Downhole conveyor belt anti-clogging automatic cleaning mechanism scheme

An automatic cleaning and conveyor belt technology, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of personnel safety, increase of personnel costs, increase of underground personnel positions, and decrease of production capacity, etc., to achieve improvement The effect of personal safety, reducing enterprise cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

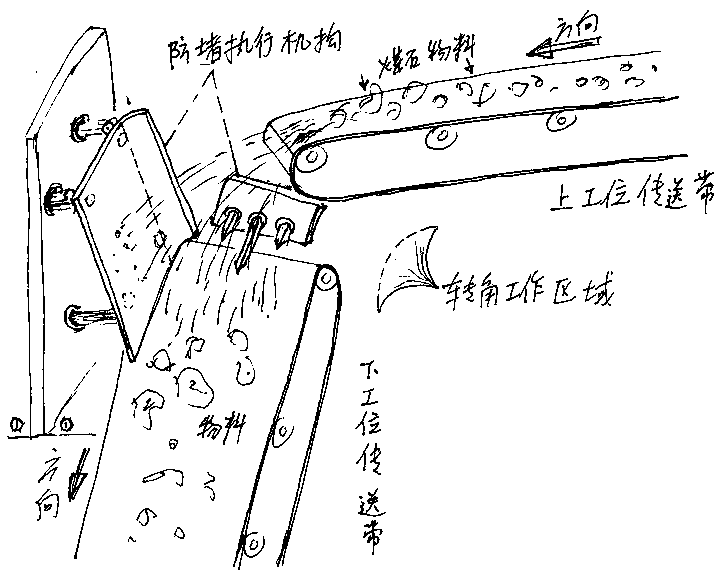

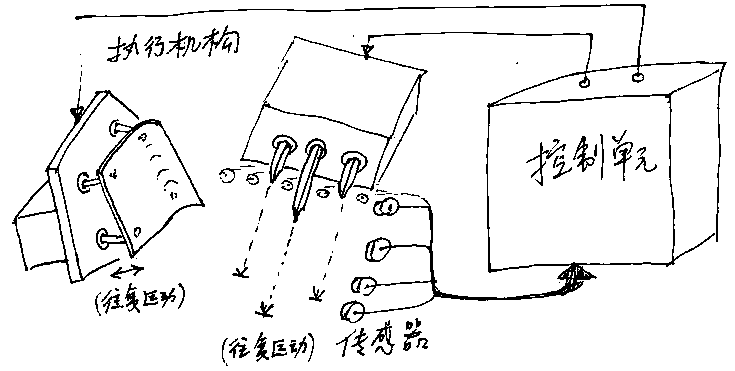

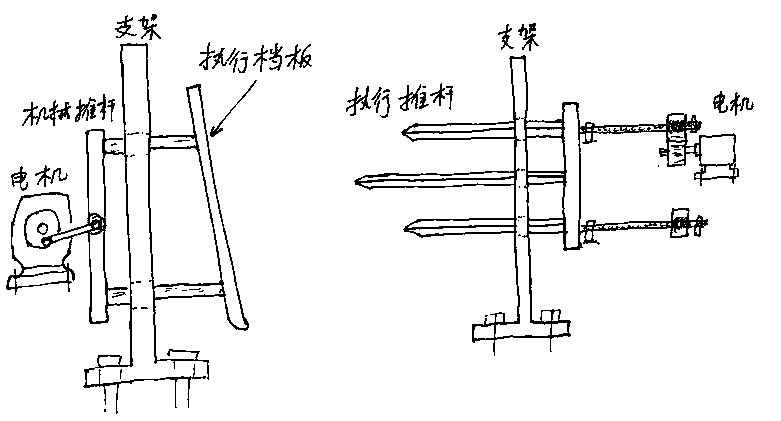

[0011] Such as figure 1 , 2 , Shown in 3, a kind of underground conveyor belt anti-blocking automatic cleaning mechanism scheme, comprises the conveyor belt of upper station, corner working area, anti-blocking sensor, anti-blocking control unit, anti-blocking actuator, the conveyor belt of lower station. The sensors are erected in the corner work area, distributed in the corner work area at the end of the upper station conveyor belt and the beginning of the lower station conveyor belt, and monitor the height and width of materials such as coal on the upper station conveyor belt and the lower station conveyor belt in real time. After the sensor signal is processed by the anti-blocking control unit, if it is detected that the height and width of coal and other materials on the conveyor belt show an upward tren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com