Benzoic acid hydrogenation continuous reaction device and method thereof

A technology of reaction device and benzoic acid, which is applied in the direction of feeding device, chemical instrument and method, chemical/physical/physicochemical fixed reactor, etc., can solve the problem that the storage of Pd/C catalyst and Ru/C auxiliary agent cannot be maintained , catalyst activity limitation, impact on production and other issues, to achieve the effect of realizing gas-liquid mass transfer capacity and material mixing capacity, reducing the probability of poisoning and deactivation, and reducing the generation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

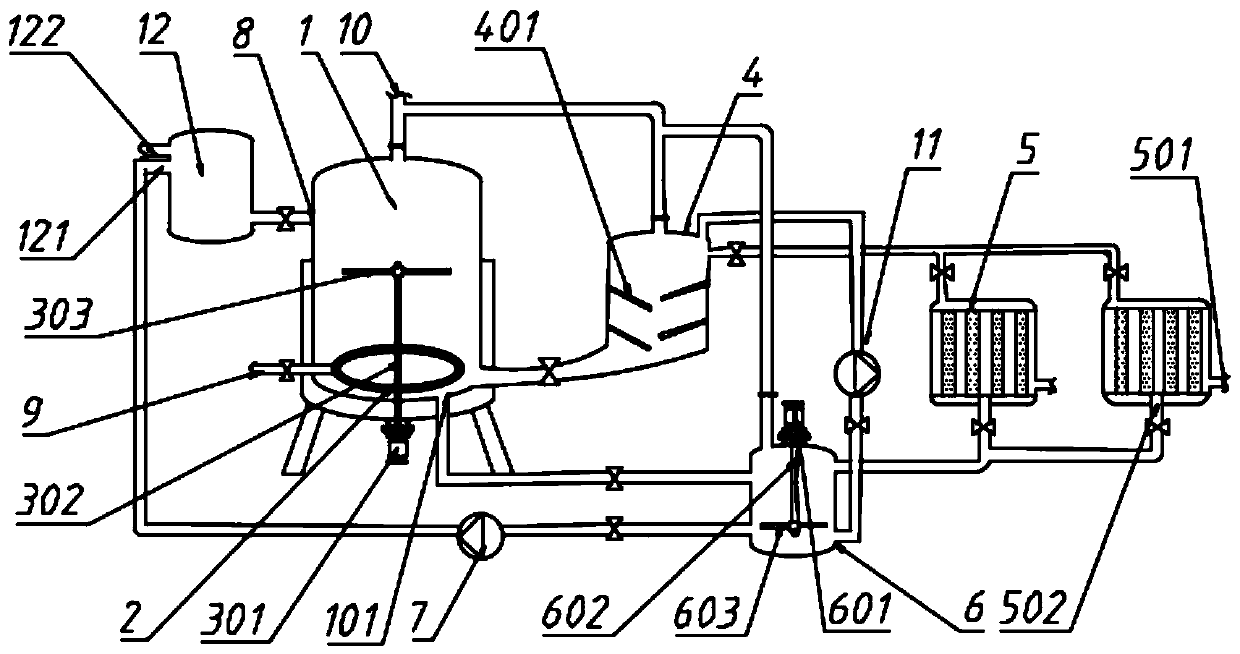

[0033] refer to figure 1 , a continuous reaction device for hydrogenation of benzoic acid, comprising a raw material tank 12, a reaction tank 1, a buffer tank 4, a carbon rod filter 5, and a liquid storage tank 6 connected in series in sequence, and the upper part of the reaction tank 1 is provided with a liquid inlet 8 and exhaust gas discharge port 10, the bottom of the reaction tank 1 is provided with a hydrogenation port 9 and a first discharge port, and the hydrogenation port 9 is connected to the aerator 2 through a pipeline; the first discharge port of the reaction tank 1 The mouth is directly communicated with the feed inlet of the buffer tank 4, the buffer tank 4 is provided with a spoiler assembly 401, and the overflow port of the buffer tank 4 is located below the liquid level of the reaction tank 1 when it is working; The center of the bottom of the reaction tank 1 is provided with a first stirring device connected to the first stirring motor 301; the top of the ra...

Embodiment 2

[0046] refer to figure 1 , the structure principle of this embodiment is similar to that of Embodiment 1, and the difference from Embodiment 1 is that it also includes a second stirring device arranged at the center of the top of the liquid storage tank 6 and connected to the second stirring motor 601, so The second stirring device includes a second stirring shaft 602 and a second stirring blade 603, and the second stirring blade 603 is connected to the second stirring shaft 602 through a connecting piece.

[0047] By arranging the second mechanical stirring device in the liquid storage tank 6, the circulating reaction liquid filtered through the carbon rod filter 5 can be mixed more evenly, avoiding pipeline blockage, and improving the catalyst and its auxiliary agent in the continuous reaction process of benzoic acid hydrogenation. The cyclic performance of the agent.

Embodiment 3

[0049] Continue to refer to figure 1 , the structure principle of this embodiment is similar to that of embodiment 1 or embodiment 2, the difference is that: the bottom of the reaction tank 1 is provided with a second discharge port 101, and the second discharge port 101 is connected to the The liquid storage tank 6 is connected; the top of the liquid storage tank 6 is provided with an exhaust port and communicates with the waste gas discharge port 10 through a pipeline, and the side wall of the liquid storage tank 6 is provided with a liquid discharge port, and the liquid discharge port passes through The hydraulic pump 11 communicates with the buffer tank 4 .

[0050] Further, the pipeline of the liquid inlet 8 of the reaction tank 1, the pipeline of the hydrogenation port 9, the pipeline of the first outlet, the pipeline of the second outlet 101, the overflow pipe of the buffer tank 4 Road, the liquid outlet pipeline of the liquid storage tank 6, the liquid discharge pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com