Method of synthesizing o-dibromobenzene by diazotization in one step at high temperature

A technology of ortho-dibromobenzene and diazotization, applied in chemical instruments and methods, organic chemistry, halogenated hydrocarbon preparation, etc., can solve problems such as low product yield, achieve high yield, stable product yield, reduce Energy consumption and effect of investment in refrigeration equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

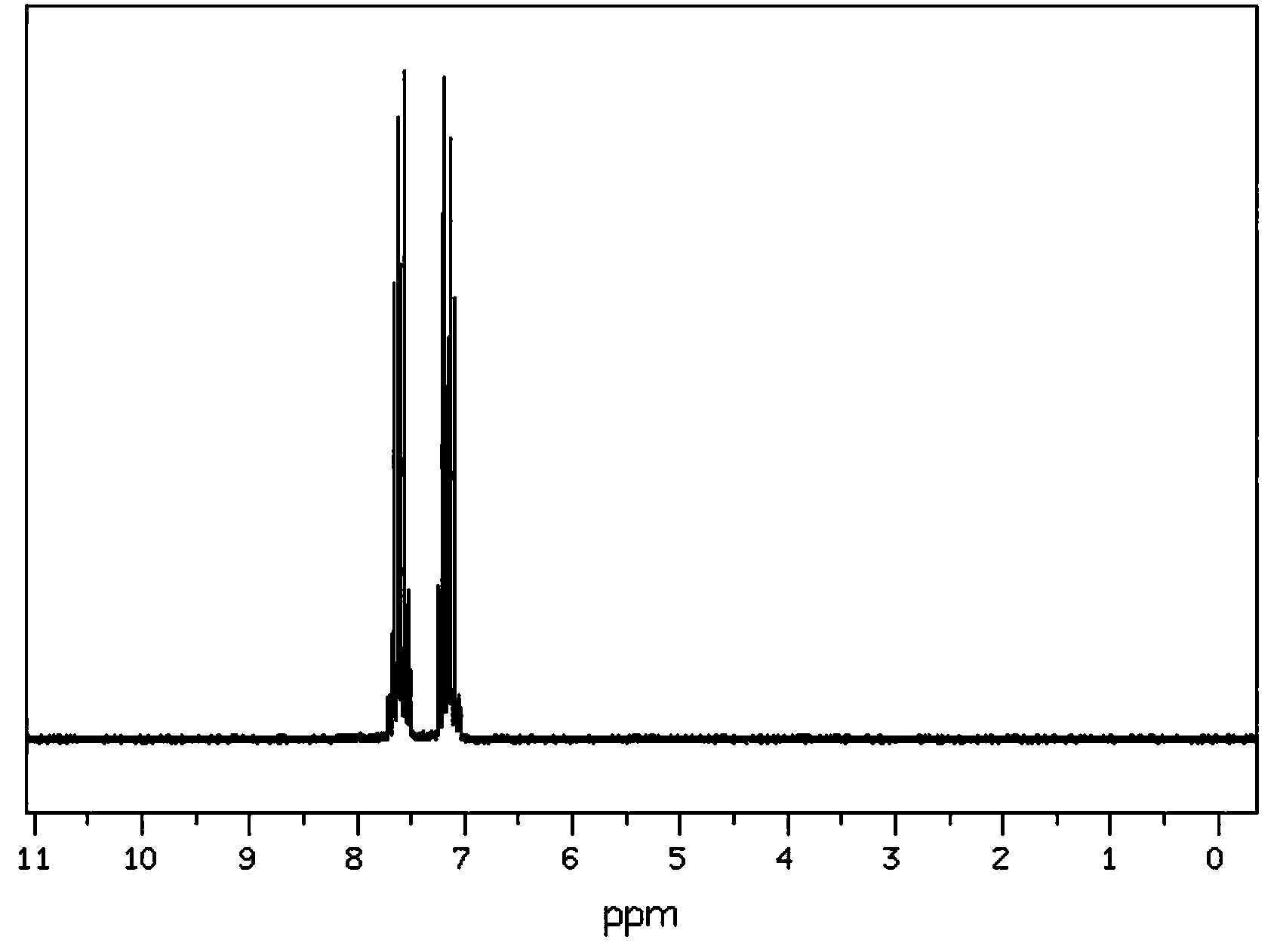

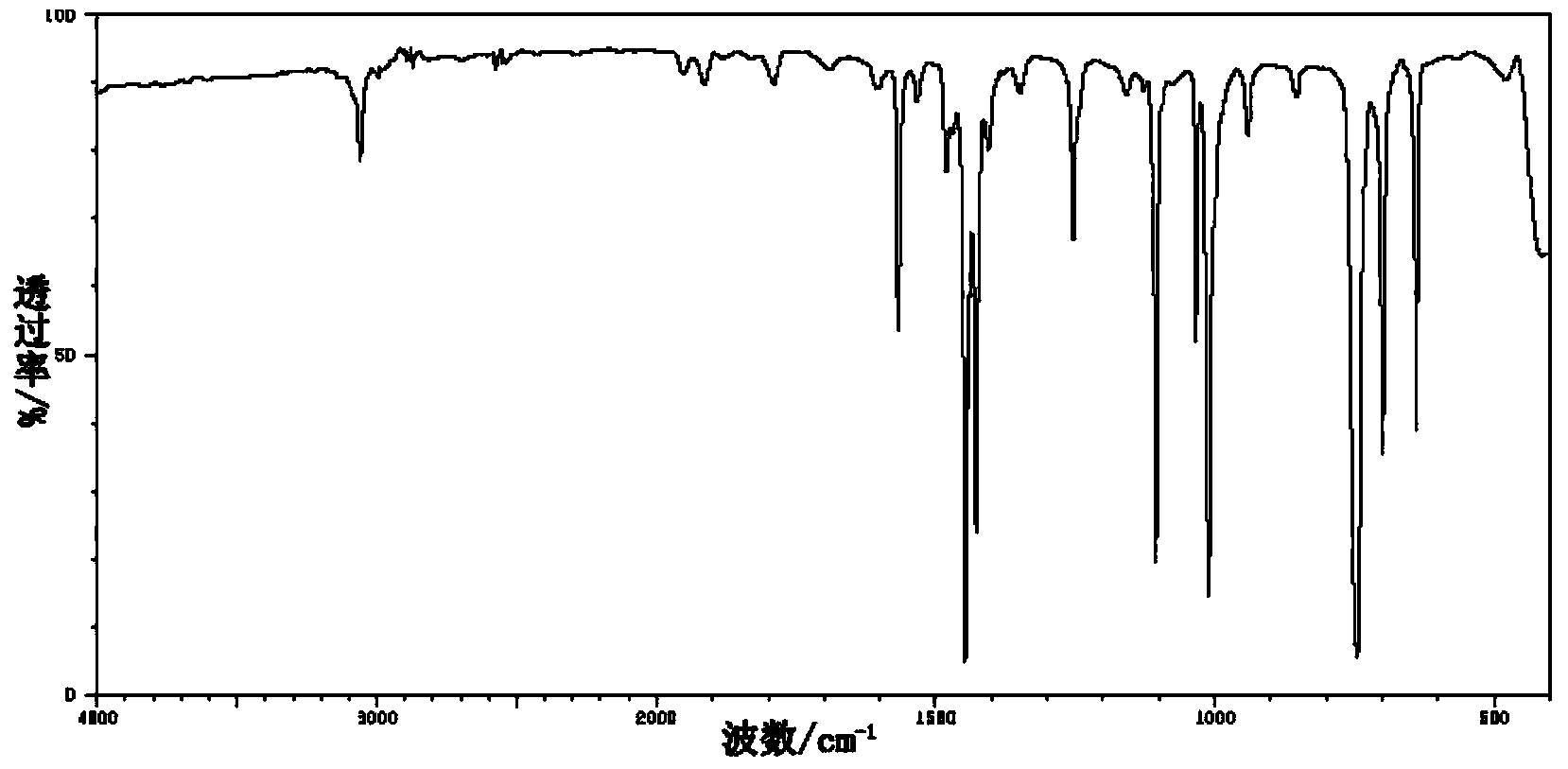

[0013] Put 500g of hydrobromic acid with a mass fraction of 48%, 10g of cuprous oxide, and 172g of o-bromoaniline into a four-necked flask equipped with a stirrer, condenser, and thermometer, stir and raise the temperature to above 80°C, and drop 72g of A solution of sodium nitrite dissolved in 100g of water, after dripping, change the distillation device with water to distill the product, separate the oil layer, wash once with 100mL of 5% liquid alkali, and then wash once with 100mL water, separate the oil layer , product 194g was evaporated under reduced pressure, content 99.2%, yield 82%. From figure 1 and figure 2 It can be confirmed that the final product obtained in the examples is o-dibromobenzene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com