Automatic polishing numerical control device

A numerical control device and automatic polishing technology, applied in the direction of automatic grinding control device, grinding/polishing safety device, grinding/polishing equipment, etc., can solve the problem of reducing continuous production capacity, reducing production efficiency, production volume, and labor costs Advanced problems, to achieve the effect of improving continuous production capacity, increasing efficiency and production volume, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

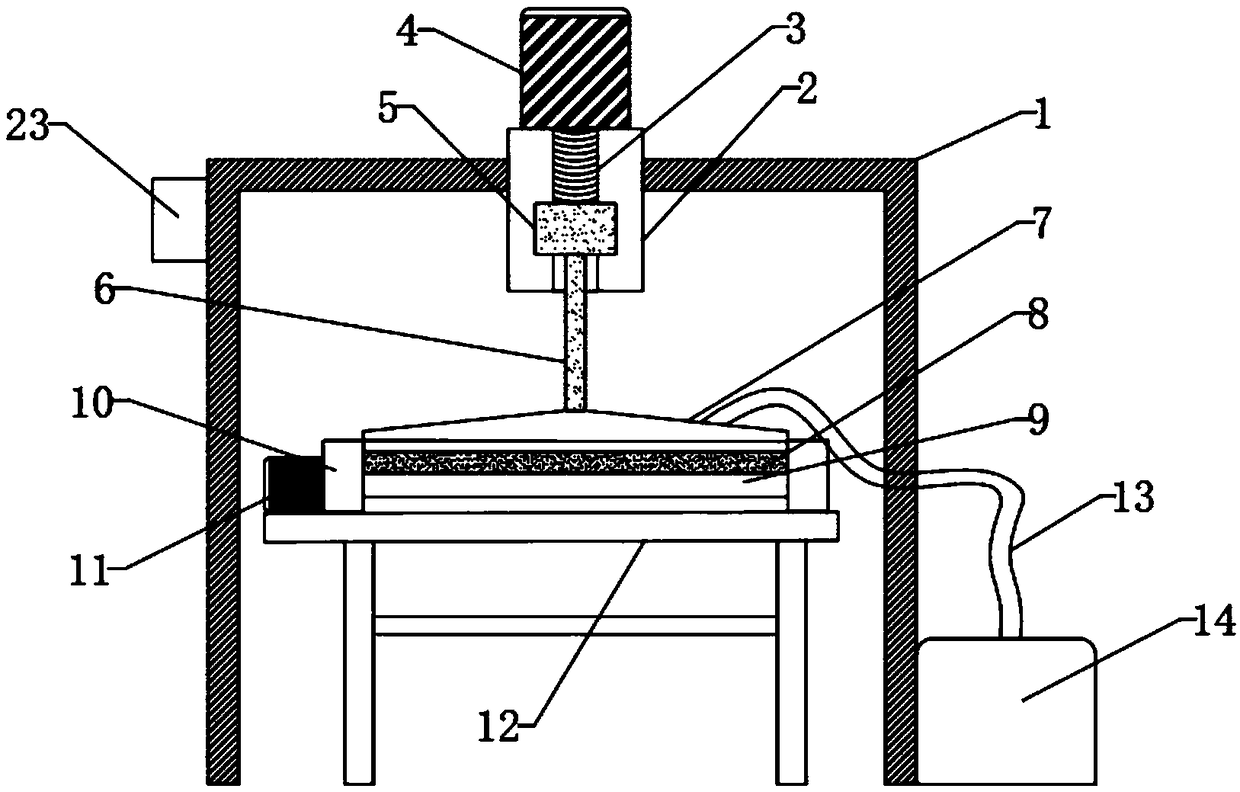

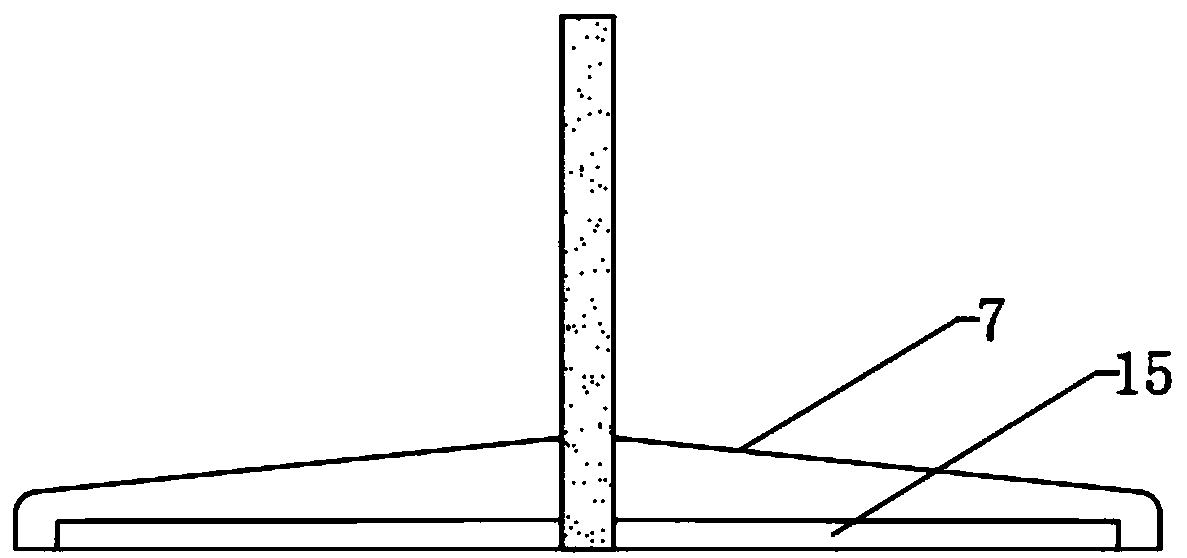

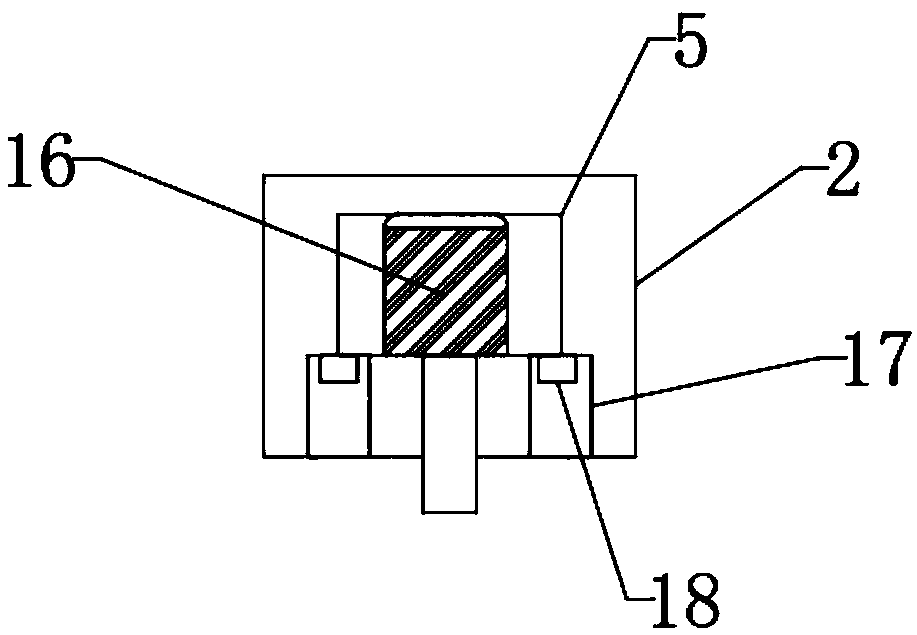

[0023] Such as Figure 1-6 As shown, the present invention provides a kind of automatic polishing numerical control device, comprises support frame 1, stepping motor 4, polishing cover 7, polishing plate 8, conveying motor 11, cyclone dust collector 14, polishing disk 15, polishing motor 16, A pressure sensor 18, a PLC controller 23, a fixed plate 2 is fixedly installed at the middle end of the top of the support frame 1, a stepper motor 4 is fixedly installed above the top of the fixed plate 2, a screw 3 is fixedly installed on the surface of the fixed plate 2, and a screw 3 is fixedly installed on the surface of the fixed plate 2. A slide block 5 is installed, and the middle end of the slide block 5 is fixedly equipped with a polishing motor 16, the bottom of the polishing motor 16 is fixedly connected with a push rod 6, the bottom end of the push rod 6 is fixedly connected with a polishing disc 15, and the top of the polishing disc 15 is fixedly equipped with a polishing dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com