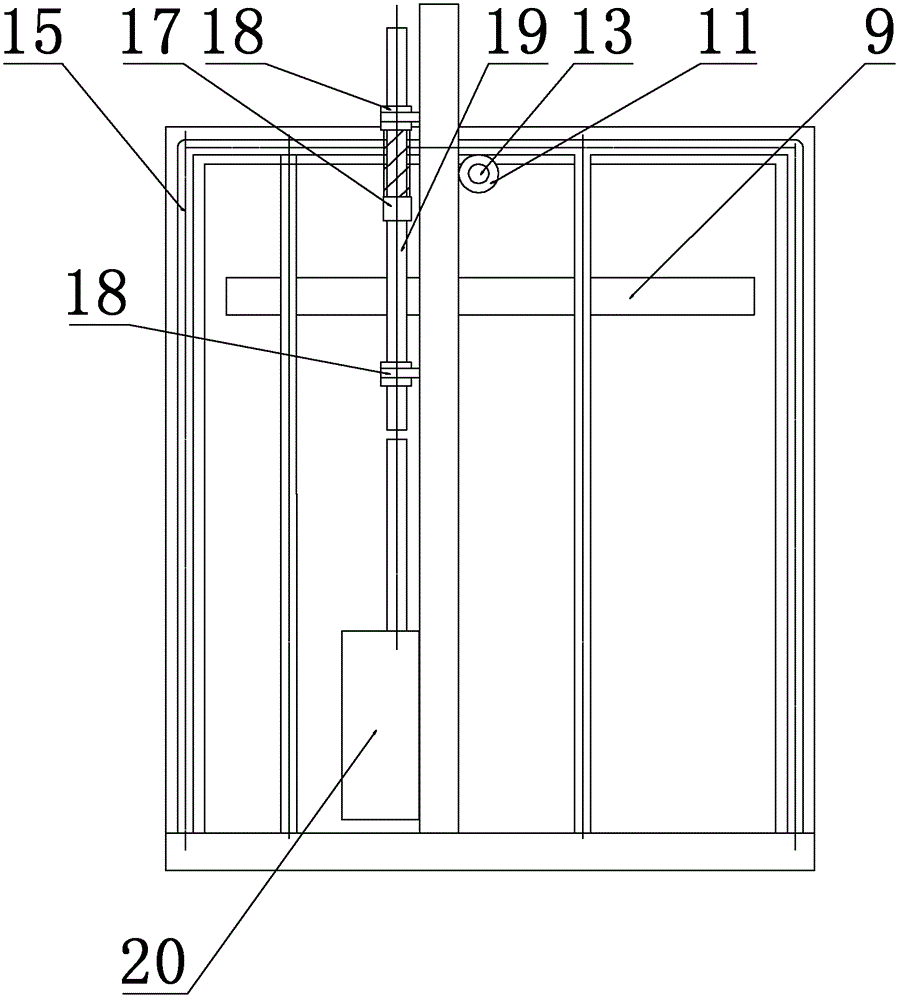

Safe box automatic welding and polishing system

PendingCN106964980ALow technical requirementsReduce labor intensityOther manufacturing equipments/toolsEngineeringMachine

A safe box automatic welding and polishing system comprises a control mechanism (1) and a six-shaft welding robot (2) fixed on the ground and further comprises conveying equipment (3), polishing equipment (4) and a six-shaft carrying robot (5) fixed on the ground. The working range of a working arm of the six-shaft carrying robot (5) is partially overlapped with the working range of a working arm of the six-shaft welding robot (2). One end of the conveying equipment (3) is located in the working range of the working arm of the six-shaft carrying robot (5). The polishing equipment (4) is also located in the working range of the working arm of the six-shaft carrying robot (5). A clamp (6) used for clamping a safe box blank is arranged on the working arm of the six-shaft carrying robot (5). The conveying equipment (3), the polishing equipment (4), the six-shaft carrying robot (5) and the six-shaft welding robot (2) are all in control connection with the control mechanism (1). Compared with the prior art, the safe box automatic welding and polishing system has the characteristics that the automation degree is high, the labor intensity of workers can be reduced by a large margin, the production efficiency can be improved by a large margin, and the production cost can be reduced by a large margin.

Owner:DELI GROUP CO LTD

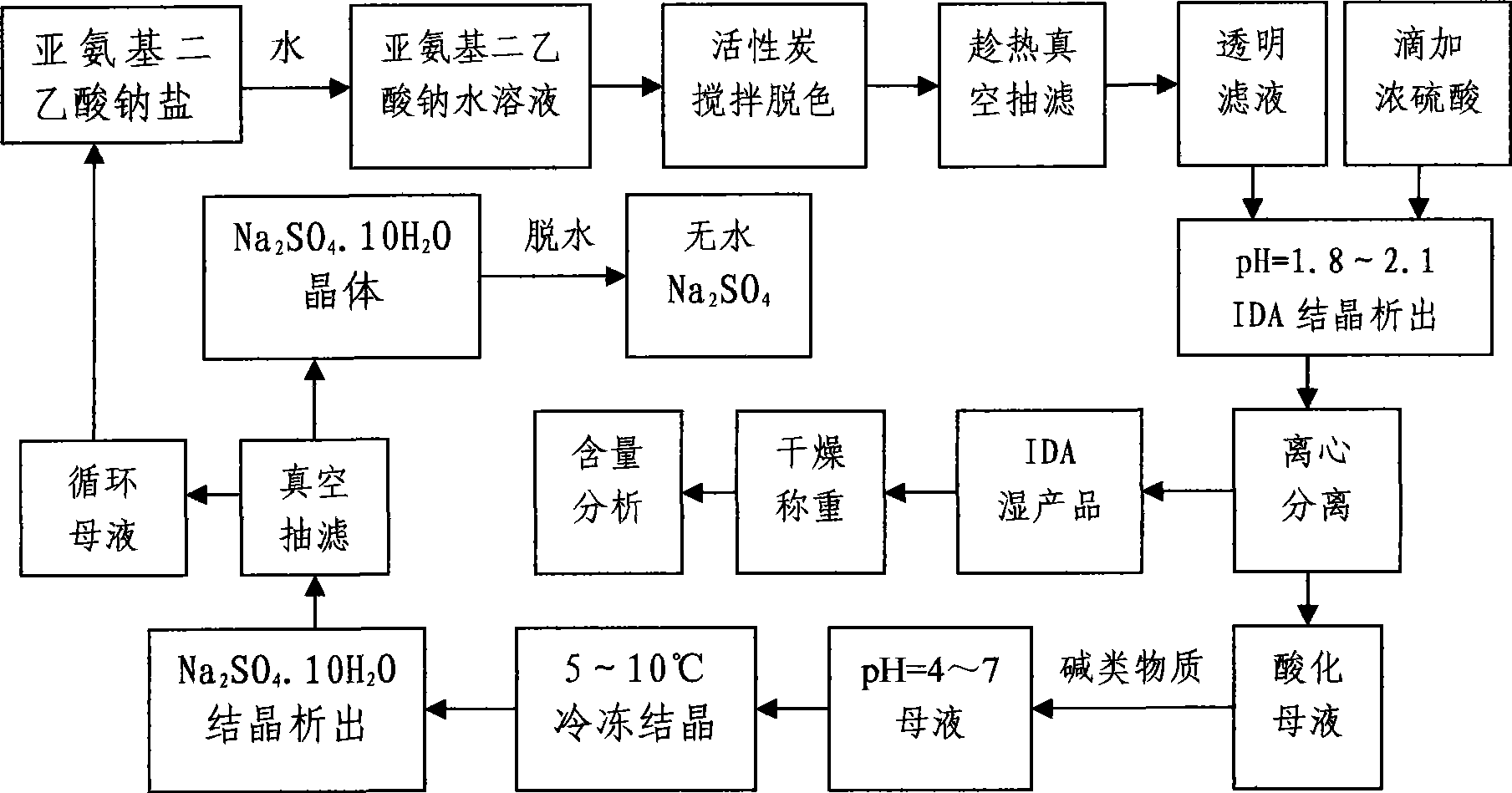

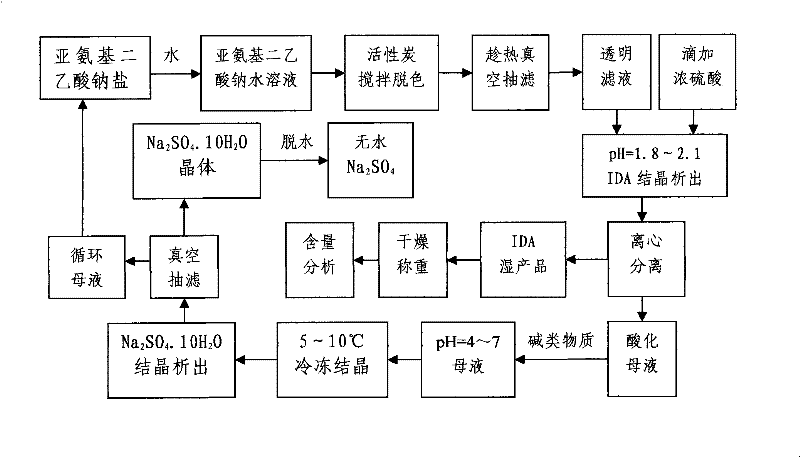

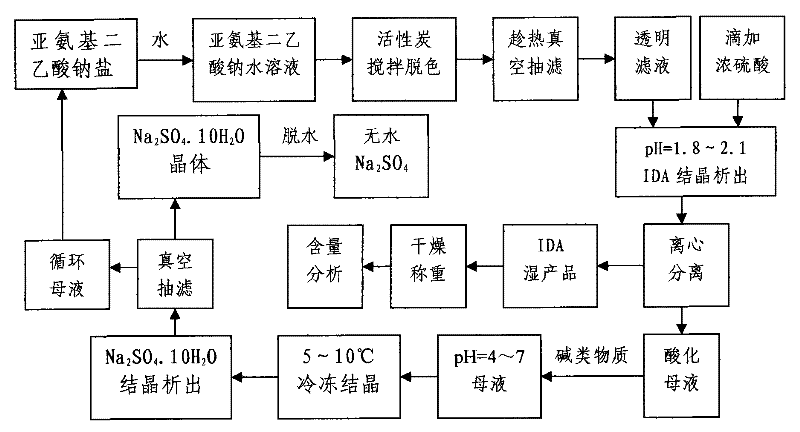

Cycling method for preparing iminodiacetic acid from iminodiacetic acid disodium salt

ActiveCN101445465AHigh purityCreate pollutionOrganic compound preparationAmino-carboxyl compound preparationIminodiacetic acidDesalination

The invention discloses a new cycling process for preparing iminodiacetic acid from iminodiacetic acid disodium salt by a freezing crystallization method. The method is characterized by comprising the following steps: taking the iminodiacetic acid disodium salt as a starting raw material; adding water and stirring to decolorize and dissolve the iminodiacetic acid disodium salt; adding concentrated sulfuric acid dropwise to control pH at 1.8-2.1; centrifuging to obtain the iminodiacetic acid; adding an alkaline matter to acid pregnant liquor until the pH equals 4-7; separating Na2SO4.10H2O out by crystallization at the temperature of 5-10 DEG C; performing vacuum filtration, and recycling the filtrate to continuously prepare the iminodiacetic acid (IDA), wherein, content and desalination rate of the IDA are above 98%, and the yield is about 97%. The pregnant liquor is not discarded in the production process and the whole process can have a plurality of cycles, thus improving production efficiency and utilization rate of the raw material, and avoiding environmental pollution.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

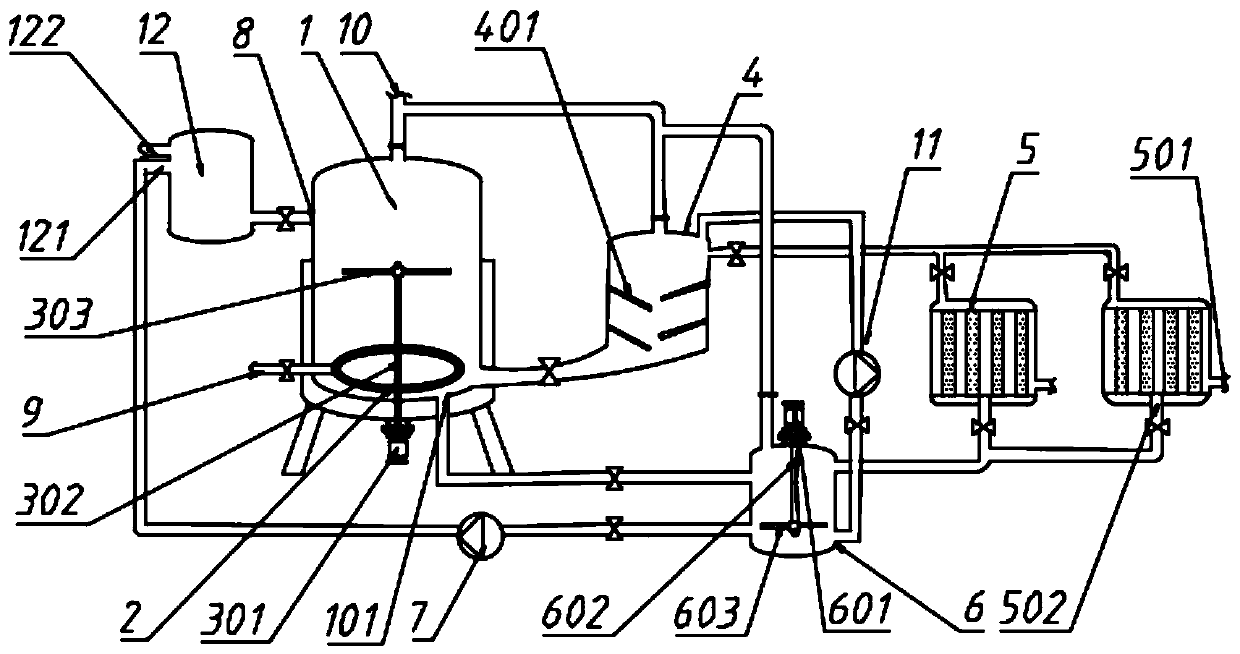

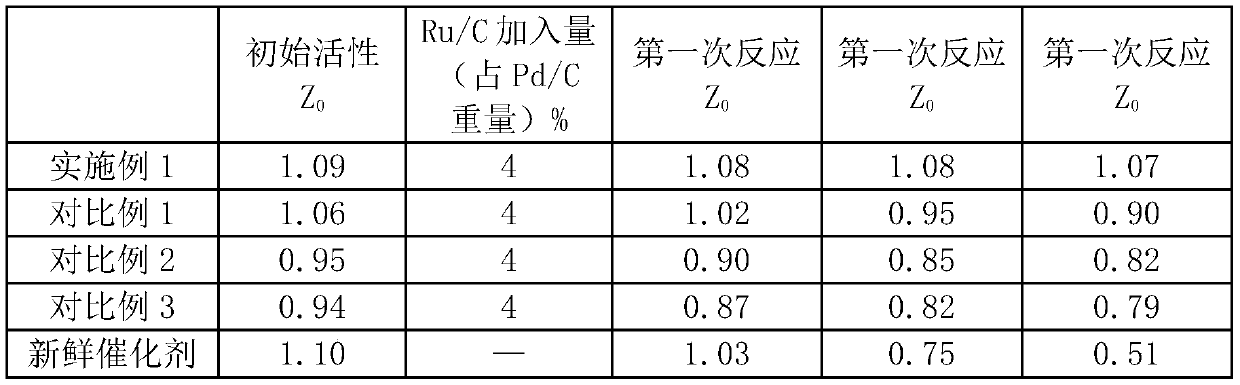

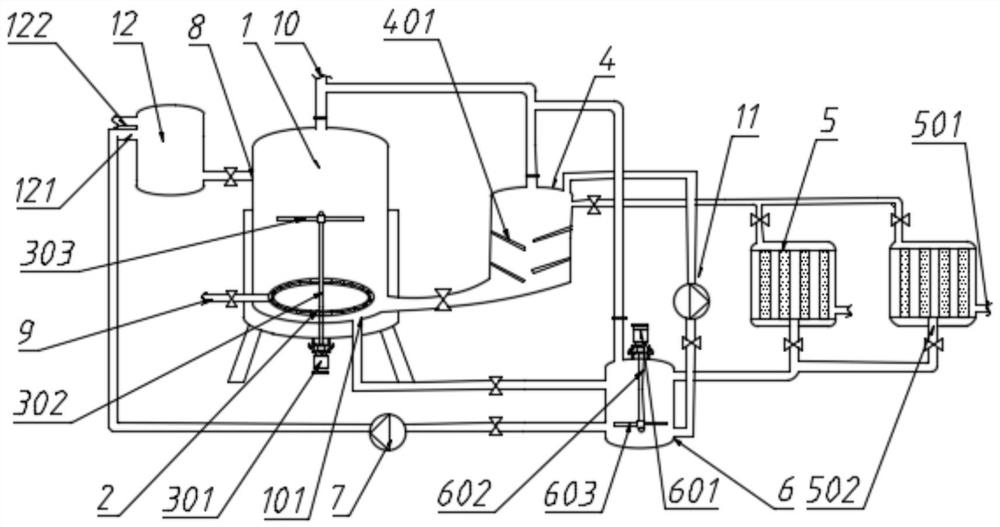

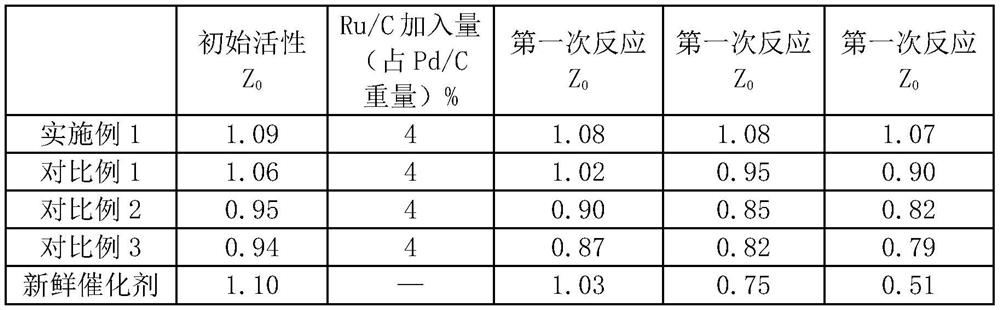

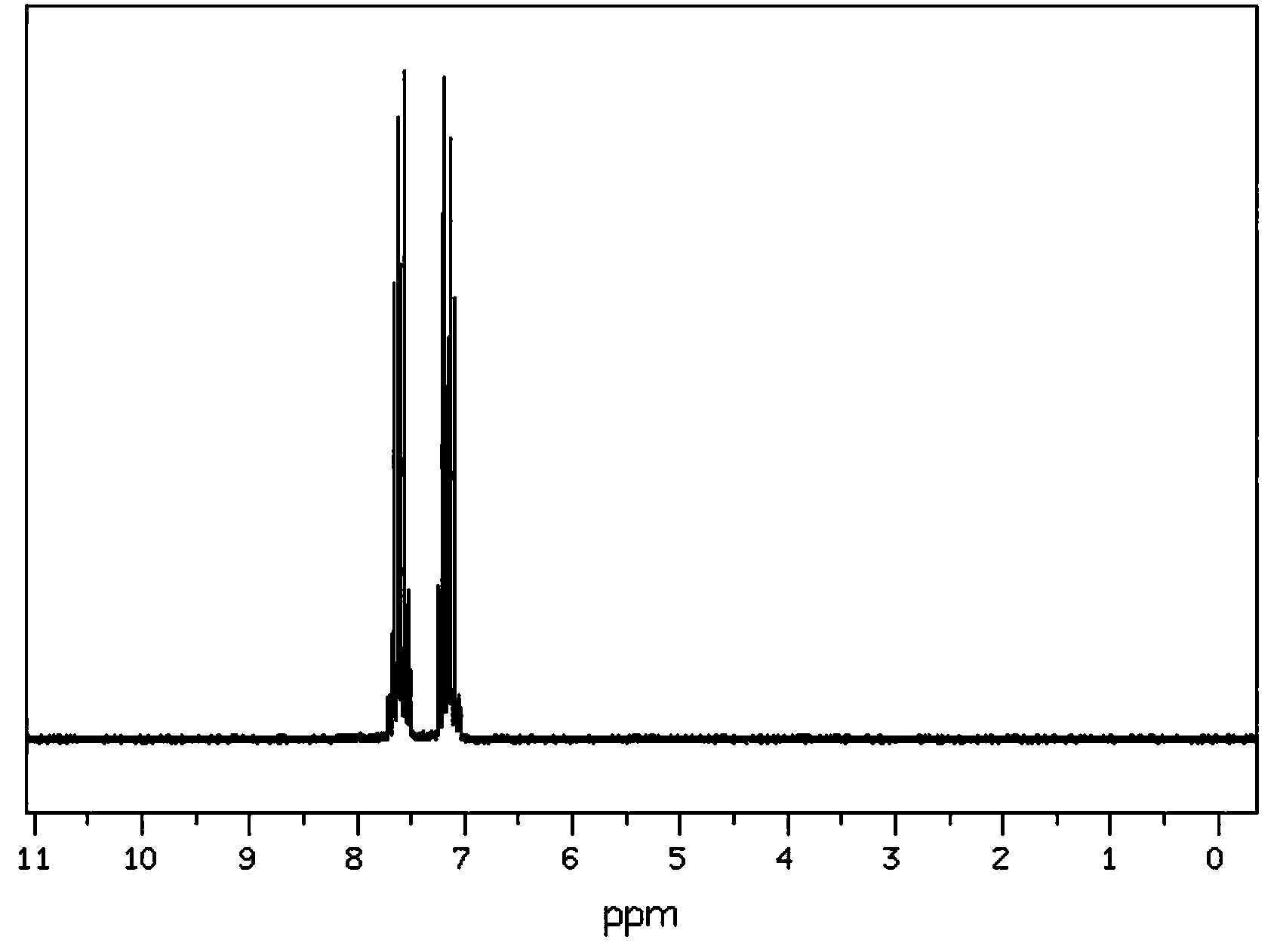

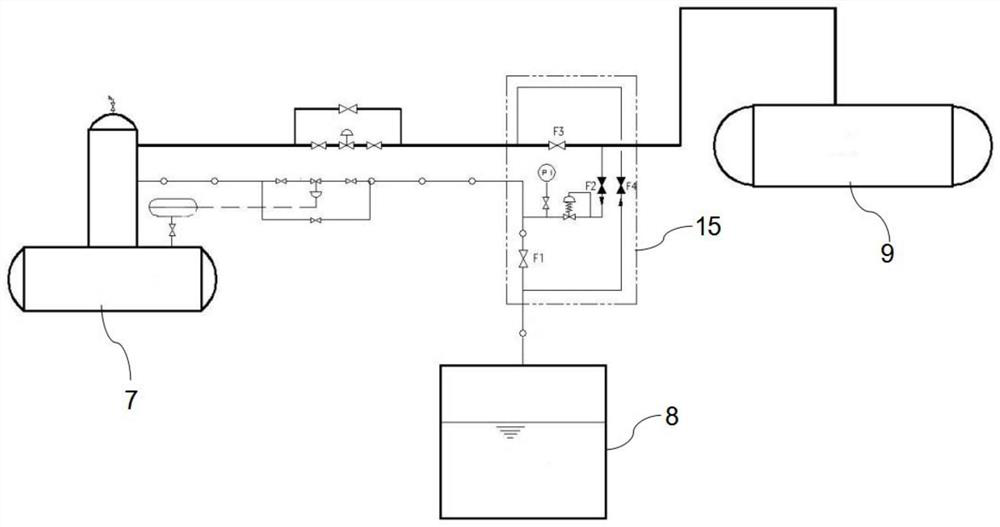

Benzoic acid hydrogenation continuous reaction device and method thereof

ActiveCN110961067AReduce manufacturing costImprove activity and stabilityProcess control/regulationCarboxylic preparation by ozone oxidationFormic acidCatalytic hydrogenation

The invention discloses a benzoic acid hydrogenation continuous reaction device and a method thereof. The method includes: under the action of a Pd / C catalyst and a Ru / C assistant, carrying out contact reaction on molten benzoic acid and hydrogen to generate cyclohexanecarboxylic acid, and after the reaction, depositing the mixed solution in a buffer tank to separate most of the Pd / C catalyst andthe Ru / C assistant from the mixed solution, and directly circulating the Pd / C catalyst and the Ru / C assistant back into the reaction tank for reuse; after the buffer tank is full, letting the mixed solution overflow from the top into a carbon rod filter for further separation, and circulating the separated turbid liquid containing the high-concentration Pd / C catalyst and Ru / C assistant back to a raw material tank system; and making the clear liquid of a carbon rod filter shell layer directly enter a next production procedure. The device does not discharge the catalyst and also has no need forfrequent adding of a fresh catalyst, so that the cost of the catalyst in the continuous preparation process can be saved, the processing cost of the benzoic acid hydrogenation reaction is lowered, thecatalytic hydrogenation activity of the Pd / C catalyst is improved, and the production capacity of the device is increased.

