Quantum dot ink based on ink-jet printing

A technology of inkjet printing and quantum dots, which is applied in ink, household utensils, applications, etc., can solve the problems that the viscosity and surface tension cannot meet the requirements of printing or film formation, and the strict requirements of quantum dot inks, so as to achieve uniform film formation, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

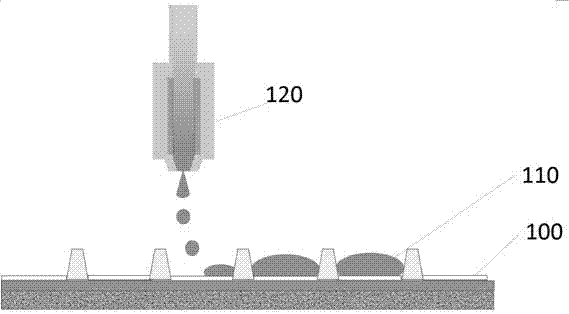

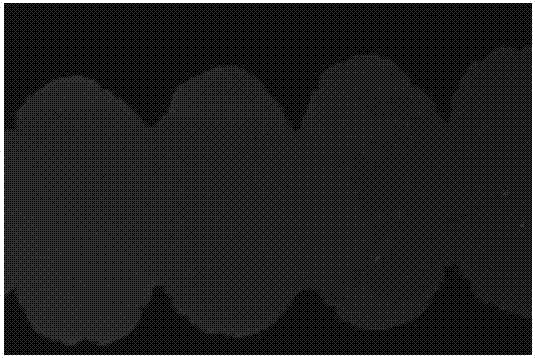

[0021] A preparation of a non-lithographic pixel bank and its application in a fully printed light-emitting display, the specific steps are:

[0022] Phenylcyclohexane (boiling point 237°C) and decane (boiling point 174°C) were mixed in a 5ml reagent bottle at a volume ratio of 4:1 and stirred evenly for use.

[0023] Red ZnSe / ZnS core-shell quantum dots with oleylamine ligands were added to the mixed solvent with a mass fraction of 1wt%, and shaken until uniformly dispersed.

Embodiment 2

[0025] Cyclodecane (boiling point 201°C) and decane (boiling point 174°C) were mixed in a 5ml reagent bottle at a volume ratio of 4:1 and stirred evenly for use.

[0026] Red CdSe / ZnS core-shell quantum dots with oleylamine ligands were added to the mixed solvent at a mass fraction of 1 wt%, and shaken until uniformly dispersed.

Embodiment 3

[0028] Cyclodecane (boiling point 201°C) and toluene (boiling point 110°C) were mixed in a 5ml reagent bottle at a volume ratio of 1:1 and stirred evenly for use.

[0029] The green inorganic perovskite CsPbBr with oleic acid ligand was added to the mixed solvent with a mass fraction of 1wt%. 3 Quantum dots, shake until evenly dispersed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com