The treatment process of copper-containing waste recycling flue gas purification

A technology of waste recycling and flue gas purification, which is applied in the direction of gas treatment, special treatment targets, pyrolysis treatment of sludge, etc., can solve the problems of not meeting environmental protection requirements, and achieve the level of perfect production automation, reduce energy consumption, and environmental protection management Normative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

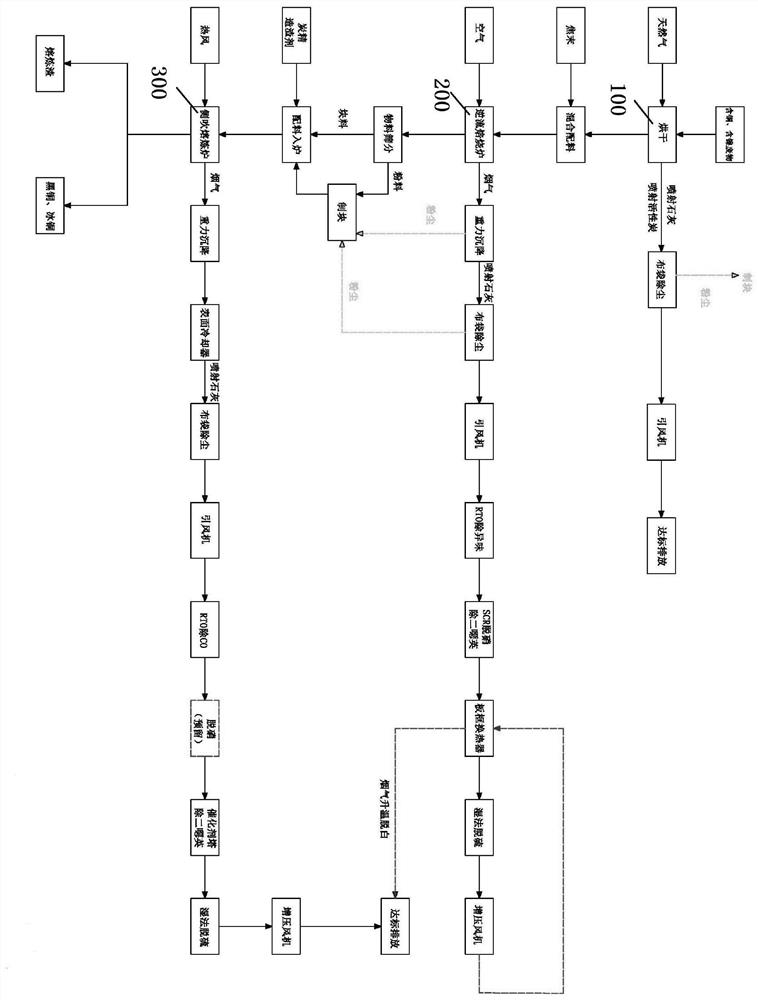

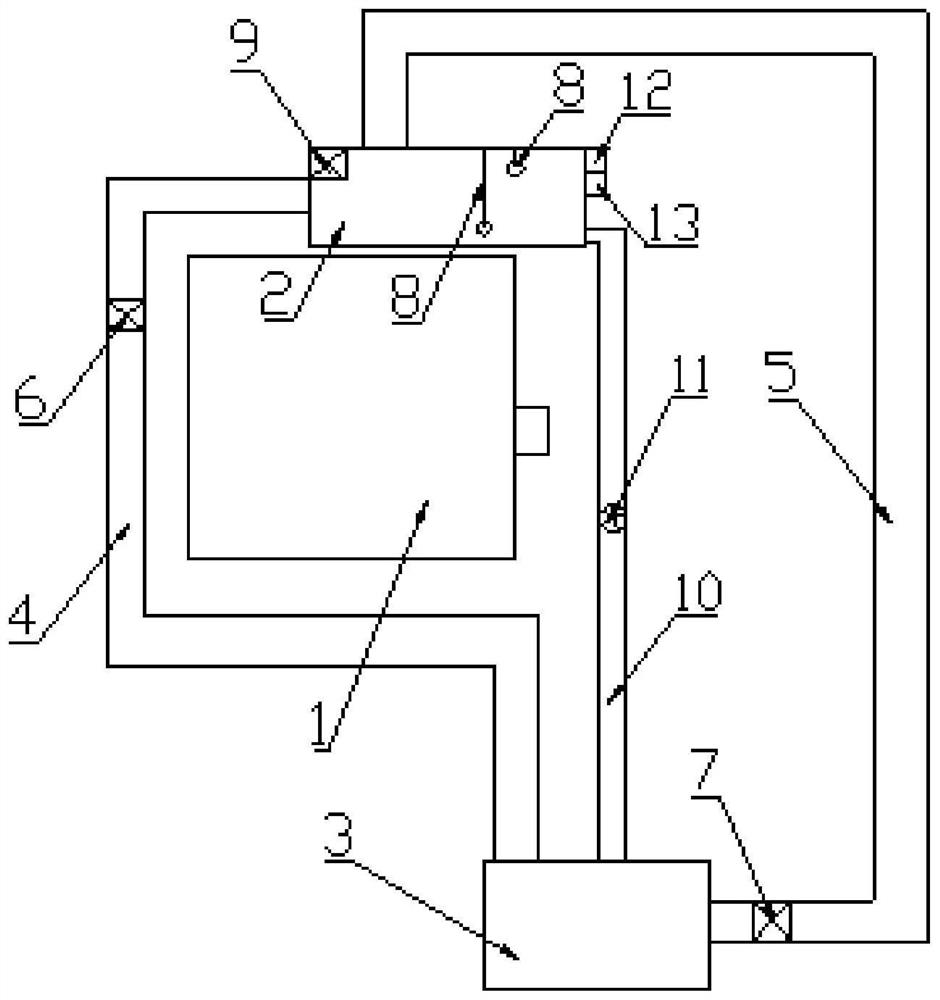

[0041] see Figure 1-2 As shown: an embodiment of the present invention specifically discloses and provides a treatment process for copper-containing waste recycling and utilization of flue gas purification, including the following steps:

