Exhaust gas adsorption regeneration gas condensation system and method

A technology of condensing system and regeneration gas, applied in the direction of steam condensation, separation method, chemical instrument and method, etc., can solve the problems of silicon powder blockage and obstruction, and achieve the effect of saving energy, enhancing safety, and reducing the number of maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

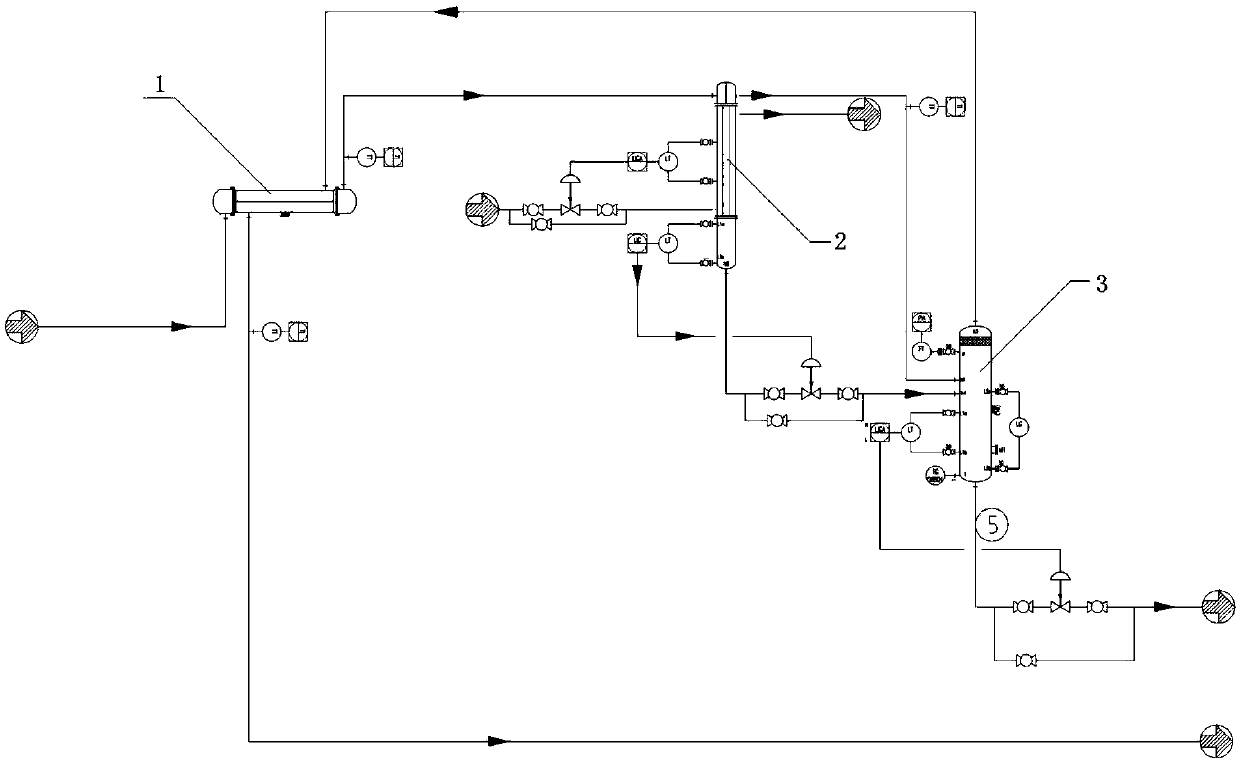

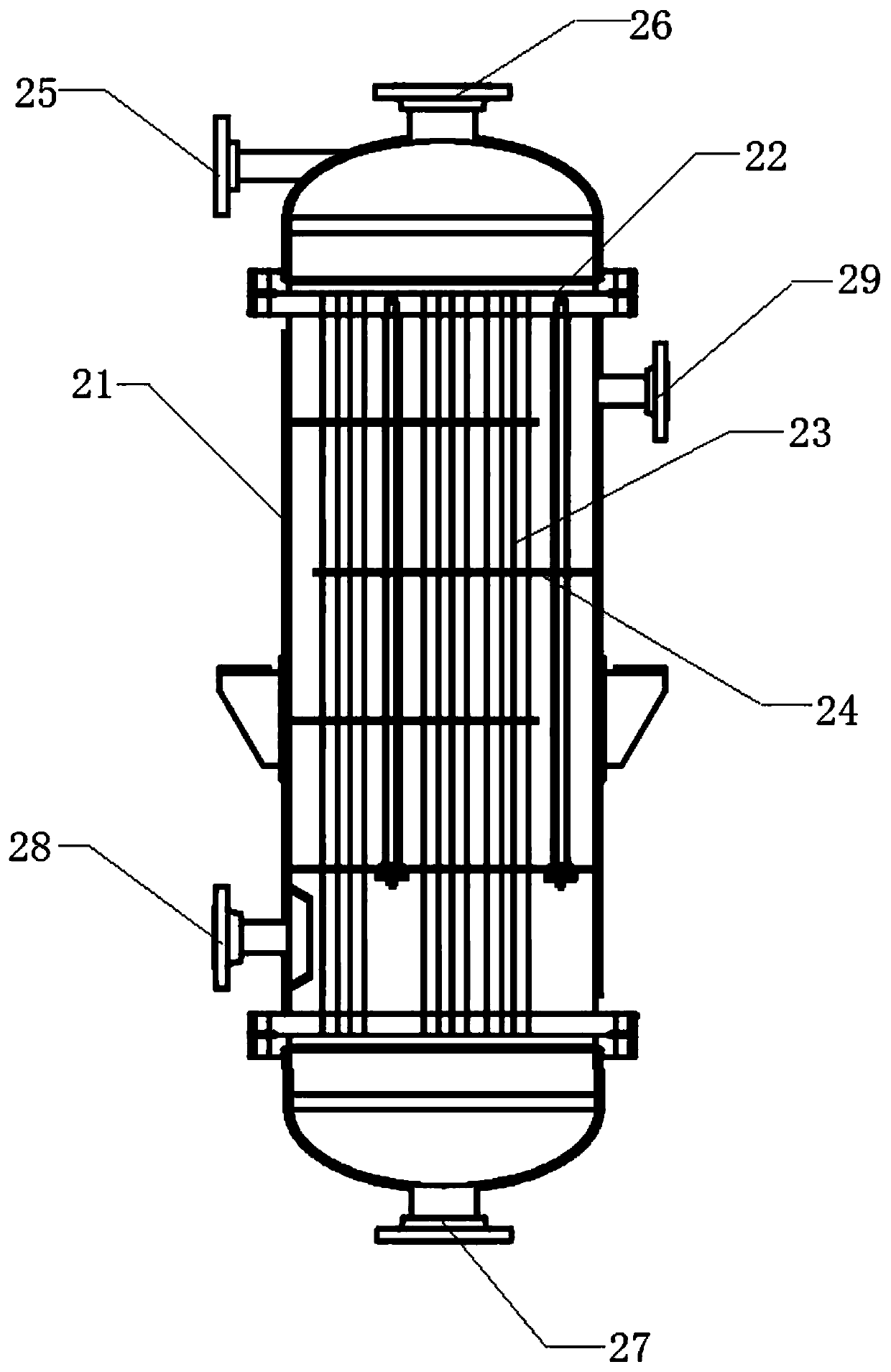

[0032] like Figure 1-Figure 4 As shown, the present invention provides a tail gas adsorption regeneration gas condensation system, including a pre-heat exchanger 