Combined resource utilization method for washing fly ash high-salinity wastewater and bypass ash

A high-salt wastewater and bypass ash technology, applied in chemical instruments and methods, perchlorate, ammonium chloride, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

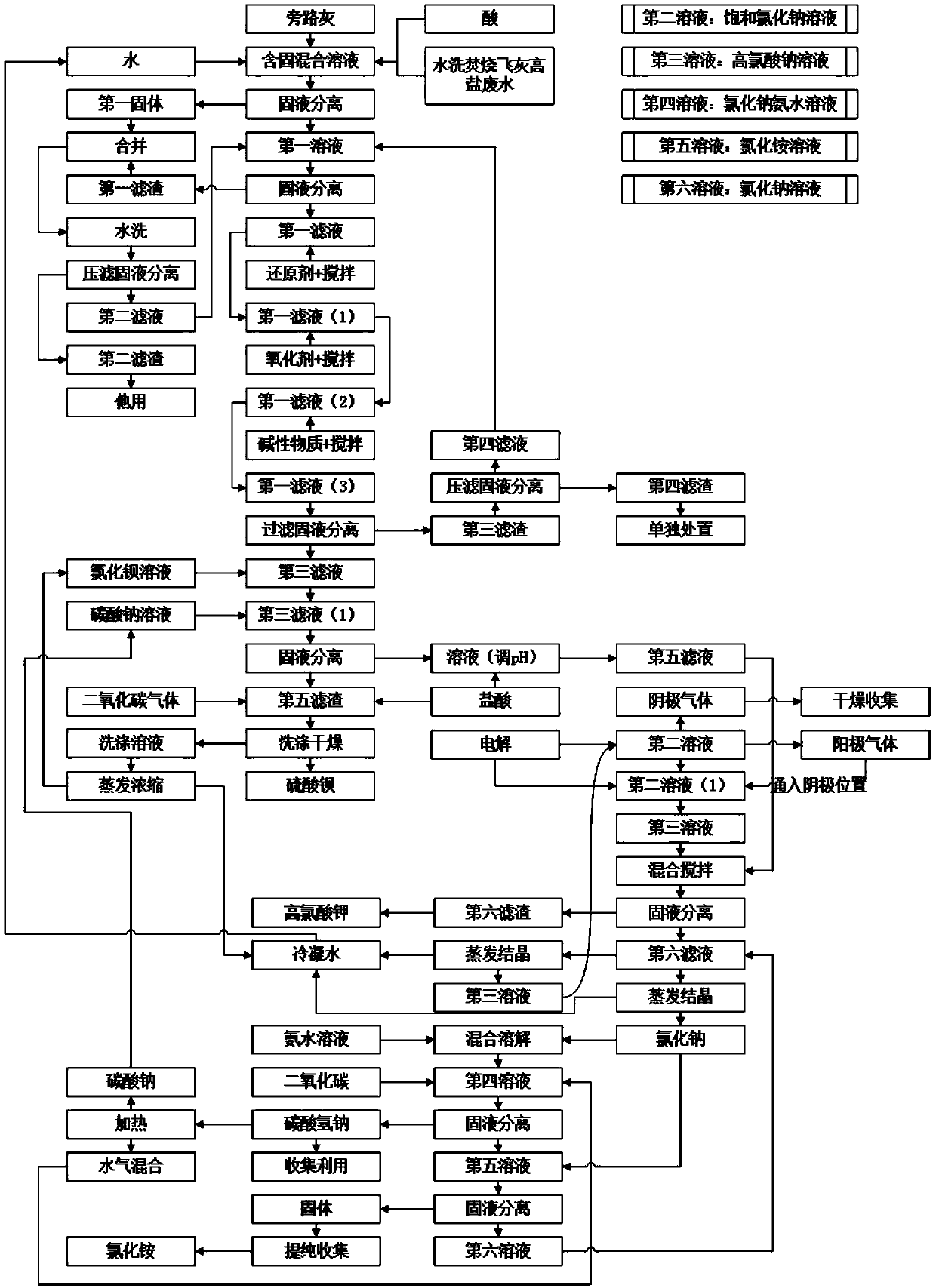

[0051] This embodiment provides a joint resource utilization method of washing fly ash high-salt wastewater and bypass ash, such as figure 1 shown, including:

[0052] Step S1, stirring and mixing the bypass hot raw meal, water, washing and incineration fly ash salty waste water and 15% concentration of hydrochloric acid solution according to a certain ratio to form a mixed solution containing solids. The pH of the mixed solution containing solids is 5.5. After mixing, the water The mass ratio of the mass to the bypass hot raw material is 4, and the solid-liquid separation is carried out to the mixed solution containing the solid, and the first solution (containing a small amount of solid) and the first solid are separated.

[0053] Step S2, performing solid-liquid separation on the first solution in step S1 to obtain a first filtrate and a first filter residue, the first filtrate enters the next step process, and a small amount of solid exists in the first filtrate.

[0054]...

Embodiment 2

[0064] This embodiment provides a joint resource utilization method of washing fly ash high-salt wastewater and bypass ash, including:

[0065] Step S1, stirring and mixing the bypass kiln dust, tap water, washed and incinerated fly ash high-salt wastewater and 20% sulfuric acid solution according to a certain ratio to form a mixed solution containing solids, the pH of the mixed solution containing solids is 5, and the water after mixing The mass ratio of the mass to the bypass kiln dust is 3, and the mixed solution containing the solid is subjected to solid-liquid separation to separate the first solution (containing a small amount of solid) and the first solid.

[0066] Step S2, performing solid-liquid separation on the first solution in step S1 to obtain a first filtrate and a first filter residue, the first filtrate enters the next step process, and a small amount of solid exists in the first filtrate.

[0067] In step S3, the first solid in step S1 and the first filter re...

Embodiment 3

[0077] This embodiment provides a joint resource utilization method of washing fly ash high-salt wastewater and bypass ash, including:

[0078] Step S1, mix the bypass air ash, seawater, washed and incinerated fly ash high-salt wastewater and 20% hydrochloric acid solution according to a certain ratio to form a mixed solution containing solids, the pH of the mixed solution containing solids is 5.5, the mass of water after mixing The mass ratio to the bypass ash is 2.5, and the mixed solution containing solids is subjected to solid-liquid separation to separate the first solution (containing a small amount of solids) and the first solid.

[0079] Step S2, performing solid-liquid separation on the first solution in step S1 to obtain a first filtrate and a first filter residue, the first filtrate enters the next step process, and a small amount of solid exists in the first filtrate.

[0080] In step S3, the first solid in step S1 and the first filter residue in step S2 are combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com