Method for preparing large-area perovskite layer and perovskite solar cell

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of many steps, poor repeatability, incomplete reaction, etc., and achieve the effects of uniform film formation, large grain size, and improved efficiency and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a perovskite solar cell, which is prepared according to the following steps:

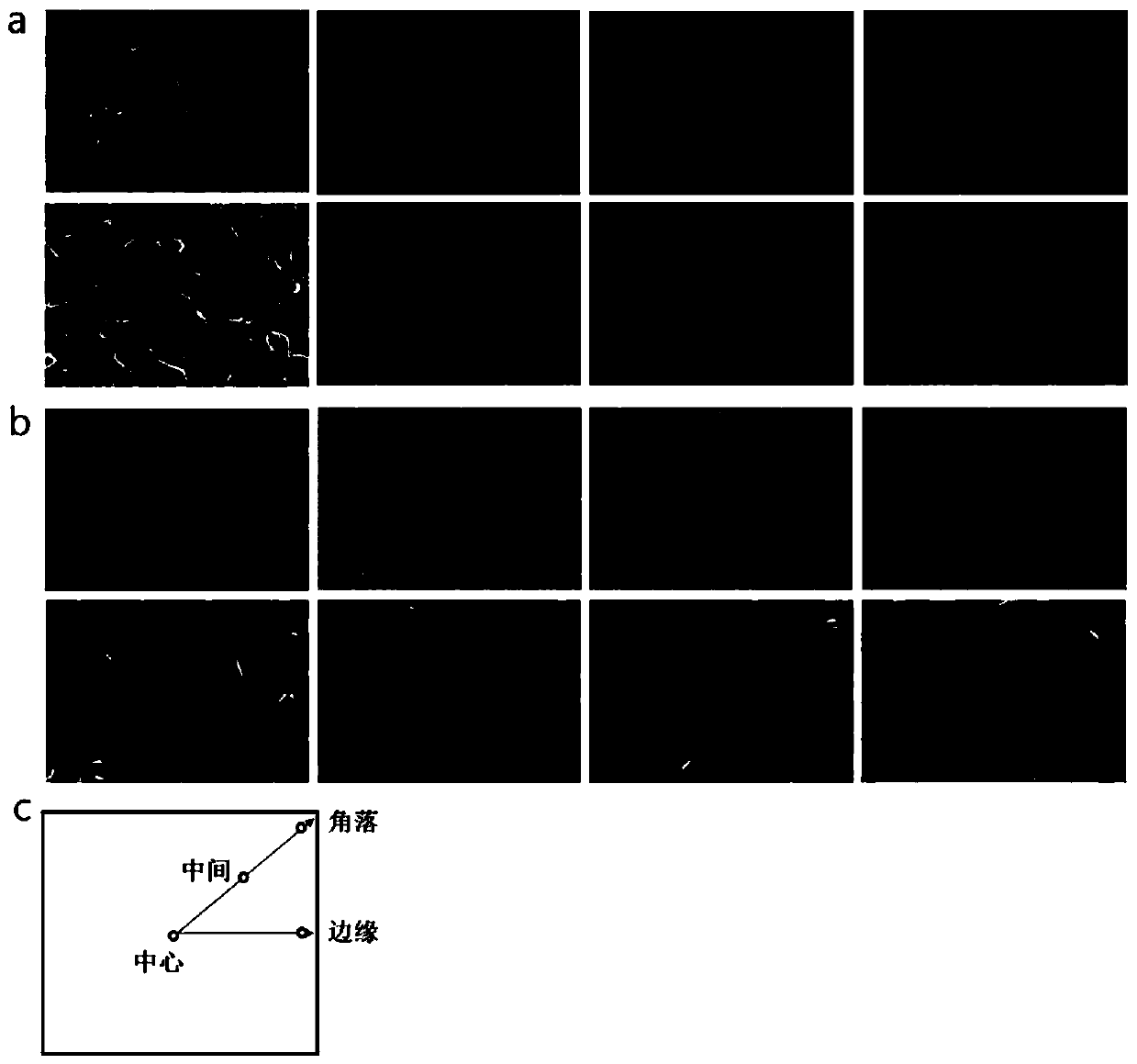

[0031] On an FTO glass substrate with an area of 10cm×10cm, 40nm dense titanium dioxide was prepared by spray pyrolysis, and a mesoporous layer TiO with a thickness of 300nm was spin-coated 2 . Then spin-coat MAPbI 3 Precursor solution in which MAPbI is dissolved 3 The solvent of the precursor is a mixed solvent of DMSO and DMF. A mixed anti-solvent of toluene and ethyl acetate (toluene: ethyl acetate volume ratio = 1:1) was added dropwise 15 seconds before the end of spin coating, and annealed at 100°C for 30 minutes to obtain a thickness of 500nm dense perovskite film. Mix graphite, carbon black, polymethyl methacrylate, and isopropanol to form a carbon slurry, and scrape-coat the carbon slurry on the perovskite film prepared above as a carbon electrode to prepare a carbon electrode perovskite solar energy Battery.

Embodiment 2

[0037]In order to study the influence of different solvent ratios in the mixed anti-solvent formed by two solvents on the performance of the formed device, this example provides a series of carbon electrode perovskite solar cells. The preparation steps are the same as in Example 1, except that acetic acid is used The volume ratios of EA in the mixed anti-solvent formed by ethyl ester (EA) and toluene (Tol) were 0, 0.2, 0.4, 0.5, 0.6, 0.8 and 1.0, respectively.