1, a heat exchange condenser 2, and a gas-liquid separator 3 connected in sequence; the gas separated by the gas-liquid separator 3 is used as a pre-heater Cooling medium in heat exchanger 1.

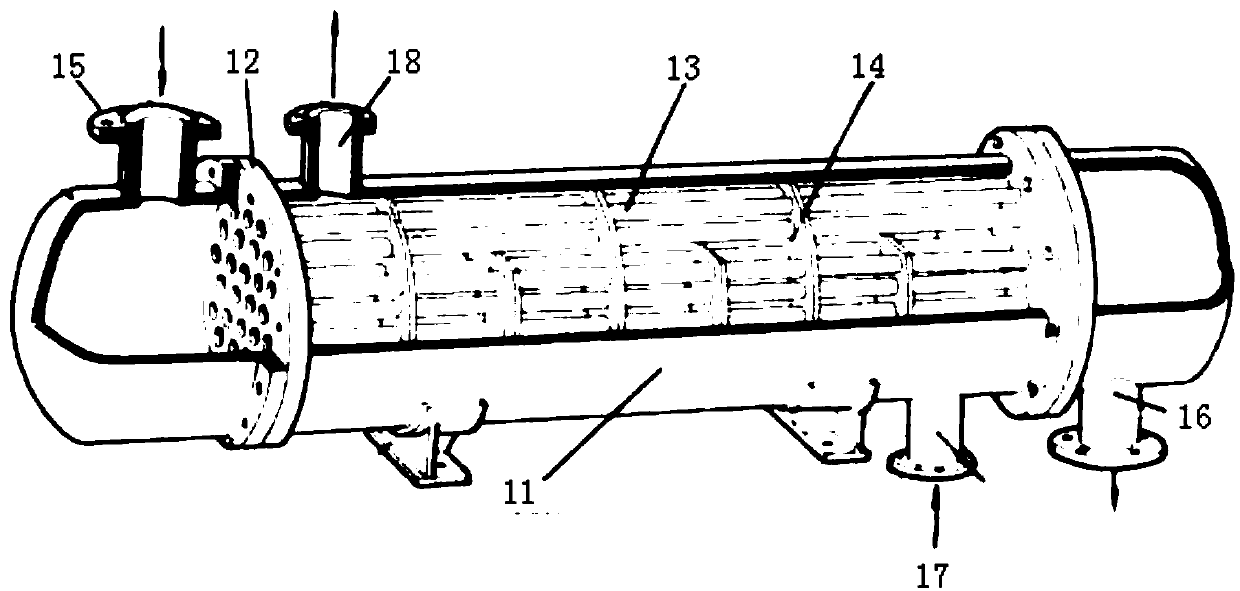

[0033] In the specific implementation process, the pre-heat exchanger 1 can be selected from the following structure: it includes a horizontal cylindrical shell 11, and the two ends of the shell 11 are closed; the shell 11 is radially provided with two front and rear sealing plates 12; A number of heat exchange tubes 13 are arranged between the sealing plates 12, and both ends of the heat exchange tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com