[0042]1) 100. Flue gas purification in the drying process: the flue gas generated when the copper-containing sludge waste is subjected to the drying process,

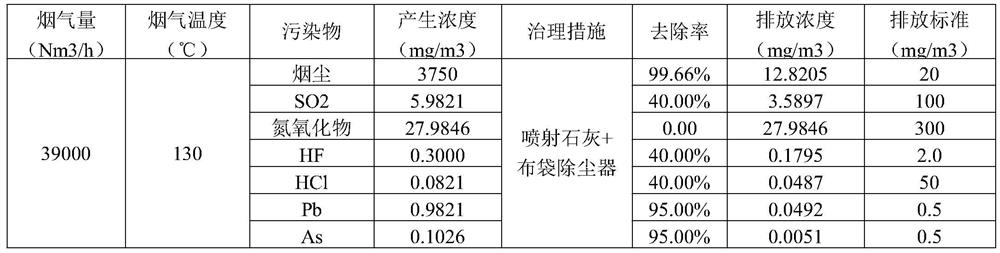

[0043] The following table shows the drying flue gas output parameters:

[0044] project unit parameter Remark Wet flue gas flow Nm 3 / h

39093 Standard State, Wet Basis, Actual Oxygen, flue gas temperature ℃ 120~150 / H2O (standard state, wet flue gas) Vol% 10~20 soot g / Nm 3

10~20 SO2 mg / Nm 3

48.67 NOx mg / Nm 3

/

[0045] The flue gas purification process adopted is "slaked lime dry deacidification + jet activated carbon + bag dust removal + induced draft fan + chimney";

[0046] The drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

| combustion efficiency | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com