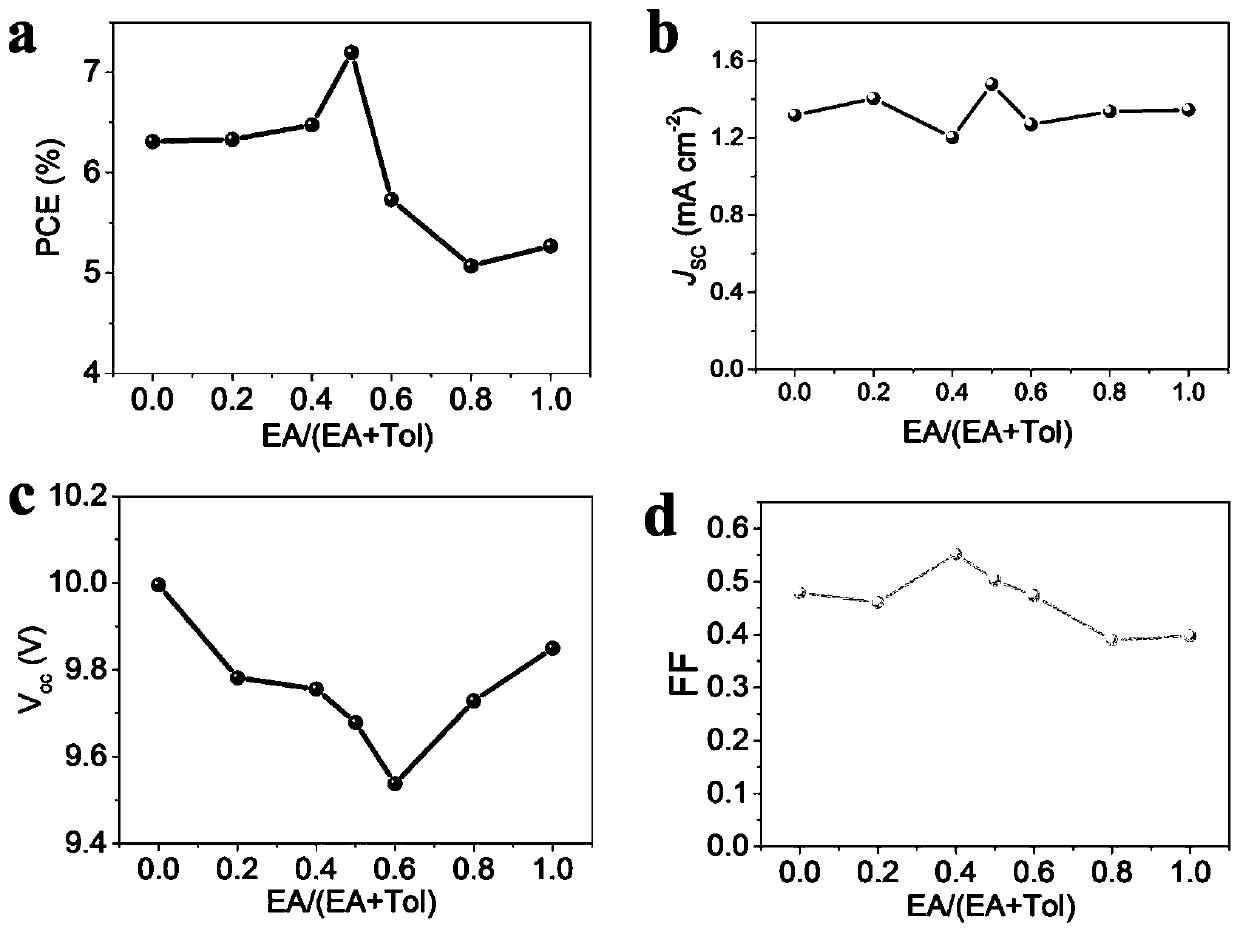

[0038] The prepared series of carbon-based solar cells were tested, and the photoelectric conversion efficiency (PCE), short-circuit current density (J SC ), the open circuit voltage (Voc) and the fill factor (FF) vary with the volume ratio of EA (EA / (EA+Tol)) as follows figure 2 shown, from figure 2 It can be seen that, compared with the use of a single solvent (ie, EA / (EA+Tol) is 0.0 or 1.0), the photoelectricity of the carbon electrode perovskite solar cell formed by increasing or decreasing the volume ratio of E...

Embodiment 3

[0040] On an FTO glass substrate with an area of 10cm×10cm, 40nm dense titanium dioxide was prepared by spray pyrolysis, and a mesoporous layer TiO with a thickness of 300nm was spin-coated 2 . Then spin-coat MAPbI 3 Precursor solution in which MAPbI is dissolved 3 The solvent of the precursor is a mixed solvent of DMSO and DMF. 15s before the end of the spin coating, a mixed anti-solvent of chlorobenzene and ethyl acetate (chlorobenzene:ethyl acetate volume ratio = 5:1) is added dropwise, and annealed at 100°C for 30 minutes to obtain Dense perovskite films with a thickness of 500 nm. Mix graphite, carbon black, polymethyl methacrylate, and isopropanol to form a carbon slurry, and scrape-coat the carbon slurry on the perovskite film prepared above as a carbon electrode to prepare a carbon electrode perovskite solar energy Battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com