Modified sodium ion positive electrode material, modified sodium ion electrode and preparation method

A positive electrode material, sodium ion technology, applied in the direction of positive electrode, active material electrode, battery electrode, etc., can solve the problem that no one has reported the mechanism of sodium ion positive electrode, and achieve improved cycle stability, low price, and improved high-temperature cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

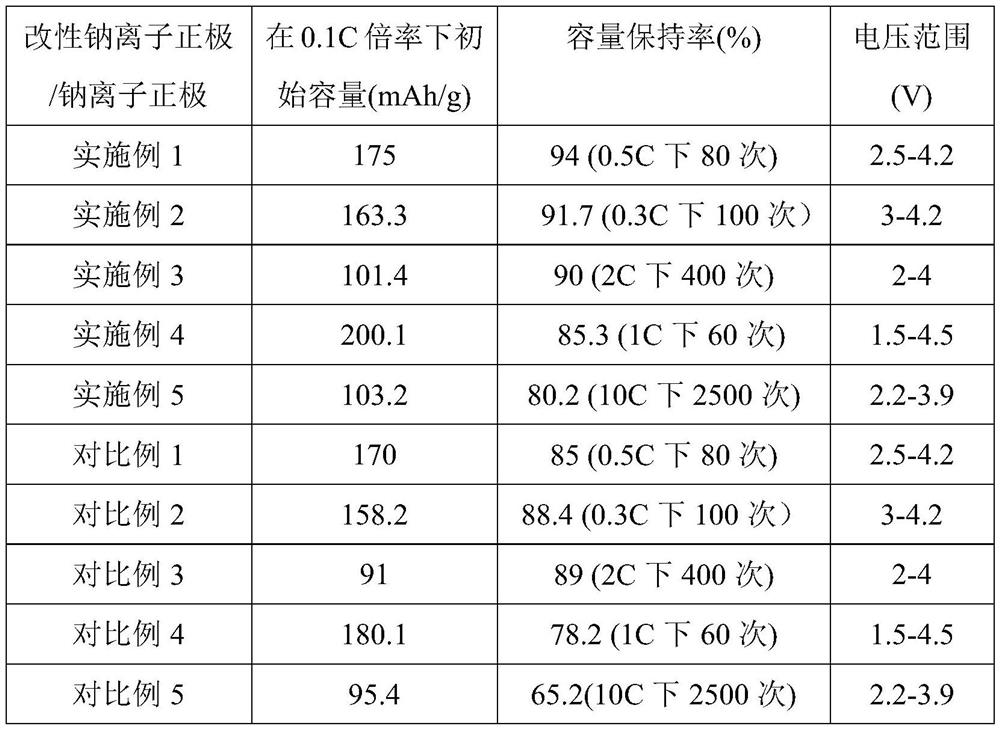

Examples

Embodiment 1

[0034] The preparation method of modified sodium ion positive electrode comprises the steps:

[0035] a. Weigh Na 2 CO 3 , NiO, MnCO 3 , so that the corresponding molar stoichiometric ratio is mixed evenly according to 1.03:0.5:0.5, and then PVDF is added to make the proportion of F element 0.01, and an appropriate amount of NMP is added to make it evenly mixed, dried, and then passed through 10° / min , heated to 850°C, maintained for calcination for 20 hours, then naturally cooled to room temperature, and the corresponding product was obtained after grinding, which was the modified sodium ion positive electrode material, and put it into a glove box filled with argon for standby;

[0036] b. Adding polyvinylidene fluoride to N-methylpyrrolidone and stirring to dissolve the polyvinylidene fluoride to obtain a polyvinylidene fluoride solution with a mass concentration of 5%;

[0037] c. Add acetylene black and modified sodium ion positive electrode material in turn, stir and d...

Embodiment 2

[0039] The preparation method of modified sodium ion positive electrode comprises the steps:

[0040] a. Weigh Na 2 CO 3 , NiO, MnCO 3 、TiO 2, so that the corresponding molar stoichiometric ratio is mixed uniformly according to 1.03:0.45:0.5:0.05, and then NaF is added to make the proportion of F element 0.03, and an appropriate amount of NMP is added to make it evenly mixed, dried, and then passed through 5° / min, heated to 900°C, maintained for calcination for 20 hours, then naturally cooled to room temperature, and the corresponding product was obtained through grinding, which was the modified sodium ion positive electrode material, and put it into a glove box filled with argon for standby;

[0041] b. Adding polyvinylidene fluoride to N-methylpyrrolidone and stirring to dissolve the polyvinylidene fluoride to obtain a polyvinylidene fluoride solution with a mass concentration of 6%;

[0042] c. Add acetylene black and modified sodium ion positive electrode material in ...

