A heart-moving machine that is convenient for retrieving materials

A technology of a centering machine and a feeding mechanism, which is applied in the field of a centering machine that is convenient for retrieving materials. It can solve problems such as movement and unfavorable connection processing, and achieve the effects of improving continuous production capacity, improving safety, and facilitating removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

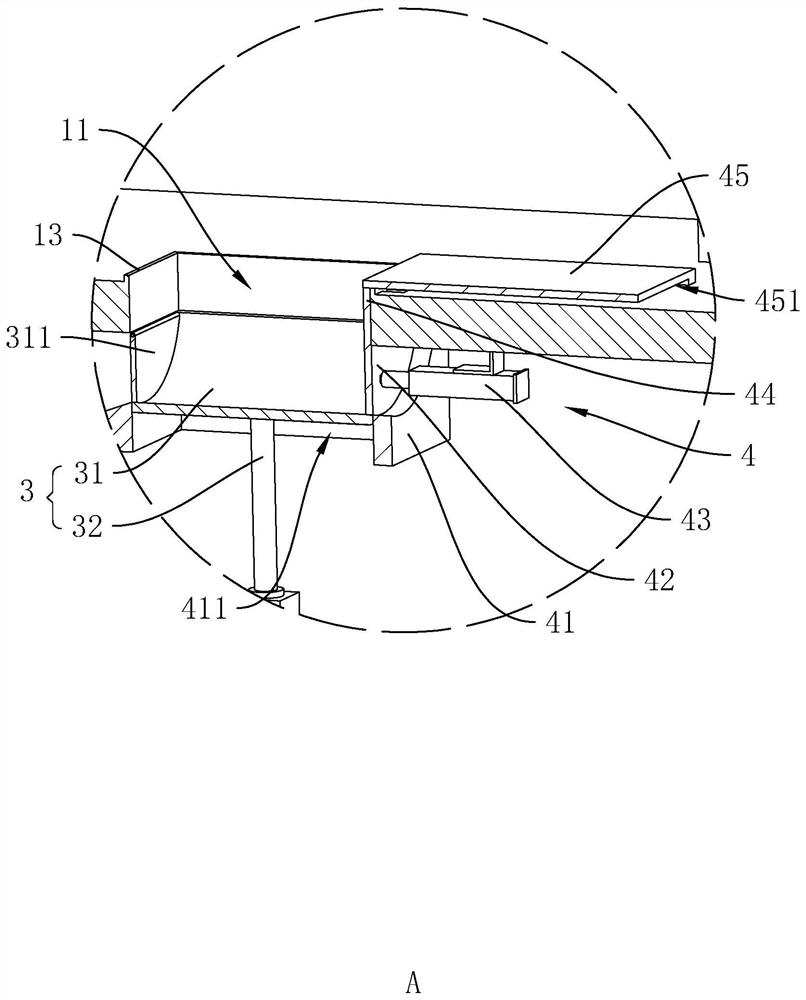

[0033] The following is attached Figure 1-5 The application is described in further detail.

