Full-automatic feeding system of polymer extruder machine

A feeding system, fully automatic technology, applied in the field of feeding system of polylactic acid (PLA) extruder, to achieve the effect of increasing continuous production capacity, stable product performance and avoiding feeding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

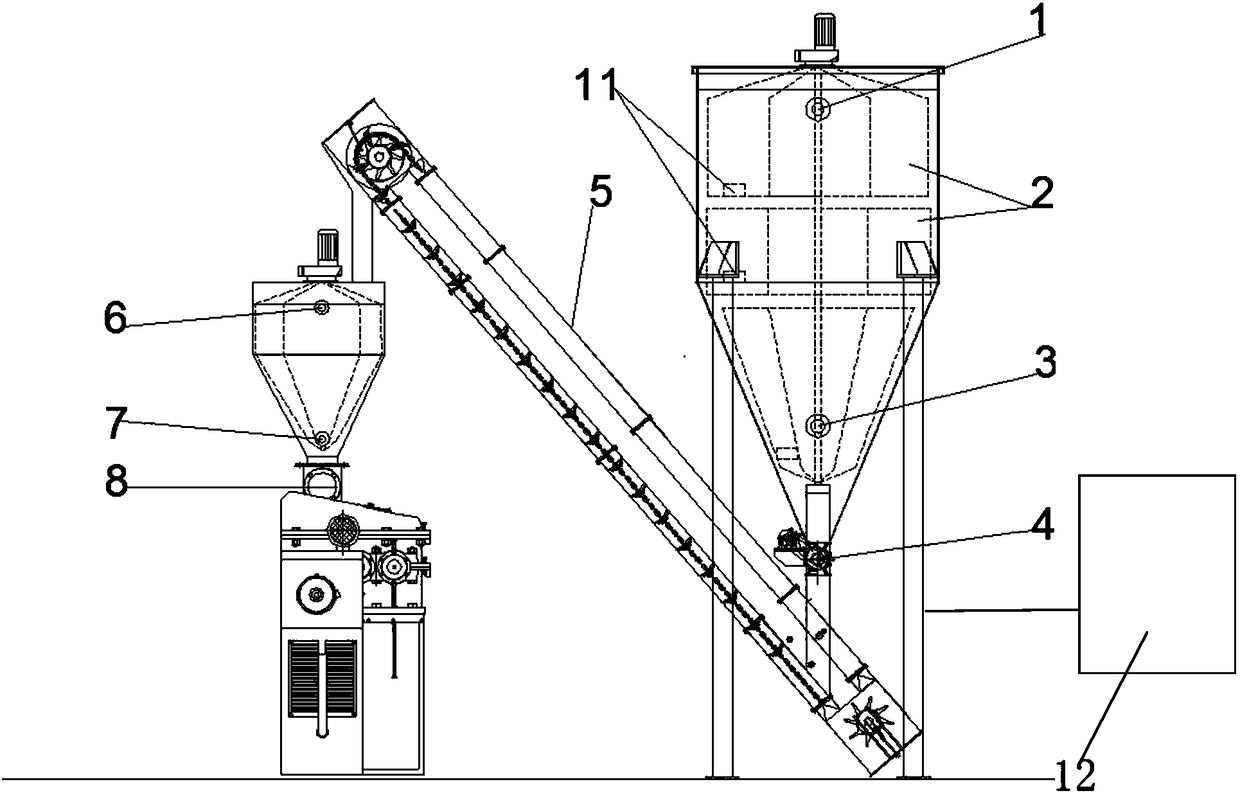

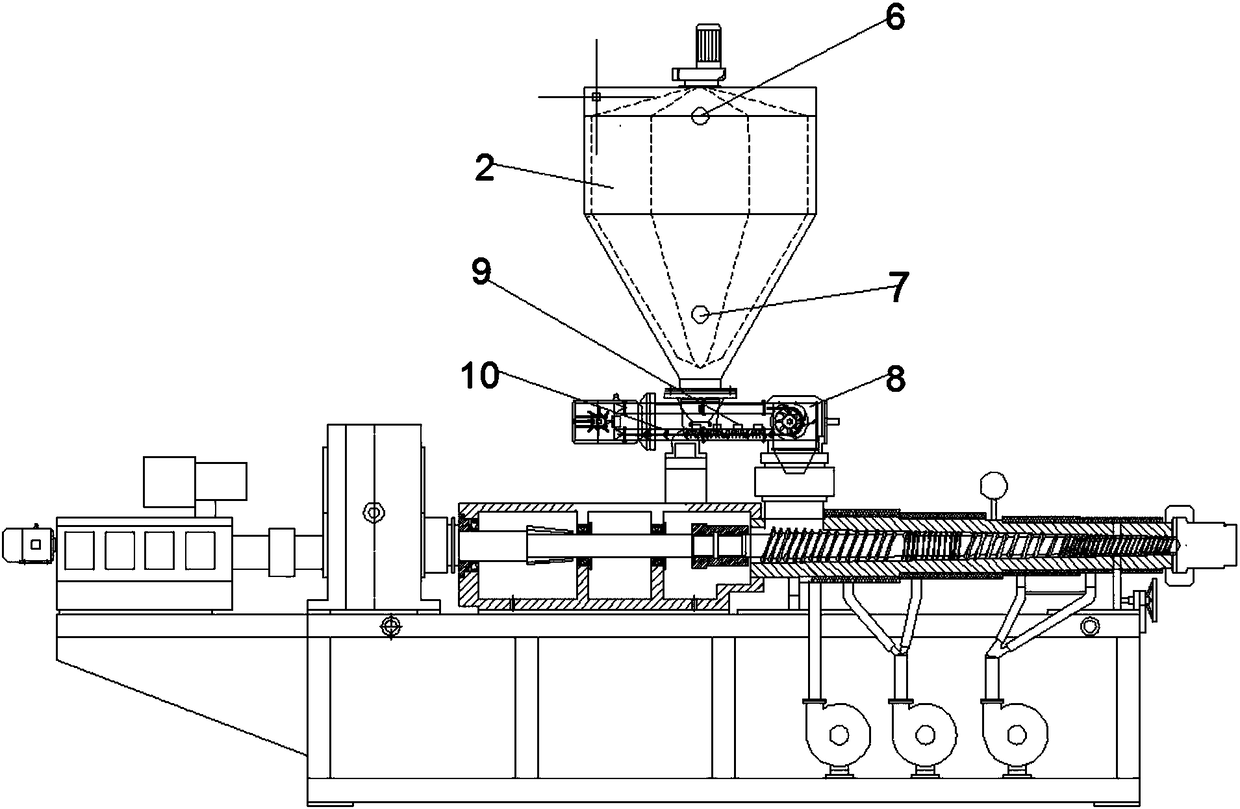

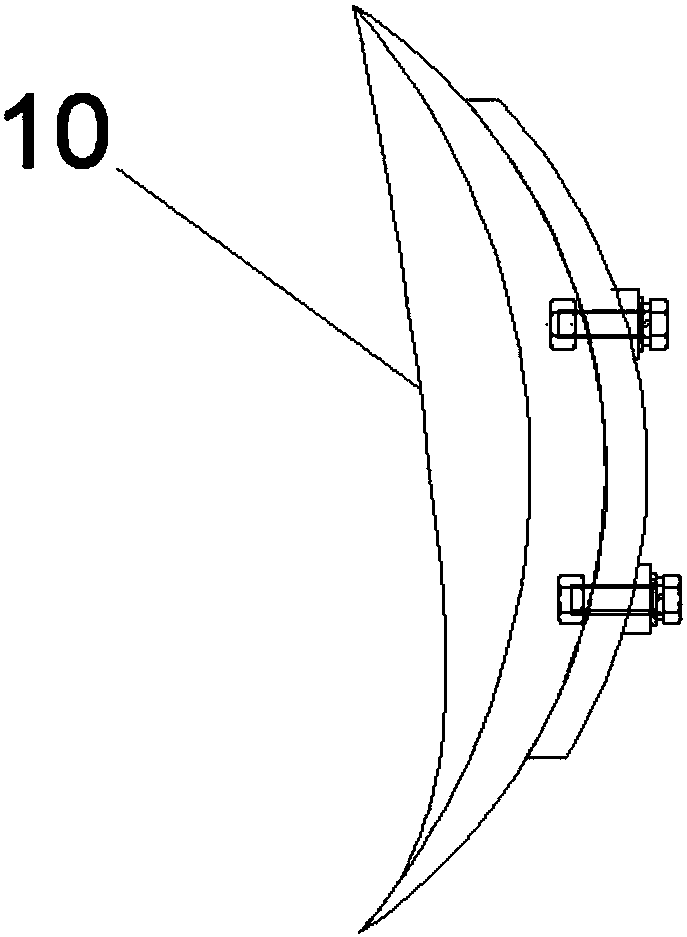

[0032] like figure 1 As shown, the present invention introduces a fully automatic feeding system for a polymer extruder, including a high material level sensor 1, an agitator 2, a low material level sensor 3, a star discharge valve 4, and a material conveyor No. 5 , pressure sensor 11; high material level sensor 6, low material level sensor 7, material conveyor II No. 8, laser scanner 9, scroll plate 10, programmable computer control system 12.

[0033] like figure 1 As shown, the storage silo can store 7-day consumption materials. There is a three-stage stirring device 2 in the storage silo. When the machine is running, the agitator starts the first-stage arc agitator and the second-stage arc agitator according to the amount of material. The device and the class III arc agitator ensure that the materials are always mixed evenly in the storage silo and the feed silo. The storage silo body is equipped with a high material level sensor 1 and a low material level sensor 3. When th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com