Continuous rotational flow falling film melt crystallizer

A technology of melting crystallizer and falling film, which is applied in crystallization separation, solution crystallization, chemical instruments and methods, etc., can solve the problems of poor crystal thickness uniformity, improve uniformity, slow down radial aggregation situation, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

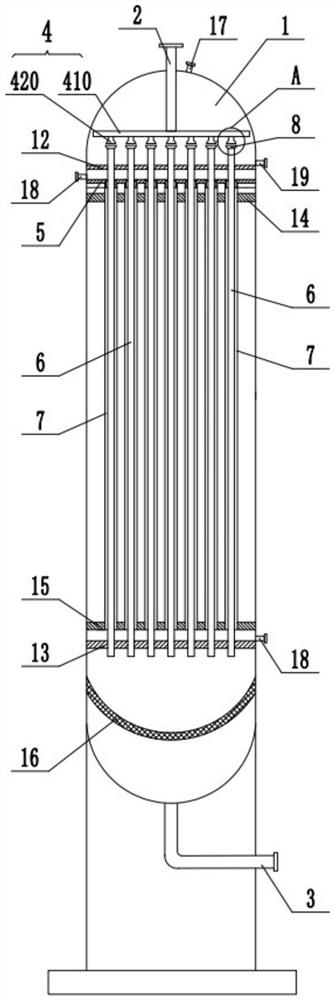

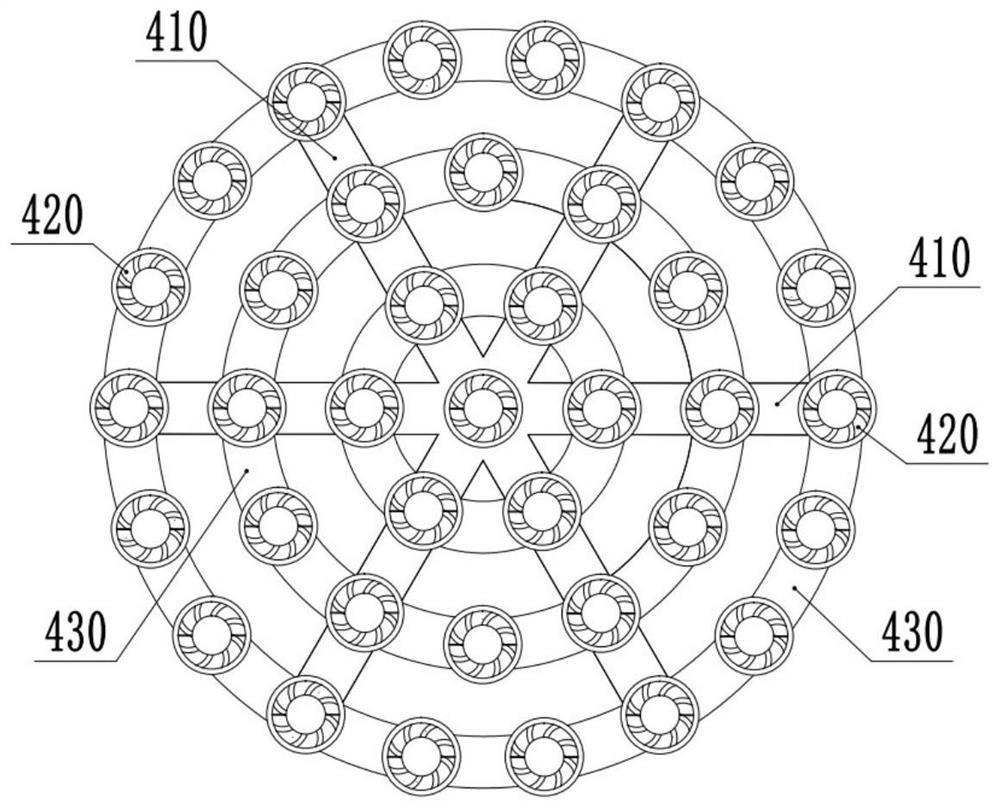

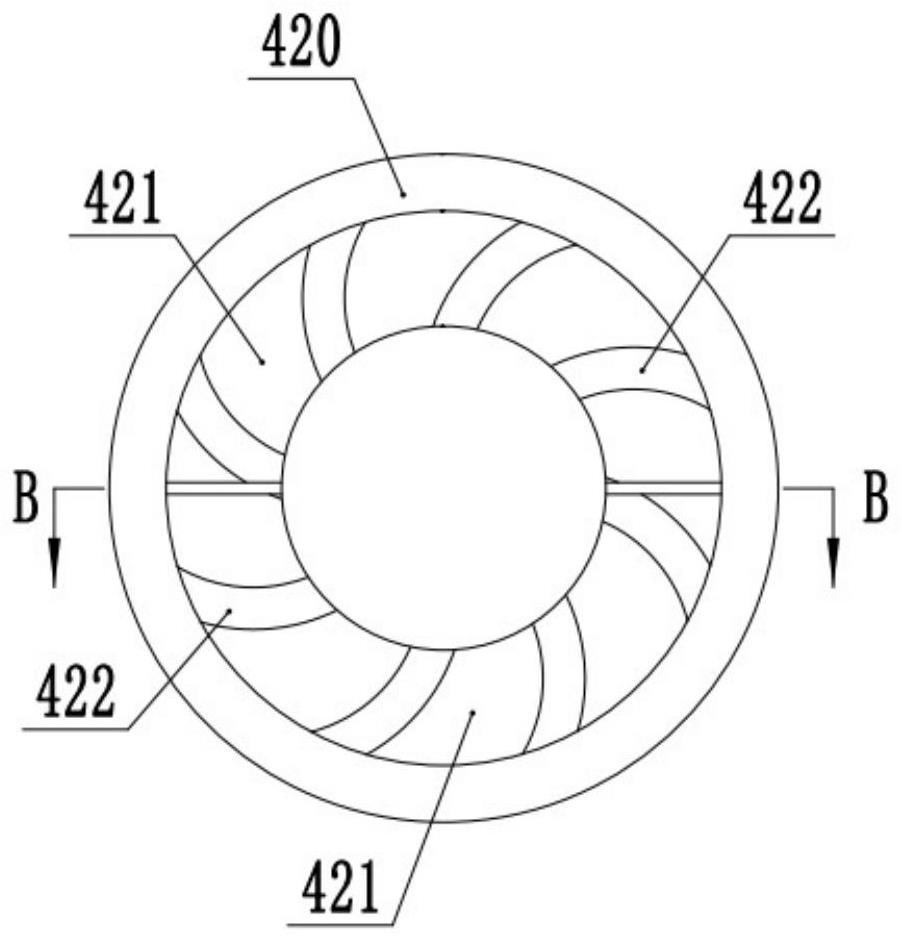

[0045] This embodiment is basically as figure 1 Shown: a continuous swirl falling film melting crystallizer, including a shell 1, a feed pipe 2 and a discharge pipe 3, the inside of the shell 1 is provided with a material distribution pipe network 4, and a cold and hot medium deflector 5 , some crystallization tubes 6 and some cold and heat medium tubes 7, combined figure 2 As shown, the material distribution pipe network 4 includes several material branch pipes 410 and several liquid separators 420, and the feed pipe 2 communicates with the material branch pipes 410. In this embodiment, the number of material branch pipes 410 is six, and the six material branch pipes 410 are close to each other. One end is connected, and this connection is also the connection between the material branch pipe 410 and the feed pipe 2 . Two adjacent material branch pipes 410 are also connected through arc-shaped pipes 430 . In this embodiment, three arc-shaped pipes 430 are designed between tw...

Embodiment 2

[0061] The only difference between this embodiment and Embodiment 1 is: Figure 12 As shown, in this embodiment, the inner diameter of the bottom of the straight pipe portion 820 gradually increases from top to bottom, that is, the longitudinal section of the inner wall of the bottom of the straight pipe portion 820 is in a figure-eight shape. In this embodiment, the inner diameter of the bottom of the straight pipe part 820 gradually increases from top to bottom. Compared with Embodiment 1, after the material forms a secondary swirl flow, it can stably transition to crystallization along the inner wall of the straight pipe part 820. On the inner wall of the tube 6, reduce the impact force on the inner wall of the crystallization tube 6 when the material enters the crystallization tube 6 from the straight tube portion 820, thereby better maintaining the swirl effect on the inner wall of the crystallization tube 6.

Embodiment 3

[0063] The only difference between this embodiment and Embodiment 1 is: Figure 13 As shown, in this embodiment, the bottom end of the liquid dispensing head 420 is located in the swirl part 810 , so as to prevent the material from splashing out of the swirl film distribution head 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com