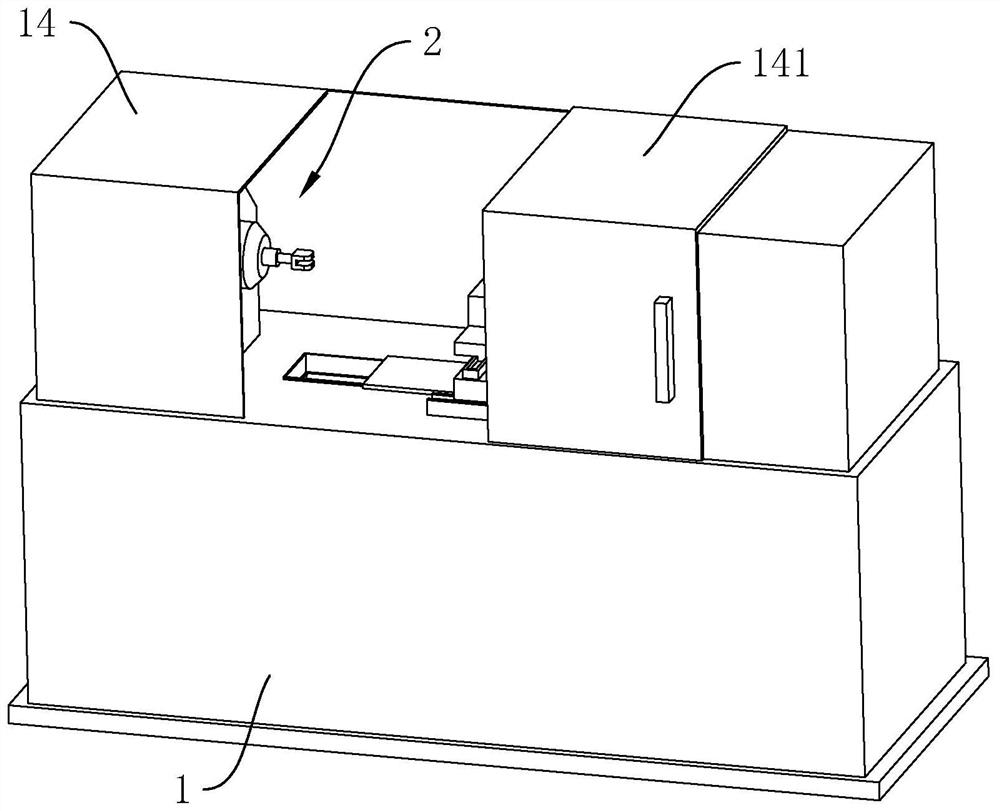

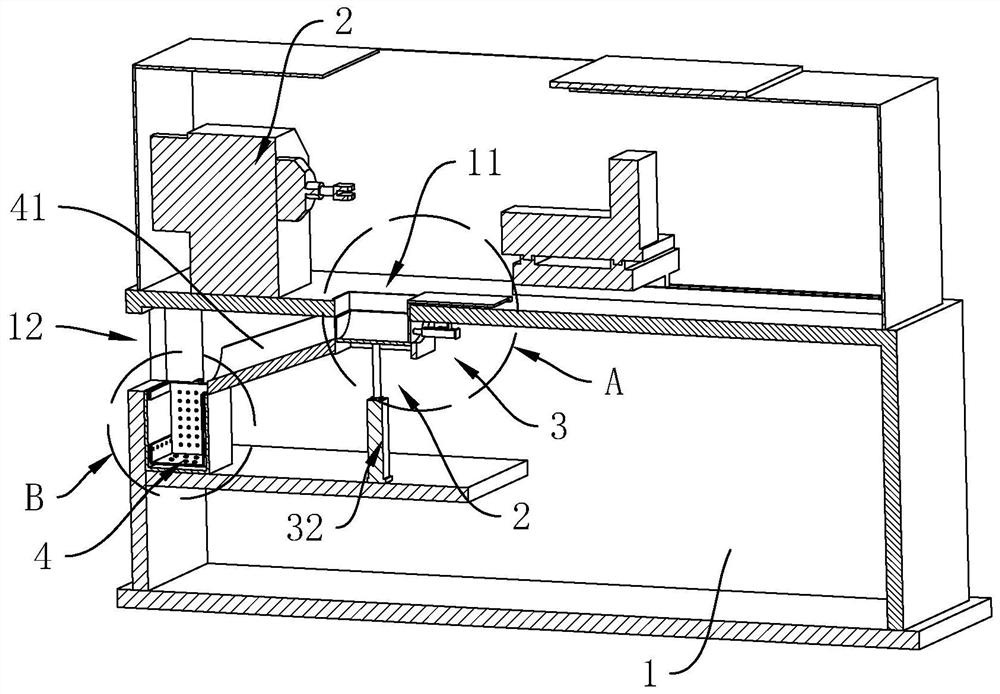

[0034] The embodiment of the present application discloses a centering machine that is convenient for taking out materials. refer to figure 1 and figure 2The centering machine includes a machine tool 1 and a clamping mechanism 2. The clamping mechanism 2 is installed on the top of the machine tool 1 for clamping the workpiece to be processed. around. One side of the protective cover 14 is equipped with a sliding door 141, and the staff can enter the protective cover 14 through the sliding door 141 to operate the equipment; The workpiece processed on the clamping mechanism 2 is picked up to the bottom of the machine tool 1, and then the workpiece is transported to the receiving mechanism 5 through the feeding mechanism 4 for centralized collection of the workpiece, without the need for staff to enter the protective cover 14 to take materials.

[0035] refer to figure 2 and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com