Owner:WUHAN YOUJI IND

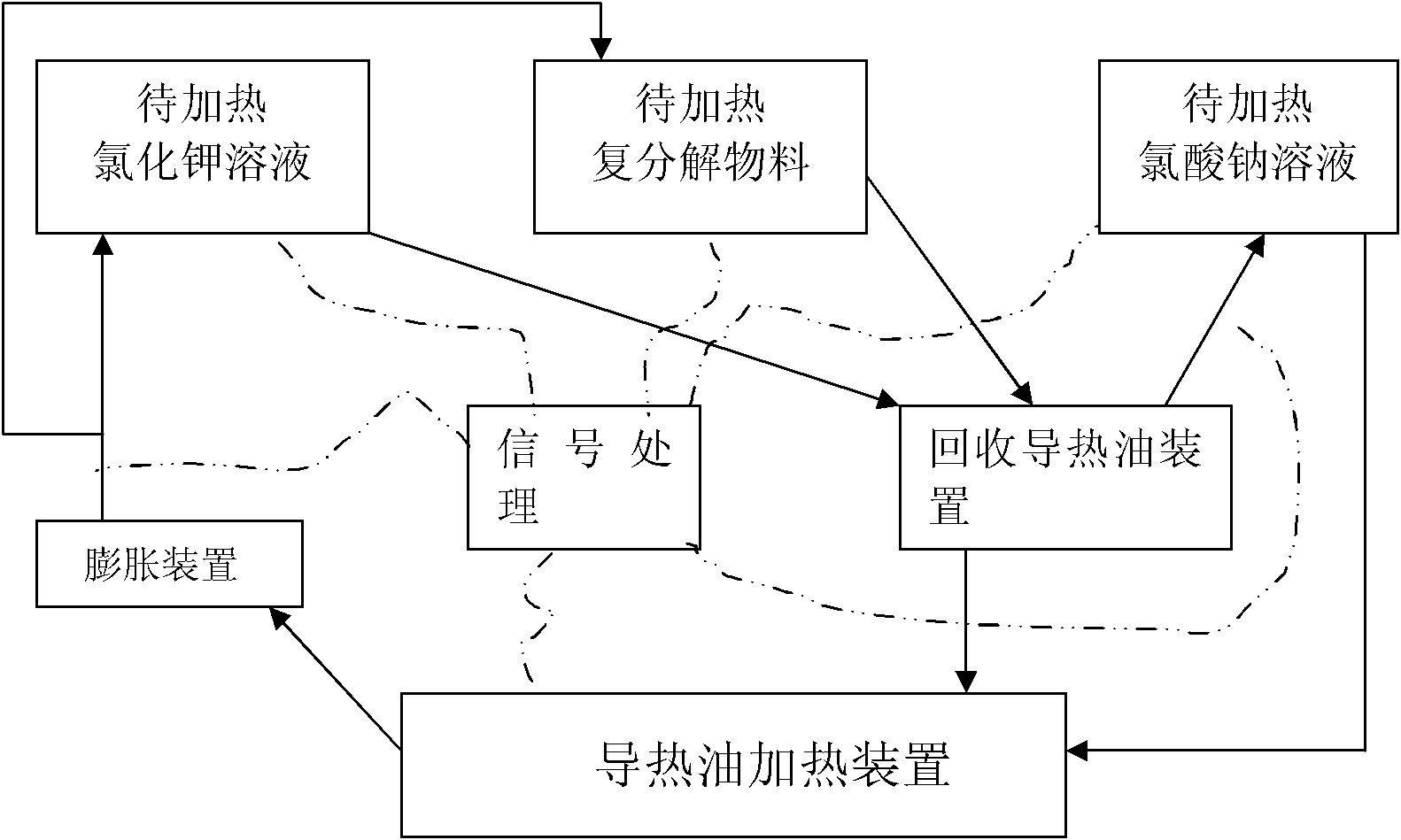

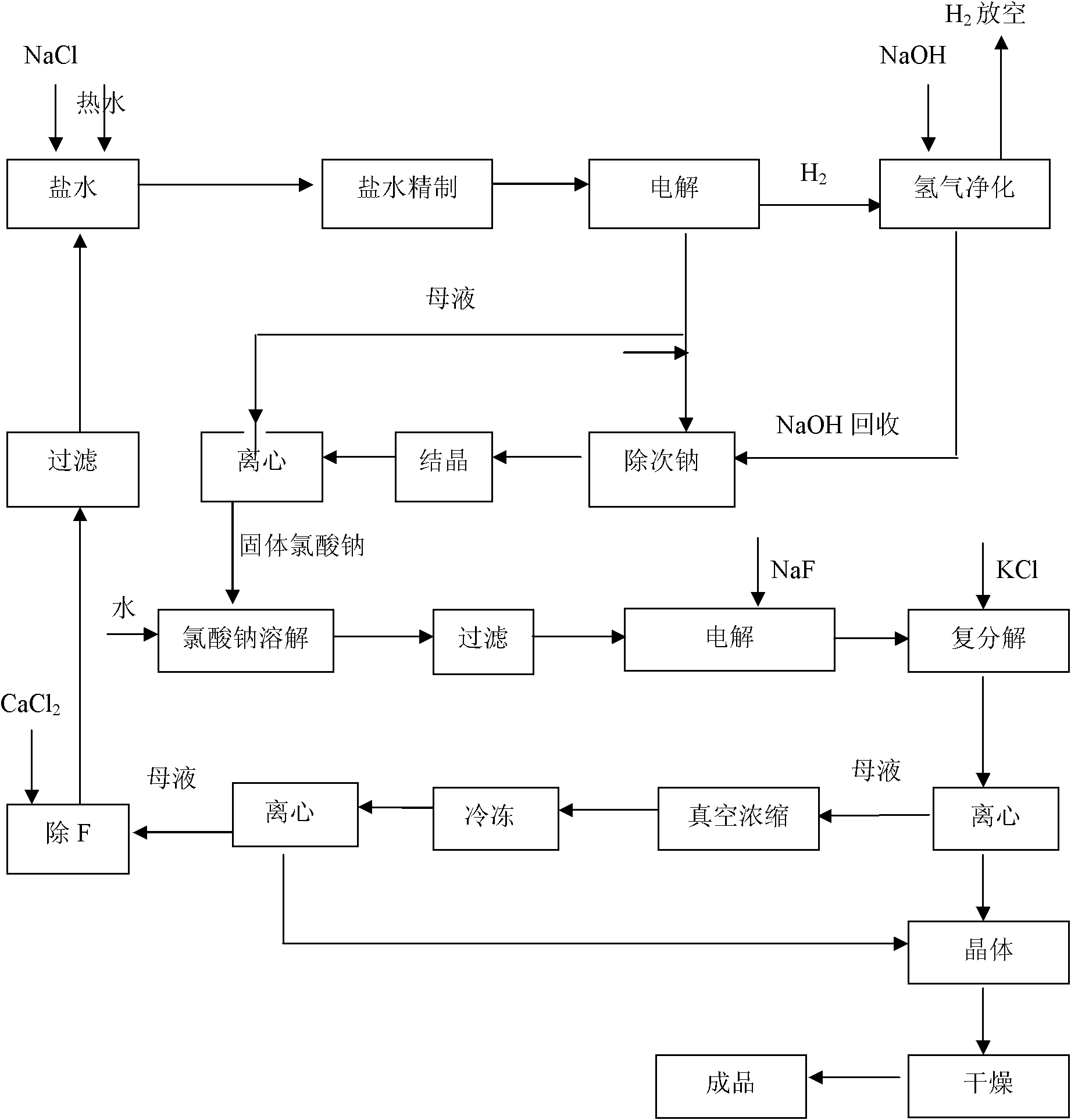

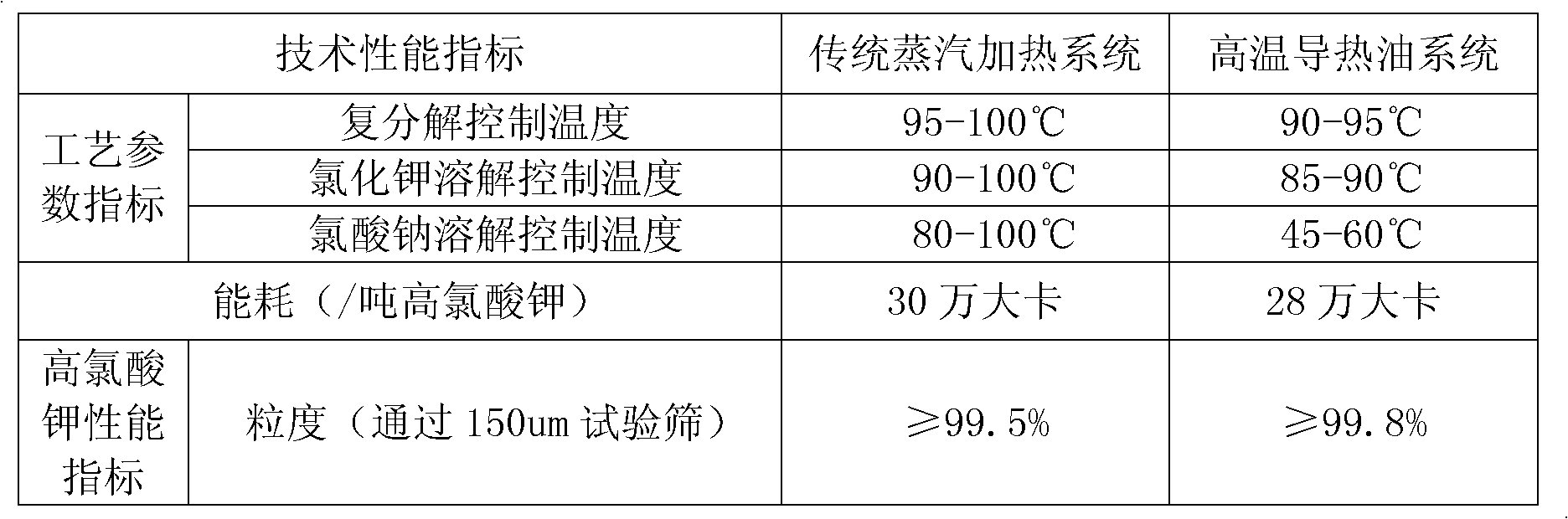

Comprehensive utilization method of heat energy in potassium perchlorate production process

InactiveCN101962174AAbundant power resourcesLow electricity priceElectrolysis componentsPerchloratesThermal energyHeat conducting

The invention relates to a comprehensive utilization method of heat energy in a potassium perchlorate production process, which belongs to the technical field of potassium perchlorate production. The invention aims to solve the technical problem of providing a new heat supplying method for the technical field of potassium perchlorate production, increases energy utilization efficiency and solves environmental pressure caused by the three wastes generated by the coal consumption of a boiler. The invention has the technical schemes of: heating by adopting high-temperature heat conducting oil, in particular to a conduction process that after the heat conducting oil is heated, transmitting heat to materials which need to be heated to cause that the temperature of the heat conducting oil is reduced, and repeatedly heating. The comprehensive utilization method increases energy utilization efficiency and reduces the environmental pressure caused by the three wastes generated by the coal consumption of a boiler, and otherwise, the comprehensive utilization method increases continuous production capacity, is suitable for large-scale production requirements and breaks the tradition that a perchloric acid double-decomposition process is only heated by steam in a long period.

Owner:茂县鑫盐化工有限公司

Baked sesame cooling device and use method thereof

InactiveCN105698561AIncrease exposureImprove cooling efficiencyDirect contact heat exchangersPotential energyAirflow

The invention discloses a baked sesame cooling device and a use method thereof. The device comprises a supporting frame, a cylinder, a motor and air exhaust pipes, wherein the cylinder, the motor and the air exhaust pipes are arranged on the supporting frame; an angle of 10-15 degrees is formed between the central axis of the cylinder and the horizontal plane; a feeding inlet is arranged at the head part of the cylinder; a rotating shaft is arranged in the cylinder; a spiral shoveling plate is arranged on the rotating shaft; the head part of the cylinder is connected with the motor through a chain; and a plurality of the air exhaust pipes are uniformly arranged on one side of the cylinder; and connected with a dust remover. The device and the use method have the advantages that sesame is shoveled by rotating the spiral shoveling plate constantly, so that the sesame can have a certain amount of potential energy and then move forward, the opportunities of the sesame to get in touch with airflow can be increased, the sesame cooling efficiency can be improved, and the continuous production capacity is improved; particularly, a spiral arc surface is adopted, so that the air resistance to the sesame in the moving process can be reduced, and the moving speed of the sesame can be further improved; and the processed sesame of which the temperature is 100-120 DEG C is not easy to broken in the suspended state, and thus the finished product ratio can be effectively improved.

Owner:CHAOHU RUIFENG OIL CO LTD

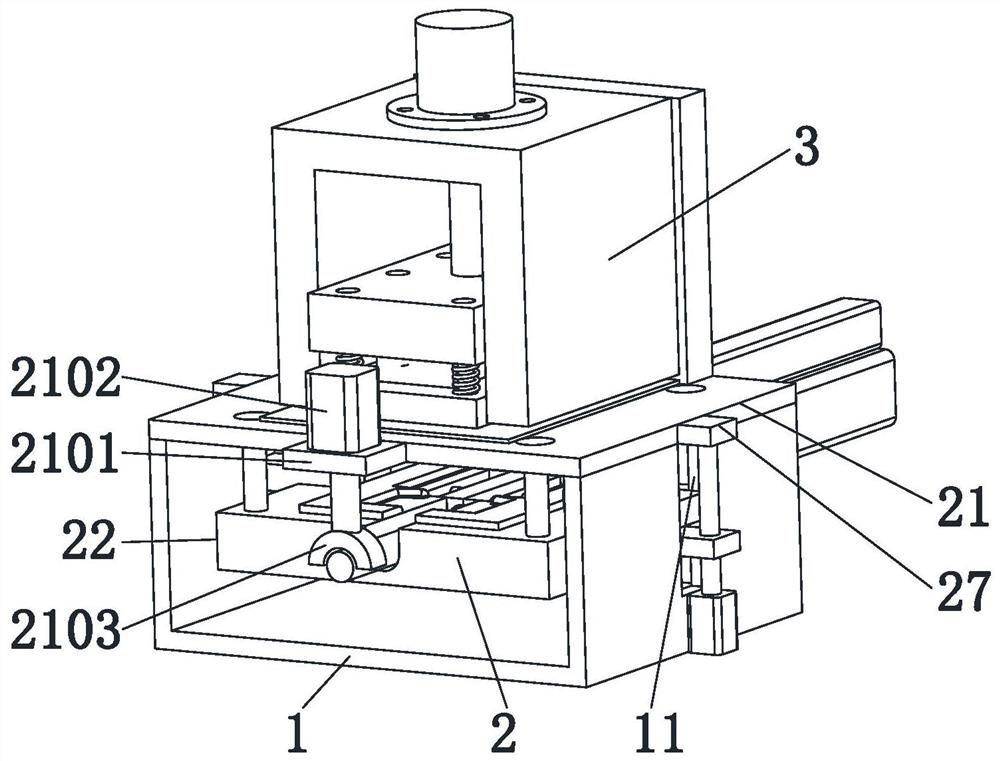

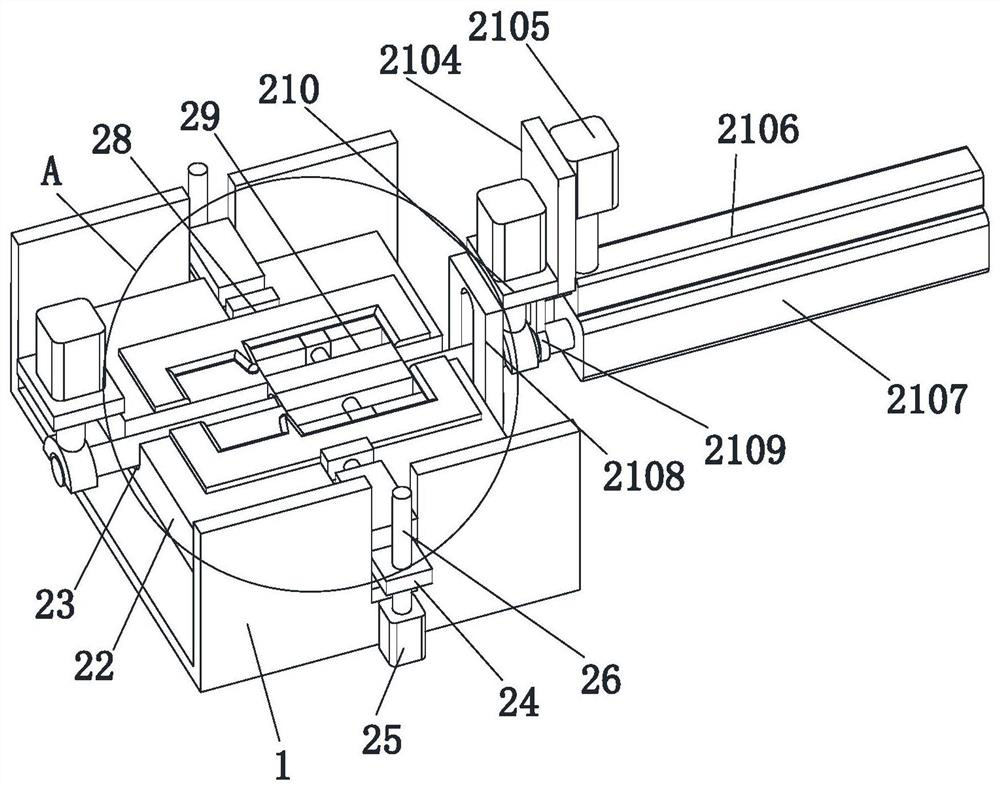

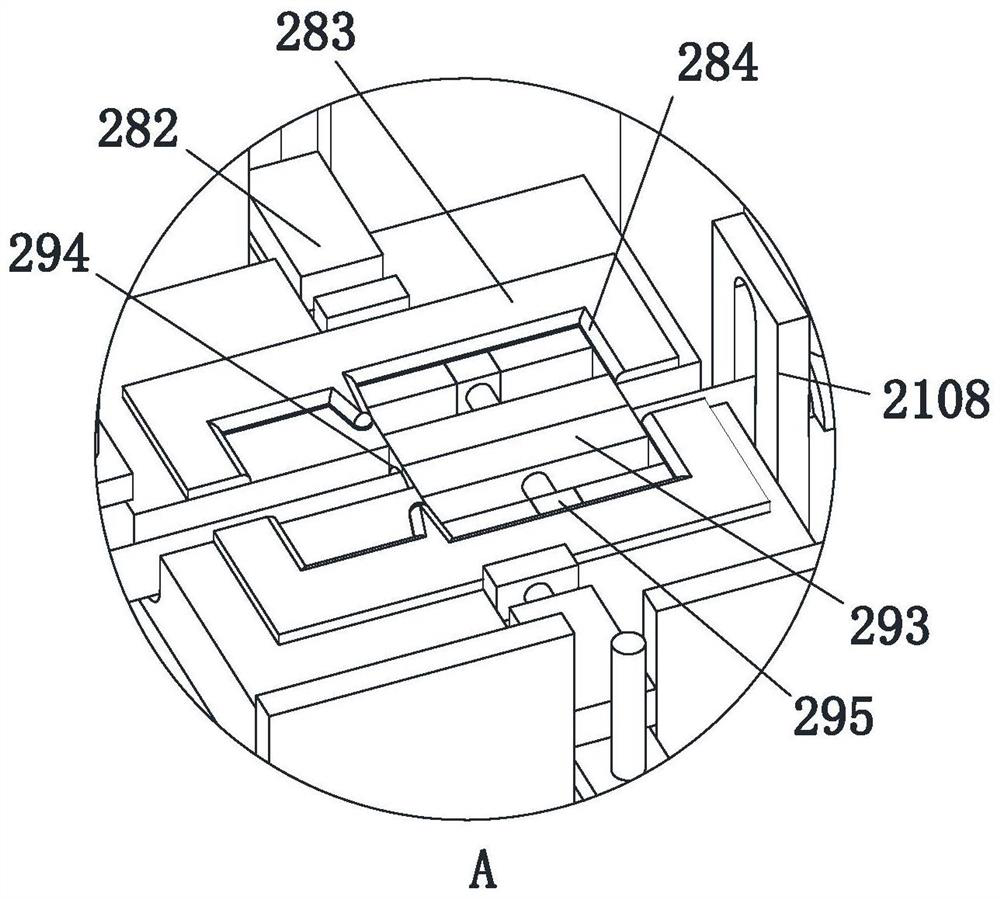

A wire harness terminal stamping forming processing equipment and forming processing technology

ActiveCN111922177BQuality improvementImprove continuityMetal-working feeding devicesPositioning devicesMechanical engineeringIndustrial engineering

The invention relates to a wire harness terminal press forming processing device and a forming processing technology. The device comprises an installation base, a forming device and a pressing device.The wire harness terminal press forming processing device can solve the following problems of wire harness terminal production devices on the market at present: firstly, during terminal production, raw materials are cut or pressed and shaped, the materials which are cut or pressed and shaped are processed into molded terminals, and two wire harness terminal production devices are used separatelyin the two steps, so that the production process is cumbersome, the device structure is complex and the cost is increased; and secondly, when the wire harness terminal production devices on the marketat present are used for cutting or pressing and shaping the raw materials, shapes of the terminals are easily deformed by pressing, and errors in subsequent production are caused to affect productionquality of the terminals. The device provided by the invention integrates production, improves production continuity and working efficiency, ensures that the processed shapes of the terminals are noteasily deformed due to errors, and the product quality is improved.