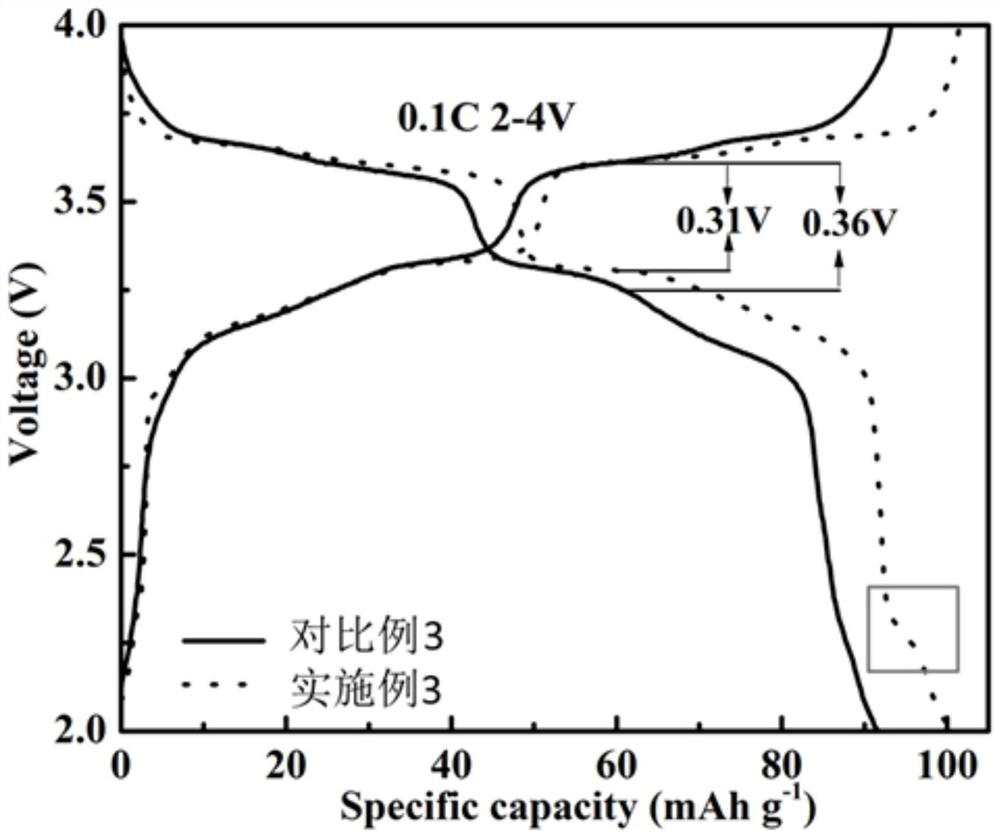

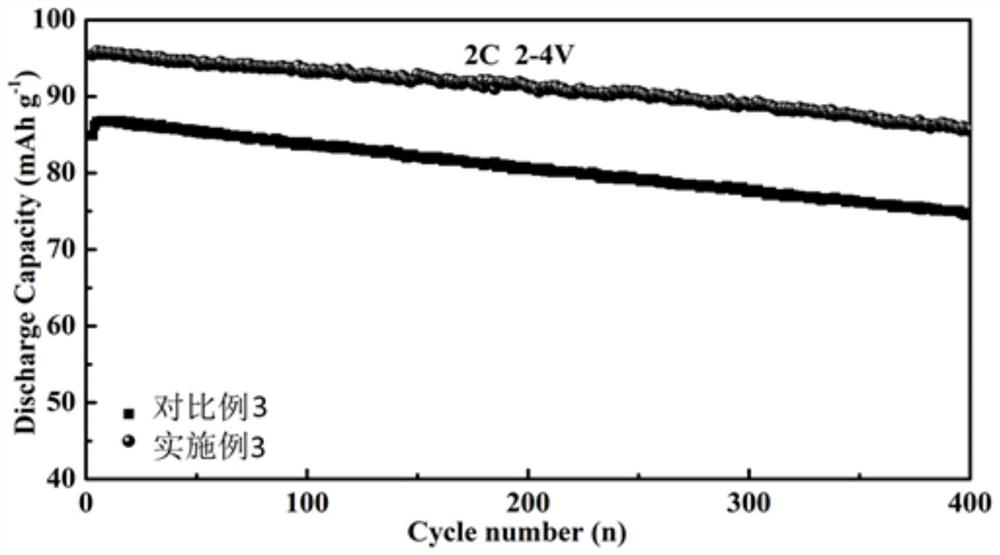

Embodiment 3

[0044] The preparation method of modified sodium ion positive electrode comprises the steps:

[0045] a. Weigh Na 2 CO 3 , NiO, MnCO 3 , so that the corresponding molar stoichiometric ratio is mixed uniformly according to 2:1:3, and then NaF is added to make the proportion of F element 0.05, and an appropriate amount of ethanol is added to make it evenly mixed, dried, and then passed through 5° / min , heating to 920°C, maintaining calcination for 12 hours, then naturally cooling to room temperature, and grinding to obtain the corresponding product, which is the modified sodium ion positive electrode material, and put it into a glove box filled with argon for standby;

[0046] b. Adding polyvinylidene fluoride to N-methylpyrrolidone and stirring to dissolve the polyvinylidene fluoride to obtain a polyvinylidene fluoride solution with a mass concentration of 6%;

[0047] c. Add acetylene black and modified sodium ion positive electrode material in turn, stir and disperse to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com