Baked sesame cooling device and use method thereof

A technology for cooling equipment and sesame, which is applied in lighting and heating equipment, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of easily broken sesame and low yield of sesame products, increase contact opportunities, improve Continuous production capacity, the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the embodiments.

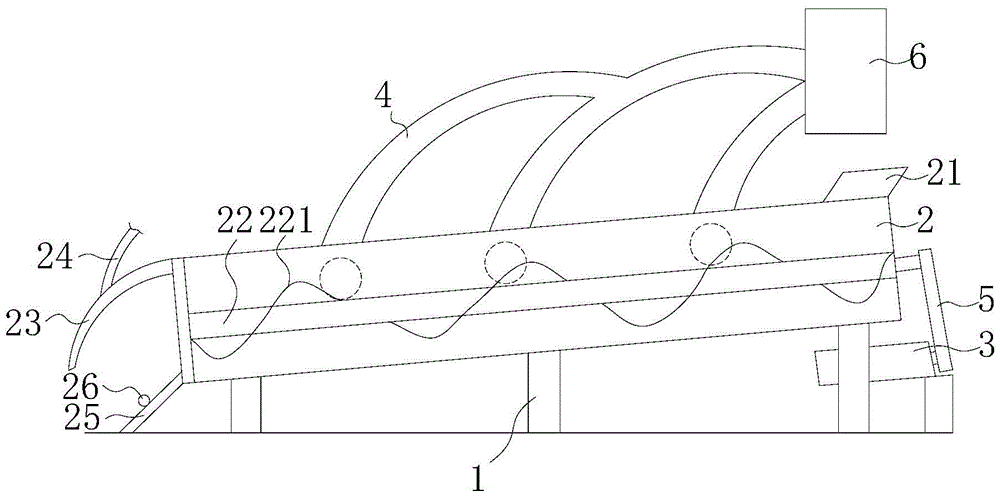

[0012] Such as figure 1 As shown, a roasted sesame cooling device includes a bracket 1, a cylinder 2 placed on the bracket, a motor 3 and an exhaust pipe 4, the central axis of the cylinder is at an angle of 10-15° to the horizontal plane, and the cylinder body The head is provided with a feed port 21, and a rotating shaft 22 is built in. The rotating shaft is provided with a spiral lifting plate 221. The head of the cylinder is connected with the motor through a chain 5, and several exhaust pipes are arranged on one side of the cylinder for exhausting air. The tube is connected to the dust removal device 6, and the fried sesame seeds at a temperature of 100-120°C enter from the feed port of the cylinder, and under the action of the spiral flight, they continue to move forward along the inclined drum. Pull out, so that the hot sesame is rapidly cooled to a temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com