Owner:浙江宏厦电气科技有限公司

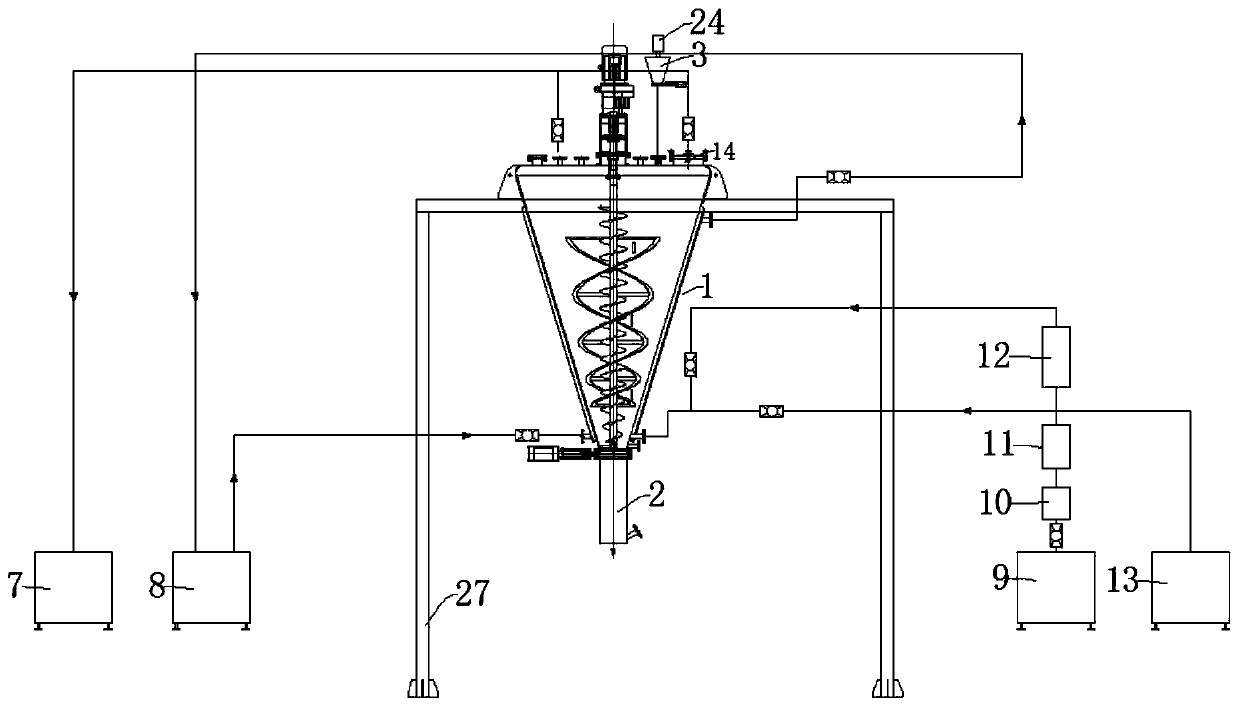

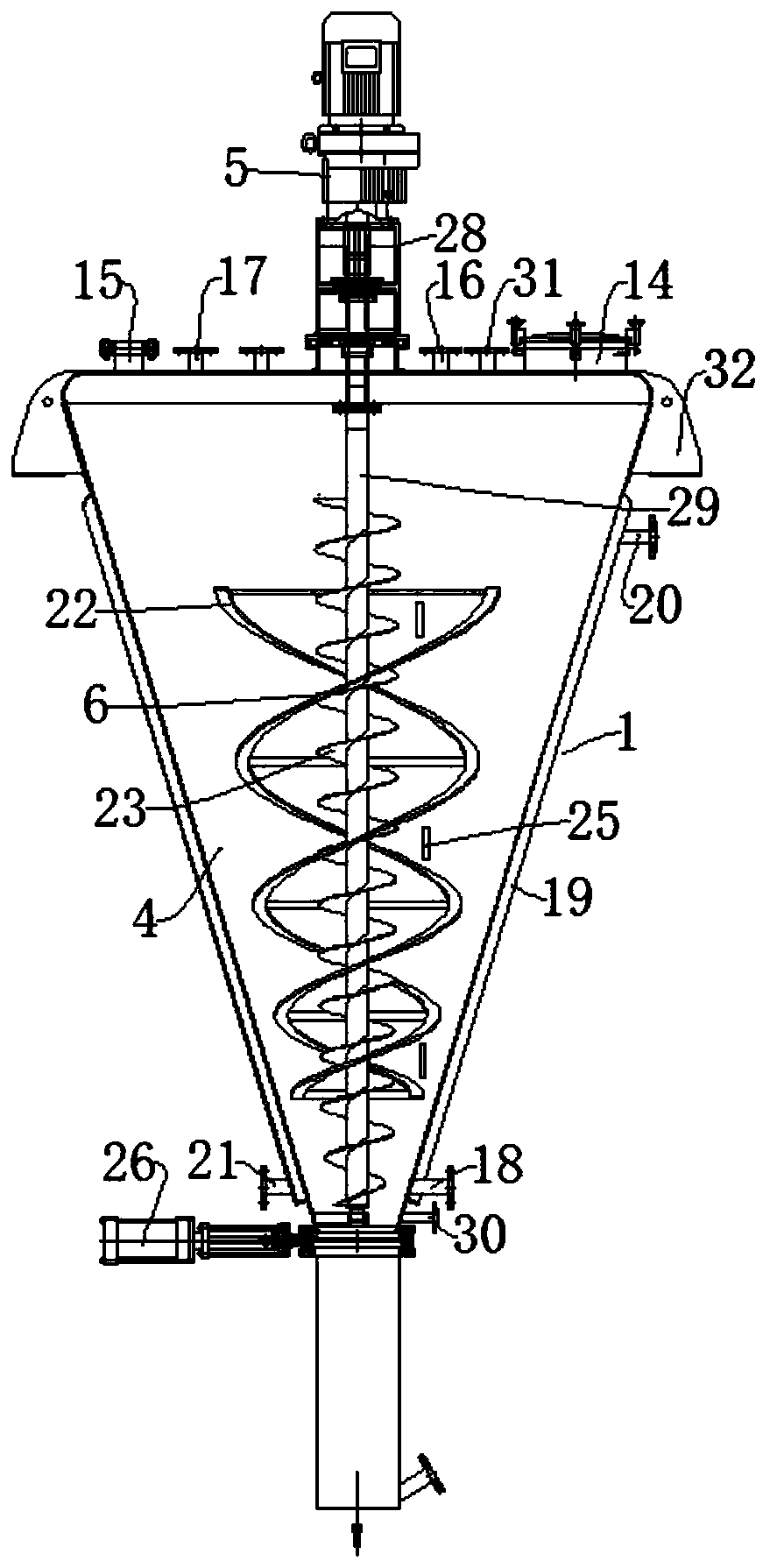

Edible mushroom vacuum stirring sterilization cooling and inoculation integral machine

PendingCN111226696AQuick Stir to MixHeating up fastDispersed particle filtrationTransportation and packagingAir filterEngineering

The invention discloses an edible mushroom vacuum stirring sterilization cooling and inoculation integral machine. The machine comprises a vacuum stirring sterilization cooling and inoculation device,a connecting tube, a bracket and a solid mushroom seed feeding machine, wherein the vacuum stirring sterilization cooling and inoculation device is arranged on the bracket; the connecting tube is arranged below the vacuum stirring sterilization cooling and inoculation device and is connected with an external packaging machine; the solid mushroom seed feeding machine is arranged above the vacuum stirring sterilization cooling and inoculation device; and the vacuum stirring sterilization cooling and inoculation device comprises a cabin, a driving motor set, a turnover stirring part, a vacuum pump, a cold water machine, an air compressor, an air filter I, an air filter II, a sterile filter and a steamer. The invention relates to the technical field of edible mushroom base processing, and inparticular provides the edible mushroom vacuum stirring sterilization cooling and inoculation integral machine which integrates stirring, sterilization, cooling and inoculation of edible mushroom rawmaterials and is efficient and energy-saving.

Owner:唐湘梅

A kind of benzoic acid hydrogenation continuous reaction device and method thereof

ActiveCN110961067BAvoid destructionGuaranteed concentrationProcess control/regulationCarboxylic preparation by ozone oxidationBenzoic acidPtru catalyst

Owner:WUHAN YOUJI IND

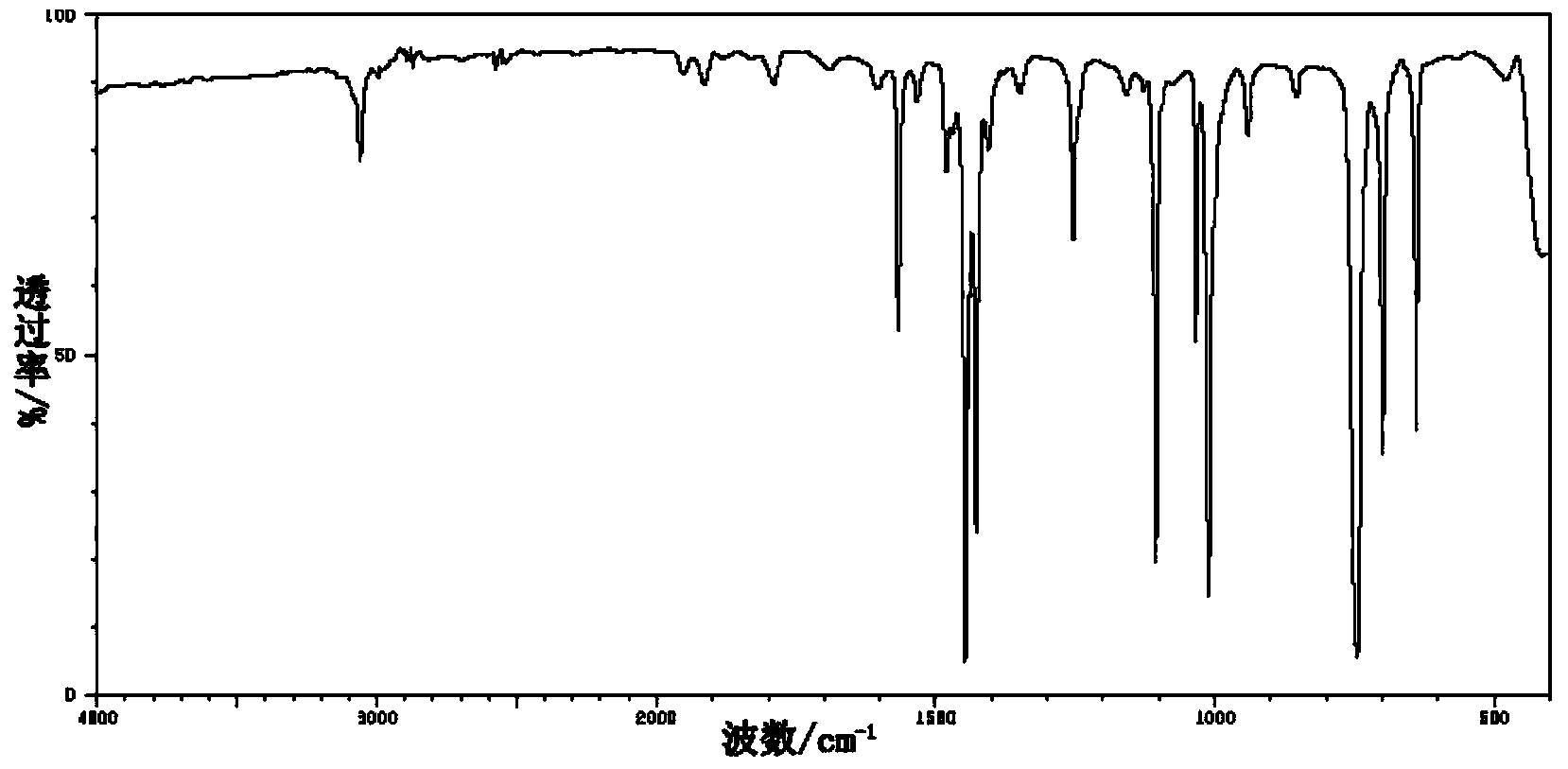

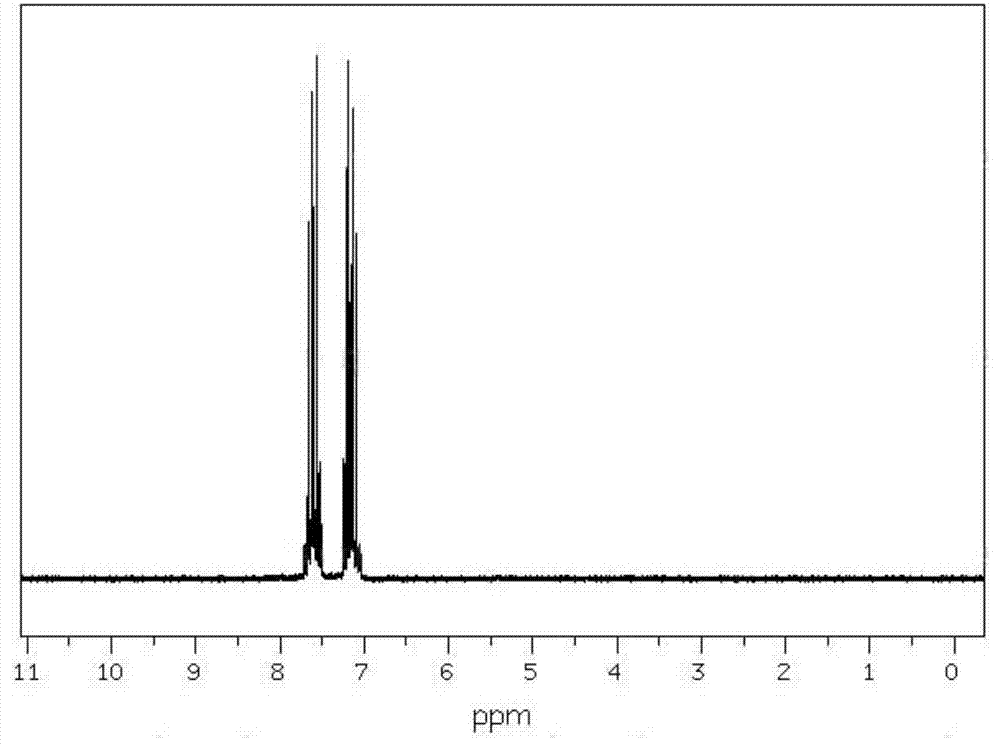

Method of synthesizing o-dibromobenzene by diazotization in one step at high temperature

The invention relates to the technical field of preparation of o-dibromobenzene, and particularly relates to a method of synthesizing o-dibromobenzene by diazotization in one step at high temperature. The method comprises the following steps: sequentially adding hydrobromic acid, cuprous oxide and bromaniline into a reactor with a stirrer, a condenser and a thermometer; heating to over 80 DEG C; maintaining the temperature within 80-100 DEG C; dropping aqueous solution of sodium nitrite under liquid level; after dropping, distilling with steam to obtain the product, and separating out the oil layer; washing once by thermonatrite; after washing once, distilling under reduced pressure to obtain a product. According to the preparation method of o-dibromobenzene provided by the invention, diazotization and decomposition reaction are carried out by using a one-step method, so that the energy consumption and investment on freezing equipment are greatly reduced, and the product is stable in yield, and yield fluctuation caused by refrigeration of a two-step method is avoided. The continuous production capacity is greatly improved, the quality of the product is consistent with that of the two-step method, the yield is slightly higher, the preparation process is simple, convenient and feasible, the product is good in quality, and the technical demand is low, so that the method is a method suitable for industrialized production.

Owner:常州市正锋光电新材料有限公司

Method of synthesizing o-dibromobenzene by diazotization in one step at high temperature

The invention relates to the technical field of preparation of o-dibromobenzene, and particularly relates to a method of synthesizing o-dibromobenzene by diazotization in one step at high temperature. The method comprises the following steps: sequentially adding hydrobromic acid, cuprous oxide and bromaniline into a reactor with a stirrer, a condenser and a thermometer; heating to over 80 DEG C; maintaining the temperature within 80-100 DEG C; dropping aqueous solution of sodium nitrite under liquid level; after dropping, distilling with steam to obtain the product, and separating out the oil layer; washing once by thermonatrite; after washing once, distilling under reduced pressure to obtain a product. According to the preparation method of o-dibromobenzene provided by the invention, diazotization and decomposition reaction are carried out by using a one-step method, so that the energy consumption and investment on freezing equipment are greatly reduced, and the product is stable in yield, and yield fluctuation caused by refrigeration of a two-step method is avoided. The continuous production capacity is greatly improved, the quality of the product is consistent with that of the two-step method, the yield is slightly higher, the preparation process is simple, convenient and feasible, the product is good in quality, and the technical demand is low, so that the method is a method suitable for industrialized production.

