Easily discharged tea frying machine

A technology of a tea frying machine and a discharge port, which is applied in the field of tea frying equipment and tea frying machines, can solve the problems of increasing the labor intensity of the staff, being fragile, and having a long working cycle, so as to improve the convenience and operability of the material. , The effect of reducing waiting time and improving continuous productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

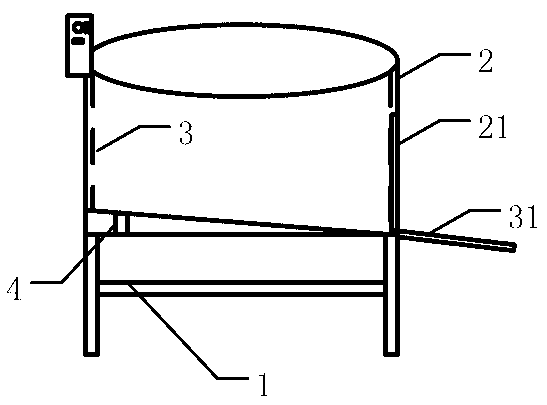

[0009] Such as figure 1 As shown, the tea frying machine of the present invention includes a bracket 1, an outer barrel 2 erected on the bracket 1, an inner pot 3 embedded in the outer barrel, and a pot connected to the outer barrel and inserted into the inner pot cavity. Kneading the tea blocker and the heating device and the motor arranged outside the bottom of the inner pot, wherein the heating device is a gas stove connected with a gas cylinder. Here, since the heating device and the rolling tea retainer are well-known technologies in the industry, they will not be described in detail. However, the technical characteristics of the present invention can be summed up. Part of the side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com