Owner:常州市正锋光电新材料有限公司

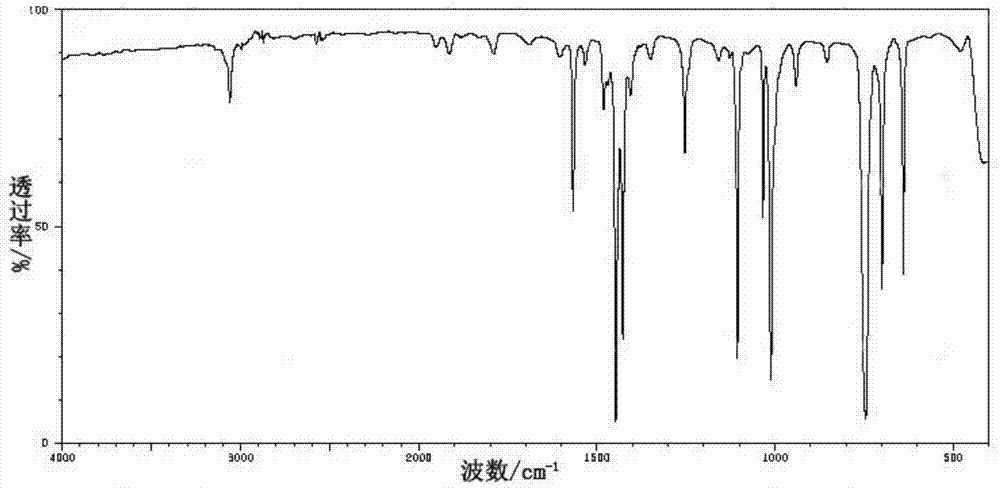

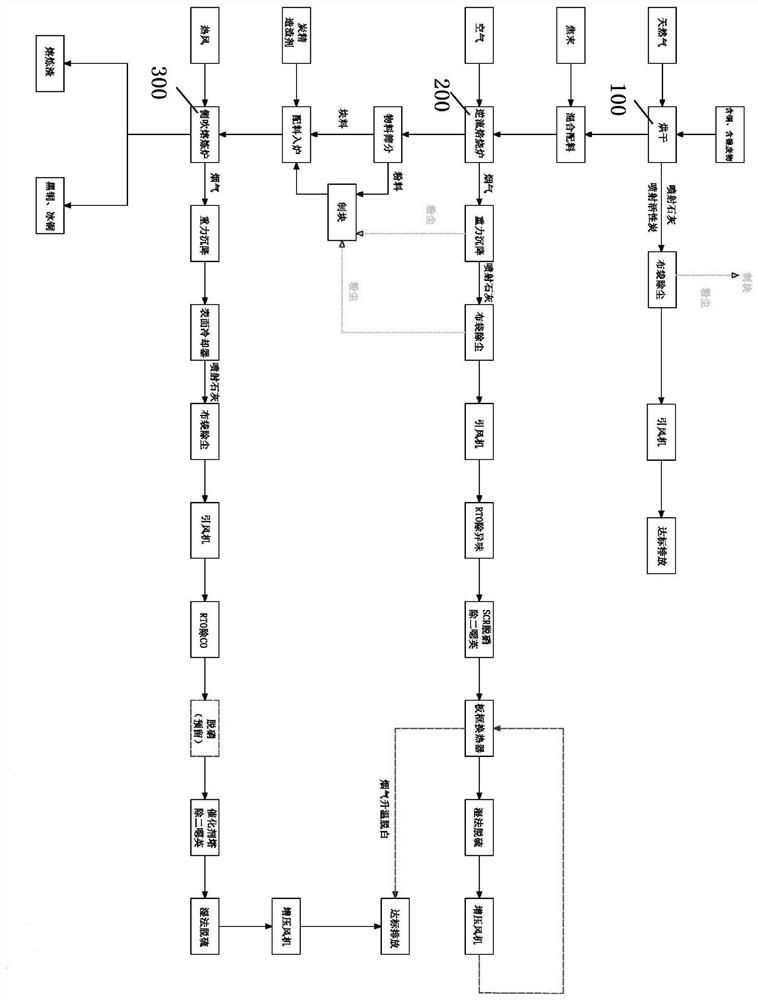

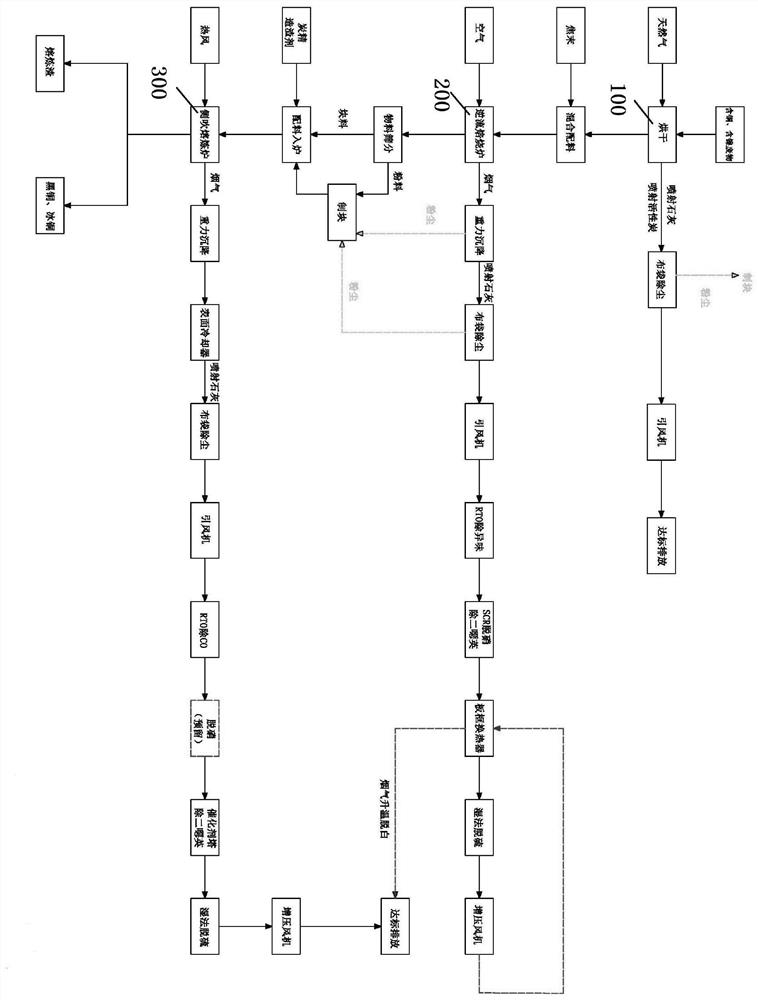

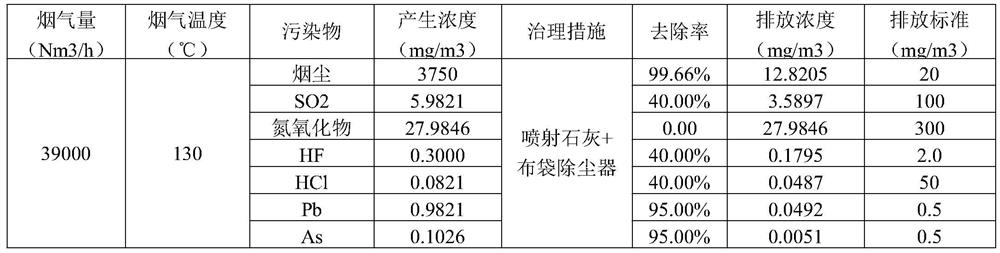

Treatment process for recycling copper-containing waste and purifying flue gas

ActiveCN112973408AIncrease the level of automationEnhance production connectionCombination devicesSludge treatment by de-watering/drying/thickeningActivated carbonSurface cooling

The invention belongs to the technical field of flue gas and waste gas purification treatment, and particularly relates to a treatment process for recycling copper-containing waste and purifying flue gas, which comprises the following steps: flue gas purification in a drying process: a flue gas purification process route is slaked lime dry deacidification, activated carbon injection, cloth bag dust removal, an induced draft fan and a chimney; the flue gas purification in the roasting process: the flue gas purification process route comprises gravity settling, slaked lime dry-process deacidification, cloth bag dust removal, induced draft fan, RTO, SCR denitration synergistic catalyst dioxin removal, a GGH plate heat exchanger, limestone, gypsum wet-process deacidification, a booster fan and the chimney; and the flue gas purification in the smelting process: the flue gas purification process route comprises gravity settling, surface cooling, slaked lime dry deacidification, cloth bag dust removal, an induced draft fan, RTO, dioxin removal by a catalyst reaction tower, limestone, gypsum wet deacidification, the booster fan and the chimney. The process provided by the invention achieves the purposes of safe transformation, environmental protection, energy conservation and emission reduction, and has important significance for improving the local ecological environment.

Owner:无锡江丰资源再生有限公司

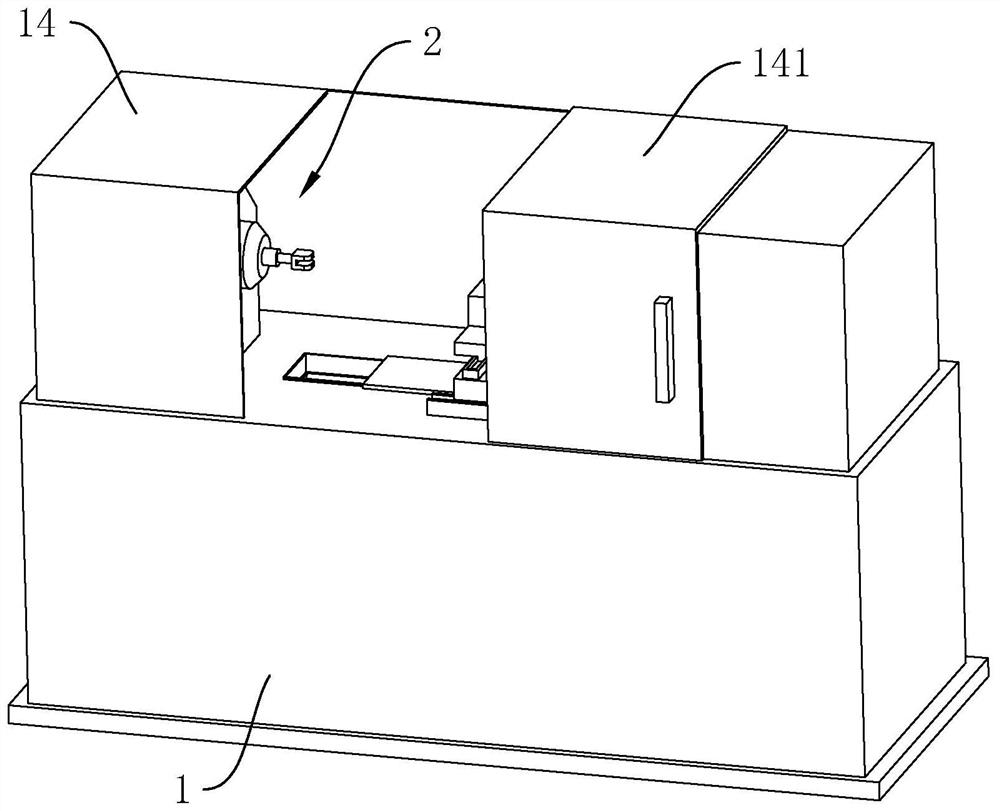

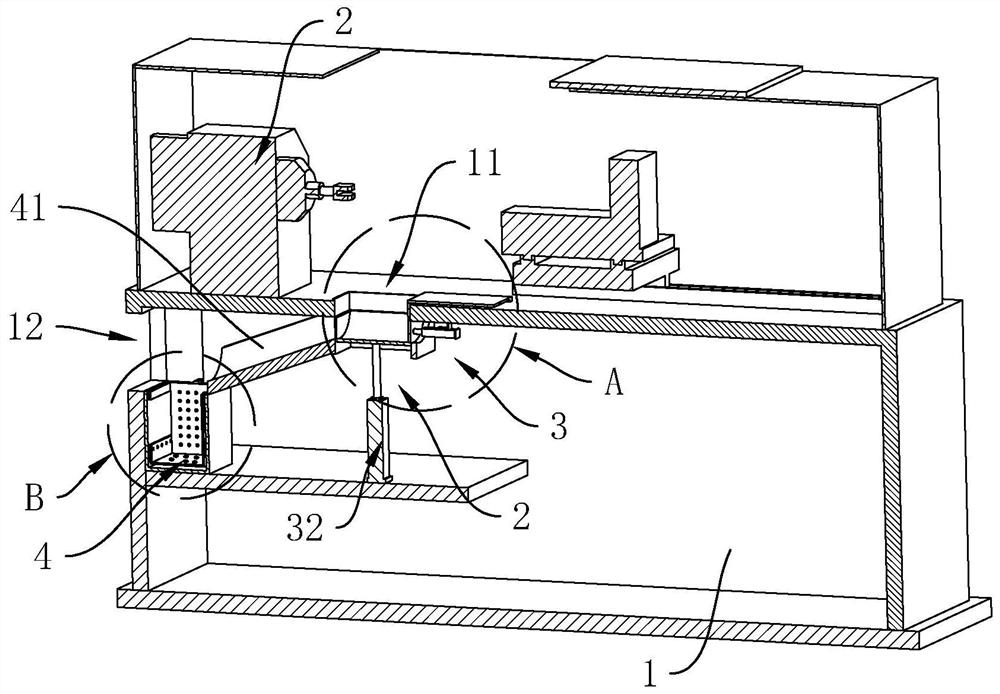

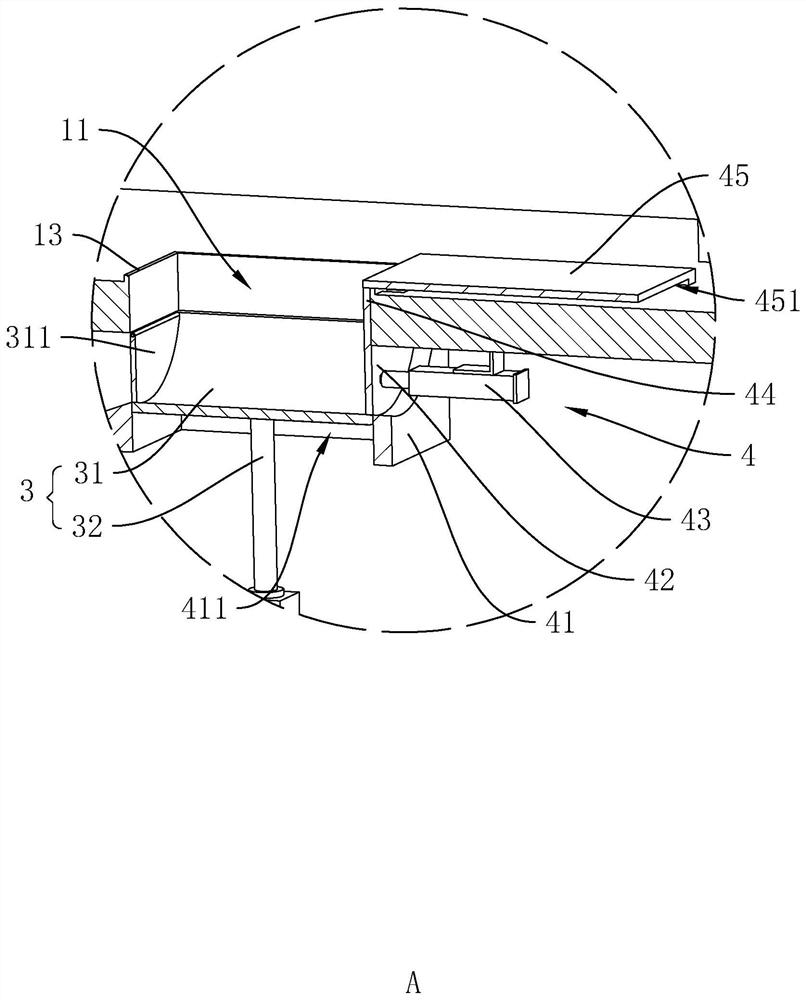

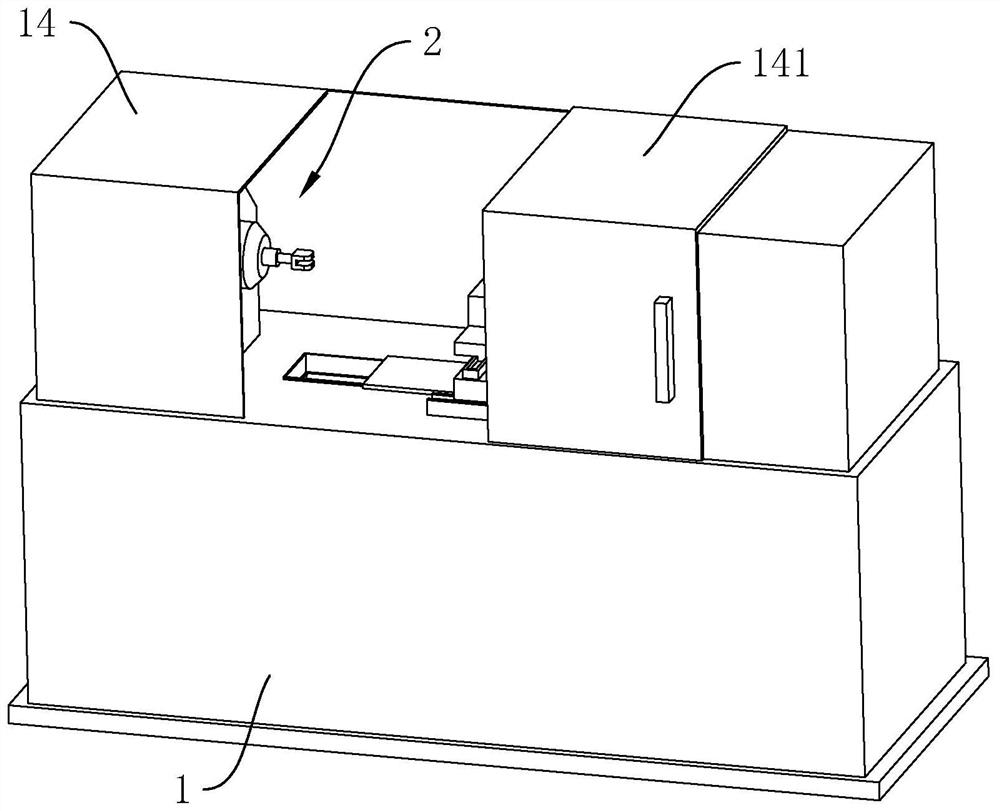

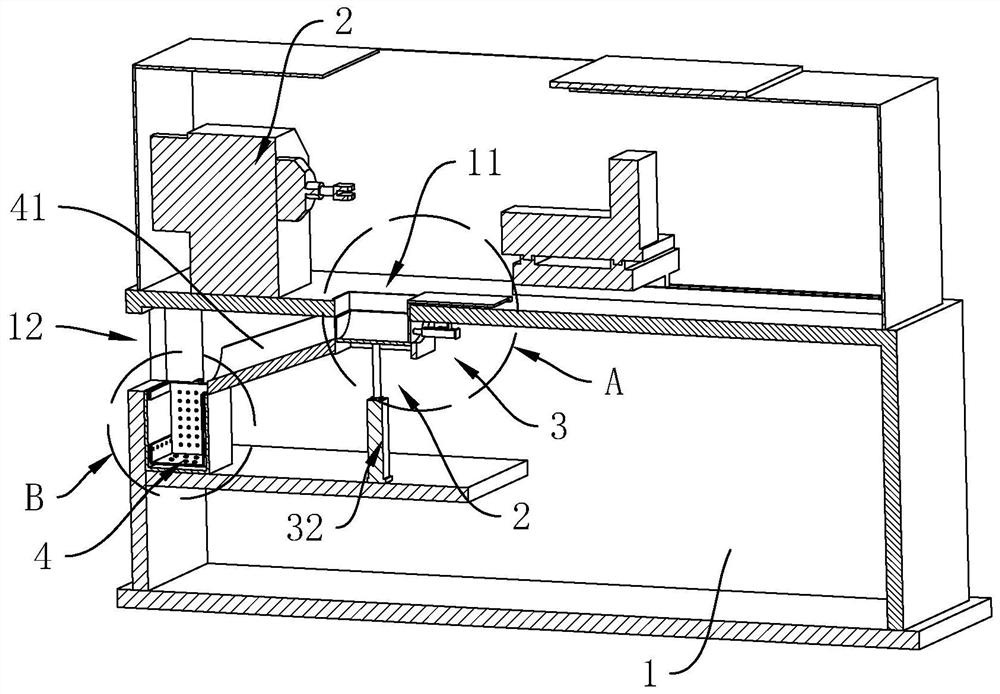

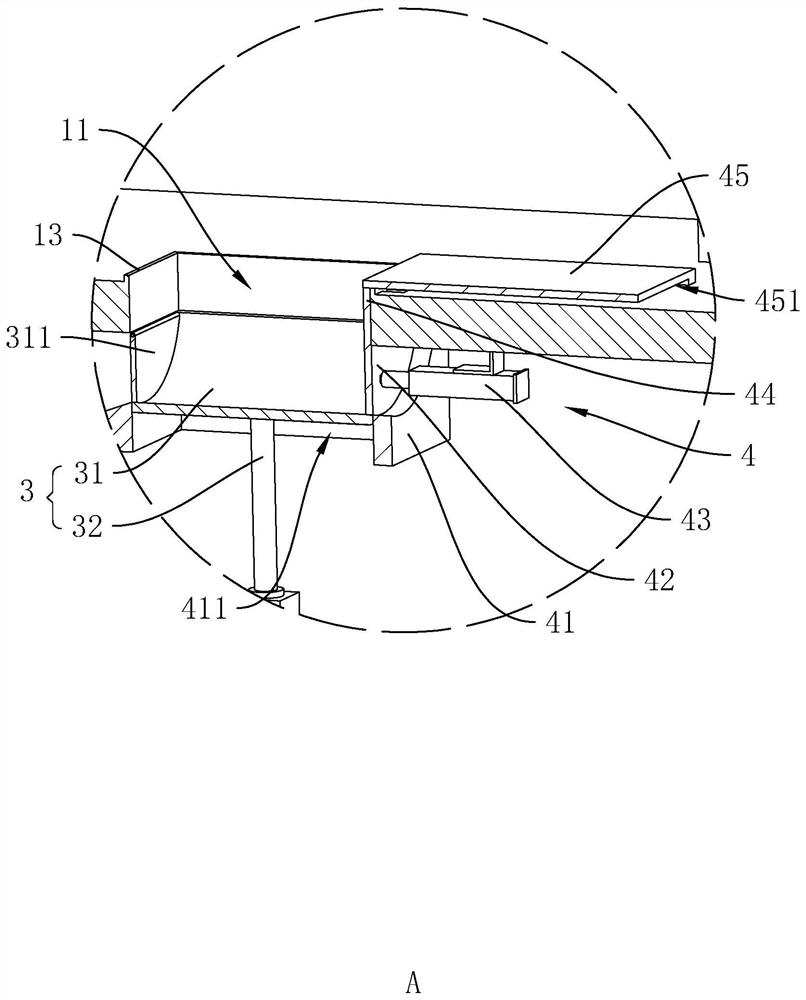

Automatic lathe capable of taking materials conveniently

ActiveCN113385700AAvoid accidentsImprove securityAuxillary equipmentPositioning apparatusEngineeringMachine tool

The invention relates to an automatic lathe capable of taking materials conveniently. The automatic lathe comprises a machine tool and a clamping mechanism, and the clamping mechanism is arranged on the machine tool and used for clamping workpieces. The automatic lathe further comprises a material receiving mechanism, a feeding mechanism and a material collecting mechanism, the material receiving mechanism comprises a material receiving plate and a first driving part, a material receiving opening matched with the material receiving plate is formed in the position, at the clamping mechanism, of the top of the machine tool, the first driving part can drive a material receiving disc to move up and down along the material receiving opening, a discharging opening is formed in one side of the machine tool, when the material receiving plate is located below the material receiving opening, the feeding mechanism is used for conveying the workpieces on the material receiving plate to the discharging opening, and the material collecting mechanism is used for collecting the workpieces at the discharging opening. The automatic lathe has the effects that workers can conveniently take out machined workpieces, the workpiece machining continuity is improved, and then the production efficiency is improved.

Owner:深圳市鲲鹏精密机械有限公司

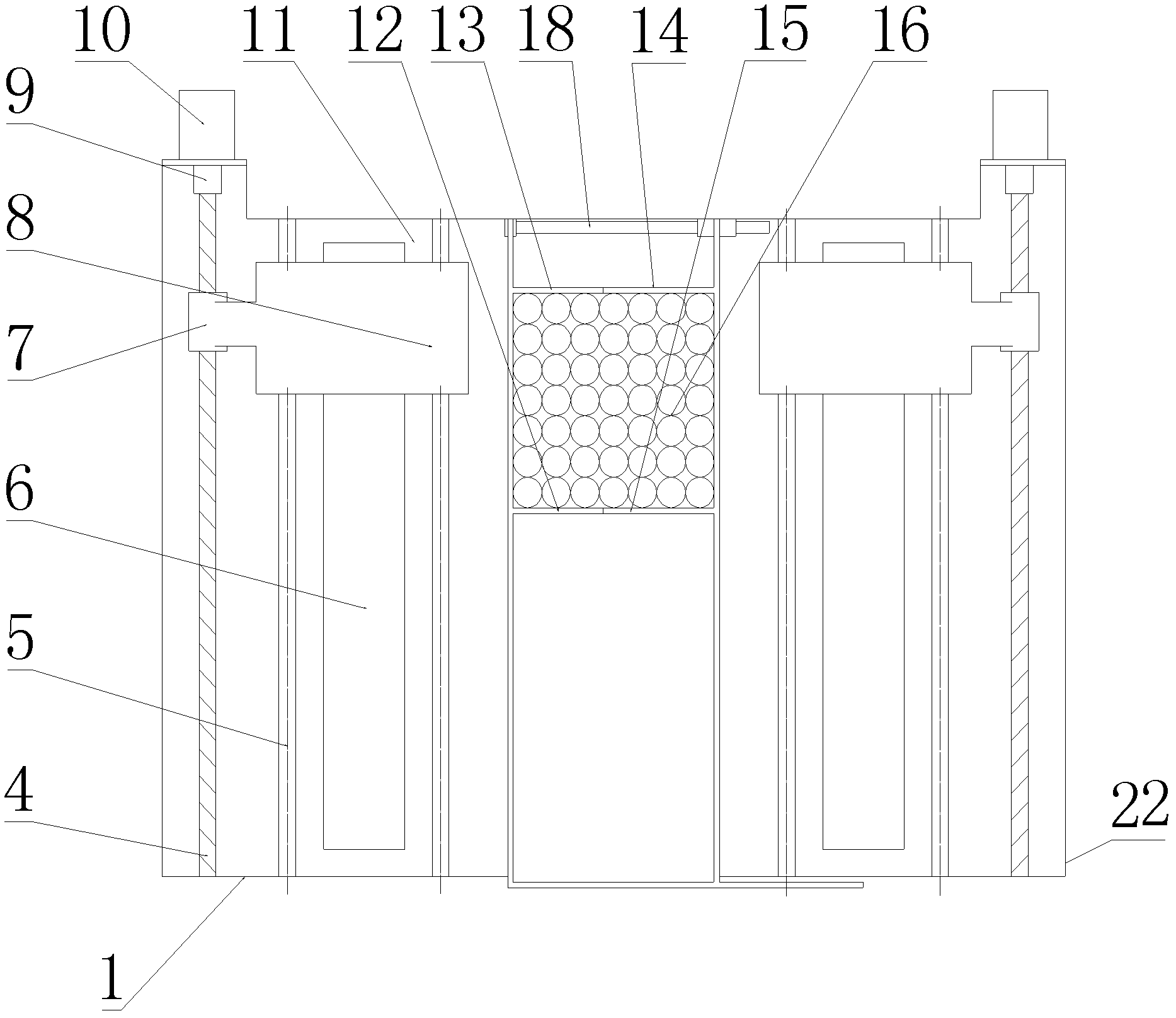

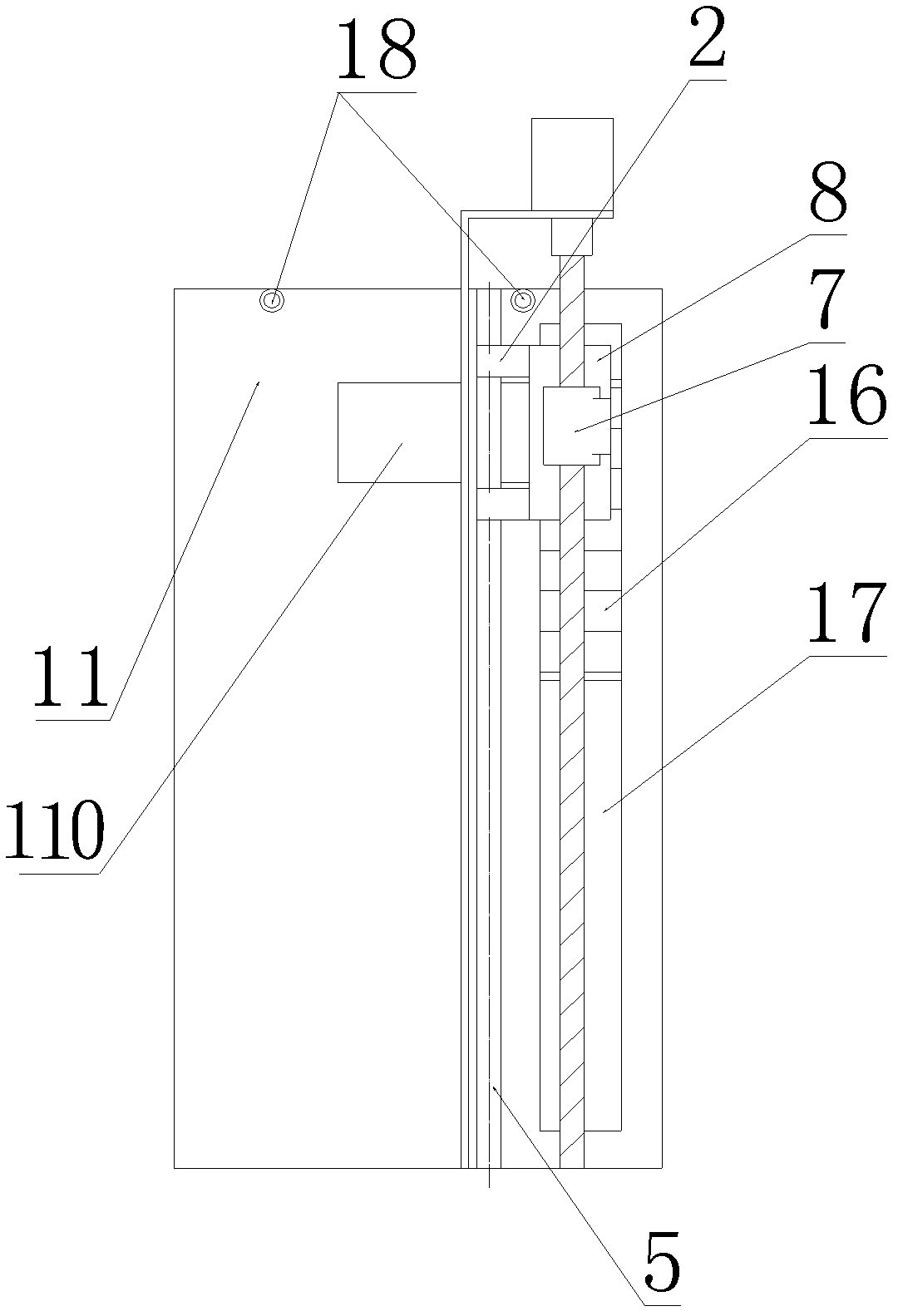

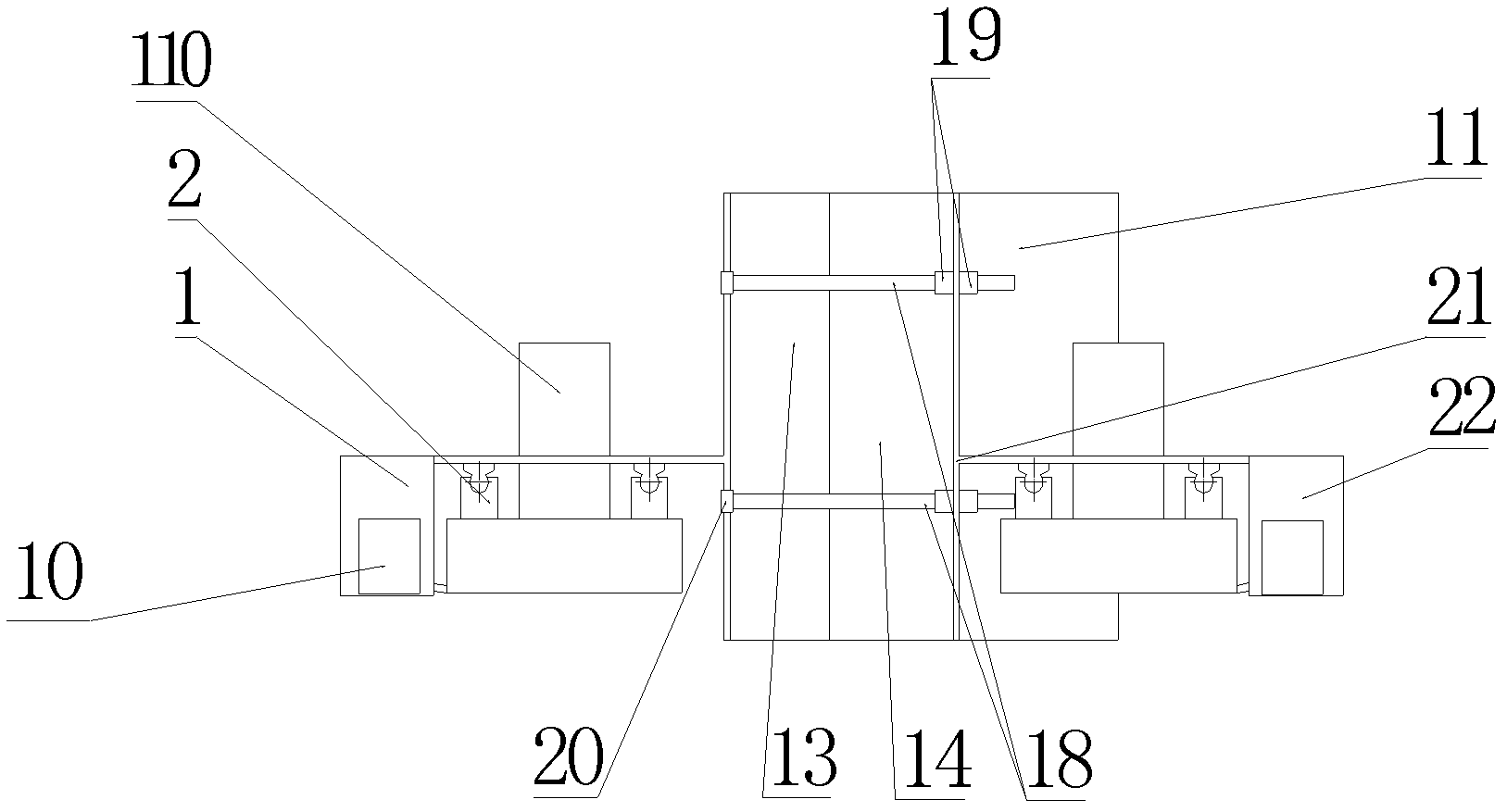

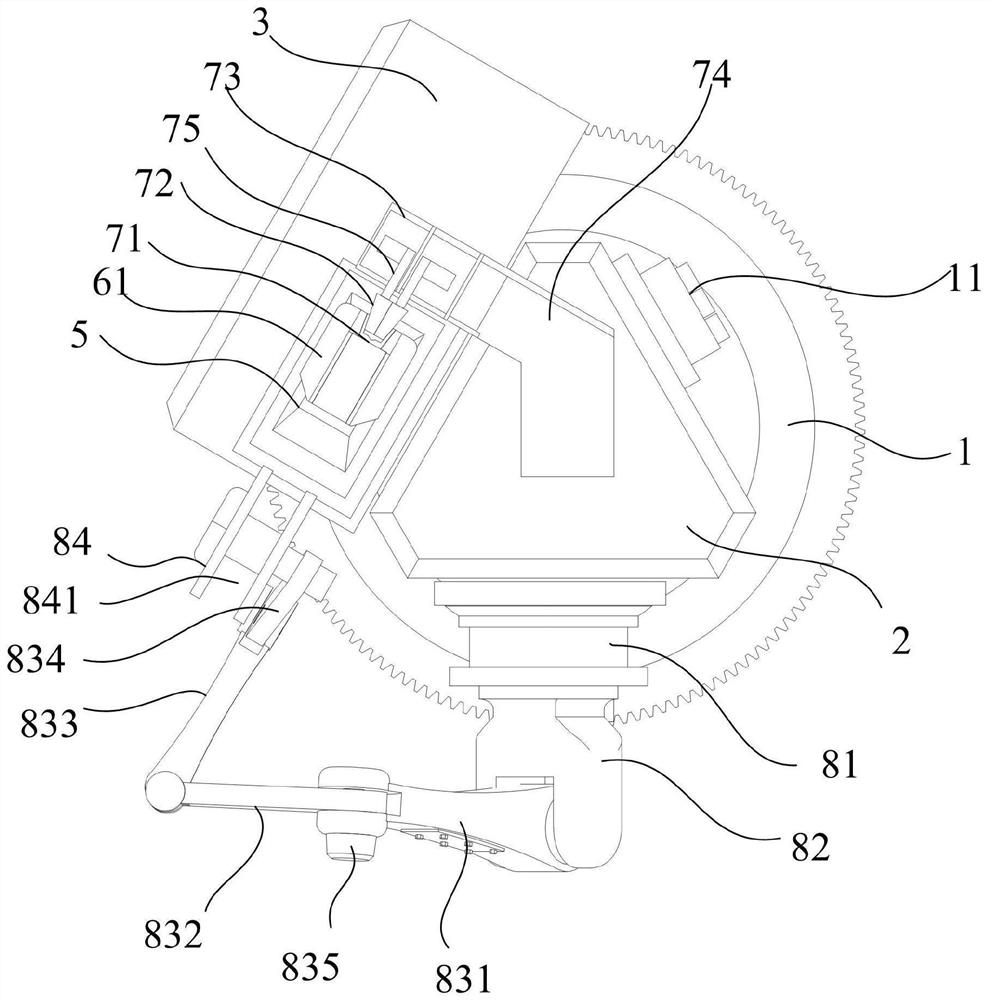

Enclosure system for firework assembly machine

The invention discloses an enclosure system for a firework assembly machine, which comprises a firework combination positioning frame with a width adjusting device. Two lateral plates of the firework combination positioning frame are provided with lead inserting openings, two positioning frames are arranged on two sides of the firework combination positioning frame, and at least one of the positioning frames is provided with a bilateral linear moving device. Two punching lead-inserting mechanisms capable of vertically linearly moving are disposed on the two positioning frames respectively, device positions of the punching lead-inserting mechanisms correspond to the lead inserting openings, and a vertically-moving driving device is arranged on each punching lead-inserting mechanism. Enclosure can be automatically completed by means of the system, production efficiency is improved greatly, and production cost is reduced. The enclosure system is adaptable to changes of firework tube specifications, equipment continuous production performance is improved, and equipment regulation and maintenance workload can be greatly reduced.

Owner:谷雨鹏

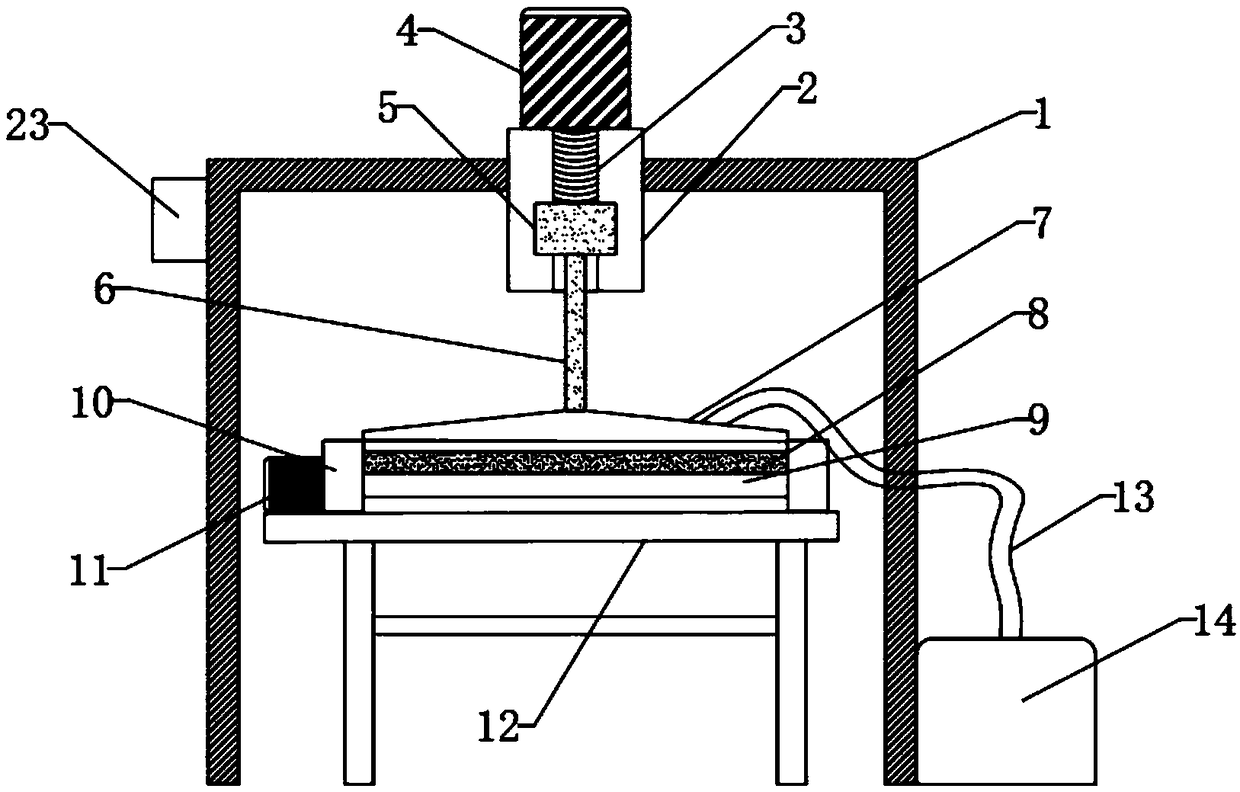

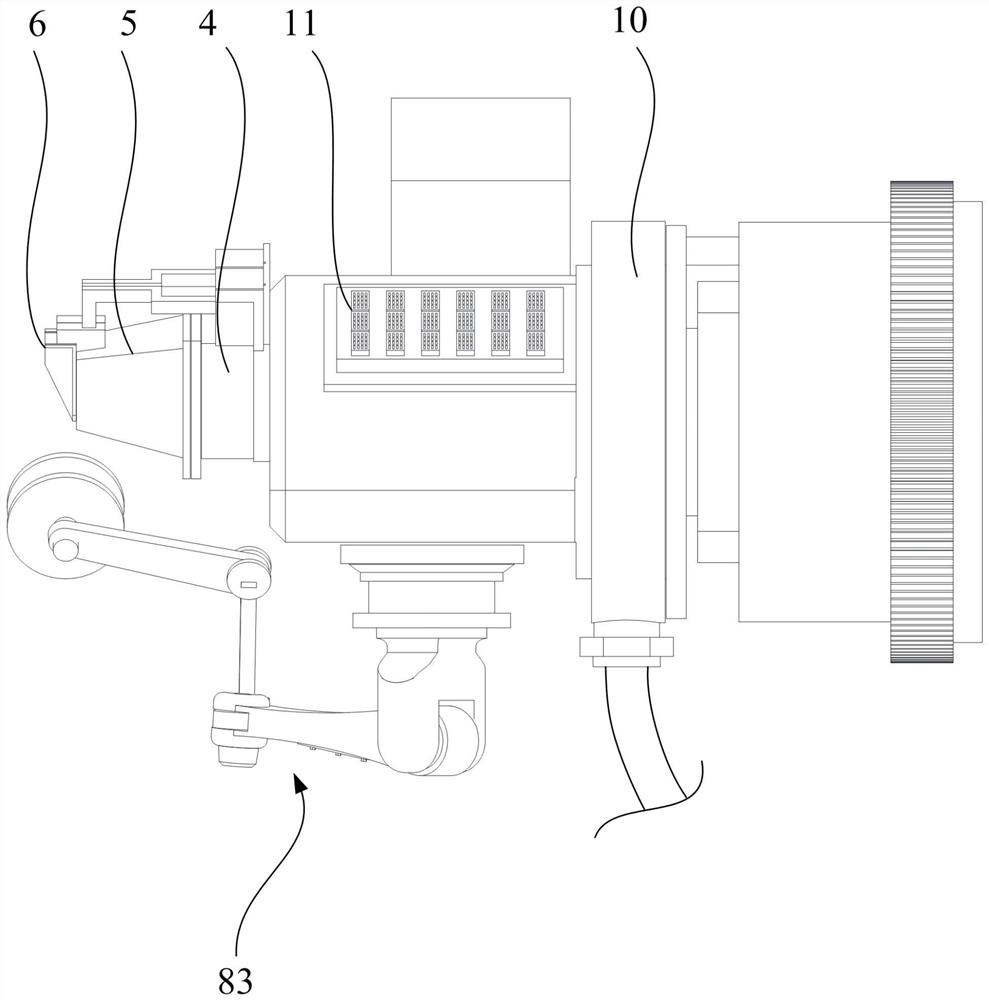

Automatic polishing numerical control device

InactiveCN108857829ASimple structureEasy to operatePolishing machinesAutomatic grinding controlProgrammable logic controllerContinuous production

The invention discloses an automatic polishing numerical control device. The automatic polishing numerical control device comprises a stepping motor, a conveyer motor, a cyclone dust collector, a polishing disk, a polishing motor, a pressure sensor and a PLC (programmable logic controller), wherein the stepping motor is fixed above the top of a fixing plate, and the surface of the fixing plate isfixedly provided with a screw; the bottom of the polishing motor is fixedly connected with a push rod, the bottom end of the push rod is fixedly connected with a polishing disk, the top of the polishing disk is fixedly connected with a polishing cover, and the bottom of the polishing disk is provided with a plate to be polished; the bottom of the conveyer motor is fixedly provided with a bottom rack, and the polishing cover and the cyclone dust collector are connected through a dust collecting pipe; the internal top end of a limiting block is fixedly provided with the pressure sensor; the lefttop end of a support frame is fixedly provided with the PLC. The automatic polishing numerical control device is simple in structure, convenient to operate, high in automation degree and capable of achieving full automation and increasing the production efficiency and yield; by means of the cyclone dust collector, the automatic polishing numerical control device can rapidly and timely clean dustto provide a comfortable polishing environment and accordingly to improve the continuous production capacity.

Owner:芜湖遥帆电子科技有限公司

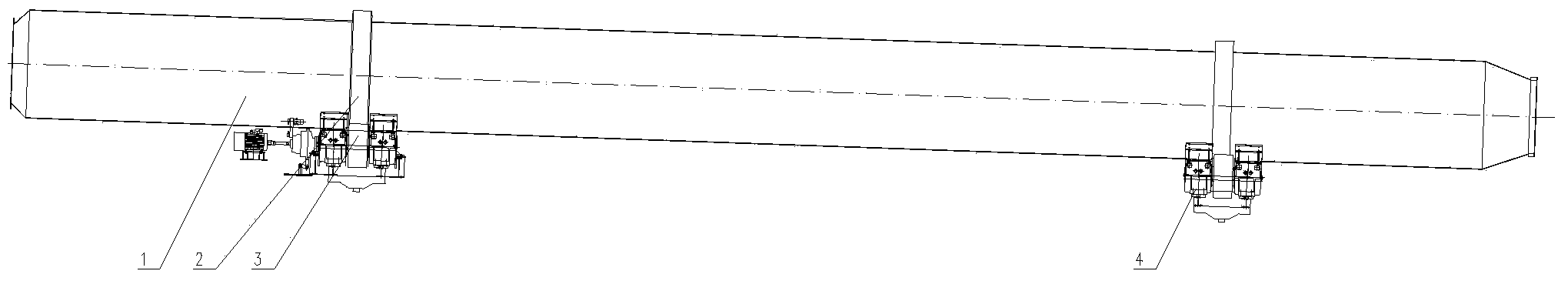

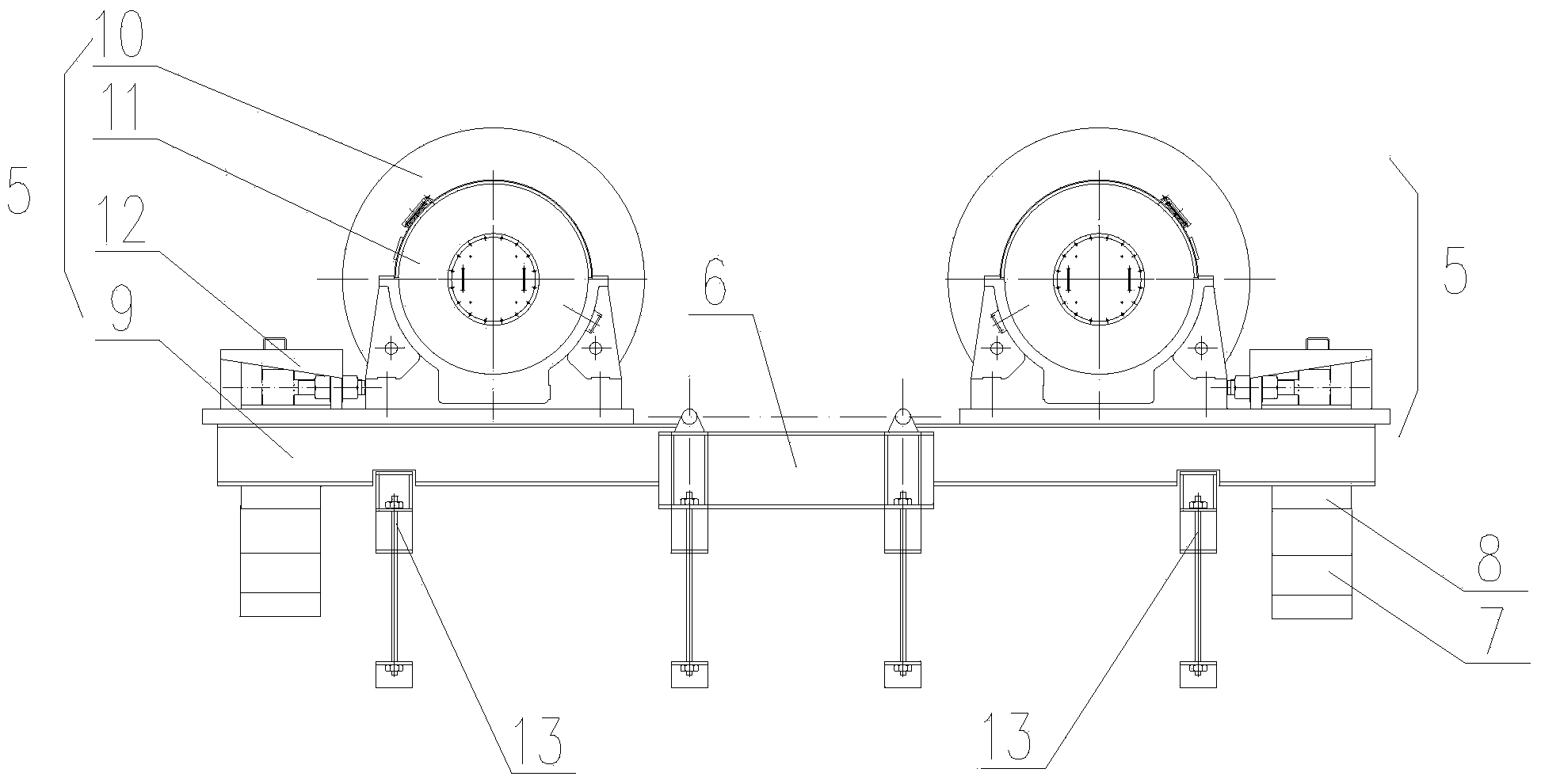

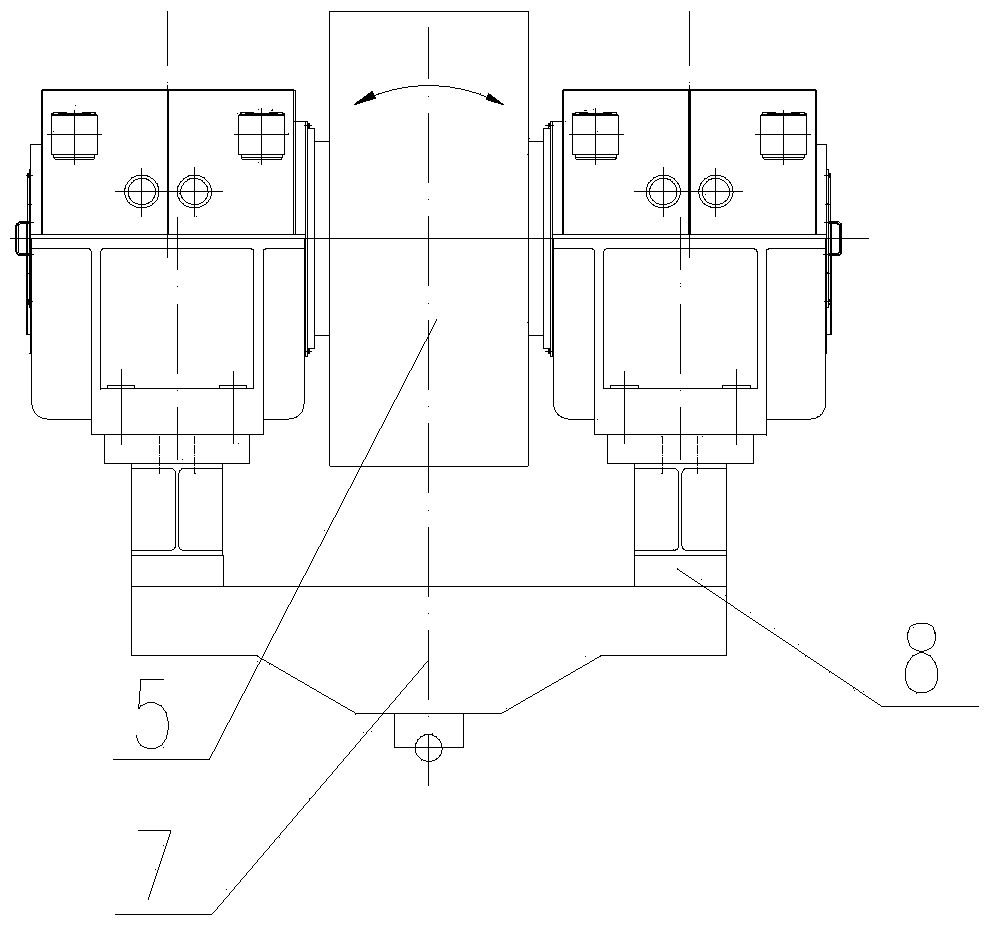

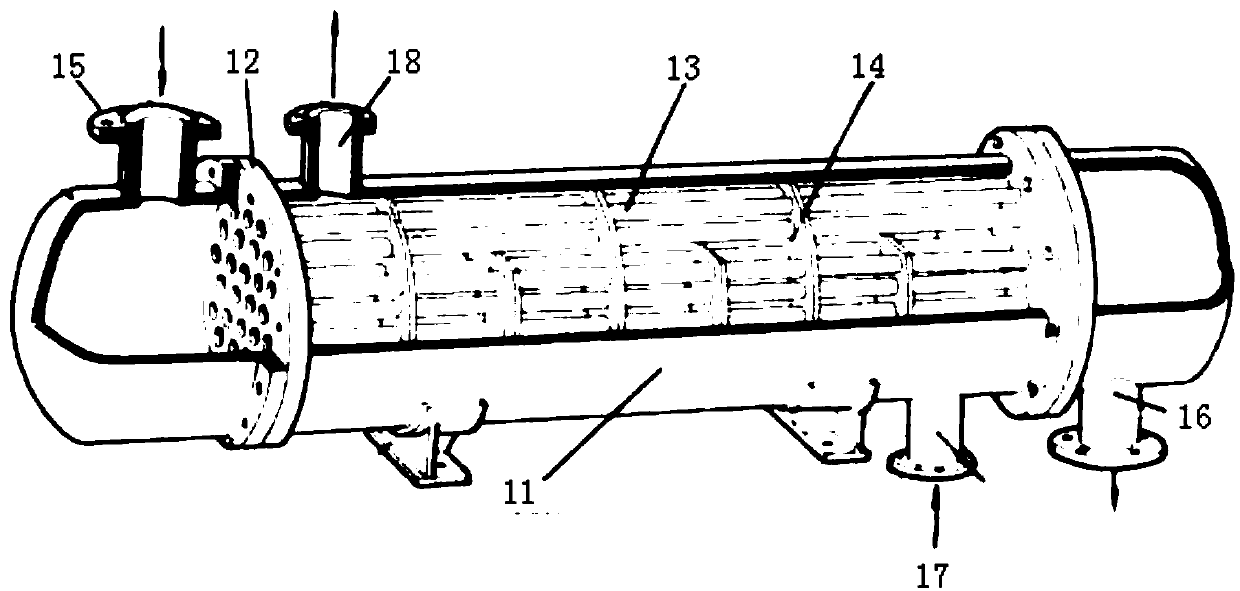

Self-centering friction drive lime rotary kiln

ActiveCN103591794BImprove the ability of continuous productionReduce maintenance costsRotary drum furnacesEngineeringMiddle line

The invention relates to the field of rotary kilns for producing lime, in particular to a self-centering friction drive lime rotary kiln. The self-centering friction drive lime rotary kiln comprises a driving riding wheel set, a driven riding wheel set, a kiln body and rolling rings. The driving riding wheel set and the driven riding wheel set are arranged below the kiln body, wherein the driving riding wheel set is matched with the rolling ring on the feed side of the kiln body. The self-centering friction drive lime rotary kiln is characterized in that the driven riding wheel set comprises two riding wheel devices which are the same in structure and are symmetrically arranged, the opposite sides of the two riding wheel devices are hinged to the two ends of a central base plate respectively, a hinge beam is arranged below the bottom portions of the other sides of the two riding wheel devices, and an elastic rubber pad is arranged between the riding wheel devices and the hinge beam; when the driven riding wheel set makes contact with the other rolling ring, the central base plate is in a floating state. Compared with the prior art, the self-centering friction drive lime rotary kiln has the advantages that the centerlines of the riding wheel sets and the axes of the rolling rings of the kiln body are automatically centered, excessive abrasion to riding wheels and the rolling rings is avoided, the service life of the riding wheels and the service life of the rolling rings are prolonged, and maintenance cost, operation cost and investment cost of the kiln body are reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Cycling method for preparing iminodiacetic acid from iminodiacetic acid disodium salt

ActiveCN101445465BHigh purityCreate pollutionOrganic compound preparationAmino-carboxyl compound preparationIminodiacetic acidDesalination

The invention discloses a new cycling process for preparing iminodiacetic acid from iminodiacetic acid disodium salt by a freezing crystallization method. The method is characterized by comprising the following steps: taking the iminodiacetic acid disodium salt as a starting raw material; adding water and stirring to decolorize and dissolve the iminodiacetic acid disodium salt; adding concentrated sulfuric acid dropwise to control pH at 1.8-2.1; centrifuging to obtain the iminodiacetic acid; adding an alkaline matter to acid pregnant liquor until the pH equals 4-7; separating Na2SO4.10H2O out by crystallization at the temperature of 5-10 DEG C; performing vacuum filtration, and recycling the filtrate to continuously prepare the iminodiacetic acid (IDA), wherein, content and desalination rate of the IDA are above 98%, and the yield is about 97%. The pregnant liquor is not discarded in the production process and the whole process can have a plurality of cycles, thus improving production efficiency and utilization rate of the raw material, and avoiding environmental pollution.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

The treatment process of copper-containing waste recycling flue gas purification

ActiveCN112973408BIncrease the level of automationEnhance production connectionCombination devicesSludge treatment by de-watering/drying/thickeningPtru catalystDust control

The invention belongs to the technical field of flue gas and waste gas purification and treatment, and in particular relates to a treatment process for copper-containing waste recycling and utilization of flue gas purification, comprising the following steps: flue gas purification in a drying process; Acid + jet activated carbon + bag dust removal + induced draft fan + chimney"; flue gas purification in roasting process: flue gas purification process route is "gravity sedimentation + slaked lime dry deacidification + bag dust removal + induced draft fan + RTO + SCR denitration synergistic catalyst to remove two Oxygen + GGH plate heat exchanger + limestone-gypsum wet deacidification + booster fan + chimney"; smelting process flue gas purification: flue gas purification process route is "gravity sedimentation + surface cooling + slaked lime dry deacidification + cloth bag Dust removal + induced draft fan + RTO + catalyst reaction tower for dioxin removal + limestone-gypsum wet deacidification + booster fan + chimney"; the process of the invention achieves the purpose of reforming safety, environmental protection, energy saving and emission reduction, and has the advantages of improving the local ecological environment. important meaning.

Owner:无锡江丰资源再生有限公司

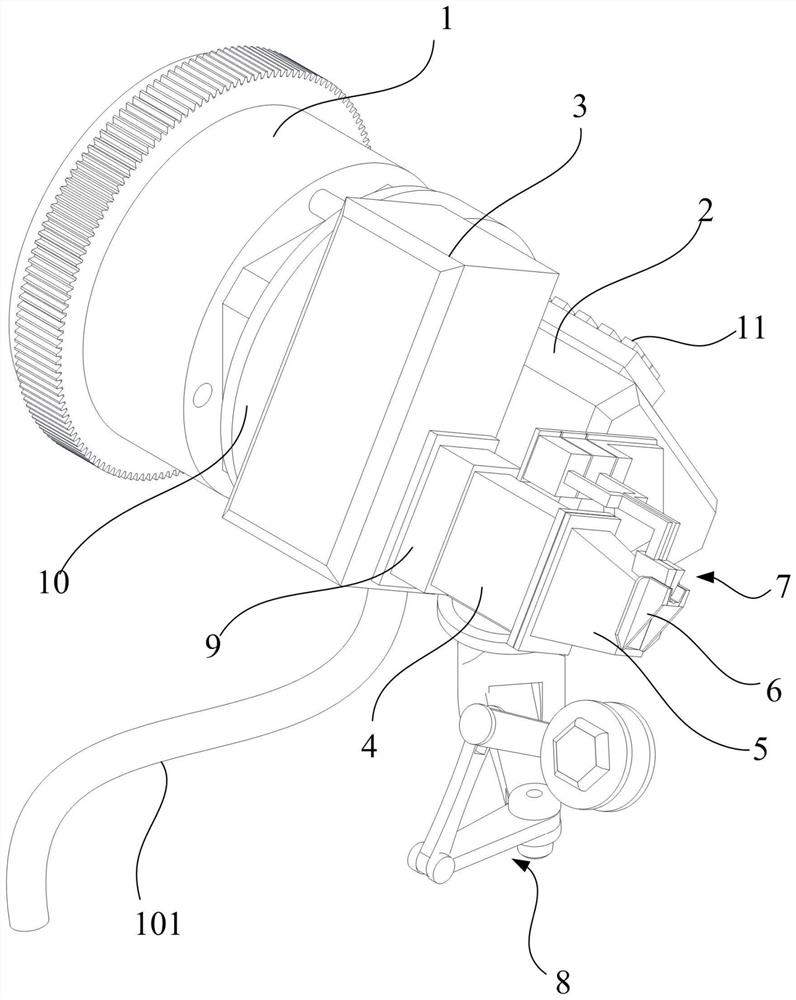

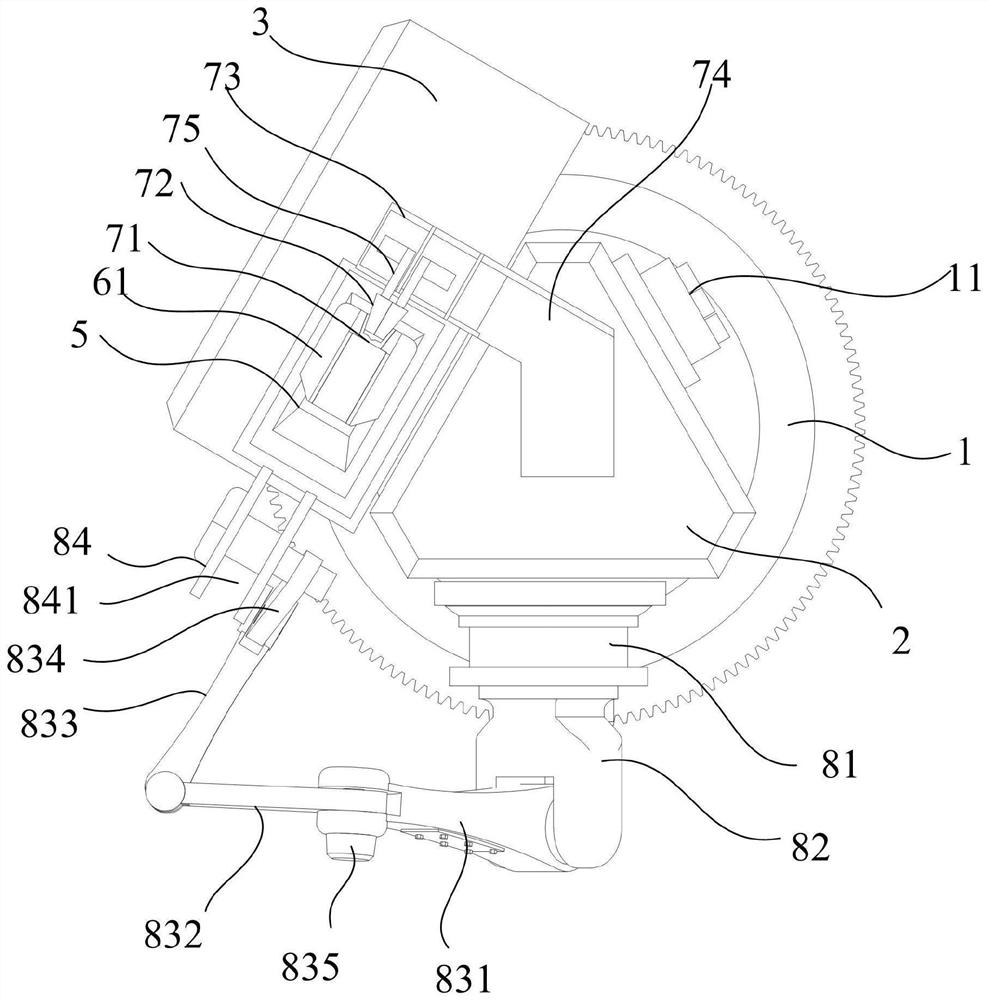

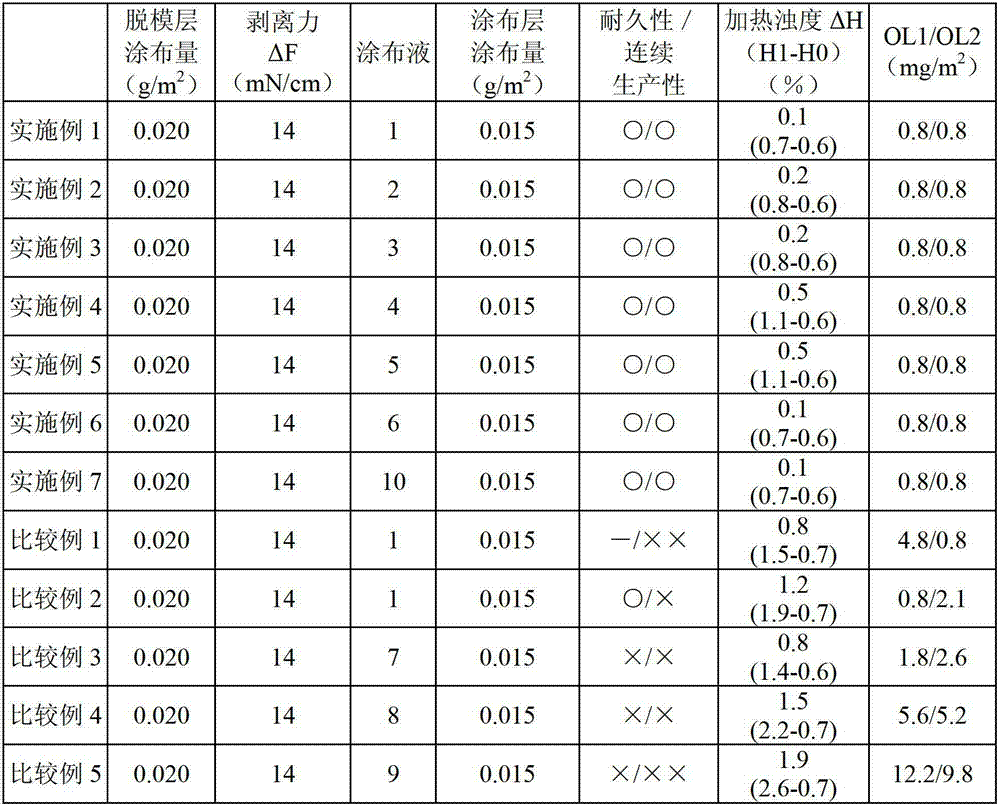

A thermoplastic spacer coating robot for insulating glass production

ActiveCN113117978BQuality assuranceQuality improvementLiquid surface applicatorsCoatingsRotary stageEngineering

The invention provides a thermoplastic spacer coating robot for hollow glass production, which includes a rotary table, a power supply, a frame, a driving mechanism, a mounting seat, a glue pump, an extrusion pipe and an extrusion nozzle. A prismatic compression pipe is arranged between the nozzles, and the extrusion nozzle includes two oppositely arranged splints. Between the splints, an ejection adjustment mechanism for controlling the diameter of the splint is arranged. There is a tracking and pressing mechanism on one side of the mounting seat, a glue flow device is arranged between the extrusion pipe and the glue pump, and a glue storage cavity is arranged inside the mounting seat, and the glue storage cavity is movably provided with a rotary connected to it. Glue mechanism. The device can extrude thermoplastic spacers with high connection quality through the use of an ejection adjustment mechanism and a splint. Coupled with the design of the tracking and pressing mechanism and the rotary gluing mechanism, the device has a high continuous production capacity. Reasonable design, suitable for large-scale promotion.

Owner:山东玻科数控设备有限公司

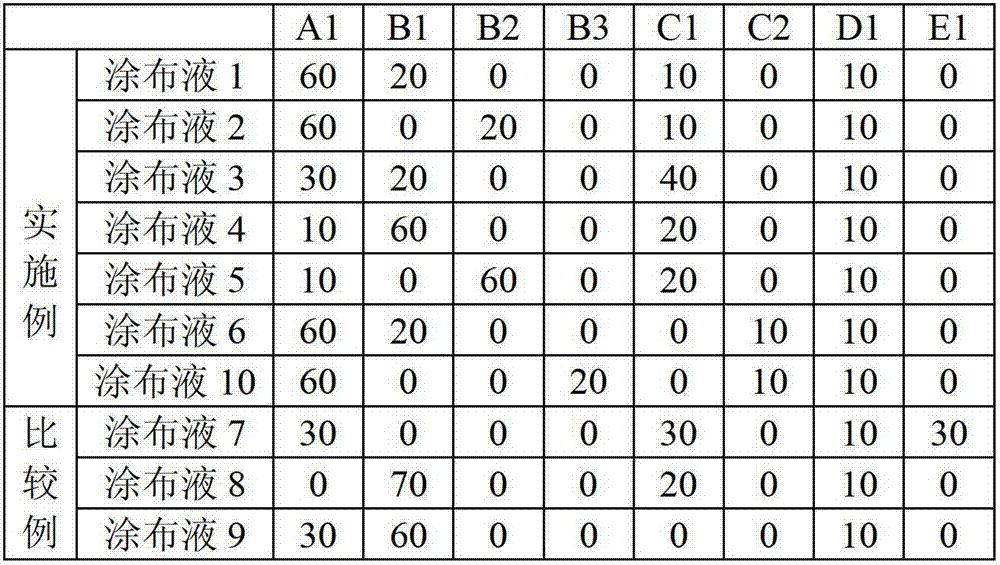

Release film

ActiveCN102648093BSuppress mix-inAvoid mixingSynthetic resin layered productsElectrical equipmentPolyesterPolymer science

Owner:MITSUBISHI CHEM CORP

Thermoplastic spacing bar coating robot for hollow glass production

ActiveCN113117978AQuality assuranceQuality improvementLiquid surface applicatorsCoatingsRotary stageGlass production

The invention discloses a thermoplastic spacing bar coating robot for hollow glass production. The thermoplastic spacing bar coating robot for hollow glass production comprises a rotating table, a power source, a rack, a driving mechanism, a mounting base, a gluing pump, an extrusion pipeline and an extrusion nozzle. A frustum-shaped compression pipeline is arranged between the extrusion pipeline and the extrusion nozzle, and the extrusion nozzle comprises two oppositely-arranged clamping plates. A spraying adjusting mechanism used for controlling the calibers of the clamping plates is arranged between the clamping plates. The spraying adjusting mechanism comprises a groove-shaped elastic piece, a wedge-shaped block and an air cylinder, a tracking profiling mechanism is arranged on one side of the mounting base, a glue flowing device is arranged between the extrusion pipeline and the gluing pump, a glue storage cavity is formed in the mounting base, and a rotary glue filling mechanism communicating with the glue storage cavity is movably arranged at the glue storage cavity. According to the thermoplastic spacing bar coating robot for hollow glass production, thermoplastic spacing bars with high connection quality can be extruded by adopting an ejection adjusting mechanism and the clamping plates, and the device has high continuous production capacity, is reasonable in design and is suitable for large-scale popularization due to the design of the tracking profiling mechanism and the rotary glue filling mechanism.

Owner:山东玻科数控设备有限公司

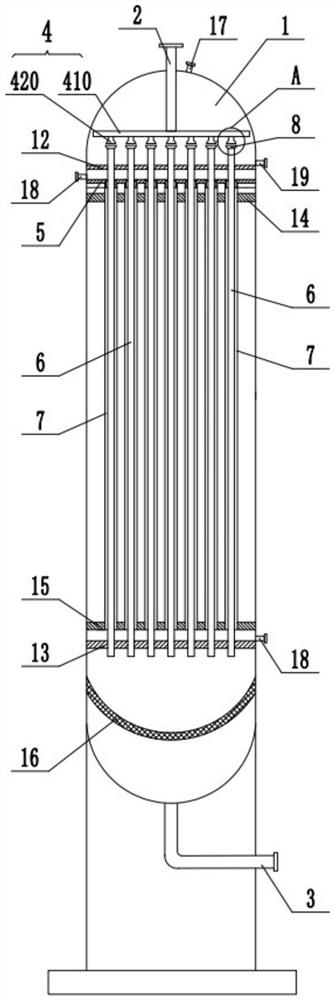

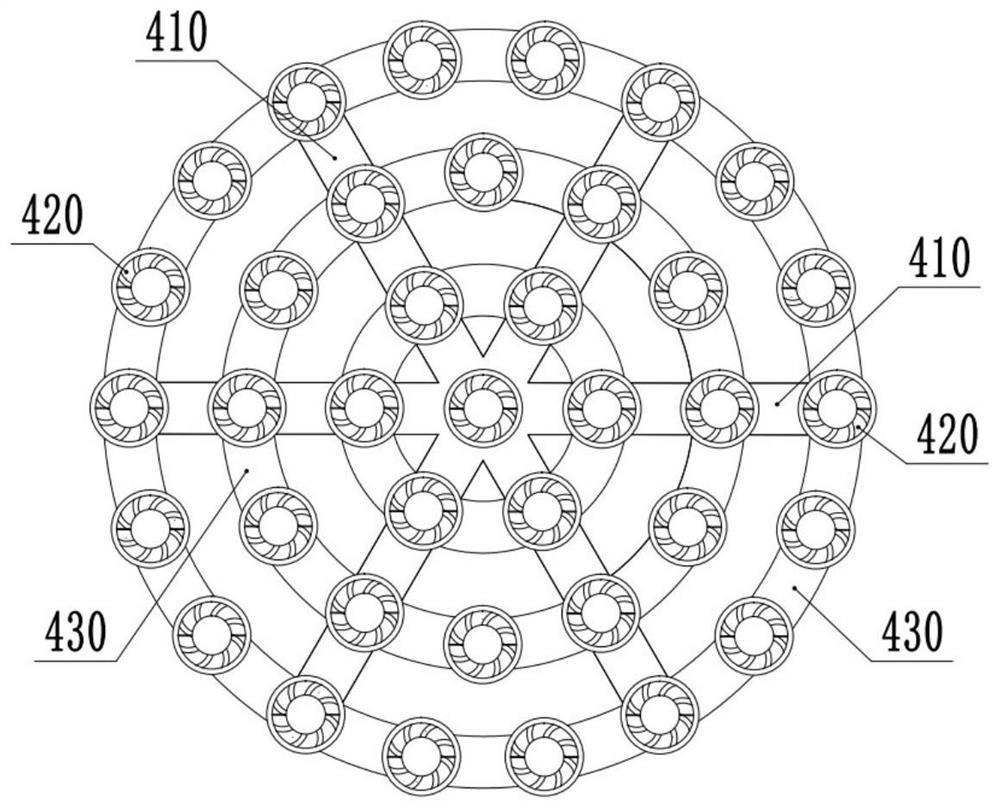

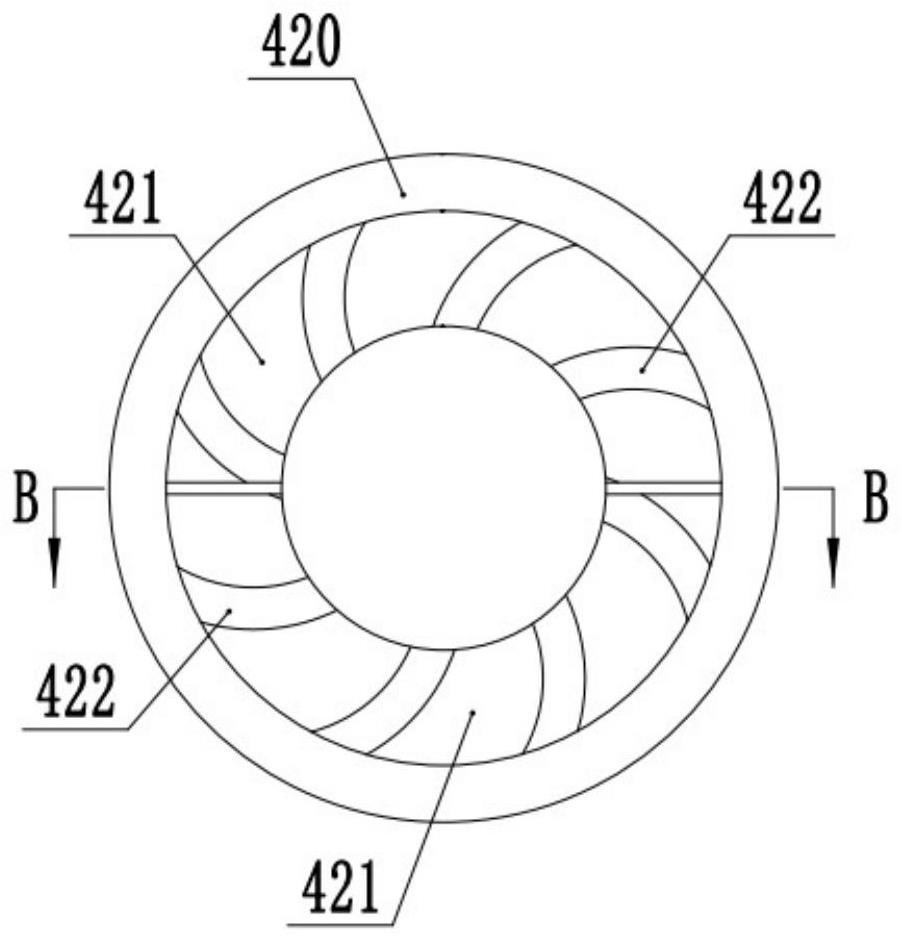

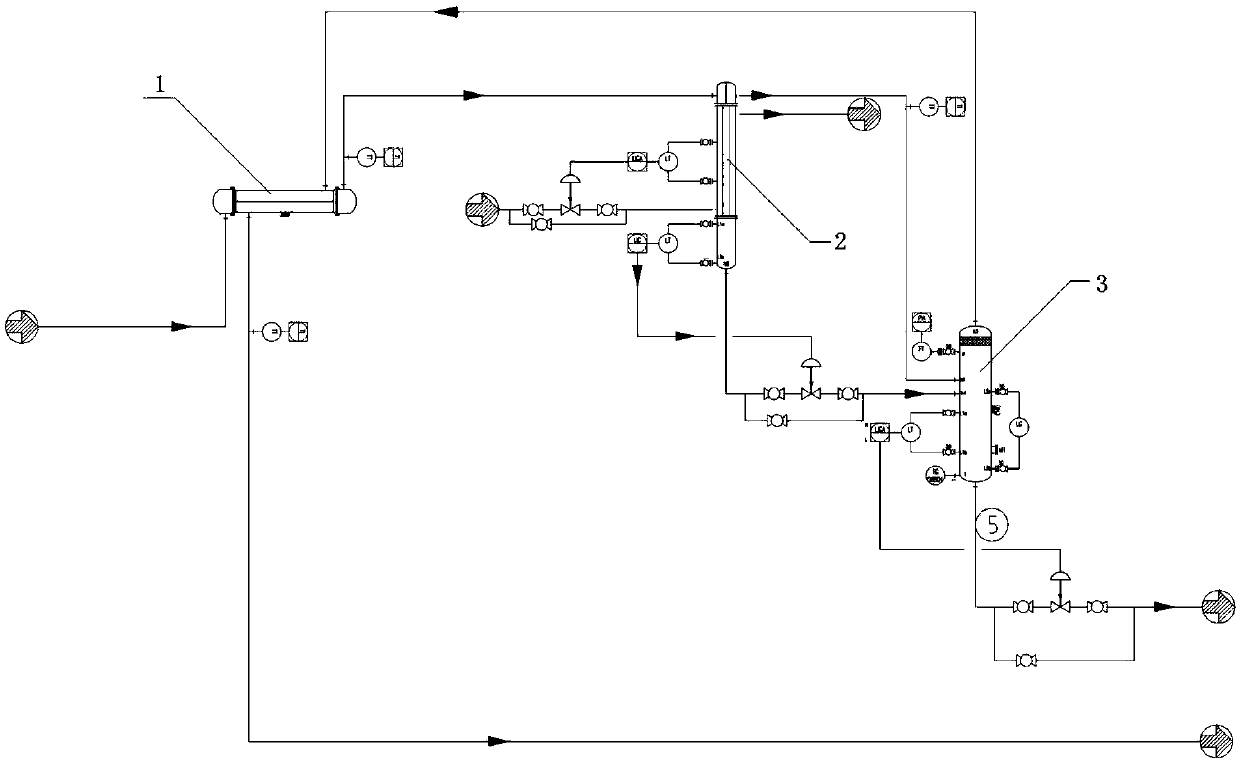

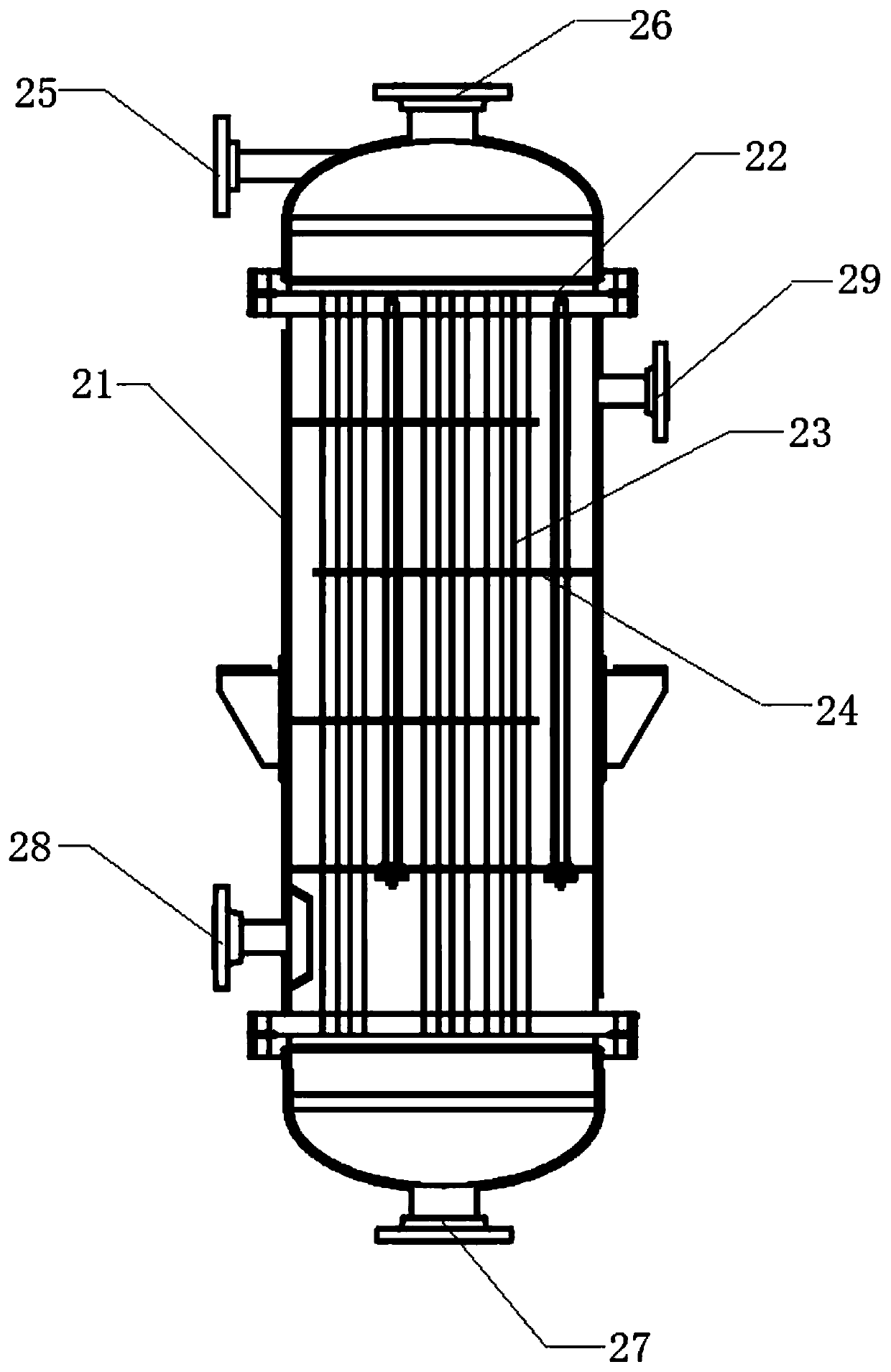

Continuous rotational flow falling film melt crystallizer

PendingCN114405050AHigh circumferential initial velocityUniform film formationSolution crystallizationStationary filtering element filtersMaterial distributionRotational flow

The invention belongs to the field of crystallization equipment, and particularly discloses a continuous rotational flow falling film melt crystallizer which comprises a material distribution pipe network and a plurality of crystallization pipes, the material distribution pipe network comprises a plurality of liquid distribution heads, the top of each crystallization pipe is communicated with a rotational flow film distribution head, and a first spiral flow guide groove is formed in the inner wall of each rotational flow film distribution head; the rotational flow film distribution heads are in one-to-one correspondence with the liquid separation heads, and emptying channels are reserved between the rotational flow film distribution heads and the corresponding liquid separation heads. According to the invention, the rotational flow film distribution head can enable the material to enter the crystallization pipe in a rotational flow manner, so that the material has a circumferential initial speed and slows down the radial aggregation situation, and the emptying channel can be used for discharging air in the crystallization pipe and is more favorable for the material to form rotational flow, thereby further enabling the material to uniformly form a film on the wall of the crystallization pipe, enabling the crystallization to be more uniform, and improving the crystallization efficiency. The uniformity of crystal thickness is improved, and crystals are not easy to fall off; and the materials are distributed on the wall of the crystallization pipe in a rotational flow manner, so that the flow speed of the materials is increased, the crystallization time is effectively shortened, and the crystallization efficiency is improved.

Owner:SHANGHAI DONGGENG CHEM TECH CO LTD

Forming system of firework assembling machine

The invention discloses a forming system of a firework assembling machine, which comprises a machine frame. Material receiving linear optical shafts, a screw rod and a screw rod driving device are arranged on the machine frame in the vertical direction, and a horizontally-arranged material receiving plate is fixedly connected with a linear optical shaft sliding sleeves and a screw rod moving sleeve. Two sides of the material receiving plate are provided with positioning forming frames with an adjustable interval. A material pressing rod parallel to the material receiving plate is arranged above the material receiving plate, and one end of the material pressing rod is fixedly connected with a lifting rod. The lower end of the lifting rod is correspondingly provided with a driving linear lifting device. The forming system connects and stacks a plurality of firework barrels with glued tops on the material receiving plate in a one-by-one mode, exerts pressure to enable the firework barrels to be bonded in a block mode and finishes the work that multiple rows of firework barrels are combined into a block-shaped whole. The forming system is stable in material receiving, reliable in work and accurate in stroke, continuous production performance of a device is improved, and debugging and maintenance work amount of the device is greatly decreased.

Owner:浏阳市百合机械制造有限公司

A heart-moving machine that is convenient for retrieving materials

ActiveCN113385700BAvoid accidentsImprove securityAuxillary equipmentPositioning apparatusEngineeringMachine tool

This application relates to a kind of centering machine that is convenient for taking materials, which includes a machine tool and a clamping mechanism, the clamping mechanism is provided on the machine tool for clamping workpieces, and also includes a material receiving mechanism, a material feeding mechanism and a material receiving mechanism, The material receiving mechanism includes a material receiving plate and a first driving member. The top of the machine tool is provided with a material receiving port matching the material receiving plate at the clamping mechanism, and the first driving member can drive the The material receiving tray moves up and down along the material receiving port, and a discharge port is provided on one side of the machine tool. When the material receiving plate is located below the material receiving port, the feeding mechanism is used to move the material receiving plate The workpieces are transported to the discharge port, and the receiving mechanism is used to collect the workpieces at the discharge port. The application has the effect of facilitating workers to take out processed workpieces, improving the continuity of workpiece processing, and further improving production efficiency.

Owner:深圳市鲲鹏精密机械有限公司

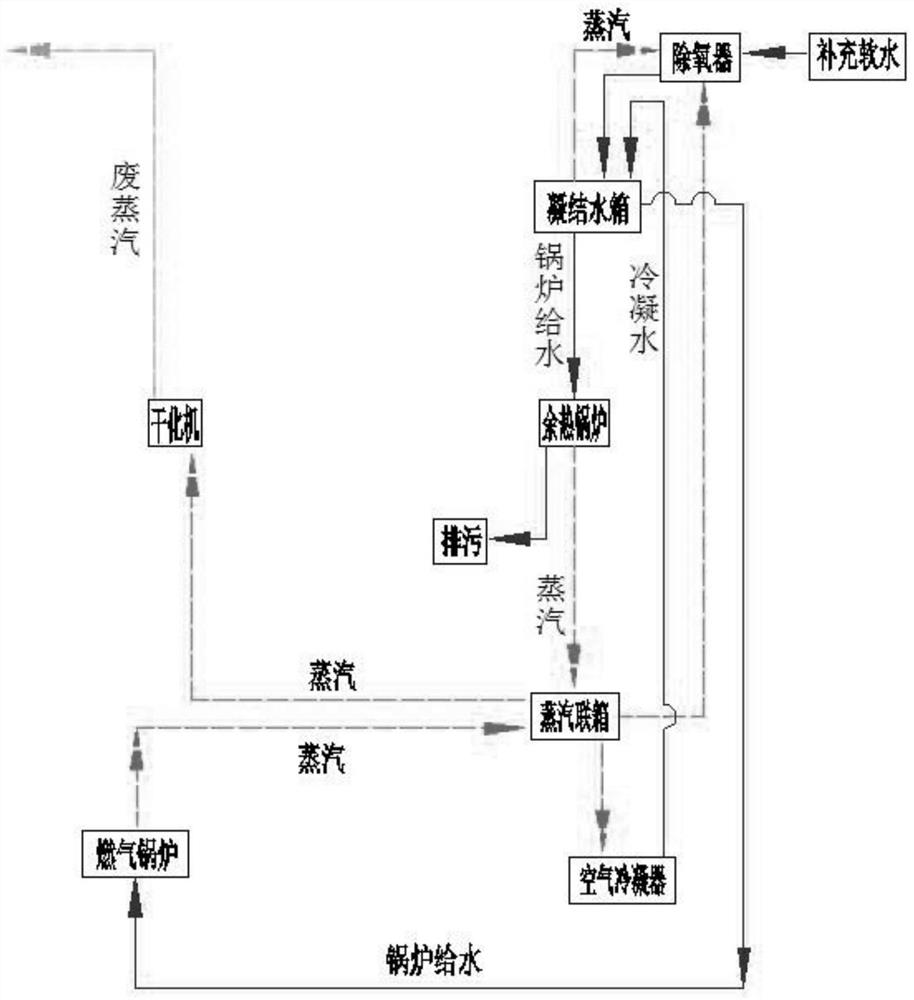

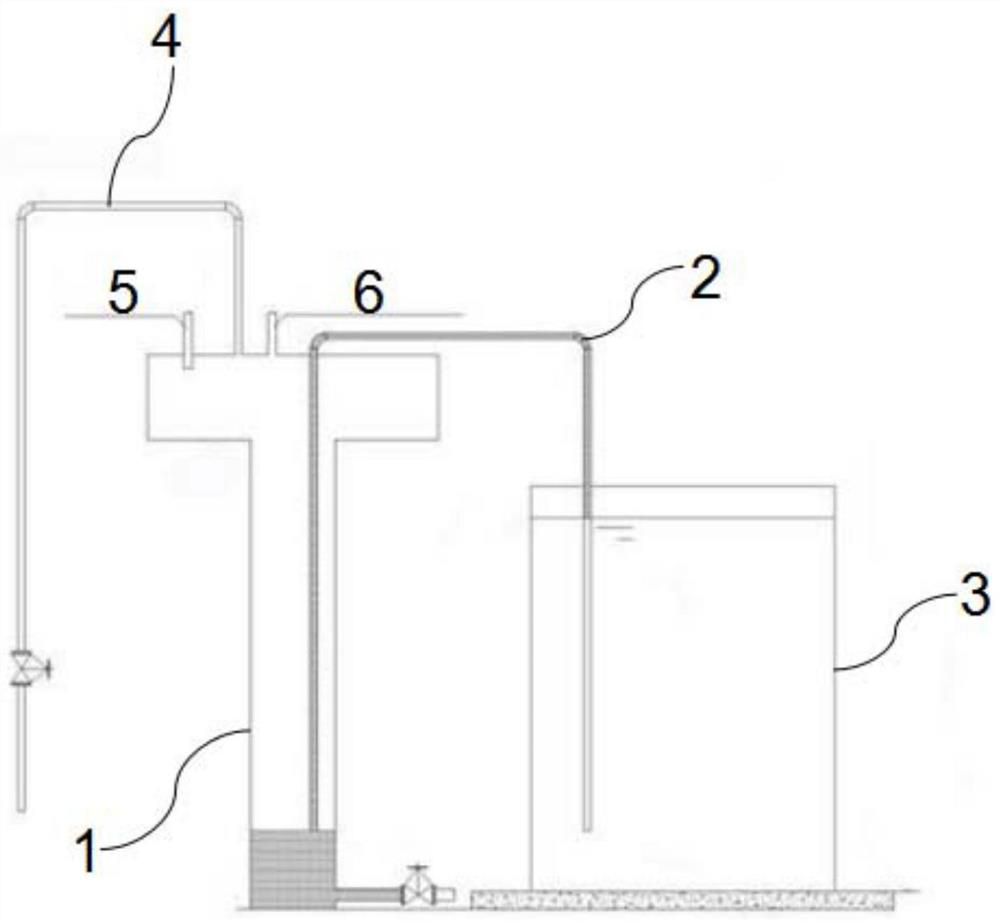

Thermal system for sludge incineration

PendingCN111678118AStable pressureStable jobLiquid degasificationIncinerator apparatusThermodynamicsSoft water

The invention discloses a thermal system for sludge incineration, belongs to the technical field of sludge incineration, and relates to the optimization and transformation and the stable production ofthe thermal system. The thermal system comprises a deaerator, a condensate tank and a steam header, and also comprises a water sealing device; the water sealing device is internally provided with a water sealing cavity, the water sealing cavity communicates with a steam exhaust pipe of the deaerator, and is also connected with a steam evacuation pipe and a water supplement pipe, and the steam evacuation pipe is provided with a regulating valve; the water sealing device also comprises a soft water tank; and the water sealing cavity is filled with soft water through the water supplement pipe, and the soft water in the water sealing cavity communicates with soft water in the soft water tank through a balance pipeline. The thermal system greatly increases the stability of the system, so thatcontinuous production capacity is significantly improved, and thus the purposes of increasing production and improving efficiency are achieved.

Owner:CHENGDU DRAINAGE CO LTD

Exhaust gas adsorption regeneration gas condensation system and method

PendingCN109603188AImprove condensation effectReduce feeding blockageMultiple-effect/fractional condensationDispersed particle separationVapor–liquid separatorFluidized bed

The invention discloses an exhaust gas adsorption regeneration gas condensation system and a method. The system comprises a preheating exchanger, a heat exchange condenser and a gas-liquid separator which are connected in sequence; a gas separated by the gas-liquid separator is used as a cooling medium in the preheating exchanger. The gas-liquid separation is carried out by preheating exchange andheat exchange condensation, which greatly improves the condensation effect of chlorosilane. The blockage and jamming of cold hydrogenated silicon powder blanking are reduced; the number of inspectionis reduced, and labor costs are saved; the safety, stability and continuous production capacity of cold hydrogenation equipment are enhanced; the entry of trichlorosilane into a cold hydrogenation fluidized bed is significantly reduced, and the energy is saved.

Owner:内蒙古通威高纯晶硅有限公司

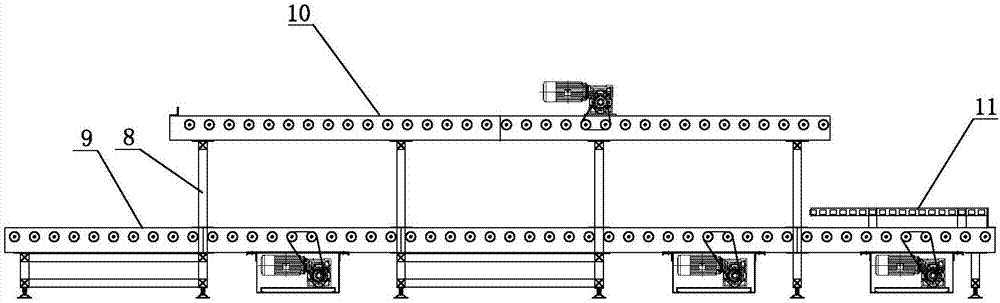

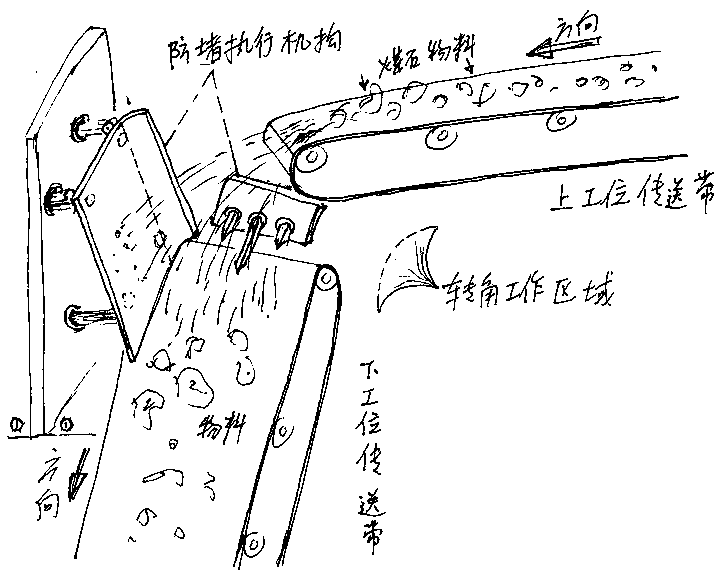

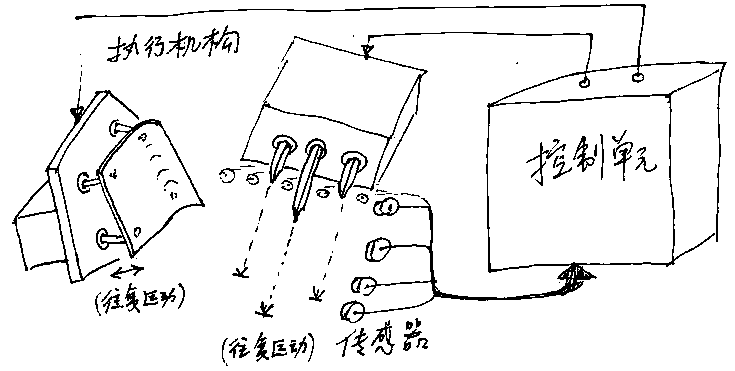

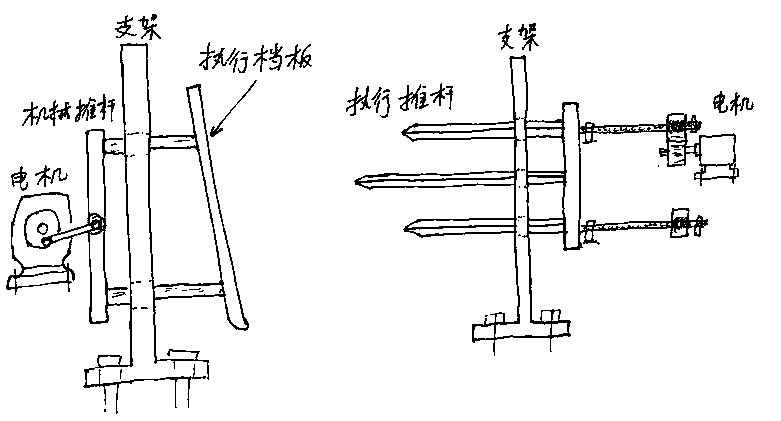

Downhole conveyor belt anti-clogging automatic cleaning mechanism scheme

The invention discloses a downhole conveyor belt anti-clogging automatic cleaning mechanism scheme. According to the scheme, the state of a conveyor belt is detected through a sensor. When large building stones or coal briquettes fall and the trend of siltation and blockage happens, a mechanism can start an automatic device to remove accumulated materials, coal briquettes and the like, dredging iscarried out in time, and the condition that the conveyor belt is clogged by siltation, and consequently downhole production and safety are affected is prevented. According to the downhole conveyor belt anti-clogging automatic cleaning mechanism scheme, automatic monitoring of the feeding condition of the conveyor belt is realized, siltation removing and dredging are automatically realized, unattended work is realized, the manpower configuration underground is reduced, and the efficiency and safety of underground production are improved.

Owner:谷文松

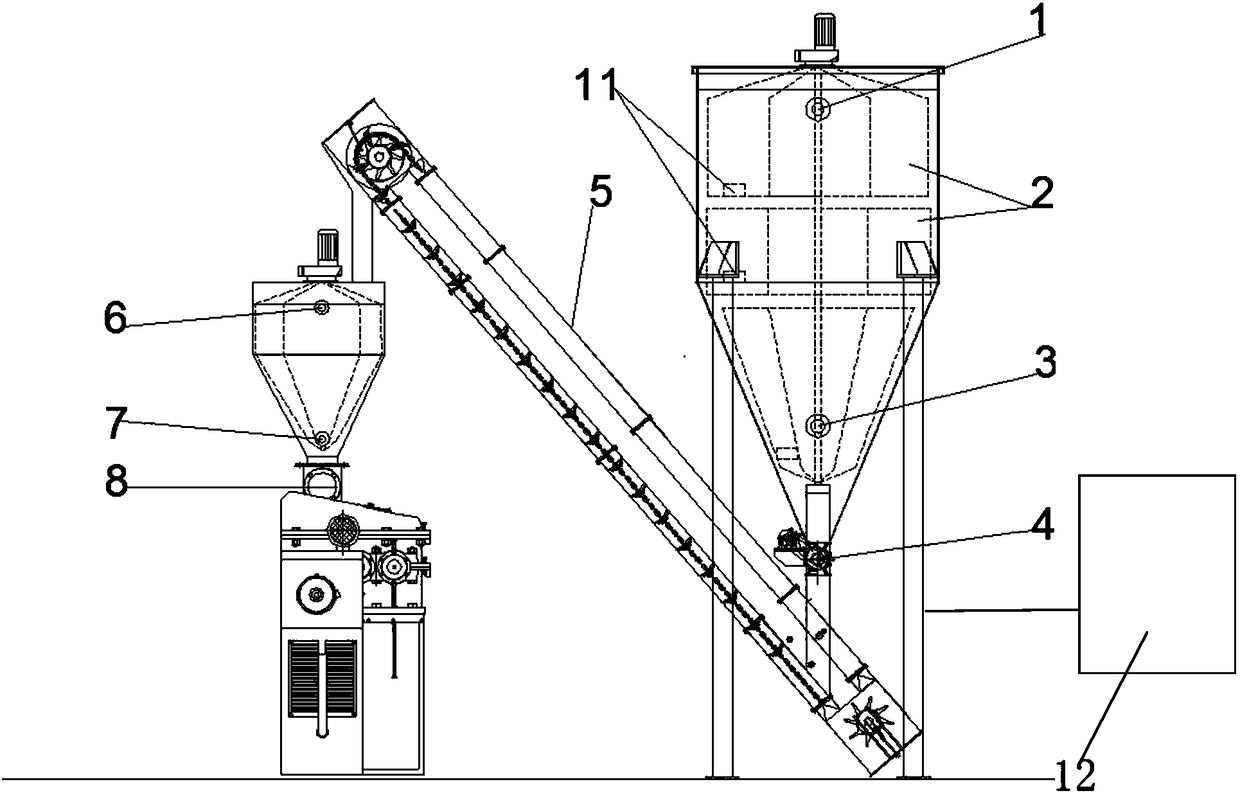

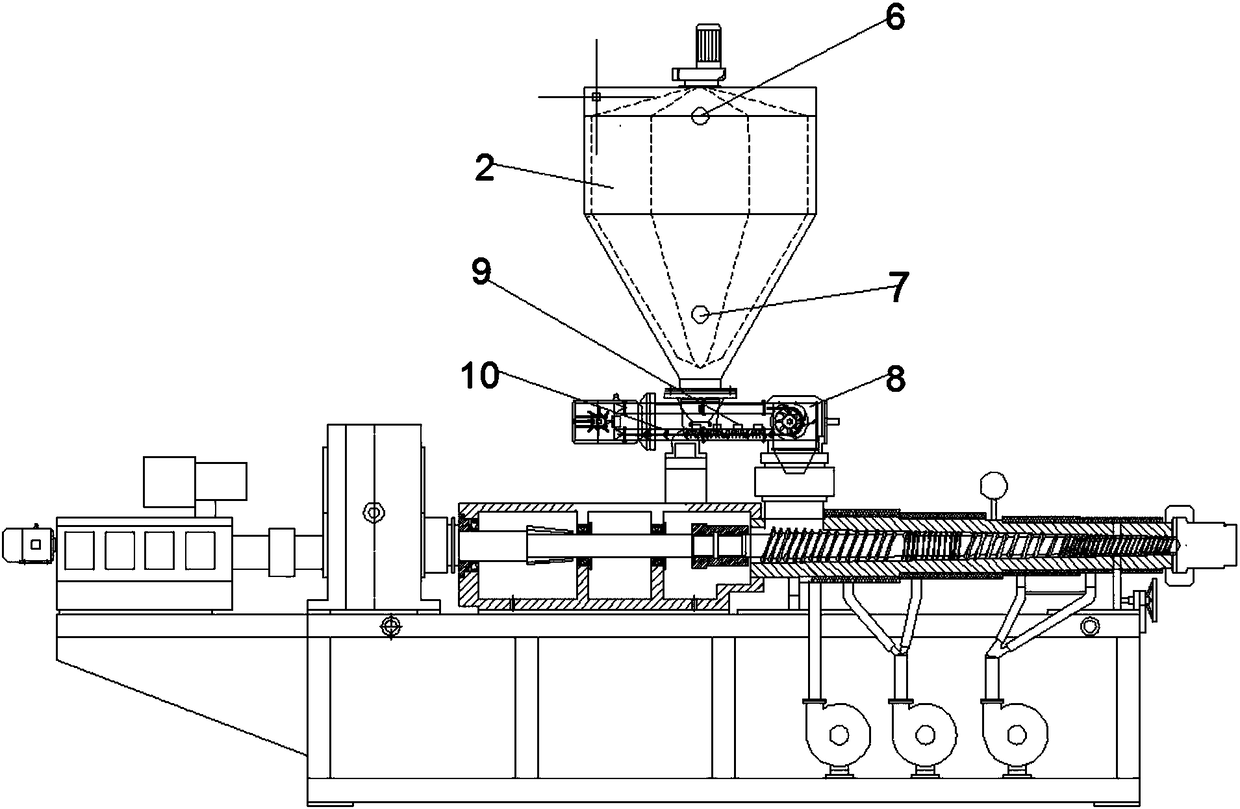

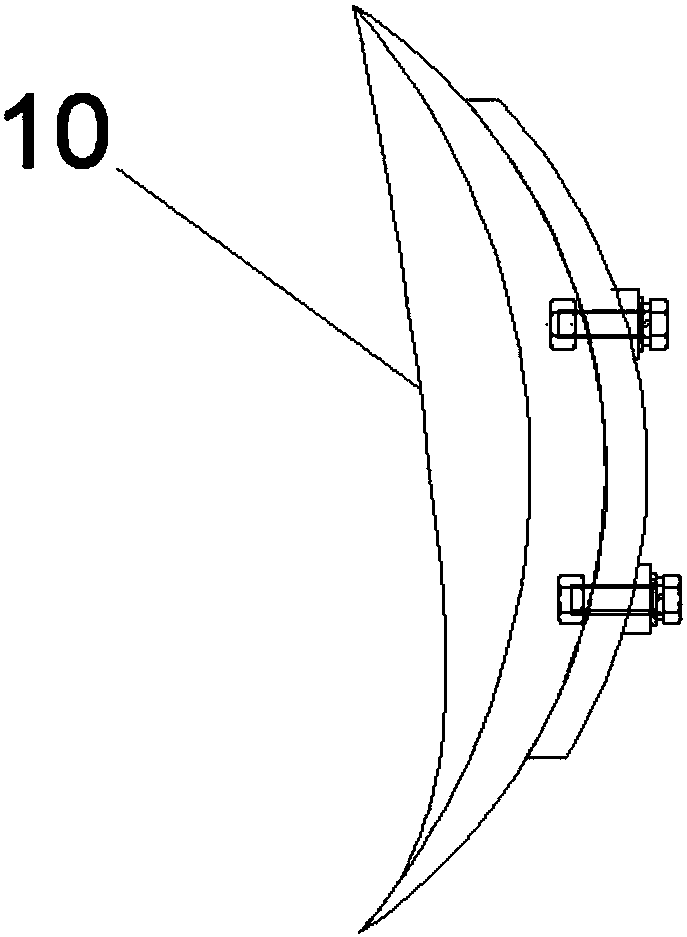

Full-automatic feeding system of polymer extruder machine

ActiveCN108127890APrevent slippingAvoid cloggingTotal factory controlComputer control systemLaser scanning

The invention relates to a full-automatic feeding system of a polymer extruder machine, and particularly relates to a full-automatic feeding mechanism capable of preventing blockage, achieving automatic speed regulation and uniformly mixing materials. The full-automatic feeding mechanism mainly comprises a material conveyor I, a material conveyor II, an upper whorl plate and whorl stir pieces arranged above a stirring mechanism in design, upper material position sensors and lower material position sensors arranged on a material storage bin, a feeding bin, and pressure sensors arranged on the stock bins, wherein the sensors are controlled by a programmable computer control system; and a material accumulation rate (namely the ratio of the volume of the material to the volume of the compartment) is monitored by the laser scanning device on the material conveyor I, wherein the laser scanning device is controlled by the programmable computer control system to feeding stably. By means of thestructure, the materials can automatically enter the extruder machine smoothly, and the materials can be uniformly mixed in the whole process.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com